How to Select the Right Packing Material for Control Valves

An essential guide for performance, compliance, and reliability.

1. Introduction

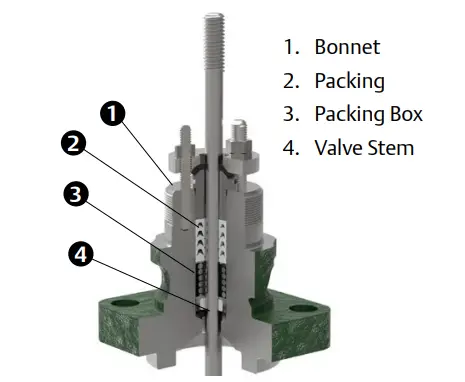

In control valve design, packing material is a crucial component that provides a seal between the valve bonnet and stem, preventing leakage of the process fluid. The right packing material ensures optimal performance, environmental compliance, and reduced maintenance costs.

2. Importance of Packing in Control Valves

Packing serves several essential purposes, including sealing against leakage, maintaining pressure, allowing stem movement, and reducing fugitive emissions. Improper selection can lead to increased downtime, safety hazards, and non-compliance with regulations.

3. Common Packing Materials

PTFE (Polytetrafluoroethylene)

Chemically inert with a low friction coefficient. Ideal for clean, non-abrasive applications in food, beverage, and pharmaceuticals. Limited by a temperature range of -200°C to +260°C.

Graphite

Offers excellent high-temperature resistance (up to 500°C+) and chemical compatibility. Commonly used in power plants and refineries. Not suitable for strong oxidizing environments.

Composite Packings

Made from a combination of materials (e.g., PTFE + graphite) to balance chemical resistance, temperature range, and sealing performance for general industrial applications.

Engineered Packing Sets (Low Emission)

Specialized systems with multiple rings and spring-loaded designs to meet stringent emission standards like ISO 15848 and API 622, crucial for VOC control.

4. Key Selection Criteria

Temperature:

Must withstand process temperatures without degrading.

Pressure:

Must contain line pressure while allowing stem movement.

Media Compatibility:

Must resist chemical attack from the process fluid.

Fugitive Emissions:

Must meet regulatory limits for leakage.

Cycling Frequency:

Low-friction materials are needed for high-cycling valves.

Environmental Conditions:

Must endure dust, contaminants, and corrosion.

5. Comparative Overview of Materials

| Property | PTFE | Graphite | Composite | Engineered Low-E |

|---|---|---|---|---|

| Temp. Range (°C) | -200 to +260 | -200 to +600 | -200 to +400 | Up to 600 |

| Chemical Resistance | Excellent | Very Good | Good | Excellent |

| Friction | Low | Moderate | Moderate | Low |

| Emissions Control | Fair | Good | Good | Excellent |

| Cost | Low | Moderate | Moderate-High | High |

6. Emission Standards and Regulatory Compliance

Selecting packing isn't just technical—it's about compliance with standards like the **EPA Clean Air Act**, **ISO 15848-1**, **TA-Luft**, and **API 622**. Failure to comply can lead to significant penalties.

7. Case Studies

Case 1: PTFE in Food Industry

In a milk processing plant, PTFE was selected for its chemical resistance and FDA approval, resulting in no contamination or leakage.

Case 2: Graphite in Power Plant

For a boiler steam control valve at 450°C, graphite packing provided excellent sealing and zero emissions.

Case 3: Low-Emission Packing in Refinery

For a VOC-sensitive valve, an API 622 tested graphite packing achieved compliance with emissions well below 100 ppm.

8. Installation and Maintenance

Proper selection must be followed by correct installation. Use the correct torque, avoid over-compression, and monitor for leaks, especially in high-cycling valves. Consider live-loaded systems to minimize re-tightening.

9. Future Trends in Packing Technology

Future innovations include nanotechnology-enhanced packings for better wear resistance, smart packings with embedded sensors, and wider adoption of eco-friendly materials and standardized emission-compliant systems.

10. Conclusion

Selecting the right packing material is a multi-dimensional decision. Proper selection, installation, and maintenance will ensure process safety and efficiency while helping industries meet their environmental and sustainability goals.

Table of Contents:

- Introduction

- Importance of Packing in Control Valves

- Common Packing Materials

- PTFE (Polytetrafluoroethylene)

- Graphite

- Asbestos (Historical Reference)

- Composite Packings

- Engineered Packing Sets

- Key Selection Criteria for Packing Materials

- Temperature

- Pressure

- Media Compatibility

- Fugitive Emission Control

- Cycling and Movement Frequency

- Environmental Conditions

- Comparative Overview of Common Packing Materials

- Emission Standards and Regulatory Compliance

- Case Studies: Packing Material in Different Applications

- Installation and Maintenance Considerations

- Future Trends in Packing Technology

- Conclusion

- Introduction

In control valve design and operation, one component that often goes unnoticed but plays a crucial role is packing material. Control valve stem packing provides a seal between the valve bonnet and stem, preventing leakage of the process fluid. The right packing material ensures optimal performance, environmental compliance, and reduced maintenance costs.

This blog provides a detailed overview of how to select the right packing material for control valves based on various process parameters and industry requirements.

- Importance of Packing in Control Valves

Packing in control valves serves several essential purposes:

- Sealing against leakage: Prevents the escape of process fluid along the valve stem.

- Maintaining pressure integrity: Ensures the valve maintains system pressure.

- Allowing stem movement: Must be flexible enough to allow the stem to move without damage.

- Reducing fugitive emissions: Especially critical in oil, gas, chemical, and pharmaceutical industries.

Improper packing selection can lead to:

- Increased maintenance and downtime

- Safety hazards due to leaks

- Non-compliance with emission regulations

- Shortened valve lifespan

- Common Packing Materials

3.1 PTFE (Polytetrafluoroethylene)

Properties:

- Chemically inert to most substances

- Low friction coefficient

- Good for clean, non-abrasive applications

- Temperature range: -200°C to +260°C

Applications:

- Food and beverage

- Pharmaceuticals

- Low-pressure steam

Limitations:

- Not suitable for high-temperature applications

- Can cold flow under high compression

3.2 Graphite

Properties:

- Excellent high-temperature resistance (up to 500°C or higher)

- Good chemical compatibility (except strong oxidizers)

- Good self-lubricating properties

- High compressibility and recovery

Applications:

- Power plants

- Refineries

- High-temperature chemical services

Limitations:

- Not suitable in oxidizing environments at high temperatures

- Requires high torque during installation

3.3 Asbestos (Historical Reference)

While asbestos was widely used in the past due to its excellent heat resistance and durability, it is now banned or restricted due to its health hazards. Modern equivalents offer similar properties without the risks.

3.4 Composite Packings

Properties:

- Made from a combination of materials (e.g., PTFE + graphite)

- Designed to balance chemical resistance, temperature range, and sealing performance

Applications:

- General industrial applications

- Moderate temperature and chemical services

Advantages:

- Lower friction than pure graphite

- Better temperature resistance than pure PTFE

3.5 Engineered Packing Sets (Low Emission Packing)

These are specialized packing systems designed to meet stringent emission standards (e.g., ISO 15848, API 622, TA-Luft).

Features:

- Multiple rings with anti-extrusion and wiper rings

- Spring-loaded packing systems

- Live-loaded designs for dynamic sealing

Applications:

- VOC control

- Greenhouse gas-sensitive applications

- Critical process valves

- Key Selection Criteria for Packing Materials

4.1 Temperature

Packing must withstand the maximum and minimum process temperatures without degrading.

- PTFE: Ideal for temperatures up to 260°C

- Graphite: Suitable for up to 500–600°C

- Composite packings: Vary depending on composition

4.2 Pressure

Packing materials must be able to contain the maximum line pressure while still allowing the stem to move freely.

- Graphite: Excellent for high-pressure systems

- PTFE: Suitable for lower pressures

- Live-loaded systems: Enhance sealing in fluctuating pressures

4.3 Media Compatibility

Different media (gas, liquid, corrosive chemicals) affect packing choice.

- Use chemical compatibility charts for specific applications.

- PTFE is resistant to most chemicals but not suitable for alkali metals.

- Graphite is chemically resistant except in oxidizing conditions.

4.4 Fugitive Emission Control

With stricter regulations (like EPA LDAR and ISO 15848), low emission packing is mandatory for many industries.

- Use graphite or composite packings with low leak rates

- Live-loaded and spring-energized packing sets are preferred

4.5 Cycling and Movement Frequency

In high-cycling valves (such as in modulating control):

- Low-friction materials like PTFE or PTFE blends are ideal.

- Packing must not wear or extrude under frequent movement.

4.6 Environmental Conditions

Packing must endure environmental factors such as:

- Dust and contaminants (use wiper rings)

- Salt-laden air (use corrosion-resistant materials)

- Sunlight and UV (PTFE and graphite are generally stable)

- Comparative Overview of Common Packing Materials

| Property | PTFE | Graphite | Composite | Engineered Low-E |

| Temp. Range (°C) | -200 to +260 | -200 to +600 | -200 to +400 | Up to 600 |

| Chemical Resistance | Excellent | Very good | Good | Excellent |

| Friction | Low | Moderate | Moderate | Low |

| Emissions Control | Fair | Good | Good | Excellent |

| Cost | Low | Moderate | Moderate-High | High |

| Common Use Cases | Clean services | High-temp gases | Multi-purpose | VOC, toxic, API 622 |

- Emission Standards and Regulatory Compliance

Selecting packing material isn’t just a technical issue—it is also about compliance:

- EPA Clean Air Act (USA)

- ISO 15848-1 for fugitive emissions

- TA-Luft (Germany)

- API 622: Type testing of packing for emissions

In many countries and industries, failing to meet these standards can result in fines, legal action, or plant shutdowns.

- Case Studies: Packing Material in Different Applications

Case 1: PTFE in Food Industry

- Application: Control valve in a milk processing plant

- Medium: Dairy fluids, CIP chemicals

- Selection: PTFE due to excellent chemical resistance and FDA approval

- Result: No contamination or leakage

Case 2: Graphite in Power Plant

- Application: Boiler steam control

- Medium: Superheated steam at 450°C

- Selection: Graphite packing with anti-extrusion rings

- Result: Excellent sealing performance, zero emissions

Case 3: Low-Emission Packing in Refinery

- Application: VOC-sensitive valve in hydrocarbon line

- Medium: Benzene

- Selection: API 622 tested low-emission graphite-based packing

- Result: Complied with ISO 15848-A, emissions < 100 ppm

- Installation and Maintenance Considerations

Proper selection must be followed by correct installation and maintenance:

- Use the correct torque during gland tightening

- Avoid over-compression, which can reduce packing life

- Always use lubricants or anti-seize compatible with packing and process

- Monitor for signs of leakage, especially in cycling valves

- Consider live-loaded systems for minimizing need for re-tightening

- Future Trends in Packing Technology

- Nanotechnology-enhanced packings: For better sealing and wear resistance

- Smart packings: Embedded sensors to detect wear and leakage

- Eco-friendly materials: Non-toxic, biodegradable components

- Standardization: Wider adoption of ISO and API emission-compliant packing systems

- Conclusion

Selecting the right packing material for control valves is a multidimensional decision that must consider temperature, pressure, chemical compatibility, regulatory compliance, and valve movement. While PTFE and graphite remain popular choices, the rise of engineered and composite packing systems offers new opportunities for performance and emission control.

Valve manufacturers and users must work closely to ensure the packing material meets both operational needs and legal requirements. Proper selection, installation, and maintenance of valve packing will not only ensure process safety and efficiency but also help industries meet their environmental and sustainability goals.

Recommended Reading:

- API 622: “Type Testing of Process Valve Packing for Fugitive Emissions”

- ISO 15848-1: “Industrial Valves – Measurement, Test and Qualification Procedures for Fugitive Emissions”

- FSA (Fluid Sealing Association) Packing Handbook