In the world of industrial automation and process control, accuracy, reliability, and intelligence are paramount. For decades, pressure transmitters have been the silent workhorses, diligently measuring and communicating a critical process variable. However, the advent of microprocessor technology has ushered in a new era of “smart” instrumentation. This blog post delves deep into the realm of smart pressure transmitters, exploring their advanced features, significant advantages over their conventional counterparts, and their diverse applications across various industries. This comprehensive guide is designed for instrumentation professionals seeking to optimize their processes and for students eager to understand the cutting edge of measurement technology.

What Makes a Pressure Transmitter “Smart”?

At its core, a pressure transmitter is a device that senses pressure and converts it into an electrical signal. A traditional or “dumb” transmitter provides a simple analog output, typically a 4-20 mA signal, directly proportional to the measured pressure. While functional, this approach offers limited information and flexibility.

A smart pressure transmitter, on the other hand, integrates a microprocessor, which acts as its brain. This onboard intelligence allows for a wealth of advanced functionalities that go far beyond simple pressure measurement.

Here’s a breakdown of the key characteristics that define a smart pressure transmitter:

- Digital Communication: Smart transmitters can communicate digitally using protocols like HART (Highway Addressable Remote Transducer), FOUNDATION Fieldbus, or Profibus. This digital communication is superimposed on the same two wires that carry the 4-20 mA analog signal, enabling two-way communication without the need for additional wiring.

- Onboard Diagnostics: The microprocessor continuously runs self-diagnostic routines, monitoring the health of the sensor and the transmitter’s internal electronics. This proactive approach to maintenance can alert operators to potential issues before they lead to a process shutdown.

- Remote Configuration and Monitoring: Technicians can remotely configure, calibrate, and monitor smart transmitters from a central control room or a handheld communicator. This eliminates the need for frequent and often hazardous trips to the field.

- Improved Accuracy and Rangeability: Smart transmitters offer higher accuracy over a wider range of operating conditions. They can be precisely calibrated and have a high turndown ratio, meaning a single transmitter can be configured for a wide range of measurement spans.

- Multivariable Measurement: Some advanced smart transmitters can measure more than just one process variable. For instance, a multivariable pressure transmitter can simultaneously measure differential pressure, static pressure, and process temperature.

Unveiling the Inner Workings: A Look Inside

To truly appreciate the capabilities of a smart pressure transmitter, let’s examine its internal architecture.

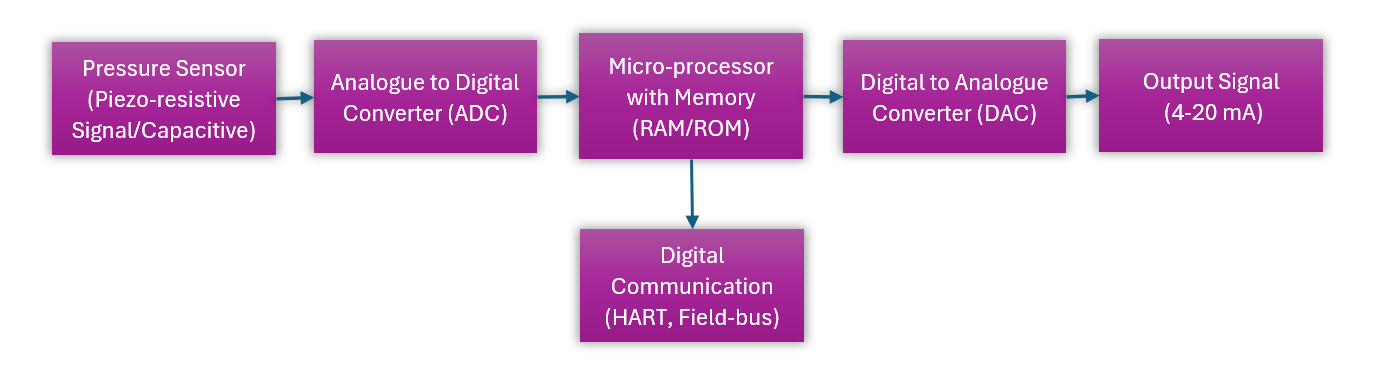

Block Diagram: Internal Components of a Smart Pressure Transmitter

- Pressure Sensor: This is the primary sensing element that comes into contact with the process fluid. Common types include piezoresistive, capacitive, and strain gauge sensors. It converts the physical pressure into a proportional electrical signal (e.g., a change in resistance or capacitance).

- Analog-to-Digital Converter (ADC): The raw analog signal from the sensor is converted into a digital format that the microprocessor can understand.

- Microprocessor: This is the heart of the smart transmitter. It performs several critical functions:

- Signal Conditioning: It linearizes the sensor output, compensating for non-linearities.

- Temperature Compensation: It corrects for variations in process and ambient temperature that can affect the accuracy of the pressure reading.

- Engineering Unit Conversion: It converts the digital pressure value into standard engineering units (e.g., psi, bar, kPa).

- Diagnostics: It continuously monitors the health of the sensor and internal electronics.

- Memory (RAM/ROM): The microprocessor uses RAM for temporary data storage and ROM to store the transmitter’s firmware and configuration data.

- Digital-to-Analog Converter (DAC): The processed digital signal is converted back into a standard 4-20 mA analog signal for compatibility with legacy control systems.

- Digital Communication Module: This enables two-way digital communication over the same wiring, allowing for remote configuration, diagnostics, and the transmission of additional process variables.

The Decisive Edge: Advantages of Smart Over Conventional Transmitters

The integration of a microprocessor gives smart pressure transmitters a significant advantage over their conventional counterparts.

| Feature | Conventional Pressure Transmitter | Smart Pressure Transmitter |

|---|---|---|

| Accuracy | Moderate, affected by environmental changes. | High, with automatic compensation for temperature and pressure variations. |

| Communication | One-way analog signal (4-20 mA). | Two-way digital communication (HART, Fieldbus) on top of the analog signal. |

| Configuration | Manual, requires physical access and adjustments (e.g., zero and span screws). | Remote and local configuration via handheld communicators or control systems. |

| Diagnostics | Limited to no self-diagnostics. | Comprehensive self-diagnostics of the sensor, electronics, and even the process. |

| Rangeability | Low turndown ratio (typically 10:1). | High turndown ratio (up to 400:1 or more), offering greater flexibility. |

| Maintenance | Reactive; troubleshooting is time-consuming. | Proactive; predictive maintenance alerts reduce downtime. |

| Information | Transmits only the primary process variable. | Transmits the primary variable, plus diagnostic data, device status, and other variables. |

| Cost | Lower initial purchase price. | Higher initial cost, but lower total cost of ownership due to reduced maintenance and improved efficiency. |

Smart Pressure Transmitters in Action: System Integration

Smart pressure transmitters are integral components of modern process control loops. Their ability to provide rich, real-time data enhances the effectiveness of Distributed Control Systems (DCS), Programmable Logic Controllers (PLCs), and asset management systems.

Block Diagram: Smart Pressure Transmitter in a Process Control Loop

In this loop:

- The smart pressure transmitter measures the pressure in the process.

- It transmits this information via a 4-20 mA signal with superimposed HART data to the control system.

- The control system not only receives the pressure reading but also diagnostic information from the transmitter.

- The control system compares the measured pressure to a setpoint and sends a signal to the final control element (e.g., a control valve) to adjust the process.

- The operator workstation provides a graphical interface for operators to monitor the process, view transmitter status, and receive alerts.

- Maintenance personnel can use a handheld communicator or asset management software to remotely interrogate the transmitter for detailed diagnostic information.

A World of Applications: Where Smart Pressure Transmitters Shine

The versatility and robustness of smart pressure transmitters make them indispensable in a wide array of industries.

- Oil and Gas: From wellhead monitoring and pipeline pressure management to refinery processes, smart transmitters provide the accuracy and reliability needed in these demanding and often hazardous environments. Their remote diagnostic capabilities are particularly valuable for offshore platforms and remote pipeline stations.

- Chemical and Petrochemical: Precise pressure control is critical for ensuring the safety and efficiency of chemical reactions. Smart transmitters are used to measure reactor pressure, distillation column pressure, and the level in storage tanks. Their corrosion-resistant materials are essential for handling aggressive chemicals.

- Power Generation: In power plants, smart pressure transmitters monitor steam pressure, boiler drum level, condenser vacuum, and turbine pressures. The high accuracy and reliability of these instruments are crucial for plant safety and operational efficiency.

- Pharmaceutical and Biotechnology: Maintaining sterile and precise conditions is paramount in pharmaceutical manufacturing. Smart transmitters with hygienic connections are used for bioreactor pressure control, filtration and separation processes, and clean-in-place (CIP) and sterilize-in-place (SIP) systems.

- Food and Beverage: Similar to the pharmaceutical industry, the food and beverage sector relies on hygienic smart pressure transmitters for applications such as tank level measurement (hydrostatic pressure), pasteurization, and filtration processes.

- Water and Wastewater: Smart transmitters are used to monitor and control pressure in water distribution networks, pump stations, and wastewater treatment plants. Their ability to detect leaks and blockages through pressure monitoring helps in efficient water management.

- Pulp and Paper: The pulp and paper industry uses smart transmitters to measure pressure in headboxes, steam lines, and chemical recovery boilers. These instruments can withstand the harsh and often corrosive environments found in paper mills.

Choosing the Right Smart Pressure Transmitter: Key Considerations

Selecting the appropriate smart pressure transmitter for a specific application is crucial for optimal performance and longevity. Here are some key factors to consider:

- Pressure Type: Determine whether you need to measure gauge, absolute, or differential pressure.

- Process Medium: Consider the chemical compatibility of the transmitter’s wetted parts (diaphragm and process connection) with the process fluid. Corrosive or abrasive fluids may require special materials like Hastelloy C or Tantalum.

- Pressure Range: The transmitter’s operating range should comfortably encompass the expected process pressures, including any potential overpressure conditions.

- Accuracy and Performance: The required level of accuracy will depend on the criticality of the measurement. For custody transfer or critical control loops, higher accuracy will be necessary.

- Operating Temperature and Pressure: Ensure the transmitter can withstand the maximum operating temperature and pressure of the process.

- Communication Protocol: Choose a transmitter with a communication protocol (HART, FOUNDATION Fieldbus, Profibus) that is compatible with your existing control system.

- Hazardous Area Approvals: If the transmitter is to be installed in a hazardous area, it must have the appropriate certifications (e.g., ATEX, IECEx, FM).

- Mounting and Installation: Consider the physical space available and the required process connection type (threaded, flanged, hygienic).

The Future is Smarter: Trends in Pressure Measurement

The evolution of smart pressure transmitters is far from over. Several exciting trends are shaping the future of this technology:

- Wireless Technology: The adoption of wireless communication standards like WirelessHART and ISA100.11a is enabling the installation of pressure transmitters in previously inaccessible or cost-prohibitive locations.

- Internet of Things (IoT) and Industry 4.0: Smart transmitters are becoming key data sources for the Industrial Internet of Things (IIoT). The wealth of data they provide can be leveraged for advanced analytics, predictive maintenance, and process optimization.

- Enhanced Diagnostics and Predictive Analytics: Future transmitters will feature even more sophisticated diagnostic capabilities, capable of not only detecting internal faults but also analyzing process noise to predict potential issues like pump cavitation or pipeline blockages.

- Miniaturization and MEMS Technology: Advances in Micro-Electro-Mechanical Systems (MEMS) technology are leading to smaller, more power-efficient, and cost-effective pressure sensors.

- Multivariable Transmitters: The trend towards measuring multiple process variables with a single device will continue, reducing installation costs and providing a more holistic view of the process.

Conclusion: The Intelligent Choice for Modern Industry

Smart pressure transmitters represent a paradigm shift in process measurement. Their onboard intelligence, two-way communication, and advanced diagnostics offer unparalleled advantages in terms of accuracy, reliability, and operational efficiency. For instrumentation professionals and students alike, understanding the features, benefits, and applications of these remarkable devices is essential for navigating the complexities of modern industrial automation. As technology continues to evolve, smart pressure transmitters will undoubtedly play an even more critical role in creating safer, more efficient, and more intelligent industrial processes worldwide.