IEC 61511 Certification: Benefits, Process, and Requirements

In the high-stakes world of the process industry, where hazardous materials and complex operations are the norms, ensuring safety is not just a priority—it’s an absolute necessity. A single failure can have catastrophic consequences, leading to loss of life, environmental damage, and significant financial repercussions. This is where international standards play a pivotal role, and for the process industry, one of the most crucial is IEC 61511.

This blog post will provide a comprehensive overview of IEC 61511, exploring its benefits, the certification process, and its key requirements. Whether you are a process engineer, a plant manager, or a safety professional, understanding this standard is essential for maintaining a safe and compliant operation.

What is IEC 61511?

IEC 61511 is a technical standard that sets out best practices for the engineering of systems that ensure the safety of an industrial process through the use of instrumentation. These systems are known as Safety Instrumented Systems (SIS). The standard provides a framework for the entire lifecycle of these systems, from initial concept and design to implementation, operation, maintenance, and eventual decommissioning.

Developed by the International Electrotechnical Commission (IEC), this standard is a sector-specific implementation of the more general IEC 61508 standard on functional safety. While IEC 61508 is a generic standard that applies to all industries, IEC 61511 is specifically tailored to the needs of the process industry sector, which includes industries such as:

Petrochemicals

Chemicals

Oil and gas

Pharmaceuticals

Pulp and paper

The primary goal of IEC 61511 is to ensure that the safety instrumented systems are designed, operated, and maintained to a level of integrity that is appropriate for the risks they are intended to mitigate.

The Pillars of IEC 61511

The standard is built upon several key principles that form the foundation of functional safety in the process industry. These pillars include:

Performance-Based Approach: Rather than prescribing specific technologies or solutions, IEC 61511 focuses on performance. It requires organizations to define the required safety performance of their SIS based on a thorough risk assessment.

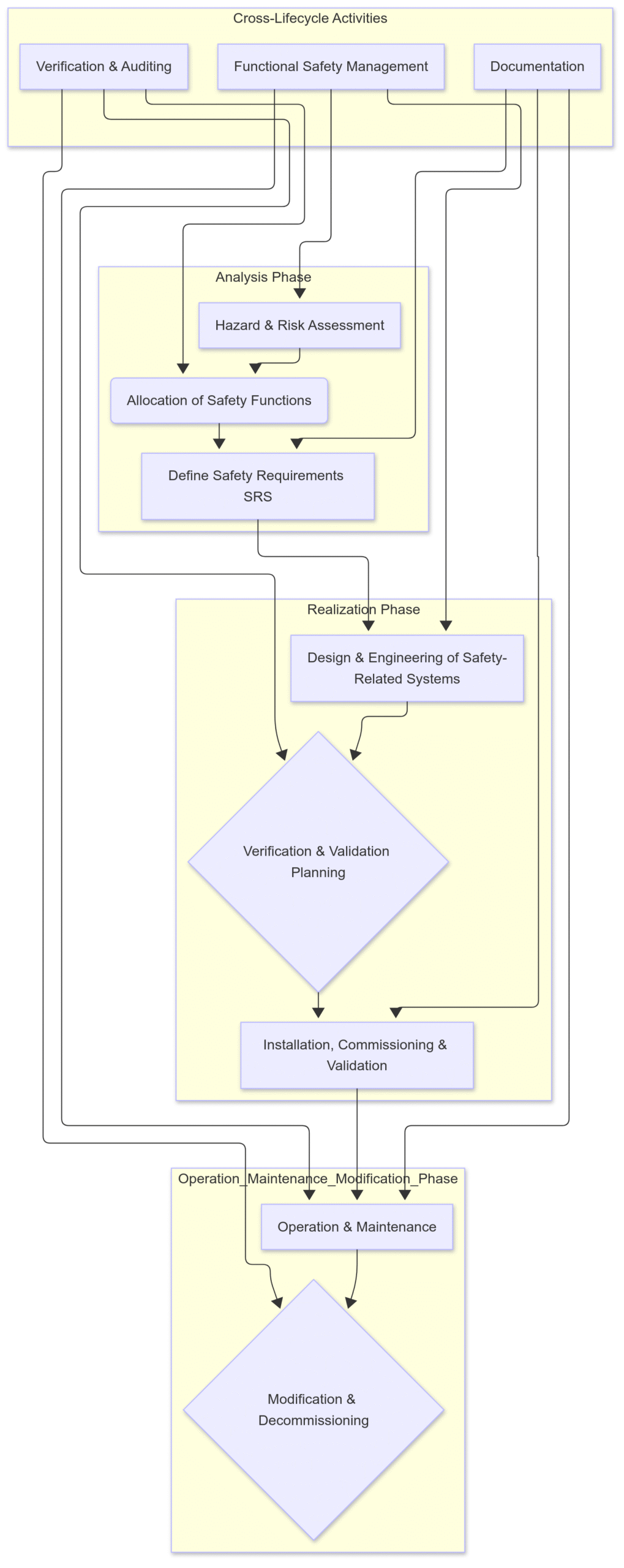

The Safety Lifecycle: The standard introduces the concept of a safety lifecycle, which is a systematic approach to managing functional safety throughout the entire lifespan of a SIS.

Competency: IEC 61511 places a strong emphasis on the competency of the personnel involved in all phases of the safety lifecycle. It requires that individuals have the necessary knowledge, skills, and experience to perform their assigned tasks.

Documentation: The standard mandates comprehensive documentation at every stage of the safety lifecycle. This documentation is crucial for demonstrating compliance, facilitating audits, and ensuring that the SIS is operated and maintained correctly.

Benefits of IEC 61511 Certification

Achieving IEC 61511 certification, whether for an individual or a company, offers a multitude of benefits that extend far beyond mere compliance.

For Companies:

Enhanced Safety and Risk Reduction: The most significant benefit is the improvement in plant safety. By implementing a robust functional safety management system based on IEC 61511, companies can systematically identify, assess, and mitigate process risks, leading to a reduction in the likelihood and severity of accidents.

Regulatory Compliance: In many countries, compliance with IEC 61511 is a legal requirement. Certification provides a clear demonstration to regulatory authorities that a company is adhering to recognized and generally accepted good engineering practices (RAGAGEP).

Competitive Advantage: Certification can be a key differentiator in the marketplace. It signals to clients, partners, and stakeholders that a company is committed to the highest standards of safety and operational excellence.

Improved Operational Efficiency: A well-designed and implemented SIS can help to reduce spurious trips and unnecessary plant shutdowns, leading to improved operational efficiency and reduced production losses.

Reduced Insurance Premiums: Many insurance companies recognize the value of IEC 61511 certification and may offer reduced premiums to companies that can demonstrate compliance.

For Individuals:

Enhanced Career Opportunities: IEC 61511 certification is a highly sought-after qualification for professionals working in the process industry. It can open up new career opportunities and lead to higher-paying positions.

Demonstrated Competency: Certification provides tangible proof of an individual’s knowledge and expertise in functional safety. It demonstrates to employers that they have the skills necessary to contribute to a safe and compliant operation.

Increased Confidence: The process of achieving certification provides individuals with a deep understanding of the standard and its requirements, giving them the confidence to make sound decisions in their day-to-day work.

The IEC 61511 Safety Lifecycle

The safety lifecycle is at the heart of IEC 61511. It is a structured engineering process that consists of a series of phases, each with its own specific objectives and deliverables. The lifecycle ensures that all aspects of functional safety are considered in a systematic and coordinated manner.

The main phases of the safety lifecycle are:

Hazard and Risk Assessment: The lifecycle begins with a thorough analysis of the process to identify potential hazards and assess the associated risks. This phase is crucial for determining the required level of safety for the SIS.

Allocation of Safety Functions to Protection Layers: Once the risks are understood, safety functions are allocated to different protection layers, including the SIS. This is where the concept of Layers of Protection Analysis (LOPA) is often applied.

Safety Requirements Specification (SRS): This is one of the most critical documents in the safety lifecycle. The SRS specifies the functional and safety integrity requirements for each safety instrumented function (SIF).

Design and Engineering of the SIS: This phase involves the detailed design of the SIS, including the selection of hardware and software, and the development of application logic.

Installation, Commissioning, and Validation: Once the SIS is designed, it is installed, commissioned, and validated to ensure that it meets the requirements of the SRS.

Operation and Maintenance: This is the longest phase of the lifecycle. It involves the ongoing operation, maintenance, and testing of the SIS to ensure that it continues to provide the required level of safety performance.

Modification: Any changes to the SIS or the process it protects must be carefully managed to ensure that they do not compromise safety.

Decommissioning: The final phase of the lifecycle involves the safe decommissioning of the SIS when it is no longer required.

The Certification Process: A Step-by-Step Guide

The certification process for IEC 61511 can vary depending on whether it is for an individual or a company.

Individual Certification:

Training: The first step is typically to attend a training course from a recognized provider. These courses cover the fundamentals of IEC 61511 and the safety lifecycle.

Examination: After completing the training, individuals must pass an examination to demonstrate their knowledge and understanding of the standard.

Experience Assessment: Some certification bodies may also require individuals to have a certain amount of practical experience in the field of functional safety.

Certification: Once all the requirements are met, the individual is awarded a certificate, which is typically valid for a certain period.

Company Certification:

Gap Analysis: The process for a company usually begins with a gap analysis to assess its current practices against the requirements of IEC 61511.

Development of a Functional Safety Management System (FSMS): Based on the results of the gap analysis, the company will need to develop and implement a comprehensive FSMS.

Implementation and Training: The FSMS is then implemented throughout the organization, and employees are trained on the new procedures and requirements.

Audit: An independent third-party certification body will conduct an audit to assess the company’s compliance with the standard.

Certification: If the audit is successful, the company is awarded a certificate of compliance.

Key Requirements of IEC 61511

While the standard is comprehensive, there are some key requirements that are particularly important.

Functional Safety Management (FSM)

IEC 61511 requires organizations to have a robust FSM system in place. This system should define the policies, procedures, and responsibilities for managing functional safety throughout the safety lifecycle.

Hazard and Risk Assessment

A thorough hazard and risk assessment is a fundamental requirement of the standard. This assessment must be conducted systematically to identify all credible hazards and to determine the required level of risk reduction.

Safety Requirements Specification (SRS)

The SRS is a critical document that forms the basis for the design and implementation of the SIS. It must be clear, concise, and unambiguous, and it must contain all the necessary information for the design team to develop a system that meets the required safety performance.

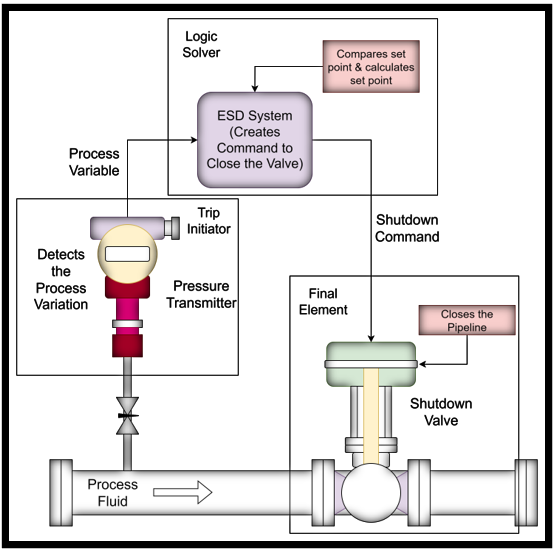

Understanding the Safety Instrumented System (SIS)

A Safety Instrumented System (SIS) is a combination of hardware and software that is designed to bring a process to a safe state when a hazardous condition is detected. It is one of the most important protection layers in the process industry.

A typical SIS consists of three main components:

Sensors: These devices monitor the process variables, such as pressure, temperature, and flow, and detect when they deviate from their normal operating range.

Logic Solver: The logic solver is the “brain” of the SIS. It receives signals from the sensors, executes the pre-programmed safety logic, and sends commands to the final control elements.

Final Control Elements: These are the devices that actually perform the safety action, such as closing a valve, shutting down a pump, or activating a deluge system.

Challenges in Implementing IEC 61511

While the benefits of IEC 61511 are clear, implementing the standard can present some challenges. These can include:

Cost: Implementing a comprehensive functional safety management system can be a significant investment.

Complexity: The standard is detailed and complex, and it can be difficult to interpret and apply correctly.

Culture Change: Implementing IEC 61511 often requires a significant culture change within an organization. It requires a move from a reactive to a proactive approach to safety.

The Future of IEC 61511

The world of functional safety is constantly evolving, and IEC 61511 is no exception. The standard is periodically updated to reflect changes in technology, best practices, and regulatory requirements. As the process industry becomes increasingly automated and interconnected, the importance of standards like IEC 61511 will only continue to grow.

Conclusion

IEC 61511 is a critical standard for the process industry. It provides a comprehensive framework for managing functional safety and for ensuring that safety instrumented systems are designed, operated, and maintained to the highest standards. While implementing the standard can be challenging, the benefits in terms of enhanced safety, regulatory compliance, and improved operational efficiency are well worth the effort. For any organization or individual involved in the process industry, a thorough understanding of IEC 61511 is not just an advantage—it’s a necessity.