Comprehensive Guide to ESD Valve Maintenance

Sustaining Performance in Oil & Gas and Process Industries

1. Introduction

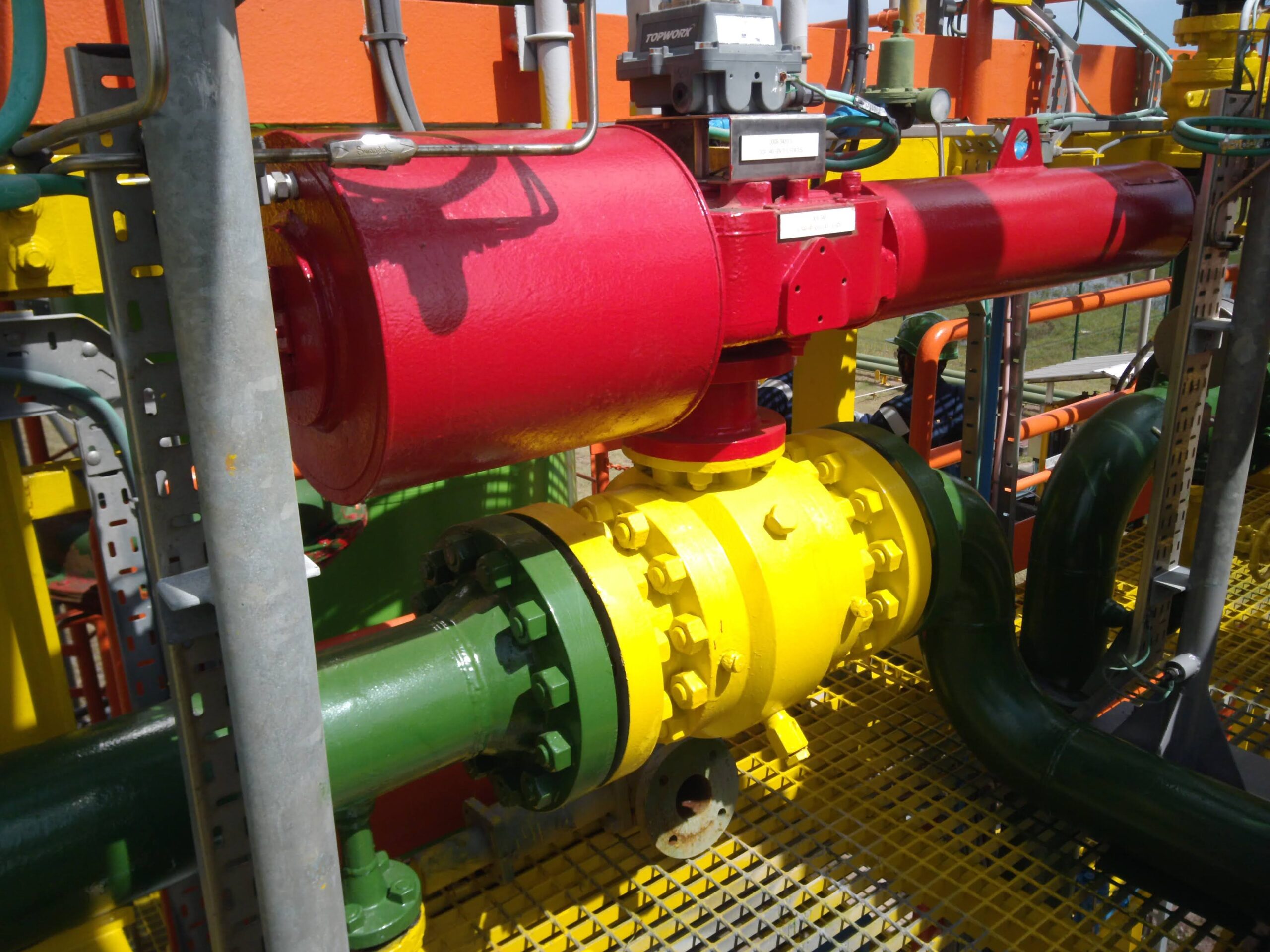

Emergency Shutdown Valves (ESDVs) are critical components in the safety systems of oil & gas and process industries. Their primary role is to isolate sections of a plant or process in emergency conditions, minimizing risk to personnel, assets, and the environment. Given their significance in ensuring process safety, maintaining ESD valves in optimal condition is not just good practice—it is essential.

2. Importance of ESD Valve Maintenance

2.1 Role of ESD Valves in Safety Instrumented Systems (SIS)

In a Safety Instrumented System (SIS), ESD valves are the final control elements that execute shutdown commands from Safety Instrumented Functions (SIFs). They are typically actuated by pneumatic, hydraulic, or electric actuators and integrated with logic solvers and field instruments.

2.2 Compliance and Regulatory Requirements

Standards such as IEC 61511 and API 556, as well as regulatory bodies like OSHA, mandate periodic inspection and validation of ESD valves to ensure they perform as intended in Safety Integrity Level (SIL) assessments.

3. Types of ESD Valves and Maintenance Considerations

- Ball Valves: Common in pipeline shut-off applications. Maintenance includes seal inspection, actuator calibration, and stem lubrication.

- Gate Valves: Used in applications requiring full open/close with minimal pressure drop. Requires attention to wedge wear, stem threads, and gearbox integrity.

- Butterfly Valves: Favored for space-constrained installations. Maintenance focuses on seat wear, disc alignment, and shaft sealing.

- Globe and Plug Valves: Used in modulating service with shutdown capabilities. Needs tight tolerance inspection and actuator/positioner synchronization.

4. Maintenance Strategies

Preventive Maintenance (PM): Scheduled servicing based on time or operating hours. Key tasks include visual inspection, cleaning, calibration, and leak testing.

Predictive Maintenance (PdM): Utilizes diagnostics and condition monitoring tools such as Partial Stroke Testing (PST), valve position feedback monitoring, acoustic and vibration analysis, and supply pressure monitoring.

Corrective Maintenance: Involves repair or replacement after a failure. Though not ideal, corrective maintenance may be unavoidable if diagnostics are neglected.

Risk-Based Maintenance (RBM): Focuses efforts on valves that pose the highest risk based on SIL level, process criticality, environmental exposure, and historical failure data.

5. Detailed Maintenance Tasks

Actuator Inspection:

Check for leakage in pneumatic or hydraulic actuators. Inspect diaphragm or piston condition. Evaluate spring tension and ensure quick response.

Solenoid Valve Checks:

Clean or replace filters and screens. Confirm coil resistance and power supply. Check function of manual override.

Limit Switch and Position Feedback:

Test for correct open/close feedback. Inspect wiring and terminals for integrity. Calibrate if deviation from setpoint is observed.

Seal and Packing Maintenance:

Evaluate condition of stem seals and body gaskets. Replace O-rings and soft seals prone to aging. Lubricate mechanical seals and rotating elements.

Stroke Testing:

Conduct full or partial stroke tests. Record valve travel time and response characteristics. Analyze deviations from baseline to detect sticking or lag.

Pressure Testing:

Perform hydrostatic or pneumatic seat tests. Measure leakage across the valve in closed condition. Verify against ANSI/FCI leakage class criteria.

6. Diagnostic Tools and Techniques

Partial Stroke Testing (PST): A key diagnostic method that moves the valve slightly (10–20%) without affecting the process. Helps verify valve movement capability, detect stiction, and reduce the need for full shutdown testing.

Valve Signature Analysis: Records parameters like travel time, pressure vs. time, and torque vs. time to detect anomalies like excessive friction or actuator undersizing.

Smart Positioners and Valve Diagnostics: Modern digital valve controllers (e.g., Emerson’s DVC6200, Siemens SIPART PS2) offer continuous diagnostics, provide alerts on degraded performance, and enable remote testing and logging.

7. Best Practices in ESD Valve Maintenance

- Maintain a Valve Asset Register: Include tag, type, size, actuator, service conditions, SIL rating, and maintenance records.

- Test During Planned Shutdowns: Always schedule full-stroke and seat-leakage tests during plant turnarounds.

- Train Personnel on Valve Safety: Ensure technicians understand lockout/tagout and are familiar with diagnostic tools.

- Align with SIL Testing Frequency: As per IEC 61511, proof testing should match the determined SIL-required interval.

8. Real-World Challenges and Mitigations

Challenge: Inaccessible Valves

Mitigation: Use wireless diagnostics and remote PST enablers. Design future installations with accessibility in mind.

Challenge: Frequent False Trips

Mitigation: Calibrate solenoids, check power supply stability, and inspect feedback wiring for EMI susceptibility.

Challenge: Valve Stiction in Long Idle Conditions

Mitigation: Schedule regular PSTs and install self-cleaning actuators in dusty environments.

Challenge: Environmental Corrosion

Mitigation: Use protective coatings, weatherproof enclosures (IP66/68), and marine-grade materials (SS316, Inconel).

Challenge: Inadequate Spare Parts

Mitigation: Maintain critical spares inventory based on risk ranking. Include actuator kits, seals, solenoids, and limit switches.

9. ESD Valve Maintenance Checklist

| Task | Frequency | Remarks |

|---|---|---|

| Visual Inspection | Monthly | Look for corrosion, label fading |

| Solenoid Function Test | Quarterly | Include manual override test |

| PST | Monthly/Quarterly | Based on SIL level |

| Full Stroke Test | Annually or during Turnaround | Must include leakage test |

| Feedback Calibration | Semi-Annually | Compare set vs actual |

| Seal Replacement | Every 2–3 years | Based on exposure |

| Actuator Pressure Test | Annually | Test spring return or piston force |

10. Case Study: Offshore Platform ESD Failure Analysis

Scenario: An offshore gas processing platform experienced an uncommanded process shutdown. Investigation revealed an ESD valve failed to close due to solenoid coil burnout caused by voltage surges and lack of grounding.

Lessons Learned:

- Install surge protectors in SIS circuits.

- Schedule solenoid resistance checks.

- Regularly validate grounding and bonding integrity.

- Consider redundancy for high-criticality valves.

11. Future Trends in ESD Valve Maintenance

IIoT and Remote Monitoring: Smart valve controllers with edge computing and wireless transmission allow real-time health reporting, remote stroke initiation, and integration into centralized asset management systems.

AI-Powered Predictive Maintenance: AI models are being developed that analyze valve signature patterns, predict failures before they happen, and recommend maintenance actions automatically.

Digital Twins: Simulation models of ESD valves can optimize testing schedules, predict seal wear and stroke time degradation, and provide training scenarios for technicians.

12. Conclusion

Emergency Shutdown Valves are lifelines of any process plant’s safety system. Ensuring their readiness through disciplined maintenance practices—backed by diagnostics, standards compliance, and risk-based strategies—helps avoid catastrophic failures and maintain operational excellence. A proactive ESD valve maintenance regime is not just about hardware—it's about safeguarding lives, assets, and the environment.

13. References

- IEC 61511: Functional safety – Safety instrumented systems

- API 556: Instrumentation and Control Systems for Fired Heaters

- ISA TR96.05: Guidelines for the Specification of Valve Actuators

- Emerson, Siemens, and ABB product documentation on digital valve controllers

- Offshore Technology Reports on ESD valve failures and lessons learned

Comprehensive Guide to ESD Valve Maintenance for Sustained Performance in Oil & Gas and Process Industries

Introduction

Emergency Shutdown Valves (ESDVs) are critical components in the safety systems of oil & gas and process industries. Their primary role is to isolate sections of a plant or process in emergency conditions, minimizing risk to personnel, assets, and the environment. Given their significance in ensuring process safety, maintaining ESD valves in optimal condition is not just good practice—it is essential.

This blog explores comprehensive ESD valve maintenance practices, technical challenges, diagnostic methods, and real-world insights aimed at sustaining performance and compliance.

- Importance of ESD Valve Maintenance

1.1 Role of ESD Valves in Safety Instrumented Systems (SIS)

In a Safety Instrumented System (SIS), ESD valves are the final control elements that execute shutdown commands from Safety Instrumented Functions (SIFs). They are typically actuated by pneumatic, hydraulic, or electric actuators and integrated with logic solvers and field instruments.

1.2 Compliance and Regulatory Requirements

Standards such as IEC 61511 and API 556, as well as regulatory bodies like OSHA, mandate periodic inspection and validation of ESD valves to ensure they perform as intended in Safety Integrity Level (SIL) assessments.

- Types of ESD Valves and Maintenance Considerations

2.1 Ball Valves

- Common in pipeline shut-off applications.

- Maintenance includes seal inspection, actuator calibration, and stem lubrication.

2.2 Gate Valves

- Used in applications requiring full open/close with minimal pressure drop.

- Requires attention to wedge wear, stem threads, and gearbox integrity.

2.3 Butterfly Valves

- Favored for space-constrained installations.

- Maintenance focuses on seat wear, disc alignment, and shaft sealing.

2.4 Globe and Plug Valves

- Used in modulating service with shutdown capabilities.

- Needs tight tolerance inspection and actuator/positioner synchronization.

- Maintenance Strategies for ESD Valves

3.1 Preventive Maintenance (PM)

Scheduled servicing based on time or operating hours. Key tasks include:

- Visual inspection for corrosion and wear.

- Cleaning and greasing of mechanical parts.

- Calibration of limit switches and solenoid valves.

- Leak testing using air or nitrogen.

3.2 Predictive Maintenance (PdM)

Utilizes diagnostics and condition monitoring tools such as:

- Partial Stroke Testing (PST)

- Valve position feedback monitoring

- Acoustic and vibration analysis

- Supply pressure monitoring

3.3 Corrective Maintenance

Involves repair or replacement after a failure. Though not ideal, corrective maintenance may be unavoidable if diagnostics are neglected.

3.4 Risk-Based Maintenance (RBM)

Focuses efforts on valves that pose the highest risk based on:

- SIL level

- Process criticality

- Environmental exposure

- Historical failure data

- Detailed Maintenance Tasks for ESD Valves

4.1 Actuator Inspection

- Check for leakage in pneumatic or hydraulic actuators.

- Inspect diaphragm or piston condition.

- Evaluate spring tension and ensure quick response.

4.2 Solenoid Valve Checks

- Clean or replace filters and screens.

- Confirm coil resistance and power supply.

- Check function of manual override.

4.3 Limit Switch and Position Feedback

- Test for correct open/close feedback.

- Inspect wiring and terminals for integrity.

- Calibrate if deviation from setpoint is observed.

4.4 Seal and Packing Maintenance

- Evaluate condition of stem seals and body gaskets.

- Replace O-rings and soft seals prone to aging.

- Lubricate mechanical seals and rotating elements.

4.5 Stroke Testing

- Conduct full or partial stroke tests.

- Record valve travel time and response characteristics.

- Analyze deviations from baseline to detect sticking or lag.

4.6 Pressure Testing

- Perform hydrostatic or pneumatic seat tests.

- Measure leakage across the valve in closed condition.

- Verify against ANSI/FCI leakage class criteria.

- Diagnostic Tools and Techniques

5.1 Partial Stroke Testing (PST)

A key diagnostic method that moves the valve slightly (10–20%) without affecting the process. Helps:

- Verify valve movement capability.

- Detect stiction and actuator wear.

- Reduce the need for full shutdown testing.

5.2 Valve Signature Analysis

Records parameters like:

- Travel time

- Pressure vs. time

- Torque vs. time

- Detects anomalies like excessive friction or actuator undersizing.

5.3 Smart Positioners and Valve Diagnostics

Modern digital valve controllers (e.g., Emerson’s DVC6200, Siemens SIPART PS2):

- Offer continuous diagnostics.

- Provide alerts on degraded performance.

- Enable remote testing and logging via HART, Foundation Fieldbus, or Profibus.

- Best Practices in ESD Valve Maintenance

6.1 Maintain a Valve Asset Register

Include:

- Valve tag

- Type, size, make/model

- Actuator type

- Service fluid and conditions

- SIL rating and SIF details

- Last maintenance and testing records

6.2 Test During Planned Shutdowns

- Always schedule full-stroke and seat-leakage tests during plant turnarounds.

- Replace parts preemptively if nearing end-of-life.

6.3 Train Personnel on Valve Safety

- Ensure field technicians understand lockout/tagout procedures.

- Familiarize them with smart diagnostic tools and software.

- Periodically certify technicians on safety system components.

6.4 Align with SIL Testing Frequency

- As per IEC 61511, proof testing should match the determined SIL-required interval.

- Perform full stroke tests if PST is not implemented or effective.

- Real-World Challenges and Mitigations

7.1 Challenge: Inaccessible Valves

Mitigation:

Use wireless diagnostics and remote PST enablers. Design future installations with accessibility in mind.

7.2 Challenge: Frequent False Trips

Mitigation:

Calibrate solenoids, check power supply stability, and inspect feedback wiring for EMI susceptibility.

7.3 Challenge: Valve Stiction in Long Idle Conditions

Mitigation:

Schedule regular PSTs and install self-cleaning actuators in dusty environments.

7.4 Challenge: Environmental Corrosion

Mitigation:

Use protective coatings, weatherproof enclosures (IP66/68), and marine-grade materials (SS316, Inconel).

7.5 Challenge: Inadequate Spare Parts

Mitigation:

Maintain critical spares inventory based on risk ranking. Include actuator kits, seals, solenoids, and limit switches.

- ESD Valve Maintenance Checklist

| Task | Frequency | Remarks |

| Visual Inspection | Monthly | Look for corrosion, label fading |

| Solenoid Function Test | Quarterly | Include manual override test |

| PST | Monthly/Quarterly | Based on SIL level |

| Full Stroke Test | Annually or during Turnaround | Must include leakage test |

| Feedback Calibration | Semi-Annually | Compare set vs actual |

| Seal Replacement | Every 2–3 years | Based on exposure |

| Actuator Pressure Test | Annually | Test spring return or piston force |

- Case Study: Offshore Platform ESD Failure Analysis

Scenario:

An offshore gas processing platform experienced an uncommanded process shutdown. Investigation revealed an ESD valve failed to close due to solenoid coil burnout caused by voltage surges and lack of grounding.

Lessons Learned:

- Install surge protectors in SIS circuits.

- Schedule solenoid resistance checks.

- Regularly validate grounding and bonding integrity.

- Consider redundancy for high-criticality valves.

- Future Trends in ESD Valve Maintenance

10.1 IIoT and Remote Monitoring

Smart valve controllers with edge computing and wireless transmission allow:

- Real-time health reporting.

- Remote stroke initiation.

- Integration into centralized asset management systems.

10.2 AI-Powered Predictive Maintenance

AI models are being developed that:

- Analyze valve signature patterns.

- Predict failures before they happen.

- Recommend maintenance actions automatically.

10.3 Digital Twins

Simulation models of ESD valves can:

- Optimize testing schedules.

- Predict seal wear and stroke time degradation.

- Provide training scenarios for technicians.

Conclusion

Emergency Shutdown Valves are lifelines of any process plant’s safety system. Ensuring their readiness through disciplined maintenance practices—backed by diagnostics, standards compliance, and risk-based strategies—helps avoid catastrophic failures and maintain operational excellence.

A proactive ESD valve maintenance regime is not just about hardware—it’s about safeguarding lives, assets, and the environment.

References

- IEC 61511: Functional safety – Safety instrumented systems

- API 556: Instrumentation and Control Systems for Fired Heaters

- ISA TR96.05: Guidelines for the Specification of Valve Actuators

- Emerson, Siemens, and ABB product documentation on digital valve controllers

- Offshore Technology Reports on ESD valve failures and lessons learned