A Comprehensive Guide to Roles, Responsibilities, and Documentation

In our increasingly automated world, the silent sentinels of functional safety are the bedrock of our trust in technology. From the anti-lock braking system in our cars to the emergency shutdown systems in a power plant, functional safety ensures that technology operates safely, and when failures do occur, they happen in a predictable and controlled manner. But this critical assurance doesn’t materialize out of thin air. It is the result of a rigorous and systematic approach known as Functional Safety Management (FSM).

This comprehensive blog post will delve deep into the core of FSM, exploring the intricate web of roles and responsibilities, the critical documentation that forms the backbone of any safety-critical project, and the overarching lifecycle that governs the entire process. We will also feature custom block diagrams to visually articulate these complex interactions, providing a clear roadmap for anyone involved in the development of safety-related systems.

The Foundation: What is Functional Safety Management?

Functional Safety Management, as defined by international standards such as IEC 61508 and its sector-specific adaptations like ISO 26262 for the automotive industry, is the overall organizational framework and set of activities aimed at achieving and maintaining functional safety. It’s not a one-time task but a continuous process that spans the entire lifecycle of a safety-related system, from its initial concept to its final decommissioning.

The primary goal of FSM is to manage and mitigate the risks associated with systematic failures – those errors that are inherent in the design, development, or operational processes. By establishing a clear structure, defining responsibilities, and mandating thorough documentation, FSM provides the necessary discipline to prevent dangerous failures of safety-related systems.

The Pillars of FSM: Key Roles and Their Responsibilities

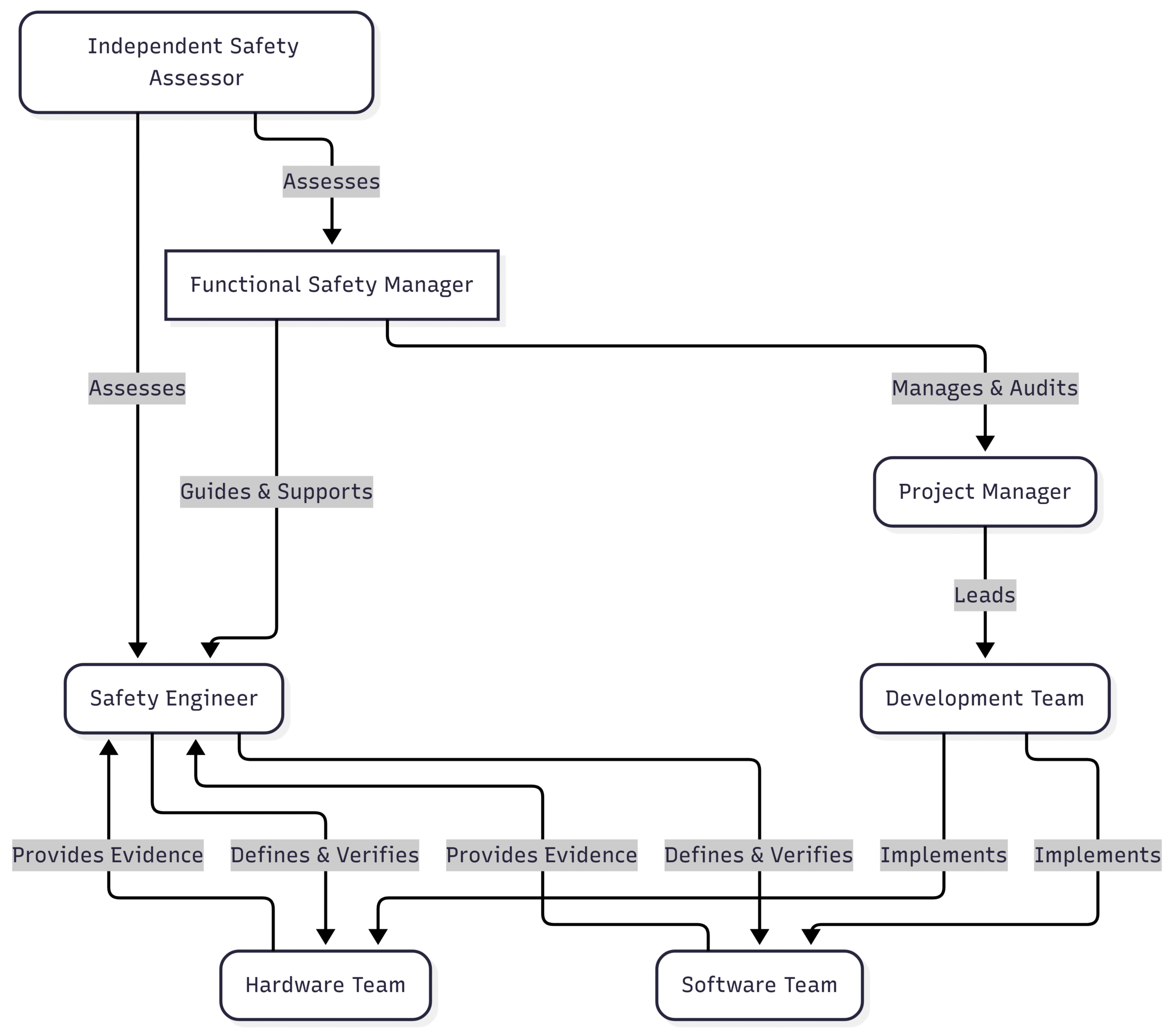

A successful FSM framework is built upon a team of dedicated professionals with clearly defined roles and responsibilities. While the specific titles and organizational structure may vary, the core functions remain consistent.

Block Diagram 1: Key Roles and their Interactions in the Functional Safety Lifecycle

1. The Functional Safety Manager (FSM): The Guardian of the Safety Culture

The Functional Safety Manager is the linchpin of the entire FSM process. This individual is not just a manager but a leader, responsible for establishing and nurturing a robust safety culture throughout the organization. The FSM operates at a strategic level, ensuring that the principles of functional safety are not just followed but are deeply embedded in the company’s DNA.

Key Responsibilities:

Defining the Functional Safety Management Plan (FSMP): The FSM is the primary author and custodian of the FSMP, the master document that outlines the organization’s approach to functional safety. This includes defining the safety lifecycle, specifying the required activities and deliverables, and establishing the criteria for demonstrating safety.

Ensuring Competence: The FSM is responsible for ensuring that all personnel involved in safety-related activities possess the necessary competence, including appropriate training, qualifications, and experience. This may involve organizing training programs and maintaining records of competency.

Independent Auditing and Assessment: A crucial aspect of the FSM’s role is to conduct or facilitate independent safety audits and assessments at various stages of the project. This ensures that the safety activities are being performed correctly and that the safety goals are being met.

Resource Management: The FSM advocates for and secures the necessary resources – both human and technical – to effectively implement the FSMP.

Communication and Reporting: The FSM acts as the central point of contact for all matters related to functional safety, communicating with senior management, project teams, and external stakeholders. They are responsible for reporting on the overall safety status of projects.

2. The Safety Engineer: The Technical Architect of Safety

The Safety Engineer is the technical expert who translates the high-level safety goals into concrete engineering requirements. They work closely with the development teams throughout the safety lifecycle, providing guidance, conducting analyses, and verifying that the system meets the specified safety targets.

Key Responsibilities:

Hazard Analysis and Risk Assessment (HARA): The Safety Engineer leads the HARA process, a systematic identification of potential hazards and an assessment of the associated risks. This is a foundational activity that determines the required level of safety for the system.

Defining Safety Requirements: Based on the HARA, the Safety Engineer defines the functional and technical safety requirements. These requirements specify what the system must do to mitigate the identified risks and are documented in the Safety Requirements Specification (SRS).

Safety Analysis: The Safety Engineer performs various safety analyses, such as Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Dependent Failure Analysis (DFA), to identify potential failure modes and their impact on system safety.

Verification and Validation: The Safety Engineer is heavily involved in the verification and validation activities, ensuring that the implemented system meets the specified safety requirements. This includes reviewing design documents, test plans, and test results.

Creating the Safety Case: The Safety Case is a structured argument, supported by evidence, that demonstrates that the system is acceptably safe for a given application in a given environment. The Safety Engineer is responsible for compiling and maintaining the Safety Case.

3. The Project Manager: The Orchestrator of the Development Process

While not a dedicated safety role in the same way as the FSM or Safety Engineer, the Project Manager plays a critical part in ensuring that functional safety is integrated into the overall project plan.

Key Responsibilities:

Integrating Safety Activities into the Project Plan: The Project Manager works with the FSM and Safety Engineer to ensure that all safety-related activities are included in the project schedule and budget.

Resource Allocation: The Project Manager allocates the necessary resources to the project team to carry out the required safety activities.

Monitoring and Control: The Project Manager monitors the progress of the safety activities and takes corrective action if any deviations from the plan occur.

Facilitating Communication: The Project Manager facilitates communication and collaboration between the development team and the safety team.

4. The Development Team (Hardware and Software Engineers): The Implementers of Safety

The development team is responsible for designing, implementing, and testing the hardware and software components of the safety-related system in accordance with the specified safety requirements.

Key Responsibilities:

Designing for Safety: The development team must adhere to specific design principles and coding standards to minimize the introduction of systematic faults.

Implementing Safety Mechanisms: They are responsible for implementing the safety mechanisms defined in the technical safety requirements, such as error detection and correction codes, watchdogs, and redundant processing channels.

Unit and Integration Testing: The development team performs unit and integration testing to verify that the individual components and the integrated system function as intended and meet the safety requirements.

Providing Evidence: The development team provides the necessary evidence, such as design documents, code reviews, and test reports, to the Safety Engineer to support the safety case.

5. The Independent Safety Assessor: The Unbiased Adjudicator

To ensure objectivity, international standards often require an independent safety assessment to be performed by individuals or an organization that is not involved in the development of the system.

Key Responsibilities:

Reviewing Safety Documentation: The Independent Safety Assessor reviews all the key safety documentation, including the FSMP, HARA, SRS, and Safety Case, to ensure that they are complete, correct, and compliant with the relevant standards.

Assessing the Safety Lifecycle Activities: They assess whether the safety activities have been performed in accordance with the FSMP.

Providing an Independent Judgment: The Independent Safety Assessor provides an independent and unbiased judgment on the adequacy of the system’s functional safety.

The Paper Trail of Safety: Essential Documentation

In the world of functional safety, the adage “if it isn’t written down, it didn’t happen” holds immense weight. Documentation is not a bureaucratic hurdle but a vital component of the FSM process. It provides a clear and traceable record of all safety-related decisions, activities, and evidence.

Block Diagram 2: The Flow of Key Functional Safety Documentation

1. The Functional Safety Management Plan (FSMP): The Constitution of Safety

The FSMP is the cornerstone of all functional safety activities. It is a high-level document that defines the “what, who, how, and when” of functional safety for a specific project or for the entire organization.

Key Contents:

The Safety Lifecycle: A detailed description of the safety lifecycle model to be used, including all phases, activities, and deliverables.

Roles and Responsibilities: A clear definition of the roles and responsibilities of all personnel involved in safety-related activities.

Competence Management: The processes for ensuring and documenting the competence of the safety team.

Documentation Plan: A list of all required safety documentation, including templates and review and approval processes.

Configuration Management Plan: Procedures for managing changes to safety-related work products.

Verification and Validation Strategy: The overall approach to verifying and validating the safety of the system.

Independent Safety Assessment Plan: The scope, timing, and responsibilities for independent safety assessments.

2. Hazard Analysis and Risk Assessment (HARA): Identifying the Enemy

The HARA is the starting point for all technical safety activities. It is a systematic process for identifying potential hazards, analyzing the risks associated with those hazards, and defining the safety goals to mitigate those risks.

Key Steps:

Item Definition: A clear and unambiguous definition of the system (the “item”) and its functions.

Hazard Identification: Brainstorming and identifying all potential hazards that could arise from the malfunctioning of the item.

Situation Analysis: Analyzing the operational situations and environmental conditions in which the hazards could occur.

Risk Evaluation: Evaluating the risk of each hazard by considering its severity, probability of exposure, and controllability.

ASIL Determination (for ISO 26262): Assigning an Automotive Safety Integrity Level (ASIL) to each safety goal, which determines the level of rigor required for its development.

3. The Safety Requirements Specification (SRS): The Blueprint for Safety

The SRS translates the safety goals identified in the HARA into a set of precise and verifiable requirements for the safety-related system. It serves as the primary input for the design and development teams.

Key Components:

Functional Safety Requirements: High-level requirements that describe the safety functions the system must perform to mitigate the identified hazards.

Technical Safety Requirements: Detailed requirements that specify the technical implementation of the safety functions, including requirements for hardware, software, and their interaction.

Safety Integrity Requirements: The required level of performance for each safety function, often expressed in terms of a Safety Integrity Level (SIL) or an ASIL.

Timing and Performance Constraints: Requirements related to the timing and performance of the safety functions.

4. Verification and Validation (V&V) Plans and Reports: Proving It Works

Verification and validation are the processes of confirming that the system has been built correctly (verification) and that the correct system has been built (validation).

Verification Plans: These documents outline the methods and activities that will be used to verify that the design and implementation of the system meet the specified safety requirements. This includes reviews, analyses, and tests.

Validation Plans: These documents describe how the overall system will be validated to ensure that it meets the needs of the stakeholders and is safe for its intended use.

V&V Reports: These reports document the results of the verification and validation activities, providing evidence that the safety requirements have been met.

5. The Safety Case: The Ultimate Argument for Safety

The Safety Case is the culmination of all the functional safety activities. It is a structured and compelling argument, supported by a body of evidence, that a system is acceptably safe for a specific application and environment.

Key Elements:

The Safety Claim: A clear statement of what is being claimed about the safety of the system.

The Evidence: A collection of all the supporting documentation, including the FSMP, HARA, SRS, V&V reports, and safety analysis results.

The Argument: A logical and coherent argument that links the evidence to the safety claim, demonstrating how the evidence supports the claim.

Conclusion: A Culture of Safety, Not a Checklist

Functional Safety Management is far more than a set of rules and documents to be ticked off a checklist. It is a philosophy and a culture that must be embraced by an entire organization. By establishing clear roles and responsibilities, fostering a culture of competence and diligence, and maintaining a meticulous trail of documentation, companies can build the robust FSM framework necessary to deliver products that are not only innovative and functional but, most importantly, safe. The investment in a strong FSM program is not just an investment in compliance; it’s an investment in public trust, brand reputation, and, ultimately, in the well-being of society.