Achieving SIL Certification with IEC 61508 Compliance: A Comprehensive Guide

In today’s increasingly automated and complex industrial landscape, ensuring the safety of processes and systems is not just a priority, it’s a necessity. From chemical processing plants to nuclear power stations and complex machinery, the potential for catastrophic failure is a constant concern. This is where Functional Safety and the international standard IEC 61508 come into play, providing a rigorous framework for managing and mitigating risks. At the heart of this standard lies the concept of the Safety Integrity Level (SIL), a measure of the reliability of a safety function.

This comprehensive blog post will delve into the intricacies of achieving SIL certification through compliance with IEC 61508. We will explore the fundamental concepts, navigate the safety lifecycle, understand the assessment process, and provide insights into designing compliant hardware and software.

Understanding Functional Safety and IEC 61508

Functional safety is the part of the overall safety of a system or piece of equipment that depends on the correct functioning of its safety-related systems. These systems are designed to automatically prevent or mitigate the consequences of hazardous events. IEC 61508, “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems,” is the cornerstone international standard that sets out the requirements for ensuring these systems work as intended.

The standard is built on two fundamental principles:

A Safety Lifecycle: A structured engineering process that addresses all activities involved in a safety system’s life, from conception to decommissioning. This systematic approach aims to prevent the introduction of design errors.

Probabilistic Failure Analysis: A method to account for the impact of random hardware failures. This involves calculating the probability that a safety function will fail on demand.

What is a Safety Integrity Level (SIL)?

A Safety Integrity Level (SIL) is a discrete level (from 1 to 4) for specifying the required reliability of a safety function. A higher SIL indicates a higher level of safety integrity, meaning a lower probability that the safety function will fail to perform its required action.

The required SIL for a specific safety function is determined through a process of hazard and risk analysis. The higher the risk associated with a particular hazard, the higher the SIL of the safety function required to mitigate that risk.

Here’s a simplified breakdown of the SIL levels and their corresponding risk reduction factors:

SIL Level | Probability of Failure on Demand (PFD) | Risk Reduction Factor (RRF) |

SIL 1 | ≥ 10⁻² to < 10⁻¹ | 10 to 100 |

SIL 2 | ≥ 10⁻³ to < 10⁻² | 100 to 1,000 |

SIL 3 | ≥ 10⁻⁴ to < 10⁻³ | 1,000 to 10,000 |

SIL 4 | ≥ 10⁻⁵ to < 10⁻⁴ | 10,000 to 100,000 |

It is crucial to understand that SIL is a property of a complete safety function, not of an individual component. A safety function typically consists of a sensor, a logic solver (controller), and an actuator.

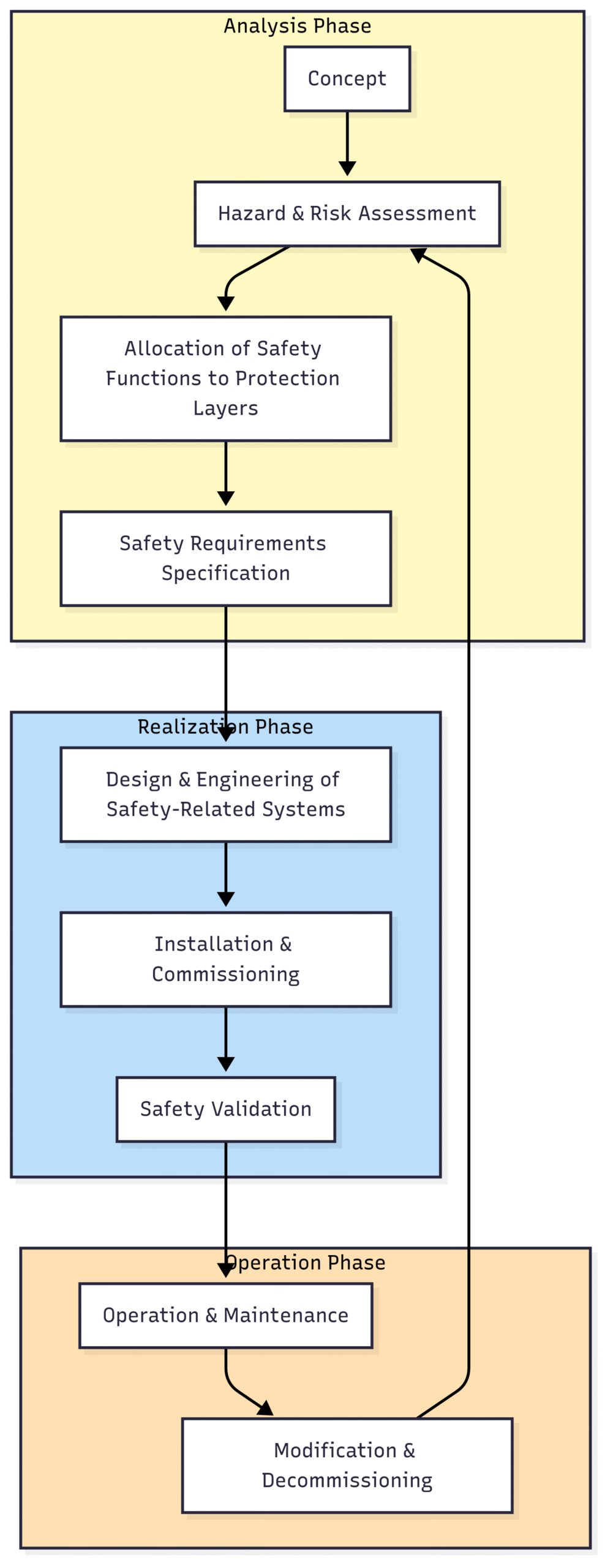

The IEC 61508 Safety Lifecycle: A Roadmap to Compliance

The IEC 61508 standard is structured around a safety lifecycle model, which provides a systematic and traceable approach to managing functional safety. This lifecycle encompasses all phases of a safety-related system’s existence, from initial concept to final decommissioning.

Block Diagram: The IEC 61508 Safety Lifecycle

Each phase of the lifecycle has specific objectives, inputs, and outputs, with verification and validation activities performed throughout. This ensures that any errors are detected and corrected as early as possible in the development process.

The Functional Safety Assessment (FSA): The Gateway to Certification

A key element of achieving SIL certification is the Functional Safety Assessment (FSA). This is an independent review conducted to confirm that the safety-related systems and the associated processes and procedures comply with the requirements of IEC 61508.

The FSA is typically carried out in stages throughout the safety lifecycle:

FSA 1 (After Safety Requirements Specification): Assesses the hazard and risk analysis, the allocation of safety functions, and the completeness and correctness of the safety requirements specification.

FSA 2 (After Design and Engineering): Reviews the design of the safety-related systems (both hardware and software) to ensure it meets the specified SIL.

FSA 3 (After Installation, Commissioning, and Validation): Confirms that the system has been installed and commissioned correctly and that the validation activities have demonstrated that the safety functions perform as required.

FSA 4 (During Operation and Maintenance): Periodically reviews the operational and maintenance procedures to ensure the ongoing integrity of the safety functions.

An independent and accredited certification body typically performs the FSA, and a successful assessment is a prerequisite for obtaining SIL certification.

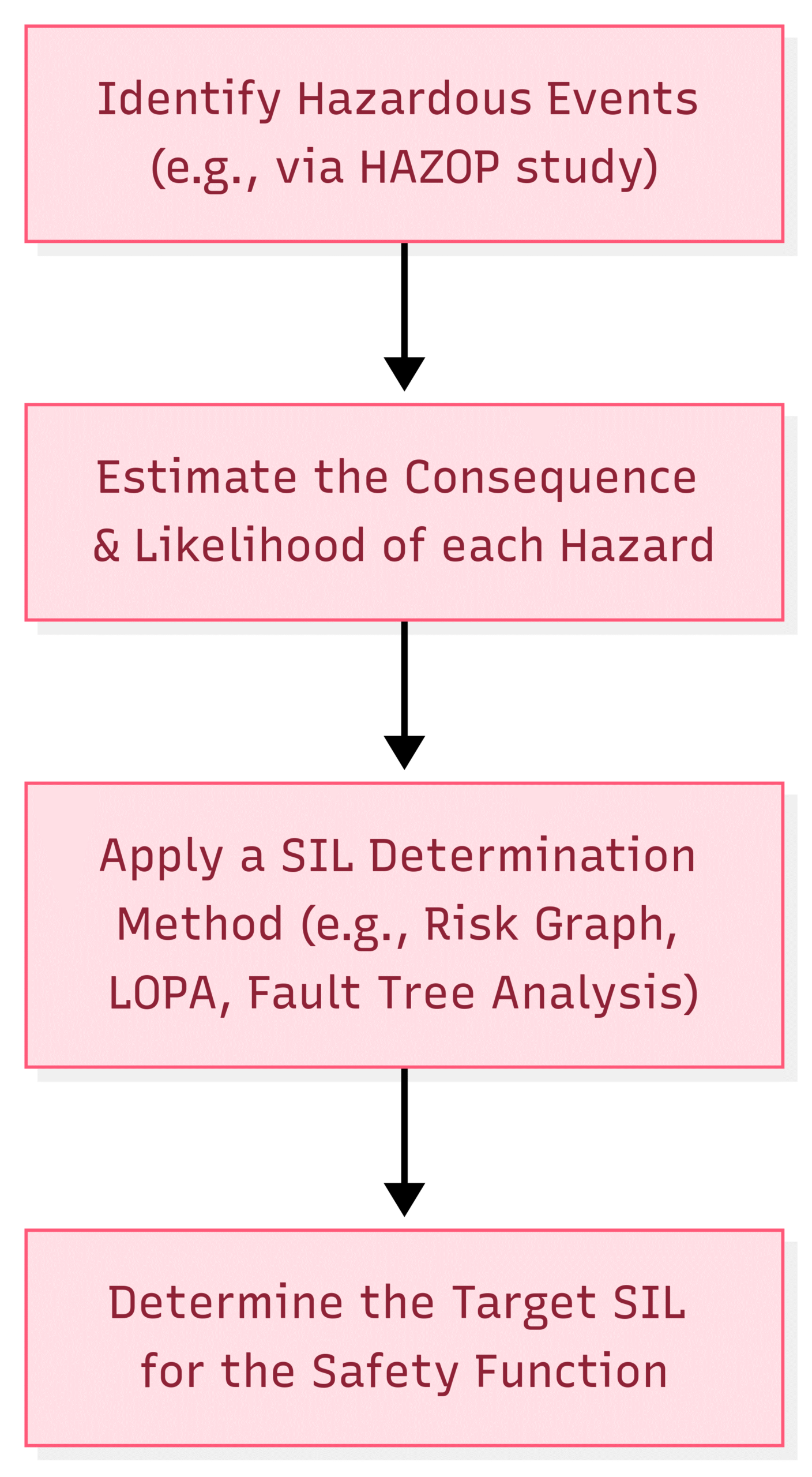

Determining the Required SIL: A Crucial Step

Before designing a safety function, it’s essential to determine the required SIL. Several techniques can be used for this, ranging from qualitative to quantitative methods.

Block Diagram: SIL Determination Process

Some common SIL determination methods include:

Risk Graph: A qualitative method that uses a graphical tool to determine the SIL based on parameters such as consequence severity, frequency of exposure to the hazard, and the possibility of avoiding the hazardous event.

Layer of Protection Analysis (LOPA): A semi-quantitative method that analyzes the independent layers of protection that are in place to prevent a hazardous event. LOPA helps to determine if the existing protection is sufficient or if an additional safety instrumented function (SIF) is required, and at what SIL.

Fault Tree Analysis (FTA): A top-down, deductive failure analysis where a specific undesirable event (the “top event”) is analyzed to determine all the potential underlying causes.

The choice of method depends on the complexity of the system and the level of rigor required.

Designing Hardware and Software for IEC 61508 Compliance

Designing hardware and software for safety-related systems requires a disciplined and systematic approach to minimize the introduction of faults and to ensure that the system behaves predictably in the event of a failure.

Hardware Design Principles

IEC 61508 emphasizes several key principles for hardware design:

Hardware Fault Tolerance (HFT): The ability of a system to continue to perform its required function in the presence of one or more hardware faults. This is often achieved through redundancy (e.g., using multiple sensors or processors).

Safe Failure Fraction (SFF): The fraction of all possible failures in a component that are either safe or detected by diagnostics. A higher SFF indicates a more robust design.

Diagnostics: The implementation of self-testing and monitoring capabilities to detect failures within the safety-related system.

Proven-in-Use Components: Using components with a well-documented and positive operational history in similar applications can provide confidence in their reliability.

Block Diagram: A Generic High-Integrity Hardware Architecture (1oo2D)

+-----------------+ +-----------------+

| Sensor A | | Sensor B |

+-----------------+ +-----------------+

| |

v v

+-----------------+ +-----------------+

| Logic Solver | | Logic Solver |

| (Channel A) | | (Channel B) |

+-----------------+ +-----------------+

| / |

v / v

+-------------------------------------+

| Voting Logic (2-out-of-2) |

+-------------------------------------+

|

v

+-----------------+

| Actuator |

+-----------------+

This “1-out-of-2 with Diagnostics” (1oo2D) architecture is a common approach to achieving a higher SIL. Both channels must agree for the system to operate. If one channel fails, the diagnostics will detect the discrepancy and the system can be brought to a safe state.

Software Design Principles

Software for safety-related systems requires an even more rigorous development process due to its complexity and the potential for systematic (design) faults. Key principles include:

Structured Development Process: Following a well-defined software development lifecycle, such as the V-model, which emphasizes verification and validation at each stage.

Clear and Unambiguous Requirements: The software safety requirements must be precisely defined and traceable throughout the development process.

Defensive Programming: Incorporating techniques to handle unexpected inputs and error conditions gracefully.

Use of Appropriate Programming Languages: Selecting a language with features that support the development of safe and reliable software, and avoiding features that are prone to errors.

Rigorous Testing and Analysis: Employing a combination of static analysis, dynamic testing, and formal methods to verify and validate the software.

Software Fault Tolerance: Implementing techniques to detect and handle software faults, such as watchdog timers and reasonableness checks.

The Benefits of SIL Certification

Achieving SIL certification is a significant undertaking, but the benefits are substantial:

Enhanced Safety: The primary benefit is a demonstrable reduction in risk, leading to a safer working environment and protecting people, the environment, and assets.

Regulatory Compliance: In many industries, SIL certification is a mandatory requirement for operating certain types of equipment or processes.

Increased Confidence and Trust: Certification from an independent body provides confidence to stakeholders, including customers, insurers, and regulators, that the safety systems are robust and reliable.

Competitive Advantage: SIL certification can be a key differentiator in the marketplace, demonstrating a commitment to safety and quality.

Improved System Reliability and Availability: The rigorous design and testing processes required for SIL certification often lead to more reliable and available systems overall.

Conclusion: A Journey Worth Taking

The path to achieving SIL certification with IEC 61508 compliance is a demanding one, requiring a deep understanding of the standard, a commitment to a rigorous safety culture, and a systematic approach to design, implementation, and assessment. However, the rewards, in terms of enhanced safety, regulatory compliance, and market credibility, are undeniable. By embracing the principles of functional safety and the framework provided by IEC 61508, organizations can not only meet their legal and moral obligations but also build more robust, reliable, and ultimately safer systems for a better future. The journey to SIL certification is not just about achieving a certificate; it’s about embedding a culture of safety that permeates every aspect of an organization’s operations.