Bridging the Gap Between IEC 61508 and IEC 61511: A Comprehensive Guide for the Process Industry

In the realm of industrial automation and safety, two standards stand as pillars of modern risk reduction: IEC 61508 and IEC 61511. While inextricably linked, they serve distinct purposes and are often a source of confusion for engineers, managers, and safety practitioners. Understanding the nuances of these standards, and more importantly, how to bridge the gap between them, is crucial for ensuring the functional safety of hazardous processes. This comprehensive guide will delve into the intricacies of both standards, explore their relationship, and provide a roadmap for a seamless transition from the foundational principles of IEC 61508 to the practical application of IEC 61511 in the process industry, complete with illustrative block diagrams.

The Foundation: IEC 61508 – The Umbrella for Functional Safety

IEC 61508, titled “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems,” is the cornerstone of functional safety. It is a generic, performance-based standard that sets out the requirements for the design, implementation, operation, and maintenance of safety-related systems. Think of it as the ‘umbrella’ standard under which various industry-specific standards are developed.

The primary objective of IEC 61508 is to ensure that safety-related systems perform their intended safety functions with a specified level of reliability, known as the Safety Integrity Level (SIL). A SIL is a measure of the risk reduction provided by a safety function, ranging from SIL 1 (lowest) to SIL 4 (highest). The standard is applicable to a wide array of industries, including manufacturing, transportation, and healthcare, wherever electrical, electronic, or programmable electronic (E/E/PE) systems are used to perform safety functions.

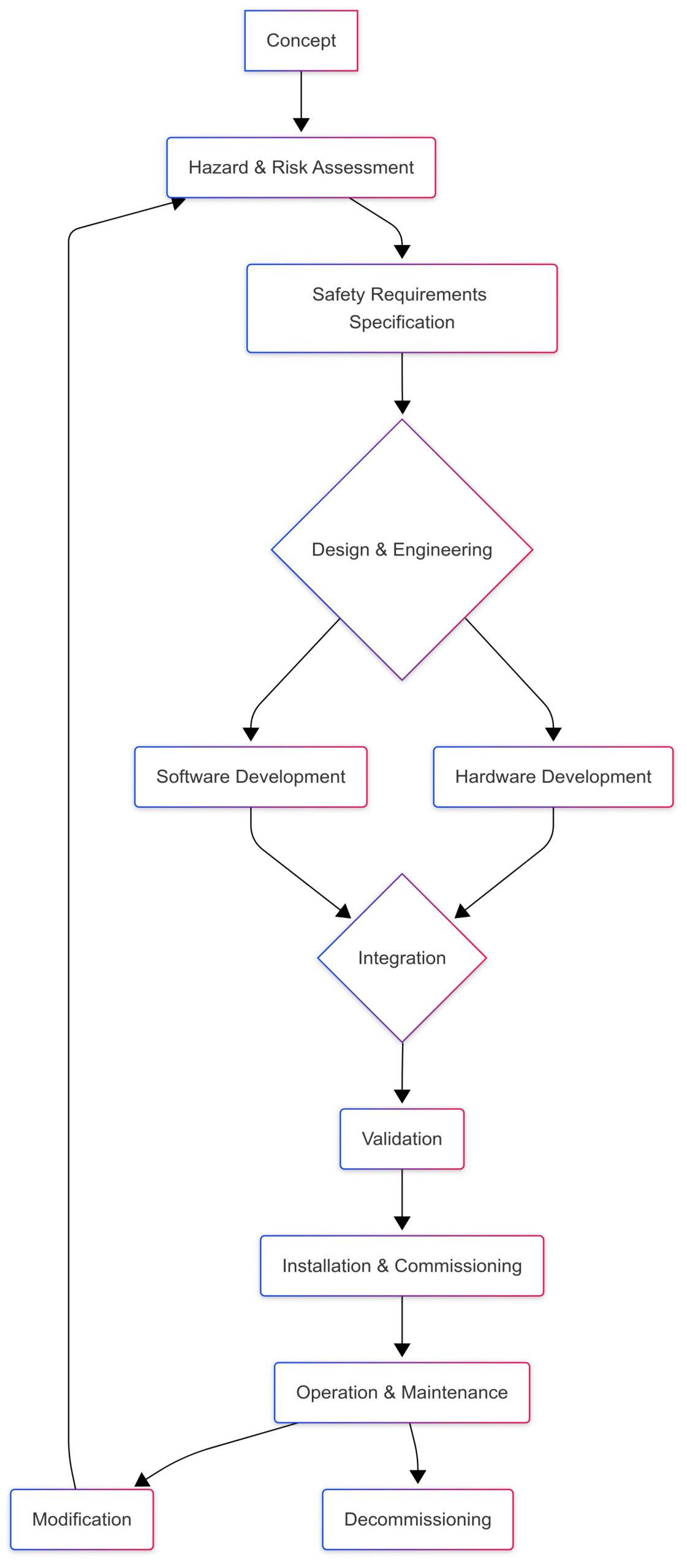

The scope of IEC 61508 is broad, covering the entire safety lifecycle of a system, from initial concept and hazard analysis to decommissioning. It places a strong emphasis on a systematic and documented approach to managing functional safety, including requirements for:

Functional Safety Management: Establishing a clear organizational structure, responsibilities, and procedures for managing all aspects of functional safety.

Hazard and Risk Assessment: Identifying potential hazards and evaluating the associated risks to determine the required SIL for each safety function.

Safety Requirements Specification (SRS): A detailed document that specifies the functional and safety integrity requirements for each safety function.

Design and Engineering: Developing the safety-related systems in accordance with the SRS, including hardware and software design principles.

Validation and Verification: Ensuring that the designed systems meet the specified safety requirements through rigorous testing and analysis.

Operation, Maintenance, and Modification: Establishing procedures for the ongoing operation, maintenance, and modification of the safety-related systems to ensure they maintain their required safety integrity throughout their operational life.

A key takeaway for IEC 61508 is its focus on the manufacturers and suppliers of safety-related components and systems. It provides them with a framework to develop products that can be certified for use in safety applications up to a certain SIL.

Block Diagram 1: The IEC 61508 Safety Lifecycle (Simplified)

This simplified diagram illustrates the cyclical and comprehensive nature of the IEC 61508 safety lifecycle, emphasizing the continuous process of risk assessment and management.

The Sector-Specific Implementation: IEC 61511 – Functional Safety for the Process Industry

While IEC 61508 provides the foundational principles, the process industry, with its unique set of hazards such as fires, explosions, and toxic releases, required a more tailored approach. This led to the development of IEC 61511, titled “Functional Safety – Safety Instrumented Systems for the Process Industry Sector.”

IEC 61511 is a direct implementation of IEC 61508 for the process industry. It takes the generic requirements of the parent standard and translates them into a language and context that is readily understandable and applicable for end-users, system integrators, and engineering contractors in sectors like oil and gas, chemicals, pharmaceuticals, and power generation.

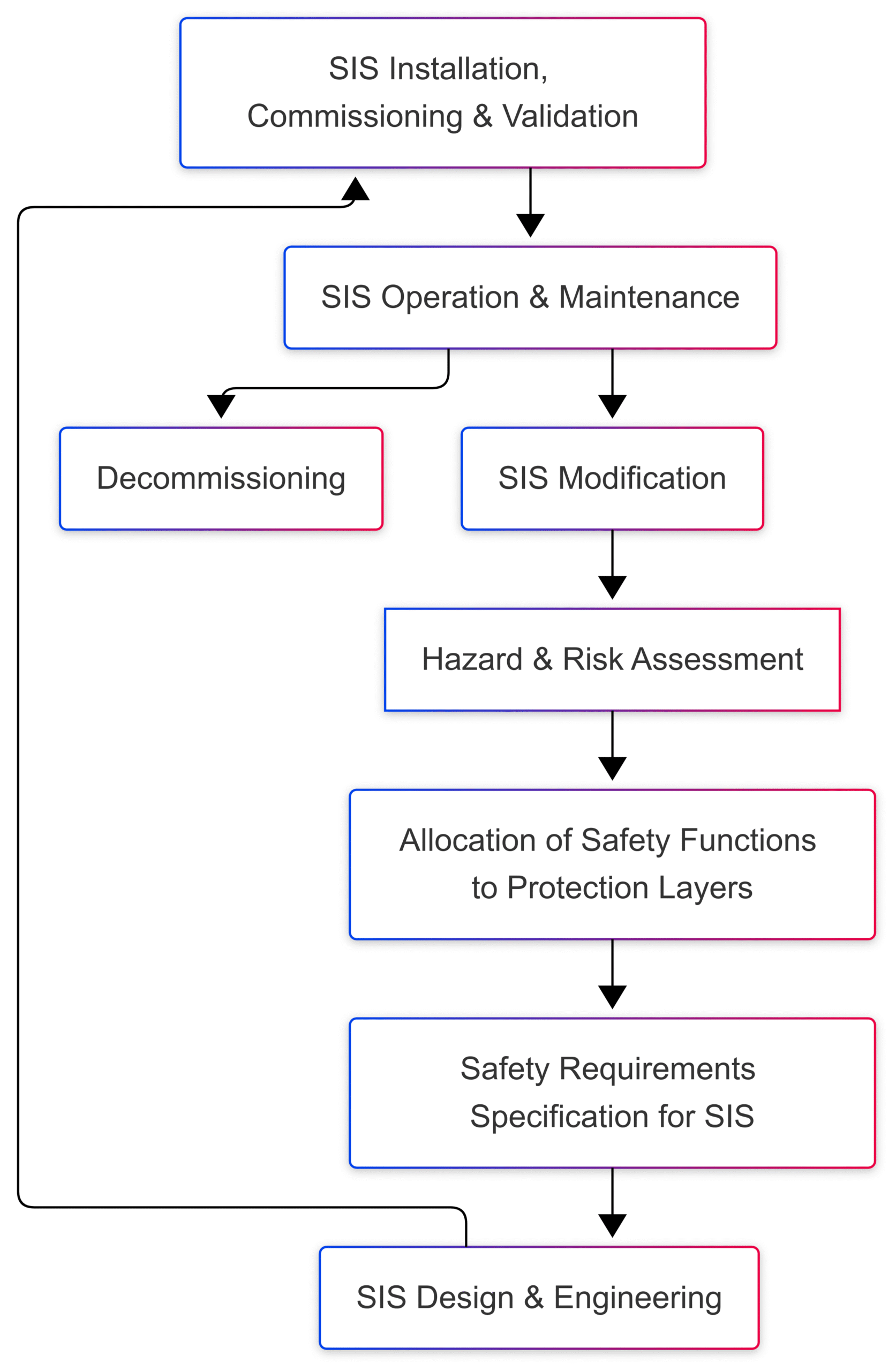

The core of IEC 61511 is the Safety Instrumented System (SIS), which is a system composed of sensors, logic solvers, and final elements designed to perform one or more Safety Instrumented Functions (SIFs). A SIF is a safety function with a specified SIL which is necessary to achieve or maintain a safe state for the process.

Key differences and areas of emphasis in IEC 61511 include:

Focus on the End-User: While IEC 61508 is primarily aimed at manufacturers, IEC 61511 is user-centric, providing guidance to the owners and operators of process plants on how to specify, design, install, operate, and maintain their SIS.

Practical Application: It provides more practical and less prescriptive guidance, allowing for flexibility in its application based on the specific needs of the process and the risk assessment.

Emphasis on the ‘As-Is’ Environment: The standard acknowledges that process plants are complex environments and provides guidance on how to manage the functional safety of existing (legacy) systems.

Consideration of Human Factors: IEC 61511 places a greater emphasis on human factors and the role of operators and maintenance personnel in ensuring the ongoing safety of the SIS.

Block Diagram 2: The IEC 61511 Safety Lifecycle (Simplified)

This diagram highlights the focus of IEC 61511 on the Safety Instrumented System (SIS) as a key protection layer within the overall safety strategy of a process plant.

Bridging the Gap: From Generic Principles to Specific Application

The “gap” between IEC 61508 and IEC 61511 is not a chasm but rather a bridge that needs to be carefully constructed to ensure a robust and compliant functional safety strategy. Bridging this gap involves translating the generic, and at times abstract, requirements of IEC 61508 into the concrete and practical realities of a process plant environment as mandated by IEC 61511.

Here’s how to build that bridge, with a focus on practical steps and considerations:

1. Establishing a Robust Functional Safety Management (FSM) System:

This is the foundation of the bridge. An effective FSM system, compliant with both standards, is paramount.

Define Roles and Responsibilities: Clearly delineate who is responsible for each stage of the SIS lifecycle, from the process hazard analysis (PHA) team to the maintenance technicians. This is a critical requirement of IEC 61511 that builds on the general FSM principles of IEC 61508.

Competency Management: Ensure that all personnel involved in the SIS lifecycle have the necessary competence and training. This goes beyond just technical skills and includes an understanding of the principles of functional safety. Documenting this competency is crucial for compliance.

Develop a Functional Safety Plan: This plan should be a living document that outlines the specific procedures, methodologies, and documentation to be used for all SIS-related activities.

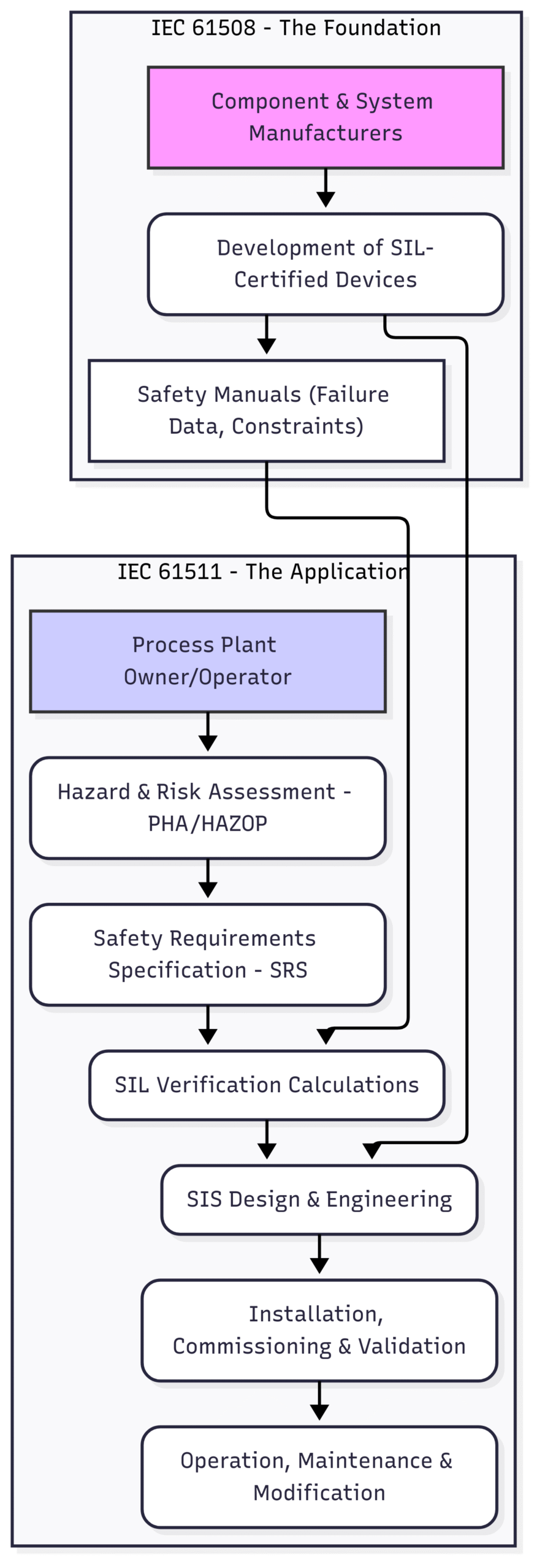

2. Leveraging IEC 61508 Certified Components:

A significant advantage of the relationship between the two standards is the ability to use components and systems that have been certified to IEC 61508.

Specifying SIL-Rated Devices: When designing an SIS, specifying sensors, logic solvers, and final elements that have been independently certified to a specific SIL according to IEC 61508 provides a high degree of confidence in their reliability.

Understanding the Safety Manual: The safety manual provided by the manufacturer of an IEC 61508 certified device is a critical document. It contains vital information on the device’s failure rates (e.g., PFDavg, λDU), architectural constraints, and proof-testing requirements. This information is essential for performing the SIL verification calculations required by IEC 61511.

3. The Crucial Role of the Safety Requirements Specification (SRS):

The SRS is the blueprint for the SIS and a key deliverable in the IEC 61511 lifecycle. It translates the findings of the hazard and risk assessment into specific requirements for the safety system.

From HAZOP to SRS: The journey starts with a Process Hazard Analysis (PHA), often a Hazard and Operability (HAZOP) study, which identifies the hazardous scenarios. The SRS then quantifies the required risk reduction for each scenario, leading to the determination of the SIL for the corresponding SIF.

Clarity and Detail: The SRS must be clear, concise, and unambiguous. It should detail not only the functional requirements of the SIF (e.g., “if the pressure in vessel V-101 exceeds 10 bar, then close valve XV-101 within 5 seconds”) but also the safety integrity requirements (the SIL), proof test intervals, and any specific operational or maintenance constraints.

4. Verification and Validation: Closing the Loop

Verification and validation are the activities that ensure the SIS is designed correctly and meets the requirements of the SRS.

SIL Verification: This is a quantitative analysis to demonstrate that the designed SIF meets its target SIL. It involves complex calculations considering the failure rates of all components, the architectural constraints (e.g., redundancy), and the effectiveness of proof testing. This is a direct application of the probabilistic principles laid out in IEC 61508.

Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT): These are practical tests to verify that the SIS has been built and installed correctly and functions as intended. The test procedures should be directly traceable to the requirements in the SRS.

5. Operation, Maintenance, and Management of Change:

The bridge must extend throughout the operational life of the plant.

Proof Testing: Regular proof testing of the SIS is essential to detect hidden failures that could prevent it from functioning on demand. The frequency and scope of these tests are determined during the design phase and documented in the SRS.

Bypass Management: There will be times when a SIF needs to be bypassed for maintenance or other operational reasons. IEC 61511 requires strict procedures for managing these bypasses to ensure that the plant remains safe.

Management of Change (MOC): Any modification to the process, the SIS, or the operational procedures must be subject to a formal MOC process. This ensures that the impact of the change on functional safety is assessed and that the SIS remains effective.

Block Diagram 3: Bridging the Gap – Information Flow from IEC 61508 to IEC 61511

This diagram clearly illustrates how the outputs of the IEC 61508 world (certified devices and their safety manuals) become critical inputs for the end-users applying IEC 61511 in their specific process plant context.

Common Challenges and How to Overcome Them

Bridging the gap is not without its challenges. Here are some common hurdles and practical advice on how to clear them:

Lack of Competency: As highlighted earlier, a lack of understanding of functional safety principles is a major roadblock. Solution: Invest in comprehensive training for all personnel involved in the SIS lifecycle. Consider engaging with certified functional safety experts (CFSEs) for guidance and support.

Inadequate Documentation: Poorly written or incomplete SRSs and other documentation can lead to misunderstandings and errors. Solution: Develop standardized templates for all functional safety documentation and ensure that they are rigorously reviewed and approved.

Legacy Systems: Many process plants have been in operation for decades, long before the advent of IEC 61511. Solution: Conduct a “gap analysis” to assess the existing safety systems against the requirements of the standard. Develop a prioritized plan to bring the systems into compliance. This may involve retrofitting new components, improving maintenance procedures, or enhancing documentation.

Over-complication: The desire to achieve compliance can sometimes lead to overly complex and burdensome procedures. Solution: Focus on a risk-based approach. The level of rigor applied should be commensurate with the level of risk.

Conclusion: A Unified Approach to a Safer Future

The relationship between IEC 61508 and IEC 61511 is a powerful example of how a foundational, generic standard can be effectively tailored to meet the specific needs of a high-hazard industry. The “gap” between them is not a void to be feared, but a space to be bridged with knowledge, process, and a commitment to safety.

By understanding the distinct roles of each standard, establishing a robust functional safety management system, leveraging the benefits of certified components, and meticulously following the safety lifecycle, organizations in the process industry can not only achieve compliance but, more importantly, can significantly reduce the risk of catastrophic incidents. The bridge between IEC 61508 and IEC 61511 is ultimately a bridge to a safer, more reliable, and more sustainable future for the process industry. It is a journey that requires diligence, expertise, and a steadfast focus on the ultimate goal: protecting people, the environment, and assets from harm.