The Digital Guardians: Top Tools Used in Functional Safety Analysis and SIL Verification

In the intricate world of industrial automation, automotive systems, and critical infrastructure, ensuring safety is not just a best practice; it’s a stringent requirement governed by international standards. Functional safety, the discipline of ensuring that safety-related systems perform as intended in the face of faults, is paramount. Central to this discipline are two intertwined concepts: Functional Safety Analysis and Safety Integrity Level (SIL) Verification. The former is the systematic investigation of potential hazards and risks, while the latter is the quantitative and qualitative assessment of a safety function’s ability to perform its duty.

Navigating the complexities of standards like IEC 61508, ISO 26262, and IEC 61511 would be an insurmountable task without the aid of specialized software tools. These digital guardians empower engineers to meticulously analyze, verify, and document safety-critical systems, ensuring they meet the required levels of risk reduction. This blog post delves into the top tools used in functional safety analysis and SIL verification, exploring their capabilities and providing block diagrams to illustrate their role in the safety lifecycle.

The Foundation: Understanding the Methodologies

Before we dive into the tools themselves, it’s crucial to understand the core methodologies they support. These analytical techniques form the bedrock of functional safety assessment:

Hazard and Operability Study (HAZOP): A systematic, team-based brainstorming technique to identify potential hazards and operability problems in a process plant or system. It works by using “guidewords” (e.g., No, More, Less) to question how the design intent of a system might be deviated from.

Failure Modes and Effects Analysis (FMEA): A bottom-up, inductive reasoning approach that analyzes potential failure modes of individual components in a system and their effects on the overall system’s operation.

Fault Tree Analysis (FTA): A top-down, deductive failure analysis in which a specific undesired event (the “top event”) is traced back to its root causes through a series of logical gates (AND, OR, etc.).

Layers of Protection Analysis (LOPA): A semi-quantitative risk analysis method that helps to determine the required SIL for a Safety Instrumented Function (SIF) by analyzing the layers of protection that stand between a hazard and its consequence.

These methodologies are not mutually exclusive; in fact, they are often used in conjunction to provide a comprehensive safety assessment. The tools we will discuss are designed to facilitate and integrate these analyses.

The Titans of Functional Safety: Integrated Toolchains

At the forefront of functional safety analysis and SIL verification are powerful, integrated software suites that cover large portions of the safety lifecycle. These tools provide a centralized platform for managing safety requirements, performing various analyses, and generating the extensive documentation required for certification.

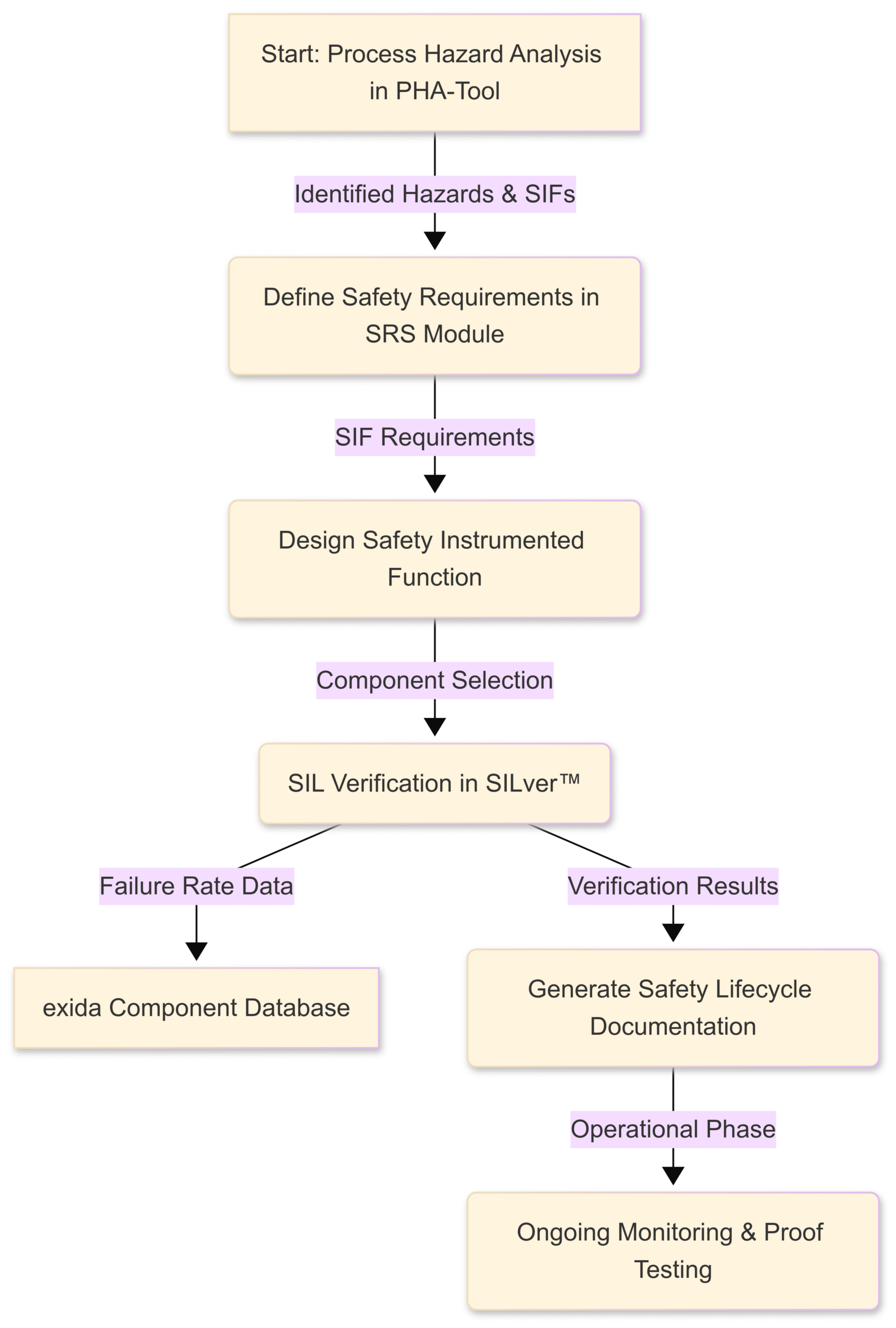

1. exida exSILentia®

exSILentia, developed by the functional safety experts at exida, is arguably one of the most recognized and widely used tool suites in the process industries. It provides a comprehensive environment for executing the safety lifecycle in accordance with IEC 61508 and IEC 61511.

Key Features:

Integrated Modules: exSILentia is comprised of several modules, including a Process Hazard Analysis (PHA) tool (for HAZOP and LOPA), a Safety Requirements Specification (SRS) module, a SIL verification tool (SILver™), and a tool for alarm rationalization.

Extensive Component Database: A cornerstone of exSILentia is its vast and continuously updated database of failure rate data for a wide range of industrial components. This data is crucial for accurate SIL calculations.

Complete Lifecycle Coverage: From initial hazard identification to ongoing operation and maintenance, exSILentia aims to provide a tool for each step of the safety lifecycle.

Proven in Use: The tool has a long track record and is trusted by many leading companies in the oil and gas, chemical, and other process industries.

Block Diagram: A Simplified exSILentia Workflow

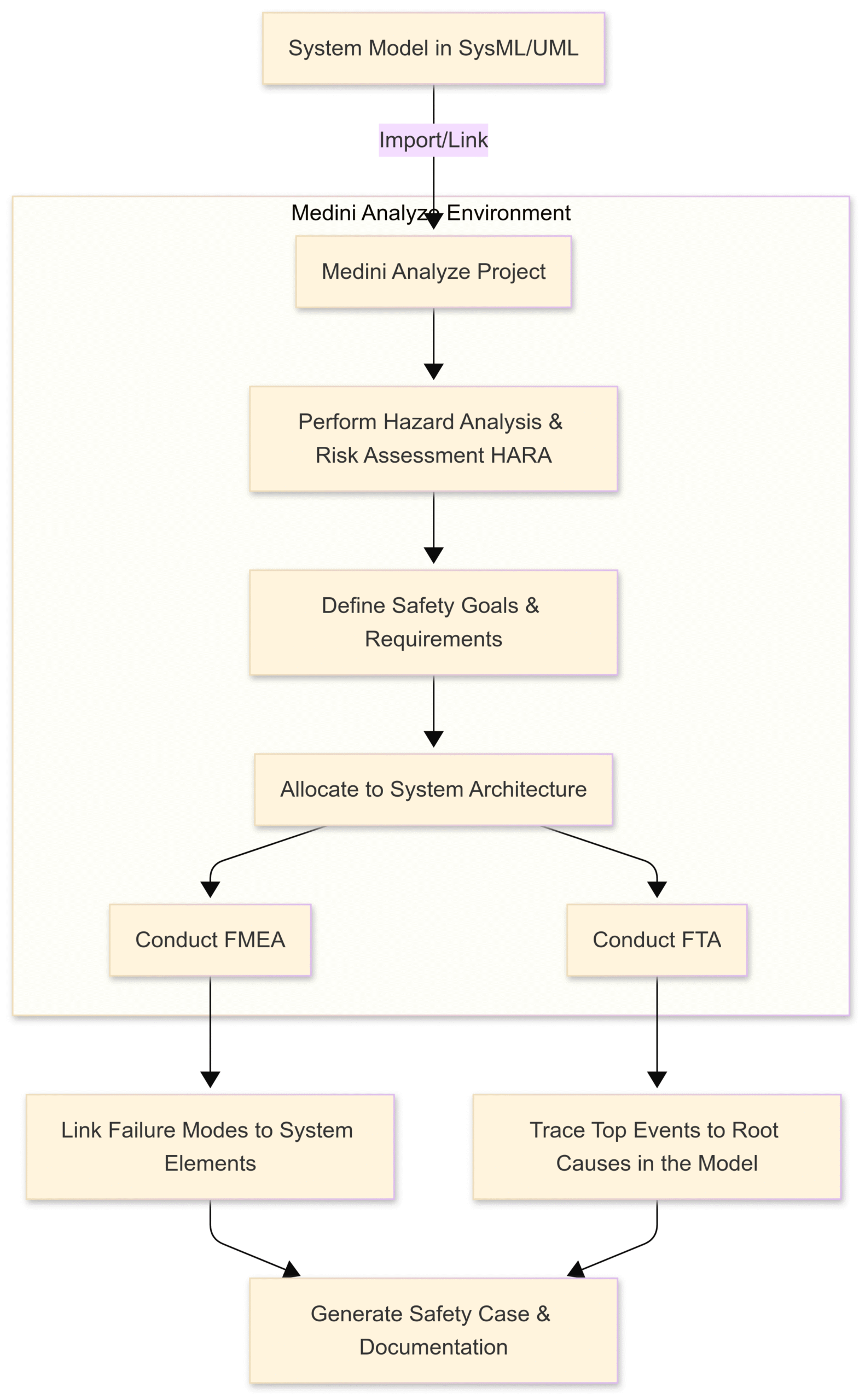

2. Ansys Medini Analyze

Ansys Medini Analyze is a model-based functional safety and reliability analysis tool that is particularly strong in the automotive and aerospace sectors, where system complexity is a major challenge. It provides a unified environment for performing the safety analyses required by standards like ISO 26262 and ARP4761.

Key Features:

Model-Based Approach: Medini Analyze integrates safety analysis with the system design model (often in SysML/UML). This ensures consistency between the design and the safety analysis, as changes in one are reflected in the other.

Support for Multiple Analyses: It seamlessly integrates various analysis techniques, including HAZOP, FMEA, FTA, and Dependent Failure Analysis (DFA).

Traceability: One of its key strengths is the ability to create and manage traceability links between safety requirements, design elements, analysis results, and verification activities. This is critical for demonstrating compliance with stringent standards.

Customization: The tool is highly customizable, allowing organizations to adapt it to their specific development processes and workflows.

Block Diagram: Model-Based Safety Analysis with Ansys Medini Analyze

Specialized Tools for Specific Tasks

While integrated suites offer a comprehensive solution, many organizations also utilize specialized tools that excel at specific types of analysis.

Tools for HAZOP and PHA

For organizations focused on process safety, dedicated HAZOP software can streamline the analysis process. These tools provide a structured environment for recording deviations, consequences, safeguards, and recommendations.

PHA-Pro: A widely used tool that helps facilitate and document process hazard analyses, including HAZOP, What-if, and LOPA studies. It provides a structured framework that guides the analysis team through the process.

Safetec SAFETI: While a broader consequence modeling tool, its PHA software component is a powerful tool for HAZOP and other risk assessments, especially in the context of major accident hazards.

Tools for FMEA and FTA

For reliability and safety engineers focused on product design, dedicated FMEA and FTA software can provide more in-depth capabilities for these specific analyses.

ReliaSoft XFMEA/BlockSim: Part of the HBM Prenscia suite, these tools offer powerful capabilities for FMEA, FMECA (Failure Mode, Effects, and Criticality Analysis), and reliability block diagram (RBD) analysis, which can be used in conjunction with FTA.

Isograph Reliability Workbench: This is a comprehensive suite that includes modules for FMEA, FTA, and other reliability analysis techniques. Its fault tree analysis module is particularly powerful, offering advanced features for calculating unavailability and importance measures.

The Rise of Open-Source and Custom Solutions

While commercial tools dominate the landscape, it’s worth noting the emergence of open-source initiatives and the continued use of custom-built solutions, often based on spreadsheets.

Open-Source Tools: While less common for certified safety-critical systems due to validation and support concerns, open-source projects can be valuable for training, research, and non-critical applications.

Spreadsheet-Based Analysis: For simpler systems or as a starting point, many organizations use customized spreadsheets for FMEA and even basic SIL calculations. However, these lack the robustness, version control, and data integrity of dedicated software and are generally not recommended for complex or high-integrity systems.

The Future of Functional Safety Tools

The landscape of functional safety tools is continually evolving. We can expect to see several key trends in the coming years:

Greater Integration with AI and Machine Learning: AI will likely play a growing role in automating parts of the analysis process, identifying potential hazards from historical data, and optimizing test strategies.

Enhanced Collaboration Features: As engineering teams become more geographically dispersed, cloud-based tools with real-time collaboration features will become increasingly important.

Cybersecurity Integration: With the growing threat of cyberattacks on industrial control systems, functional safety tools will need to integrate more closely with cybersecurity analysis to address the intersection of safety and security.

Digital Twin Integration: The concept of the digital twin, a virtual replica of a physical asset, will enable more dynamic and predictive safety analysis throughout the system’s lifecycle.

Conclusion

The tools used in functional safety analysis and SIL verification are more than just software; they are the digital bedrock upon which the safety of our modern world is built. From the comprehensive, lifecycle-spanning capabilities of integrated suites like exSILentia and Ansys Medini Analyze to the focused power of specialized analysis tools, these digital guardians empower engineers to meet the ever-increasing demands for safety and reliability.

As systems become more complex and interconnected, the importance of these tools will only grow. By providing a structured, systematic, and data-driven approach to safety, they ensure that when it matters most, our safety-critical systems will perform their duty, protecting lives, the environment, and valuable assets. The continued innovation in this field is not just a matter of technological advancement; it’s a commitment to a safer future for all.