In the high-stakes world of the process industry—where chemicals, oil and gas, pharmaceuticals, and other volatile substances are handled daily—safety is not just a priority; it’s a prerequisite. A catastrophic failure in these environments can have devastating consequences for human life, the environment, and business continuity. This is where IEC 61511, the international standard for the functional safety of safety instrumented systems (SIS) in the process industry, plays a pivotal role. This comprehensive blog post will delve into the intricacies of IEC 61511, demystifying its core concepts and providing a roadmap for its practical application.

The Genesis of Functional Safety: From IEC 61508 to IEC 61511

To understand IEC 61511, we must first acknowledge its parent standard, IEC 61508. Published by the International Electrotechnical Commission (IEC), IEC 61508 is a generic functional safety standard that applies to all industries. It provides a foundational framework and a set of requirements for the design, implementation, and operation of safety-related electrical, electronic, and programmable electronic (E/E/PE) systems.

However, the process industry has unique characteristics and challenges that necessitate a more tailored approach. Recognizing this, the IEC developed IEC 61511, a sector-specific implementation of IEC 61508. While IEC 61508 is primarily aimed at manufacturers and suppliers of safety devices, IEC 61511 focuses on the end-users—the plant owners, operators, and engineering contractors—who are responsible for the overall safety of their processes. In essence, IEC 61511 translates the principles of IEC 61508 into a practical and pragmatic language for the process industry.

The Core Philosophy: The Safety Lifecycle

At the heart of IEC 61511 lies the concept of the Safety Lifecycle. This is a systematic, cradle-to-grave approach to managing the functional safety of a process. It encompasses all phases, from the initial hazard and risk assessment to the eventual decommissioning of the safety system. The safety lifecycle ensures that safety is not an afterthought but is an integral part of the entire process design and operation.

A simplified block diagram of the IEC 61511 Safety Lifecycle is as follows:

Let’s break down the key phases of this lifecycle:

1. Analysis Phase:

Hazard and Risk Assessment (HRA): This is the starting point. It involves identifying potential hazards in the process (e.g., a runaway reaction, a vessel overpressure) and assessing the associated risks. Techniques like Hazard and Operability studies (HAZOP) are commonly used in this phase.

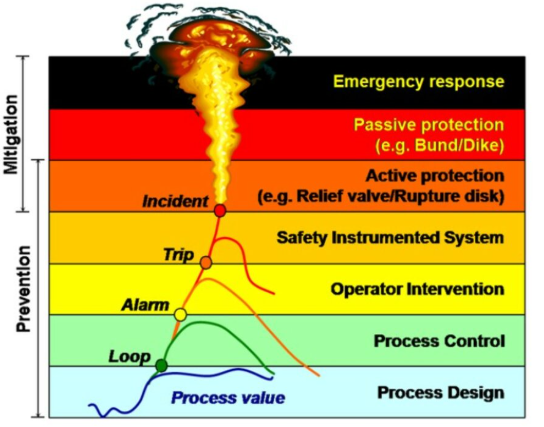

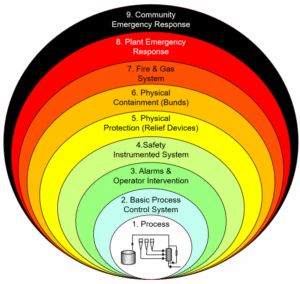

Allocation of Safety Functions to Protection Layers: No single safety measure is foolproof. Therefore, a “layers of protection” approach is adopted. These layers can include the basic process control system (BPCS), alarms, and physical protections like relief valves. If the risk cannot be reduced to a tolerable level by these layers, a Safety Instrumented Function (SIF) is required.

Safety Requirements Specification (SRS): Once a SIF is deemed necessary, a detailed SRS must be developed. This is a critical document that specifies what the SIF must do, under what conditions, and with what level of reliability. It defines the functional and integrity requirements for the SIF.

2. Realization Phase:

Design and Engineering of the SIS: Based on the SRS, the Safety Instrumented System (SIS) is designed. This involves selecting appropriate sensors (e.g., pressure transmitters, temperature sensors), logic solvers (e.g., safety PLCs), and final elements (e.g., emergency shutdown valves). The design must meet the specified Safety Integrity Level (SIL).

Installation, Commissioning, and Validation: The designed SIS is then installed and commissioned. The validation step is crucial; it involves testing the SIS to ensure that it functions as specified in the SRS and meets the required safety integrity.

3. Operation Phase:

Operation and Maintenance: The SIS must be operated and maintained correctly throughout its life to ensure it remains effective. This includes periodic proof testing to detect any hidden failures.

Modification: Any changes to the process or the SIS must be carefully managed through a formal Management of Change (MOC) process to ensure that the safety integrity is not compromised.

Decommissioning: When the process or the SIS reaches the end of its life, it must be decommissioned safely.

Quantifying Safety: Safety Integrity Level (SIL)

A cornerstone of IEC 61511 is the concept of Safety Integrity Level (SIL). SIL is a discrete level (from 1 to 4) that represents the required level of risk reduction provided by a safety function. A higher SIL indicates a higher level of safety performance and a lower probability of failure on demand.

The determination of the required SIL for a particular SIF is a risk-based decision. It depends on several factors, including:

The severity of the potential consequences of the hazard.

The frequency at which the hazardous event is likely to occur without the SIF.

The effectiveness of other independent protection layers.

The relationship between SIL and the Probability of Failure on Demand (PFDavg) for a low-demand mode of operation (where the safety function is only called upon in the event of a failure) is as follows:

Safety Integrity Level (SIL) | Probability of Failure on Demand (PFDavg) | Risk Reduction Factor (RRF) |

4 | ≥ 10⁻⁵ to < 10⁻⁴ | 10,000 to 100,000 |

3 | ≥ 10⁻⁴ to < 10⁻³ | 1,000 to 10,000 |

2 | ≥ 10⁻³ to < 10⁻² | 100 to 1,000 |

1 | ≥ 10⁻² to < 10⁻¹ | 10 to 100 |

Achieving a specific SIL requires a combination of:

Hardware Safety Integrity: This relates to the reliability of the hardware components and is addressed through architectural constraints (e.g., redundancy) and the calculation of the PFDavg.

Systematic Safety Integrity: This focuses on preventing systematic failures, which are errors introduced during the design, implementation, or operational phases. This is managed through strict adherence to the safety lifecycle procedures and robust quality management.

Layers of Protection Analysis (LOPA)

A common methodology used in the process industry to determine the required SIL is the Layers of Protection Analysis (LOPA). LOPA is a semi-quantitative risk assessment method that helps in analyzing and assessing the risk of a hazardous scenario.

Here’s a simplified block diagram illustrating the LOPA concept:

LOPA starts with an identified hazardous scenario (an initiating event and its potential consequence). It then systematically evaluates the effectiveness of each independent protection layer (IPL) in reducing the likelihood of that scenario. If the combined risk reduction of the non-SIF protection layers is insufficient to meet the tolerable risk criteria, a SIF is required, and LOPA helps in determining the necessary SIL for that SIF.

The People, Processes, and Documentation: The Three Pillars of Compliance

Complying with IEC 61511 is not just about technology; it’s about establishing a robust safety culture supported by three key pillars:

Competent People: All personnel involved in the safety lifecycle, from engineers to operators and maintenance technicians, must have the necessary competence, training, and experience for their respective roles.

Well-defined Processes: The entire safety lifecycle must be governed by clear, documented procedures. This includes procedures for hazard analysis, SRS development, design, testing, and management of change.

Comprehensive Documentation: Meticulous documentation is a fundamental requirement of IEC 61511. This includes the hazard and risk assessment reports, the SRS, design calculations, validation test records, proof test procedures and results, and records of any modifications. This documentation provides the evidence that the SIS is designed, operated, and maintained in accordance with the standard.

The Practical Implementation: Challenges and Best Practices

Implementing IEC 61511 in a real-world process plant can be a complex undertaking. Some of the common challenges include:

Legacy Systems: Many existing plants have older safety systems that were not designed to meet the requirements of IEC 61511. Bringing these systems into compliance can be a significant engineering and financial challenge.

Data Collection: Accurate data on component failure rates is crucial for SIL verification calculations. Obtaining reliable data, especially for older or less common devices, can be difficult.

Maintaining Competency: Ensuring that all relevant personnel remain competent in the principles and practices of functional safety requires an ongoing commitment to training and development.

To overcome these challenges, here are some best practices for implementing IEC 61511:

Phased Approach: For existing facilities, a phased approach to compliance, starting with the highest-risk processes, is often the most pragmatic strategy.

Leverage Expertise: Don’t hesitate to engage external experts and consultants who have a deep understanding of IEC 61511 and its application.

Invest in Tools: There are various software tools available that can assist with tasks such as SIL determination, SIL verification calculations, and managing the safety lifecycle documentation.

Foster a Safety Culture: Ultimately, the success of any functional safety program depends on a strong safety culture that permeates all levels of the organization, from top management to the plant floor.

The Future of Functional Safety: Evolving Standards and Technologies

The world of functional safety is not static. The IEC continues to review and update its standards to reflect advances in technology and a better understanding of risk management. The second edition of IEC 61511, published in 2016, introduced several important clarifications and new requirements, including a greater emphasis on cybersecurity for safety instrumented systems.

As technology evolves, we can expect to see further developments in areas such as:

Wireless Instrumentation: The use of wireless sensors and final elements in safety applications is becoming more common, bringing new challenges and opportunities.

Data Analytics and Machine Learning: The vast amount of data generated by modern process plants can be leveraged to improve the performance and reliability of safety systems through predictive maintenance and anomaly detection.

Human Factors Engineering: A deeper understanding of human factors will lead to the design of more intuitive and error-tolerant safety systems.

Conclusion: A Non-Negotiable Commitment to Safety

IEC 61511 is more than just a set of technical requirements; it is a comprehensive framework for managing risk in the process industry. By adopting a lifecycle approach, quantifying safety through SILs, and emphasizing the importance of competent people and robust processes, the standard provides a clear path to achieving and maintaining functional safety.

While the journey to full compliance can be challenging, the benefits are undeniable: a safer working environment, protection of the community and the environment, enhanced operational reliability, and a stronger business reputation. In an industry where the stakes are so high, a steadfast commitment to the principles of IEC 61511 is not just good engineering practice; it is a non-negotiable responsibility.