Absolute vs. Gauge Pressure: A Comprehensive Guide to Understanding the Key Differences

In the world of industrial processes, scientific experiments, and even everyday applications, the precise measurement of pressure is paramount. However, the term ‘pressure’ itself can be ambiguous without a proper frame of reference. This is where the crucial distinction between absolute pressure and gauge pressure comes into play. Understanding this difference is not just a matter of semantics; it’s a fundamental concept that ensures accuracy, safety, and efficiency in a vast array of applications.

This comprehensive guide will delve deep into the world of pressure measurement, demystifying the concepts of absolute and gauge pressure. We will explore their definitions, working principles, real-world applications, and the critical factors to consider when choosing between them. By the end of this 2500-word article, you will have a robust understanding of these two fundamental pressure measurement types, complete with illustrative block diagrams to solidify your knowledge.

What is Pressure? A Quick Refresher

Before we dissect the differences between absolute and gauge pressure, let’s briefly revisit the concept of pressure itself. In physics, pressure (P) is defined as the force (F) applied perpendicular to the surface of an object per unit area (A) over which that force is distributed.

P=AF

This force is exerted by gases, liquids, or solids. The air we breathe, the water in our pipes, and the hydraulic fluid in a machine all exert pressure. The key to our discussion is the reference point from which this pressure is measured.

The Crucial Role of the Reference Point: Introducing Atmospheric Pressure

The primary factor that distinguishes absolute and gauge pressure is their reference point. The common link between them is atmospheric pressure (also known as barometric pressure). This is the pressure exerted by the weight of the Earth’s atmosphere.

Imagine a column of air extending from the ground to the edge of space. The weight of this air column pressing down on a surface is the atmospheric pressure. This pressure is not constant; it varies with altitude, weather conditions, and temperature.

- At sea level, the standard atmospheric pressure is approximately 1013.25 millibars, which is equivalent to 14.7 pounds per square inch (psi) or 1 atmosphere (atm).

- As altitude increases, the column of air above decreases, and so does the atmospheric pressure. This is why you might feel your ears pop when flying in an airplane or driving up a mountain.

Now, let’s see how this ever-present atmospheric pressure serves as the dividing line between our two key pressure types.

Absolute Pressure: The Ultimate Reference Point

Absolute pressure is measured relative to a perfect vacuum, which is a space completely devoid of matter. This means that an absolute pressure reading takes into account the pressure of the system or process plus the atmospheric pressure. Its reference point is absolute zero pressure, a theoretical state that cannot be achieved but can be closely approximated in a laboratory setting.

Therefore, the formula for absolute pressure can be expressed as:

Absolute Pressure = Gauge Pressure + Atmospheric Pressure

Since absolute pressure is measured from a true zero point, it provides a complete and unambiguous measurement of the total pressure being exerted.

How Absolute Pressure is Measured: The Sealed Sensor

Absolute pressure sensors are designed with a sealed reference chamber that is evacuated to a near-perfect vacuum. This chamber is located on one side of a sensing diaphragm, while the process medium (the gas or liquid whose pressure is being measured) is on the other side.

The pressure from the process medium causes the diaphragm to deflect. This deflection is then converted into an electrical signal, which is calibrated to provide the absolute pressure reading. Because the reference chamber is sealed and at a constant near-zero pressure, the sensor’s output is unaffected by changes in the surrounding atmospheric pressure.

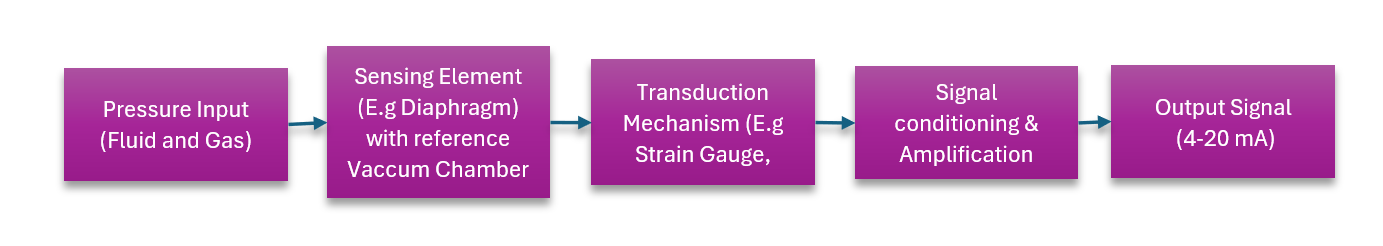

Block Diagram: Working Principle of an Absolute Pressure Sensor

Description of the Block Diagram:

- Process Medium: The gas or liquid whose pressure needs to be measured is introduced to one side of the sensing diaphragm.

- Sensing Diaphragm: This is a flexible membrane that separates the process medium from the sealed reference chamber.

- Sealed Reference Chamber: This chamber is evacuated to a near-perfect vacuum, creating the absolute zero pressure reference point.

- Deflection: The pressure from the process medium causes the diaphragm to deflect towards the vacuum chamber. The amount of deflection is directly proportional to the absolute pressure.

- Transduction Element: This element, often a piezoresistive strain gauge or a capacitive sensor, converts the mechanical deflection of the diaphragm into an electrical signal.

- Signal Conditioning and Amplification: The raw electrical signal is processed and amplified to a standard output format.

- Output Signal: The final output signal, typically in the form of a 4-20mA current loop or a 0-5V voltage signal, represents the measured absolute pressure.

Applications of Absolute Pressure

Absolute pressure measurements are critical in applications where the influence of atmospheric pressure is significant or where a process is sensitive to changes in total pressure. Some key applications include:

- Vacuum Measurement: In processes that operate under a vacuum, such as in the manufacturing of semiconductors, pharmaceuticals, and food packaging, absolute pressure sensors are essential for accurately measuring the level of vacuum.

- Altitude Measurement (Altimeters): Aircraft altimeters are essentially absolute pressure sensors that correlate the measured atmospheric pressure to altitude. As the aircraft ascends, the atmospheric pressure decreases, and the altimeter indicates a higher altitude.

- Weather Forecasting: Barometers, which measure atmospheric pressure, are a type of absolute pressure instrument. Meteorologists use changes in barometric pressure to forecast weather patterns.

- Scientific Research: Many scientific experiments, particularly in physics and chemistry, require precise pressure measurements that are independent of ambient conditions.

- Vapor Pressure Measurement: In chemical processing and storage, absolute pressure sensors are used to measure the vapor pressure of liquids, which is crucial for preventing cavitation in pumps and ensuring process stability.

- Food and Beverage Packaging: In vacuum-sealed food packaging, absolute pressure sensors ensure the correct level of vacuum is achieved to preserve freshness and extend shelf life.

Gauge Pressure: The Relative Measurement

Gauge pressure is the pressure of a system or process measured relative to the surrounding atmospheric pressure. In other words, gauge pressure is the difference between the absolute pressure and the atmospheric pressure.

The formula for gauge pressure is:

Gauge Pressure = Absolute Pressure – Atmospheric Pressure

A positive gauge pressure indicates that the pressure in the system is higher than the atmospheric pressure. A negative gauge pressure, often referred to as vacuum gauge pressure, indicates that the pressure in the system is lower than the atmospheric pressure.

When a pressure gauge reads zero, it doesn’t mean there is no pressure; it means the pressure being measured is equal to the current atmospheric pressure.

How Gauge Pressure is Measured: The Vented Sensor

Gauge pressure sensors are designed to use the current atmospheric pressure as their reference point. They achieve this by having a vent that exposes the reference side of the sensing diaphragm to the surrounding atmosphere.

The process medium is applied to the other side of the diaphragm. The diaphragm deflects based on the pressure difference between the process medium and the atmosphere. This deflection is then converted into an electrical signal, which represents the gauge pressure.

Because the reference pressure is always the current atmospheric pressure, any fluctuations in atmospheric pressure will be compensated for, and the gauge will only indicate the pressure relative to the immediate surroundings.

Block Diagram: Working Principle of a Gauge Pressure Sensor

Description of the Block Diagram:

- Process Medium: The gas or liquid whose pressure needs to be measured is applied to one side of the sensing diaphragm.

- Sensing Diaphragm: A flexible membrane that separates the process medium from the vented reference chamber.

- Reference Chamber (Vented to Atmosphere): This chamber has a vent that allows the surrounding atmospheric pressure to act on the reference side of the diaphragm.

- Deflection: The diaphragm deflects based on the difference between the process pressure and the atmospheric pressure. The direction and magnitude of the deflection indicate whether the gauge pressure is positive or negative.

- Transduction Element: Similar to an absolute pressure sensor, this element converts the mechanical deflection into an electrical signal.

- Signal Conditioning and Amplification: The electrical signal is processed and amplified.

- Output Signal: The final output signal represents the measured gauge pressure.

Applications of Gauge Pressure

Gauge pressure is the most common type of pressure measurement used in industrial and everyday applications. This is because many processes are not affected by changes in atmospheric pressure and only require the measurement of pressure relative to the ambient environment. Key applications include:

- Tire Pressure: The pressure you measure in your car tires is gauge pressure. A reading of 32 psi means the pressure inside the tire is 32 psi above the current atmospheric pressure.

- Blood Pressure: Medical professionals measure blood pressure as gauge pressure. The readings (systolic and diastolic) represent the pressure of the blood against the artery walls relative to atmospheric pressure.

- HVAC Systems: Heating, ventilation, and air conditioning systems rely on gauge pressure measurements to monitor and control the flow of refrigerants and air.

- Hydraulic and Pneumatic Systems: In industrial machinery, gauge pressure is used to monitor the pressure in hydraulic and pneumatic lines to ensure proper operation and prevent over-pressurization.

- Water Pressure: The pressure in your home’s water pipes is measured as gauge pressure.

- Tank Level Measurement: In open or vented tanks, a pressure sensor at the bottom of the tank can be used to determine the liquid level. Since the tank is open to the atmosphere, a gauge pressure sensor is used to measure the hydrostatic pressure of the liquid column, which is directly proportional to the level.

Head-to-Head Comparison: Absolute vs. Gauge Pressure

To summarize the key distinctions, here’s a side-by-side comparison of absolute and gauge pressure:

| Feature | Absolute Pressure | Gauge Pressure |

|---|---|---|

| Reference Point | Perfect Vacuum (Absolute Zero) | Atmospheric Pressure |

| Relationship to Atmospheric Pressure | Independent of atmospheric pressure changes. | Directly referenced to and affected by atmospheric pressure. |

| Zero Point | A true zero pressure, representing a complete absence of matter. | Equal to the current atmospheric pressure. |

| Measurement Value | Always a positive value. | Can be positive, negative (vacuum), or zero. |

| Sensor Design | Features a sealed, evacuated reference chamber. | Features a vented reference chamber open to the atmosphere. |

| Common Units | psia (pounds per square inch absolute) | psig (pounds per square inch gauge) |

| Typical Applications | Vacuum measurement, altimetry, scientific research, food packaging. | Tire pressure, blood pressure, HVAC, hydraulics, pneumatics. |

Choosing the Right Pressure Measurement for Your Application

Selecting the correct type of pressure measurement is crucial for obtaining accurate and meaningful data. The choice between absolute and gauge pressure depends entirely on the specific requirements of the application. Here are some guiding questions to help you decide:

Is the process influenced by atmospheric pressure?

- If yes, and you need to measure the total pressure independent of atmospheric fluctuations (e.g., in a sealed container or a vacuum process), you need an absolute pressure sensor.

- If no, and the process is referenced to the surrounding atmosphere (e.g., tire pressure, open tank level), a gauge pressure sensor is the appropriate choice.

Are you measuring a vacuum?

- For precise vacuum measurements, especially in high-vacuum applications, an absolute pressure sensor is essential. While a gauge pressure sensor can indicate a vacuum (negative gauge pressure), an absolute pressure sensor will provide a more accurate and stable reading.

What is the operating environment?

- If the application is at a high altitude or in an environment where atmospheric pressure can change significantly, and you need to measure a pressure that is not affected by these changes, an absolute pressure sensor is necessary.

Are you measuring the level in a vented or sealed tank?

- For a vented tank, a gauge pressure sensor is used to measure the hydrostatic head of the liquid, as the atmospheric pressure acts on both the liquid surface and the sensor’s reference.

- For a sealed tank, an absolute pressure sensor is often used to measure the pressure of the gas blanket above the liquid, or a differential pressure sensor is used to measure the difference between the top and bottom of the tank.

Conclusion: The Power of Perspective in Pressure Measurement

The distinction between absolute and gauge pressure is a fundamental concept with far-reaching implications. It highlights the importance of having a clear and consistent frame of reference in any measurement. While both measure the same physical phenomenon—the force exerted per unit area—their different reference points make them suitable for distinct and specific applications.

Absolute pressure provides a complete picture, measuring against the ultimate zero point of a perfect vacuum. It is the go-to choice for applications that are sensitive to atmospheric pressure changes or operate in a vacuum.

Gauge pressure offers a relative perspective, measuring against the ever-present atmospheric pressure. It is the workhorse of countless industrial and everyday applications where the pressure relative to the surroundings is the critical parameter.

By understanding the key differences, the working principles of their respective sensors, and the applications for which they are best suited, engineers, technicians, and scientists can ensure they are selecting the right tool for the job. This not only guarantees the accuracy and reliability of their measurements but also contributes to the safety, efficiency, and success of their processes and products. The next time you encounter a pressure reading, take a moment to consider its frame of reference—it makes all the difference in the world.