An Overview of Pressure Transmitters: Working and Applications

In the intricate world of industrial automation and process control, precision is paramount. Myriad variables—temperature, flow, level, and pressure—must be meticulously monitored and controlled to ensure safety, efficiency, and product quality. Among the unsung heroes of this domain are pressure transmitters, robust devices that form the bedrock of countless measurement and control systems. This comprehensive overview delves into the working principles of pressure transmitters, explores their diverse types, and highlights their critical applications across a spectrum of industries. This article is crafted for instrumentation professionals seeking to deepen their knowledge and for students aspiring to embark on a journey into this fascinating field.

What is a Pressure Transmitter?

At its core, a pressure transmitter is a device that measures the pressure of a fluid or gas and converts it into a standardized electrical signal. This signal, typically a 4-20 mA current loop, a 0-10 VDC voltage signal, or a digital signal (like HART or Fieldbus), can be transmitted over long distances to a control system, such as a Distributed Control System (DCS) or a Programmable Logic Controller (PLC). These systems then interpret the signal to display the pressure reading, trigger alarms, or actuate control elements like valves and pumps.

The fundamental purpose of a pressure transmitter is to bridge the gap between the physical world of pressure and the digital realm of control systems. This seemingly simple function is indispensable for maintaining operational integrity and safety in a vast array of industrial processes.

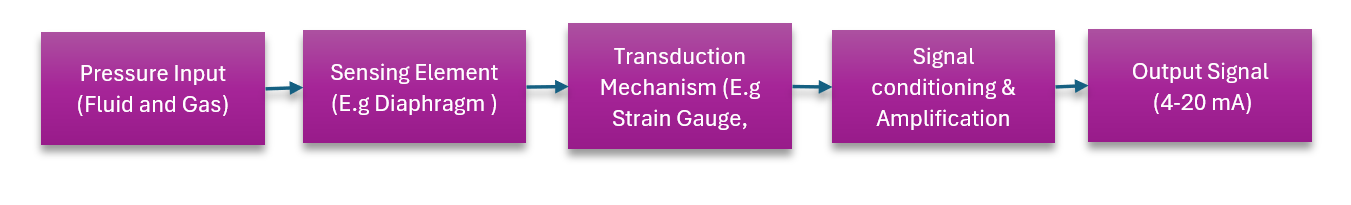

The Inner Workings: A Generic Block Diagram

Before we delve into the specifics of different pressure transmitter types, let’s understand the fundamental components and their interplay through a generic block diagram.

Block Diagram of a Generic Pressure Transmitter

- Process Connection & Diaphragm: This is the interface between the transmitter and the process fluid. The process pressure exerts a force on a flexible diaphragm, causing it to deflect. The material and design of the diaphragm are crucial for chemical compatibility and pressure range.

- Sensing Element: The deflection of the diaphragm is detected by a sensing element. The type of sensing element is the primary differentiator between various pressure transmitter technologies.

- Transduction Mechanism: This is the heart of the transmitter. It converts the physical change in the sensing element (e.g., strain, capacitance change) into a proportional electrical signal.

- Signal Conditioning & Amplification: The raw electrical signal from the transduction mechanism is often weak and non-linear. This stage conditions the signal by amplifying, linearizing, and compensating for temperature variations to ensure an accurate and stable output.

- Output Signal: Finally, the conditioned signal is converted into a standard industrial output signal, ready for transmission to the control system.

Types of Pressure Transmitters and Their Working Principles

Pressure transmitters are not a one-size-fits-all solution. The choice of transmitter depends on the specific application, the nature of the process fluid, the required accuracy, and environmental conditions. Let’s explore the most common types:

1. Strain Gauge Pressure Transmitters

Strain gauge transmitters are one of the most prevalent types due to their robustness and reliability.

Working Principle: These transmitters utilize the principle of piezoresistivity, where the electrical resistance of a material changes in response to applied mechanical stress. A strain gauge, a thin wire or foil arranged in a grid pattern, is bonded to the sensing diaphragm. When pressure deflects the diaphragm, the strain gauge is either stretched or compressed, altering its resistance.

Block Diagram of a Strain Gauge Pressure Transmitter:

The change in resistance of the strain gauge is typically measured using a Wheatstone bridge circuit. The output voltage of the bridge is directly proportional to the applied pressure. This voltage is then amplified and conditioned to produce the standard output signal.

Applications:

- Hydraulic and pneumatic systems

- Industrial machinery and equipment

- Test and measurement benches

- General industrial pressure monitoring

2. Capacitive Pressure Transmitters

Capacitive pressure transmitters are renowned for their high accuracy and excellent long-term stability.

Working Principle: These transmitters work on the principle of capacitance variation. The sensing element consists of two parallel conductive plates separated by a dielectric material. One plate is fixed, while the other is a flexible diaphragm exposed to the process pressure. As the pressure changes, the distance between the plates changes, leading to a change in capacitance.

Block Diagram of a Capacitive Pressure Transmitter:

The change in capacitance is measured by an electronic circuit and converted into a voltage or frequency signal. This signal is then processed to generate the final output signal.

Applications:

- Critical process control in chemical and petrochemical industries

- Level measurement in tanks

- Flow measurement using differential pressure

- Custody transfer applications requiring high accuracy

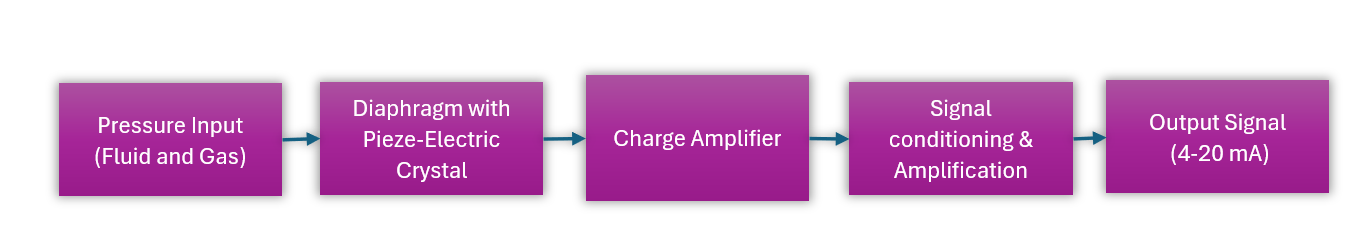

3. Piezoelectric Pressure Transmitters

Piezoelectric pressure transmitters are ideal for measuring dynamic or rapidly changing pressures.

Working Principle: These transmitters leverage the piezoelectric effect, where certain crystalline materials (like quartz) generate an electrical charge when subjected to mechanical stress. A piezoelectric crystal is coupled to the sensing diaphragm. When pressure is applied, the crystal is compressed, producing a charge proportional to the pressure change.

Block Diagram of a Piezoelectric Pressure Transmitter:

A charge amplifier converts this high-impedance charge signal into a usable low-impedance voltage signal, which is then conditioned to provide the final output. It’s important to note that piezoelectric sensors are not suitable for measuring static pressures as the charge dissipates over time.

Applications:

- Engine combustion analysis

- Ballistics and explosion testing

- High-frequency pressure pulsation measurement in pipelines

- Dynamic pressure monitoring in hydraulic systems

4. Other Types of Pressure Transmitters

- Resonant Wire Pressure Transmitters: These use a vibrating wire whose resonant frequency changes with the tension applied by the process pressure. They offer excellent long-term stability.

- Optical Pressure Transmitters: These utilize fiber optic technology where pressure-induced changes in the properties of light (like intensity or wavelength) are measured. They are immune to electromagnetic interference and are suitable for harsh environments.

Classification of Pressure Transmitters based on Measurement Type

Pressure transmitters can also be classified based on the type of pressure they measure:

- Gauge Pressure Transmitters: These measure pressure relative to the local atmospheric pressure. This is the most common type of pressure measurement.

- Absolute Pressure Transmitters: These measure pressure relative to a perfect vacuum (absolute zero pressure). The sensing element is housed in a vacuum-sealed chamber. They are used in applications where atmospheric pressure variations can affect the process, such as in vacuum packaging and altitude measurement.

- Differential Pressure (DP) Transmitters: These measure the difference in pressure between two points. They have two process connections, a high-pressure side and a low-pressure side. DP transmitters are incredibly versatile and are widely used for:

- Flow Measurement: By measuring the pressure drop across a primary flow element like an orifice plate or venturi tube.

- Level Measurement: By measuring the hydrostatic head of a liquid in a tank.

- Filter Monitoring: By measuring the pressure drop across a filter to determine its clogging level.

- Multivariable Transmitters: These advanced transmitters can measure multiple process variables simultaneously, such as differential pressure, static pressure, and temperature, all in a single device. They can then calculate compensated flow rates, providing a more accurate measurement.

Applications of Pressure Transmitters Across Industries

The applications of pressure transmitters are vast and varied, touching nearly every aspect of modern industry. Here are some key examples:

Oil and Gas Industry

- Upstream: Monitoring wellhead pressure, pipeline pressure, and separator pressure.

- Midstream: Ensuring safe and efficient transportation of oil and gas through pipelines by monitoring pressure at various points.

- Downstream: Controlling pressure in distillation columns, reactors, and storage tanks in refineries.

Chemical and Petrochemical Industries

- Maintaining precise pressure control in chemical reactors to ensure desired reaction rates and product quality.

- Monitoring pressure in distillation columns for efficient separation of components.

- Ensuring the safe handling and storage of volatile chemicals by monitoring tank pressures.

Power Generation

- Monitoring steam pressure in boilers and turbines in thermal power plants.

- Measuring hydraulic pressure in hydroelectric power plants.

- Controlling gas pressure in gas-fired power plants.

Pharmaceutical and Food & Beverage Industries

- Ensuring sterile conditions by monitoring pressure in autoclaves and sterilization processes.

- Controlling pressure in bioreactors for optimal cell growth.

- Monitoring and controlling pressure in filling and bottling lines.

- Ensuring the integrity of packaging through leak detection using pressure decay methods.

Water and Wastewater Treatment

- Monitoring water pressure in distribution networks.

- Controlling pump operation based on pressure levels.

- Measuring sludge and water levels in tanks using differential pressure transmitters.

Aerospace and Automotive Industries

- Testing and monitoring hydraulic and pneumatic systems in aircraft.

- Measuring engine performance parameters.

- Controlling tire pressure monitoring systems (TPMS).

Calibration and Maintenance: Ensuring Accuracy and Reliability

For pressure transmitters to perform their function reliably, they must be calibrated and maintained regularly.

- Calibration: This is the process of comparing the output of the pressure transmitter against a known standard of higher accuracy. It involves adjusting the transmitter’s zero and span to ensure its output accurately reflects the process pressure. The frequency of calibration depends on the criticality of the application and the manufacturer’s recommendations.

- Maintenance: Regular maintenance practices include:

- Visual Inspection: Checking for any physical damage, corrosion, or leaks.

- Impulse Line Cleaning: Ensuring the lines connecting the transmitter to the process are not clogged or blocked.

- Zero and Span Checks: Periodically verifying the transmitter’s output at zero and full-scale pressure.

The Future of Pressure Transmitters

The field of pressure measurement is continuously evolving. The future of pressure transmitters is being shaped by several key trends:

- Wireless Technology: Wireless pressure transmitters are gaining popularity as they eliminate the need for costly and complex wiring, especially in remote or hazardous locations.

- Smart Transmitters: Modern transmitters are becoming “smarter” with embedded microprocessors that offer advanced diagnostics, self-calibration capabilities, and digital communication protocols like Foundation Fieldbus and Profibus.

- Miniaturization: Advances in MEMS (Micro-Electro-Mechanical Systems) technology are leading to smaller, more compact, and more energy-efficient pressure sensors.

- Internet of Things (IoT) Integration: Pressure transmitters are increasingly being integrated into IoT platforms, enabling remote monitoring, data analytics, and predictive maintenance.

Conclusion

Pressure transmitters are the silent workhorses of the instrumentation world. From the deepest oil wells to the most advanced pharmaceutical labs, these devices play a pivotal role in ensuring the safety, efficiency, and quality of countless processes. Understanding their working principles, the nuances of different types, and their diverse applications is fundamental for any instrumentation professional or student. As technology continues to advance, the capabilities of pressure transmitters will only expand, further solidifying their indispensable role in the ever-evolving landscape of industrial automation. The next time you see a complex industrial facility, remember that within its intricate network of pipes and vessels, countless pressure transmitters are diligently working to keep everything under control.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.