The Unseen Guardian: Why Functional Safety is Non-Negotiable in Process Industries

In the heart of sprawling industrial landscapes, where colossal networks of pipes, vessels, and reactors hum with immense energy, a silent, ever-vigilant guardian stands watch. This guardian is not a person in a hard hat, but a deeply embedded principle, a rigorous discipline known as functional safety. In process industries—be it oil and gas, chemical manufacturing, pharmaceuticals, or power generation—the stakes are astronomically high. A single failure can trigger a catastrophic chain of events, leading to devastating consequences for human life, the environment, and business continuity. This blog post delves into the critical importance of functional safety in these high-hazard environments, exploring its core tenets, the standards that govern it, and the life-saving role it plays in preventing disasters.

What is Functional Safety? More Than Just a Safety Switch

At its core, functional safety is the part of the overall safety of a system or piece of equipment that depends on the correct functioning of safety-related systems in response to their inputs. It’s about ensuring that the active safety systems—the ones that are designed to intervene automatically when things go wrong—perform their intended function, every single time.

Think of it as the emergency brake system in your car. You hope you never have to use it, but you have absolute confidence that it will work flawlessly the moment you slam your foot on the pedal. Functional safety in a chemical plant operates on the same principle, but on a vastly more complex and critical scale. It’s not about the inherent strength of a pressure vessel (that’s mechanical integrity), but about the automated system that will safely shut down a process if the pressure inside that vessel exceeds a critical limit.

A Bitter Lesson: The High Cost of Functional Safety Failures

History, unfortunately, is littered with tragic reminders of what happens when functional safety is neglected. These incidents are not mere accidents; they are stark illustrations of systemic failures where automated safety systems did not perform as intended.

One of the most infamous examples is the 1984 Bhopal gas tragedy in India. While rooted in multiple failures, a critical contributing factor was the non-operational state of safety systems, including the vent gas scrubber and the flare tower, which were designed to neutralize the toxic methyl isocyanate gas. Had these functional safety systems been active and effective, the scale of the disaster could have been significantly mitigated.

More recently, the 2005 Texas City Refinery explosion in the United States, which killed 15 workers and injured more than 180, was a direct result of a cascade of failures, including a non-functioning high-level alarm and an overflowing hydrocarbon distillation tower. The safety instrumented system in place was inadequate and improperly managed, a textbook case of functional safety failure.

These events, and countless others, have underscored a fundamental truth: in process industries, functional safety is not a luxury, but a moral and legal imperative.

The Pillars of Modern Functional Safety: IEC 61508 and IEC 61511

In the wake of such disasters, the need for a standardized, systematic approach to functional safety became glaringly apparent. This led to the development of international standards that provide a framework for managing functional safety throughout the entire lifecycle of a plant. The two most important standards for the process industries are:

-

IEC 61508: “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems”: This is the foundational, or “umbrella,” standard for functional safety. It sets out the general requirements for the design, implementation, and management of safety systems for any industry. It introduces the concept of Safety Integrity Levels (SILs), which we will discuss later.

-

IEC 61511: “Functional safety – Safety instrumented systems for the process industry sector”: This is the sector-specific implementation of IEC 61508 for the process industries. It provides more detailed guidance on how to apply the principles of functional safety in environments like chemical plants, refineries, and pharmaceutical manufacturing facilities. It takes the generic requirements of IEC 61508 and puts them into the practical context of process control and safety.

These standards are not just technical documents; they represent a paradigm shift in how safety is approached. They move away from a reactive, “after-the-fact” investigation of accidents to a proactive, risk-based approach that aims to prevent them from ever happening.

The Functional Safety Lifecycle: A Cradle-to-Grave Approach

A cornerstone of both IEC 61508 and IEC 61511 is the concept of the safety lifecycle. This is a systematic, engineering process that covers all phases of a safety system’s life, from initial conception to final decommissioning. The lifecycle approach ensures that safety is considered at every stage and that all activities are properly planned, documented, and verified. The key phases include:

-

Hazard and Risk Assessment: This is the starting point. It involves identifying all potential hazards in a process and evaluating the associated risks. Techniques like Hazard and Operability Studies (HAZOP) are commonly used.

-

Allocation of Safety Functions: Once risks are understood, decisions are made on how to reduce them to a tolerable level. This may involve a combination of different protection layers, including the Basic Process Control System (BPCS), alarms, and, crucially, Safety Instrumented Systems (SIS).

-

Safety Requirements Specification (SRS): This is a detailed document that specifies exactly what the safety system must do. It defines the Safety Instrumented Functions (SIFs) and their required Safety Integrity Level (SIL).

-

Design and Engineering: This is where the SIS is designed based on the SRS. This includes selecting the appropriate sensors, logic solvers, and final elements.

-

Installation, Commissioning, and Validation: The designed system is installed, tested, and validated to ensure it meets the requirements of the SRS.

-

Operation and Maintenance: The SIS must be operated and maintained correctly throughout its life to ensure it remains effective. This includes regular proof testing and management of any changes.

-

Modification: Any changes to the process or the SIS must be carefully managed to ensure that the integrity of the safety system is not compromised.

-

Decommissioning: Even at the end of its life, the safety system must be decommissioned in a safe manner.

The Heart of Functional Safety: The Safety Instrumented System (SIS)

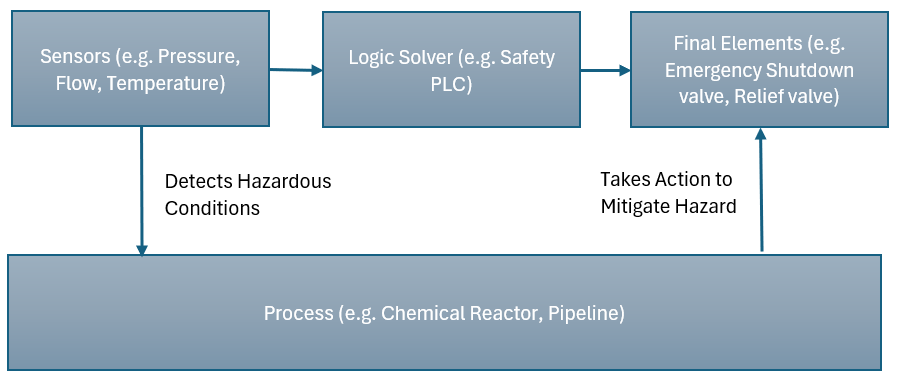

The active implementation of functional safety in the process industries is the Safety Instrumented System (SIS). The SIS is an automated system that is independent of the basic process control system and is designed to take the process to a safe state when a hazardous condition is detected. An SIS is composed of three key elements, as illustrated in the block diagram below:

Block Diagram of a Safety Instrumented System (SIS)

1. Sensors: These are the “eyes and ears” of the SIS. They are responsible for measuring process variables such as pressure, temperature, flow, and level. In a hazardous situation, it is the sensors that first detect the deviation from safe operating limits. For example, a pressure transmitter on a reactor vessel would detect a dangerous rise in pressure.

2. Logic Solver: This is the “brain” of the SIS. It is typically a dedicated safety-certified Programmable Logic Controller (PLC) or a hard-wired relay system. The logic solver receives the signals from the sensors and executes the pre-programmed safety logic. It continuously monitors the process variables and, if they cross a predefined threshold, it makes the decision to activate the final elements. For instance, if the pressure transmitter signals a high-pressure condition, the logic solver will initiate the shutdown sequence.

3. Final Elements: These are the “hands” of the SIS. They are the devices that actually perform the physical action to bring the process to a safe state. Final elements can include emergency shutdown valves, relief valves, blowdown valves, motors, and pumps. In our reactor example, the logic solver would send a signal to an emergency shutdown valve on the reactant feed line, causing it to close and stop the flow of material that is causing the pressure to rise.

These three components work in a tightly integrated and highly reliable manner to form a Safety Instrumented Function (SIF). A single SIS may be responsible for executing multiple SIFs.

Quantifying Safety: Safety Integrity Level (SIL)

A critical concept in functional safety is the Safety Integrity Level (SIL). SIL is a measure of the risk reduction provided by a safety function. There are four SIL levels, from SIL 1 to SIL 4, with SIL 4 providing the highest level of risk reduction.

The required SIL for a particular safety function is determined during the hazard and risk assessment phase. A higher SIL is required for functions that protect against more severe hazards or hazards with a higher likelihood of occurrence. Each SIL level corresponds to a specific range of Probability of Failure on Demand (PFD), which is the probability that the safety function will fail to perform its duty when required.

|

SIL Level |

Probability of Failure on Demand (PFD) |

Risk Reduction Factor (RRF) |

|

SIL 1 |

≥ 10⁻² to < 10⁻¹ |

10 to 100 |

|

SIL 2 |

≥ 10⁻³ to < 10⁻² |

100 to 1,000 |

|

SIL 3 |

≥ 10⁻⁴ to < 10⁻³ |

1,000 to 10,000 |

|

SIL 4 |

≥ 10⁻⁵ to < 10⁻⁴ |

10,000 to 100,000 |

Achieving a higher SIL requires more stringent design, implementation, and maintenance practices, such as using more reliable components, implementing redundancy (e.g., multiple sensors or valves), and performing more frequent proof testing.

The Tangible Benefits of a Robust Functional Safety Program

While the primary motivation for implementing functional safety is the protection of people and the environment, the benefits extend far beyond this. A well-designed and managed functional safety program can deliver significant business advantages:

-

Enhanced Safety and Reduced Incidents: This is the most obvious and important benefit. A robust functional safety program directly leads to a safer working environment and a reduction in the likelihood of catastrophic accidents.

-

Regulatory Compliance: Adherence to standards like IEC 61511 is often a legal requirement. A strong functional safety program ensures compliance with national and international regulations, avoiding hefty fines and legal battles.

-

Improved Plant Availability and Reduced Downtime: While a spurious (unwanted) trip of a safety system can lead to costly downtime, a well-designed SIS is less likely to have such nuisance trips. Furthermore, by preventing major incidents, functional safety avoids long and expensive plant shutdowns for repairs and investigations.

-

Increased Operational Efficiency: The structured and disciplined approach of the safety lifecycle can lead to better-designed and more reliable control systems overall.

-

Enhanced Reputation and Stakeholder Confidence: A strong safety record builds trust with employees, customers, investors, and the surrounding community. It demonstrates a company’s commitment to responsible operation.

-

Lower Insurance Premiums: Insurance companies often recognize a strong functional safety program as a sign of reduced risk and may offer lower premiums as a result.

The Path Forward: A Culture of Safety

Ultimately, functional safety is not just about technology and standards; it’s about culture. It requires a deep-seated commitment from everyone in an organization, from the boardroom to the plant floor, to prioritize safety above all else. It’s about fostering an environment where hazards are proactively identified, risks are openly discussed, and safety systems are meticulously maintained.

In the complex and high-stakes world of process industries, the silent guardian of functional safety is an indispensable ally. It is the unseen force that allows us to harness the power of modern industry while protecting what matters most: human life and the world we share. The investment in a robust functional safety program is not a cost; it is an investment in a safer, more sustainable, and more prosperous future.