Decoding the Flow: 10 Critical Factors to Consider When Choosing a Flow Meter

In the industrial processes, the precise measurement of fluid flow is the rhythm that dictates efficiency, safety, and quality. Whether it’s water, corrosive chemicals, viscous oils, or invisible gases, accurately quantifying their movement is paramount. The instrument at the heart of this critical task is the flow meter. However, with a dizzying array of technologies and a multitude of application-specific nuances, selecting the right flow meter can be a daunting endeavor. A suboptimal choice can lead to inaccurate measurements, process inefficiencies, costly downtime, and even safety hazards.

This comprehensive guide will walk you through the 10 critical factors to consider when choosing a flow meter. By the end of this post, you will be equipped with the knowledge to navigate the complexities of flow meter selection and make an informed decision that aligns with your specific needs and budget.

1. Fluid Properties: The Nature of the Flowing Medium

The first and most fundamental consideration in selecting a flow meter is the nature of the fluid itself. Different flow meter technologies are designed to handle specific fluid characteristics. Key properties to evaluate include:

- State of the Fluid (Liquid, Gas, or Steam): This is the initial branching point in your selection journey. Some flow meters are designed exclusively for liquids, others for gases, and some can handle both. Steam, with its high temperature and potential for phase changes, requires specialized meters.

- Composition (Clean, Slurry, or Corrosive): The presence of suspended solids (slurries) can clog or damage meters with moving parts, such as turbine or positive displacement meters. For such applications, non-intrusive technologies like ultrasonic or magnetic flow meters are often preferred. Corrosive fluids necessitate the use of meters constructed from materials that can withstand chemical attack.

- Viscosity: A fluid’s resistance to flow, its viscosity, can significantly impact the performance of certain flow meters. High-viscosity fluids can pose a challenge for meters that rely on the fluid’s velocity profile. Positive displacement and Coriolis meters are generally well-suited for viscous applications.

- Density: For volumetric flow meters, changes in fluid density due to temperature or pressure fluctuations can introduce measurement errors. If precise mass flow measurement is required, a mass flow meter like a Coriolis or thermal mass flow meter is the ideal choice.

- Conductivity: Magnetic flow meters operate on the principle of Faraday’s Law of electromagnetic induction and are only suitable for conductive liquids. They are an excellent choice for water-based solutions but will not work with hydrocarbons or deionized water.

2. Flow Rate Range and Turndown Ratio: Quantifying the Flow

Understanding the operational flow rate of your process is crucial. You need to determine the minimum, normal, and maximum flow rates the meter will need to measure accurately. This leads to a critical parameter known as the turndown ratio, which is the ratio of the maximum measurable flow rate to the minimum measurable flow rate.

- Turndown Ratio = Maximum Flow Rate / Minimum Flow Rate

A high turndown ratio indicates that the meter can accurately measure a wide range of flow rates. This is particularly important in applications where the flow varies significantly. For instance, a batching process might have a high initial flow rate that tapers off towards the end. A meter with a low turndown ratio might not be able to accurately capture both the high and low ends of this range.

3. Accuracy and Repeatability: The Precision You Demand

The required level of accuracy is a significant driver of both the technology choice and the cost of the flow meter. It’s essential to realistically assess the accuracy needed for your application. Over-specifying accuracy can lead to unnecessary expense, while under-specifying can compromise process control and product quality.

- Accuracy: This refers to how close a measurement is to the true value. It is often expressed as a percentage of the actual reading or of the full-scale range.

- Repeatability: This refers to the ability of the flow meter to consistently reproduce the same measurement under the same conditions. High repeatability is crucial for process control applications where consistency is more important than absolute accuracy.

For critical applications like custody transfer (the transfer of ownership of a fluid), high accuracy is non-negotiable. For general process monitoring, a lower accuracy might be acceptable.

4. Pipe Size and Installation Constraints: The Physical Environment

The physical constraints of your piping system play a vital role in flow meter selection. Key considerations include:

- Pipe Diameter: Flow meters are designed for specific pipe sizes. While some technologies, like clamp-on ultrasonic meters, can be adapted to a range of pipe sizes, others require a precise match.

- Straight Pipe Run Requirements: Many flow meter technologies, particularly those that measure velocity, require a certain length of straight, unobstructed pipe both upstream and downstream of the meter. This is to ensure a fully developed and non-swirling flow profile, which is essential for accurate measurement. The manufacturer’s specifications will detail these straight-run requirements (often expressed in terms of pipe diameters, e.g., 10D upstream and 5D downstream).

- Orientation: Some flow meters must be installed in a specific orientation (horizontal or vertical) to function correctly.

- Accessibility: Consider the need for future maintenance and calibration. The meter should be installed in a location that is safely and easily accessible.

5. Pressure and Temperature Conditions: The Operating Extremes

The operating pressure and temperature of the process fluid can significantly affect a flow meter’s performance and structural integrity.

- Operating Pressure: The flow meter must be able to withstand the maximum operating pressure of the system. This includes any potential pressure spikes.

- Operating Temperature: Both the fluid temperature and the ambient temperature can impact the meter’s electronics and materials. High-temperature applications may require specialized meters with cooling fins or remote electronics.

Exceeding the pressure and temperature limits of a flow meter can lead to catastrophic failure.

6. Pressure Drop Allowance: The Energy Cost of Measurement

Many flow meters, by their very design, create a restriction in the flow path, resulting in a pressure drop. This pressure drop represents an energy loss in the system.

In some applications, particularly those with low-pressure systems or where energy efficiency is a primary concern, a low-pressure drop is essential. Technologies like magnetic and ultrasonic flow meters offer the advantage of having no or very low-pressure drop as they do not obstruct the flow. In contrast, differential pressure meters, which rely on creating a pressure difference, inherently introduce a pressure drop.

7. Output Signal and Connectivity: Communicating the Data

The flow meter is not an isolated device; it is a component of a larger control and monitoring system. The type of output signal required is a critical practical consideration. Common output signals include:

- Analog: 4-20 mA is a widely used industry standard for transmitting flow data to a PLC, DCS, or chart recorder.

- Pulse/Frequency: These outputs are often used for totalization or as an input to a batch controller.

- Digital Communication Protocols: Modern “smart” flow meters often feature digital communication protocols like HART, Modbus, FOUNDATION Fieldbus, or Profibus. These protocols allow for the transmission of not only the primary flow variable but also diagnostic information and allow for remote configuration and calibration.

8. Material of Construction and Chemical Compatibility: Resisting the Elements

The materials that come into contact with the process fluid (the “wetted” parts) must be chemically compatible to prevent corrosion, erosion, and contamination. The choice of materials will depend on the nature of the fluid, its temperature, and its pressure.

Common materials of construction include:

- Metals: Stainless steel, Hastelloy, Monel, and Titanium for a wide range of applications, including those with corrosive fluids.

- Plastics: PVC, PVDF, and PFA for applications where metal compatibility is an issue.

- Liners: Materials like PTFE and rubber are often used as liners in magnetic flow meters to provide chemical resistance.

Consulting a chemical compatibility chart is essential to ensure the longevity of the flow meter and the purity of the process fluid.

9. Total Cost of Ownership (TCO): Beyond the Initial Price Tag

A common mistake is to select a flow meter based solely on its initial purchase price. A more holistic approach is to consider the Total Cost of Ownership (TCO), which encompasses all costs associated with the meter over its entire lifecycle. These costs include:

- Initial Purchase Price: The upfront cost of the flow meter.

- Installation and Commissioning Costs: The labor and materials required to install and set up the meter.

- Maintenance and Calibration Costs: The ongoing costs of routine maintenance, inspections, and periodic calibration to ensure continued accuracy. Meters with no moving parts generally have lower maintenance requirements.

- Operational Costs: This can include the energy costs associated with the pressure drop created by the meter.

- Potential Downtime Costs: The cost of lost production if the meter fails or requires frequent maintenance.

A meter with a lower initial price may end up being more expensive in the long run due to higher maintenance requirements or a shorter lifespan.

10. Agency Approvals and Certifications: Meeting Regulatory Standards

In many industries, adherence to specific regulatory standards and certifications is mandatory. It is crucial to identify any required approvals for your application. These may include:

- Custody Transfer Approvals: For applications where the flow measurement is used for billing purposes (e.g., oil and gas, water distribution), the flow meter must have legal metrology approvals (e.g., OIML, NTEP).

- Hazardous Area Approvals: In environments where flammable gases or dust are present, the flow meter must be certified for use in hazardous areas (e.g., ATEX, IECEx, FM).

- Sanitary/Hygienic Approvals: For the food and beverage, pharmaceutical, and biotechnology industries, flow meters must meet stringent hygienic design standards to prevent bacterial growth and ensure product purity (e.g., 3-A, EHEDG).

- Safety Integrity Level (SIL): In safety-critical applications, a flow meter may need to be certified to a specific Safety Integrity Level (SIL), which indicates its reliability in performing a safety function.

Block Diagrams of Common Flow Meter Types

To further aid in your understanding, here are simplified block diagrams illustrating the working principles of some common flow meter technologies:

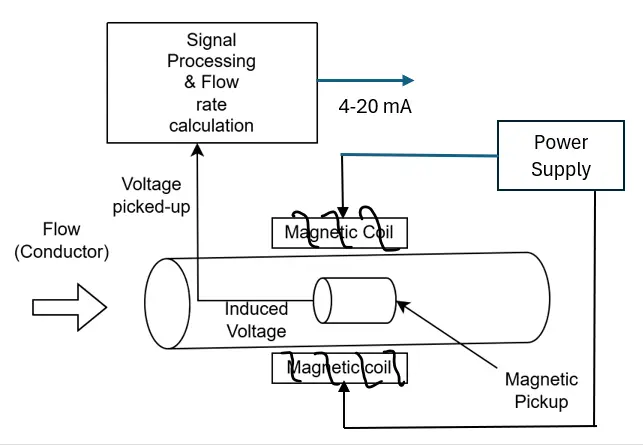

Magnetic Flow Meter

Working Principle: Based on Faraday’s Law of Electromagnetic Induction. As a conductive fluid flows through a magnetic field, it generates a voltage proportional to the flow velocity.

Best for: Clean, conductive liquids, slurries. Advantages: No moving parts, low-pressure drop, high accuracy. Limitations: Only for conductive fluids.

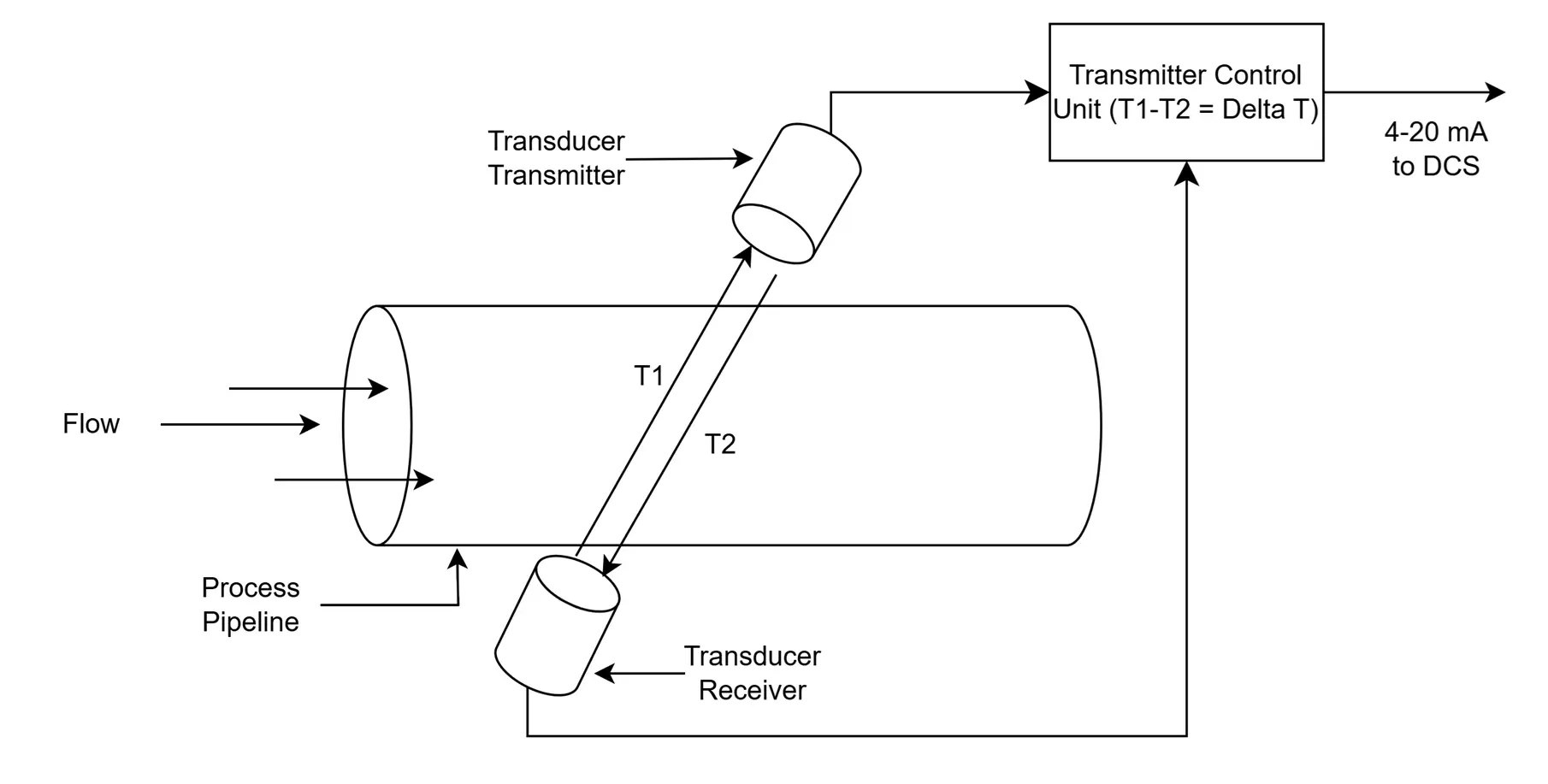

Ultrasonic Flow Meter (Transit-Time)

Working Principle: Measures the time difference between ultrasonic pulses sent upstream and downstream. The time difference is directly proportional to the fluid velocity.

Best for: Clean liquids and gases. Clamp-on versions are available for non-intrusive measurement. Advantages: No pressure drop, can be installed on the outside of the pipe. Limitations: Can be affected by solids or bubbles in the fluid.

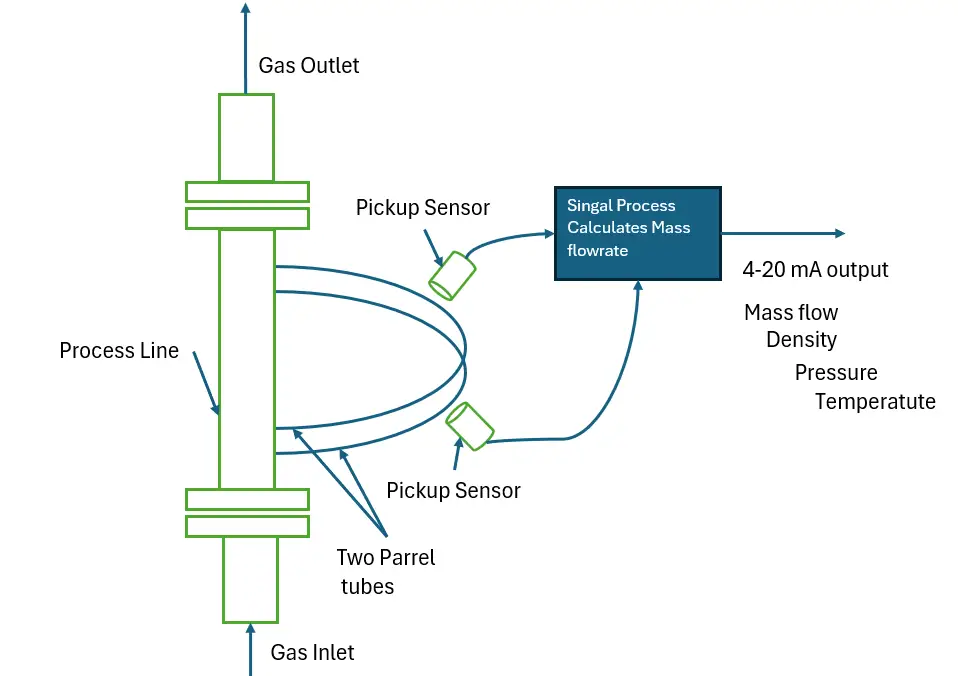

Coriolis Mass Flow Meter

Working Principle: Based on the Coriolis effect. The fluid flows through vibrating tubes, causing them to twist. The amount of twist is directly proportional to the mass flow rate.

Best for: A wide range of liquids and gases where high accuracy mass flow measurement is critical. Advantages: Measures mass flow directly, highly accurate, can also measure density and temperature. Limitations: Higher initial cost, can be sensitive to vibrations.

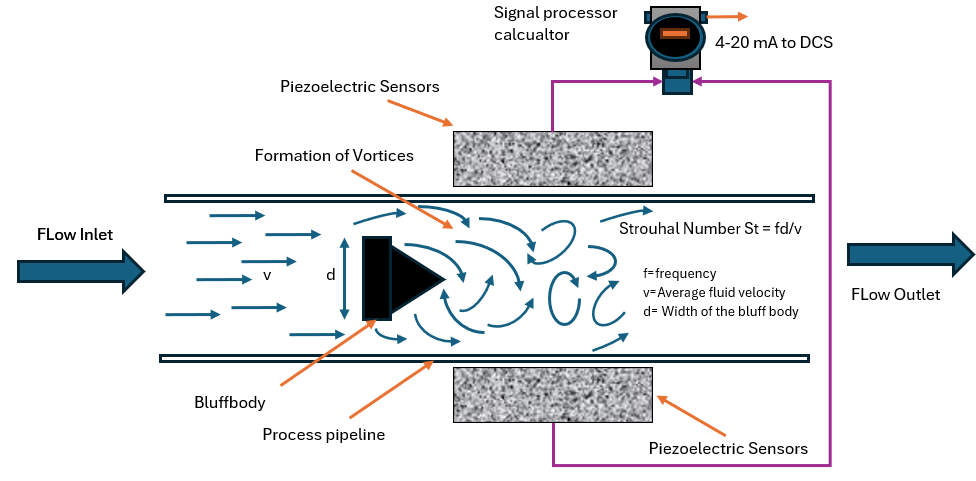

Vortex Flow Meter

Working Principle: A bluff body (shedder bar) placed in the flow path creates vortices (swirls). The frequency of these vortices is directly proportional to the flow velocity.

Best for: Liquids, gases, and steam. Advantages: No moving parts, good for a wide range of fluids. Limitations: Requires a well-developed flow profile, introduces some pressure drop.

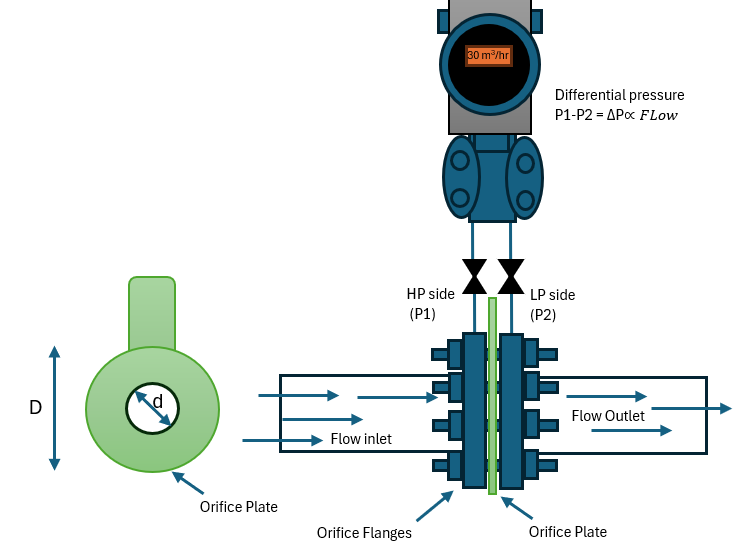

Differential Pressure Flow Meter (with Orifice Plate)

Working Principle: An obstruction (like an orifice plate) creates a pressure drop. The square root of this pressure drop is proportional to the flow rate.

Best for: Clean liquids, gases, and steam. A very common and well-understood technology. Advantages: Low cost, simple construction. Limitations: Significant pressure drop, lower accuracy and turndown ratio compared to newer technologies.

Conclusion: Making the Right Choice

Selecting the right flow meter is a critical decision that can have a significant impact on your operational efficiency, product quality, and safety. By systematically evaluating these 10 critical factors – from the fundamental properties of your fluid to the total cost of ownership and required certifications – you can demystify the selection process. Remember that there is no one-size-fits-all solution. The optimal choice will always be the one that best aligns with the unique demands of your application. Consulting with experienced instrumentation engineers and reputable flow meter manufacturers can provide invaluable guidance in making this crucial investment. By taking a thoughtful and informed approach, you can ensure that your chosen flow meter provides accurate, reliable, and cost-effective performance for years to come.