Globe Valve vs. Ball Valve vs. Butterfly Valve for Control Applications

Choosing the right control valve is crucial for optimizing the performance and efficiency of any process plant. Three of the most common types of control valves are globe valves, ball valves, and butterfly valves. Each type has its unique characteristics, advantages, and disadvantages, making them suitable for different control applications. This blog post will delve into a detailed comparison of these three valve types, providing instrumentation engineers with the insights needed to make informed decisions.

Understanding Control Valves

A control valve is a power-operated device used to regulate the flow rate of a fluid (liquid, gas, or slurry) within a process control system. It typically consists of a valve body, an actuator (pneumatic, electric, or hydraulic), and a positioner that ensures the valve stem and hence the flow control element moves to the desired position as dictated by the control system. The primary function of a control valve is to manipulate the fluid flow in response to signals received from a controller, thereby maintaining process variables such as pressure, temperature, level, and flow at their desired setpoints.

Globe Valve: The Precision Controller

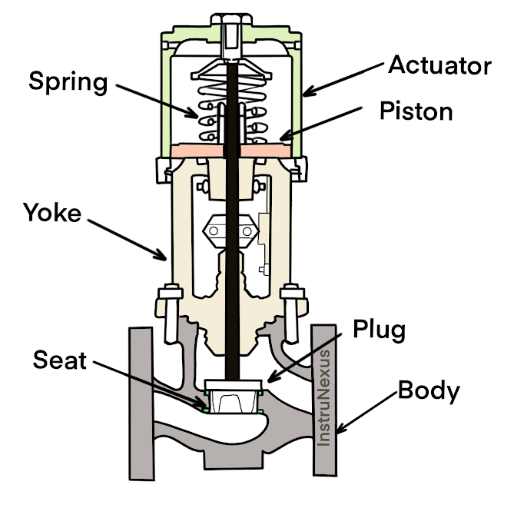

Working Principle:

Globe valves operate on a linear motion principle. The valve plug, connected to the actuator stem, moves perpendicularly into or out of the valve seat located within the valve body. This linear movement allows for precise control of the flow as the opening between the plug and the seat changes proportionally to the stem travel. The S-body or Z-body design is common, providing a relatively tortuous flow path that contributes to pressure drop but also aids in effective flow modulation.

Advantages:

- Excellent Throttling Capability: The design allows for precise and repeatable flow control over a wide range. The linear relationship between valve stem position and flow rate makes them ideal for modulating applications.

- Tight Shut-off: With proper seating, globe valves can provide excellent shut-off capabilities, minimizing leakage when the valve is closed.

- Suitability for High Pressure and Temperature: Globe valves are often robustly constructed and can handle high pressure and temperature applications, depending on the material selection.

- Versatility: They can be used for a wide variety of fluids, including clean liquids, gases, and steam.

Disadvantages:

- High Pressure Drop: The tortuous flow path inherent in the globe valve design results in a significant pressure drop across the valve, which can impact energy efficiency.

- Higher Cost: Generally, globe valves tend to be more expensive than ball or butterfly valves of the same size and pressure rating due to their more complex construction.

- Higher Actuation Force Required: The design often necessitates larger and more powerful actuators to overcome the pressure forces acting on the valve plug.

- Not Ideal for Slurries or Viscous Fluids: The flow path can be prone to clogging or erosion when handling slurries or highly viscous fluids.

Typical Control Applications for Globe Valves:

Globe valves are the preferred choice for applications requiring precise flow control, such as:

- Flow Regulation: Controlling the flow rate of liquids, gases, and steam in various process lines.

- Pressure Control: Used as pressure regulating valves to maintain desired downstream pressure.

- Level Control: Regulating the flow into or out of vessels to maintain a specific liquid level.

- Temperature Control: Controlling the flow of heating or cooling media to maintain a desired temperature.

Ball Valve: The On-Off Specialist with Modulating Capabilities

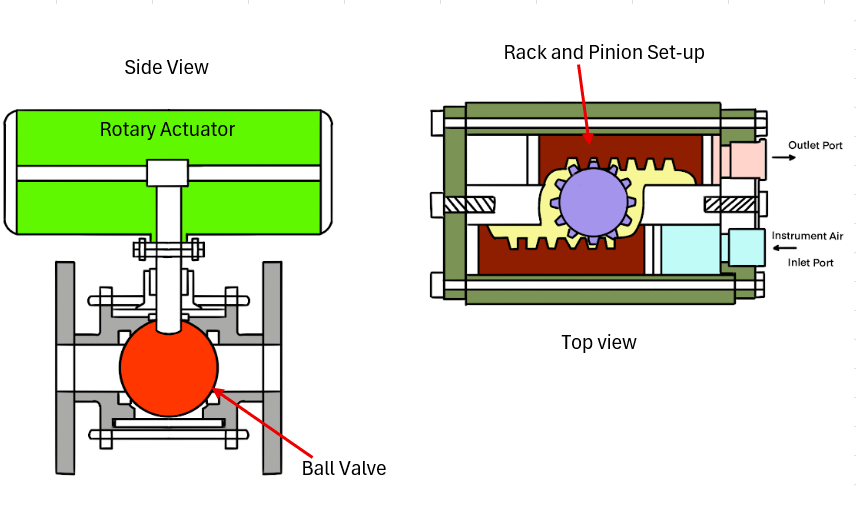

Working Principle:

Ball valves are quarter-turn rotary motion valves that use a ball-shaped disc with a bore through the center to control flow. When the valve is open, the bore is aligned with the flow path, allowing unobstructed flow. When the valve is closed, the ball is rotated 90 degrees, and the solid part of the ball blocks the flow. While primarily known for on-off service, segmented or V-notch ball valves are specifically designed for throttling control.

Advantages:

- Low Pressure Drop: In the fully open position, the straight-through bore offers minimal obstruction to flow, resulting in a very low pressure drop and high flow capacity.

- Quick Operation: The quarter-turn actuation allows for rapid opening and closing, making them suitable for emergency shut-down systems.

- Tight Shut-off (for many designs): Most ball valve designs, especially those with soft seats, can provide excellent bubble-tight shut-off.

- Relatively Low Cost: Generally, standard ball valves are less expensive than globe valves of comparable size and rating.

- Compact Design: Ball valves tend to be more compact and lighter than globe valves, saving space and reducing piping support requirements.

Disadvantages:

- Poor Throttling Capability (standard designs): Standard full-bore ball valves are not well-suited for precise throttling in partially open positions. The flow characteristics are non-linear, and they can experience significant wear and cavitation if used for prolonged throttling.

- Potential for Cavitation and Flashing: Under high differential pressure conditions, ball valves can be susceptible to cavitation and flashing, especially in throttling applications.

- Limited Suitability for Slurries (standard designs): While some specialized ball valves are designed for slurries, standard designs can experience seat wear and clogging.

Typical Control Applications for Ball Valves:

While primarily used for on-off service, specialized ball valves find applications in:

- On-Off Control: Providing quick and tight shut-off or full flow in various process lines.

- Emergency Shut-Down (ESD) Systems: Their fast actuation makes them ideal for safety-critical applications.

- Isolation Service: Used to isolate sections of a process for maintenance or other purposes.

- Modulating Control (with segmented or V-notch designs): Segmented or V-notch ball valves offer improved throttling capabilities for applications where precise linear control is not critical but good rangeability is needed. These are often used in less demanding control loops.

Butterfly Valve: The Economical Large-Diameter Solution

Working Principle:

Butterfly valves are quarter-turn rotary motion valves that control flow by rotating a disc within the valve body. The disc, which is mounted on a stem, is positioned perpendicular to the flow in the closed position, blocking the fluid passage. When the valve is opened, the disc is rotated, allowing flow to pass around it. The degree of opening is proportional to the angle of rotation of the disc.

Advantages:

- Low Cost, Especially for Large Diameters: Butterfly valves are generally the least expensive option, particularly for large pipe sizes, due to their simpler design and fewer parts.

- Lightweight and Compact: Their wafer or lug-style designs make them lightweight and require minimal installation space.

- High Flow Capacity: When fully open, the thin disc offers relatively low obstruction to flow, resulting in a good flow capacity and lower pressure drop compared to globe valves.

- Quick Operation: Like ball valves, the quarter-turn actuation allows for rapid opening and closing.

Disadvantages:

- Poorer Throttling Capability Compared to Globe Valves: The non-linear flow characteristics and the potential for turbulence caused by the disc in the flow stream make precise throttling challenging. Control accuracy is generally lower than with globe valves.

- Lower Pressure and Temperature Limits (generally): Standard butterfly valves may have lower pressure and temperature limitations compared to robust globe valves. However, high-performance butterfly valves are available for more demanding conditions.

- Potential for Leakage: Achieving a tight shut-off can be more challenging with some butterfly valve designs, especially at high pressures or with certain fluids. However, high-performance butterfly valves with advanced seat designs offer improved shut-off capabilities.

- Not Ideal for Slurries or Viscous Fluids (standard designs): The disc can obstruct the flow of slurries, and viscous fluids can cause increased pressure drop.

Typical Control Applications for Butterfly Valves:

Butterfly valves are widely used in various industries for:

- Large Diameter Applications: Their cost-effectiveness makes them the preferred choice for controlling flow in large pipelines, such as in water treatment plants, power generation, and HVAC systems.

- Low to Medium Pressure and Temperature Services: Suitable for a wide range of applications within their pressure and temperature ratings.

- Cooling Water Systems: Commonly used to regulate the flow of cooling water.

- Air and Gas Handling: Used for controlling the flow of air and other gases.

- Modulating Control (with specialized designs): High-performance butterfly valves with characterized discs and tight sealing capabilities are increasingly used for modulating control in applications where precise linearity is not paramount but good rangeability and cost-effectiveness are desired.

Head-to-Head Comparison: Key Differences Summarized

To provide a clearer overview, the following table summarizes the key differences between globe, ball, and butterfly valves for control applications:

| Feature | Globe Valve | Ball Valve | Butterfly Valve |

|---|---|---|---|

| Working Principle | Linear motion of a plug into a seat | Quarter-turn rotation of a ball with a bore | Quarter-turn rotation of a disc |

| Throttling Capability | Excellent, precise linear control | Poor (standard), Good (segmented/V-notch) | Fair to Good (high-performance) |

| Shut-off | Excellent | Excellent (most designs) | Good to Excellent (high-performance) |

| Pressure Drop | High | Very Low (fully open) | Low to Medium |

| Cost | Higher | Lower (standard), Medium (specialized) | Lowest (especially large diameters) |

| Size & Weight | Larger and heavier | Compact and lighter | Lightweight and compact |

| Operation Speed | Slower | Fast | Fast |

| Slurry/Viscous Fluids | Generally Not Suitable | Limited Suitability (standard) | Limited Suitability (standard) |

| High P & T Service | Good to Excellent | Fair to Good | Fair to Good (high-performance) |

| Typical Applications | Precise flow, pressure, level, temp control | On-off, isolation, some modulating control | Large diameter, low to medium P & T, some modulating control |

Making the Right Choice: Factors to Consider

Selecting the most appropriate control valve involves a careful evaluation of several factors specific to the application:

- Control Requirements: How precise does the flow control need to be? Is a linear relationship between the control signal and flow rate required?

- Pressure Drop Limitations: Can the system tolerate a significant pressure drop across the valve?

- Shut-off Requirements: How critical is bubble-tight shut-off when the valve is closed?

- Fluid Characteristics: What are the properties of the fluid being controlled (clean liquid/gas, slurry, viscous)? Are there concerns about corrosion or erosion?

- Operating Conditions: What are the maximum pressure and temperature the valve will be subjected to?

- Valve Size: What is the pipe size? For large diameters, cost becomes a significant factor.

- Actuation Requirements: What type of actuator is needed (pneumatic, electric, hydraulic)? What are the speed and force requirements?

- Budget: What is the allowable cost for the valve and its associated components?

Humanized Considerations:

Beyond the technical specifications, consider the practical aspects of valve selection:

- Ease of Maintenance: How easy is it to inspect, clean, and repair the valve? Are spare parts readily available?

- Reliability and Lifespan: What is the expected lifespan of the valve under the given operating conditions? What is its track record for reliability?

- Industry Standards and Best Practices: Are there specific industry standards or best practices that dictate the type of valve to be used for a particular application?

- Operator Familiarity: Are the plant personnel familiar with the operation and maintenance of the chosen valve type?

Conclusion:

Globe valves, ball valves, and butterfly valves each offer a unique set of characteristics that make them suitable for different control applications. Globe valves excel in providing precise throttling control but come with higher pressure drop and cost. Ball valves are ideal for on-off service and offer low pressure drop, with specialized designs extending their modulating capabilities. Butterfly valves provide a cost-effective solution, particularly for large diameters and low to medium pressure applications, with improving modulating capabilities in high-performance designs.

By carefully considering the specific requirements of your control application and weighing the advantages and disadvantages of each valve type, instrumentation engineers can make informed decisions that lead to optimized process performance, energy efficiency, and long-term reliability. Remember to look beyond the initial cost and consider the total cost of ownership, including maintenance, energy consumption, and potential downtime. Choosing the right control valve is an investment in the efficiency and safety of your process plant.