The 4-20 mA Current Loop

A Deep Dive into Transmitter Electronics and Signal Conversion

Why Use 4-20 mA Instead of Voltage?

In industrial automation, accurately transmitting data from sensors is critical. A process variable (PV)—like pressure, temperature, flow, or level—is measured and converted into a standard signal. While voltage signals exist, the 4-20 mA current loop is the industry standard for analog data transmission for several compelling reasons.

Noise Immunity

Current signals are far less susceptible to electromagnetic interference (EMI) and signal loss over long distances.

Long-Distance Transmission

A 4-20 mA signal can travel hundreds of meters through wires without significant degradation, ensuring data integrity.

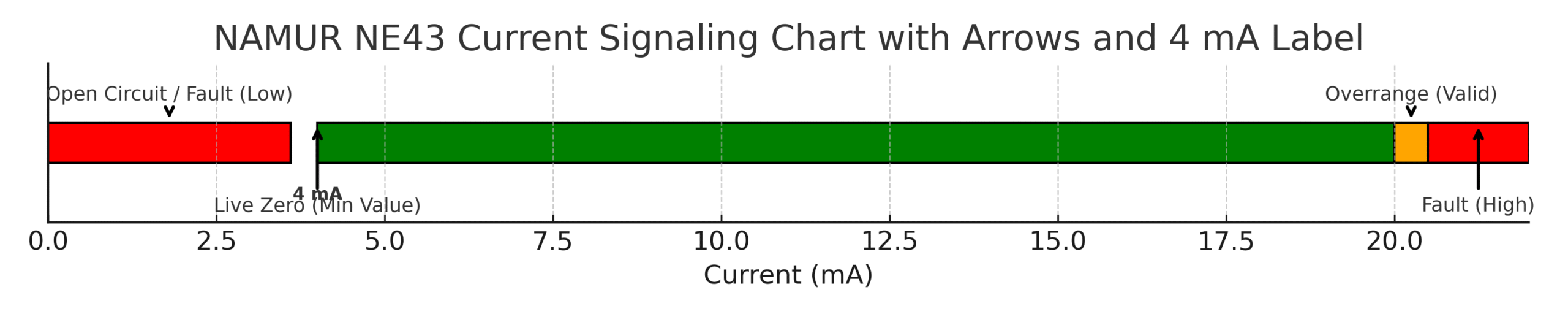

Live Zero & Fault Detection

Using 4 mA as the minimum signal (a "live zero") allows the system to instantly detect a broken wire or sensor failure (which would result in 0 mA).

Loop-Powered Simplicity

Devices can be powered by the same two wires that transmit the signal, simplifying wiring and reducing costs.

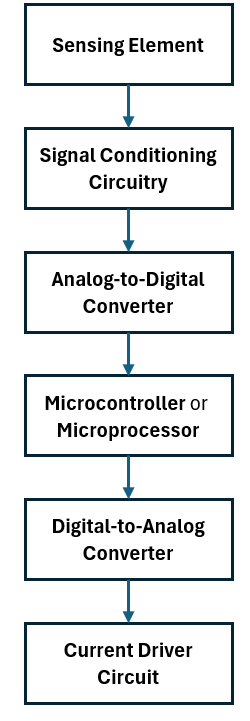

Anatomy of a Transmitter

A transmitter is the heart of this process. It's an electronic device that converts the raw output from a sensor (like a thermocouple, RTD, or strain gauge) into the standardized 4-20 mA output signal. While designs vary, most modern transmitters share a common internal architecture.

- Sensing Element: The primary sensor that interacts with the process variable.

- Signal Conditioning Circuitry: Amplifies, filters, and linearizes the often weak and non-linear raw sensor signal.

- Analog-to-Digital Converter (ADC): In smart transmitters, this converts the analog signal into a digital value for processing.

- Microcontroller: The "brain" that processes the digital value, applies calibration data, and calculates the correct output current.

- Digital-to-Analog Converter (DAC): Converts the calculated digital command back into an analog voltage.

- Current Driver Circuit: This final stage takes the voltage from the DAC and generates a precisely regulated 4-20 mA current for the loop.

The Step-by-Step Conversion Process

Let's walk through how a physical measurement becomes a current signal.

Sensor Measurement: A sensor (e.g., an RTD measuring temperature) generates a small change in resistance corresponding to the process variable.

Signal Conditioning: The raw signal is cleaned up. It's amplified to increase its strength, filtered to remove noise, and linearized to ensure a proportional response.

Digital Processing (Smart Transmitter): An ADC converts the conditioned signal to a digital value. The microcontroller then compares this value against its calibrated range (e.g., 0 to 100°C) and calculates the required output current.

Current Output Generation: A DAC converts the microcontroller's digital command to a voltage. This voltage drives the current regulator circuit, which forces the precise corresponding current (between 4 and 20 mA) into the loop.

For example, if a temperature transmitter is ranged from 0 to 100 °C, and the current temperature is 50 °C (50% of the range), the microcontroller calculates the output as:

Output = 4 mA + (20 mA - 4 mA) * (50 °C / 100 °C)

Output = 4 mA + (16 mA) * 0.5

Output = 12 mA

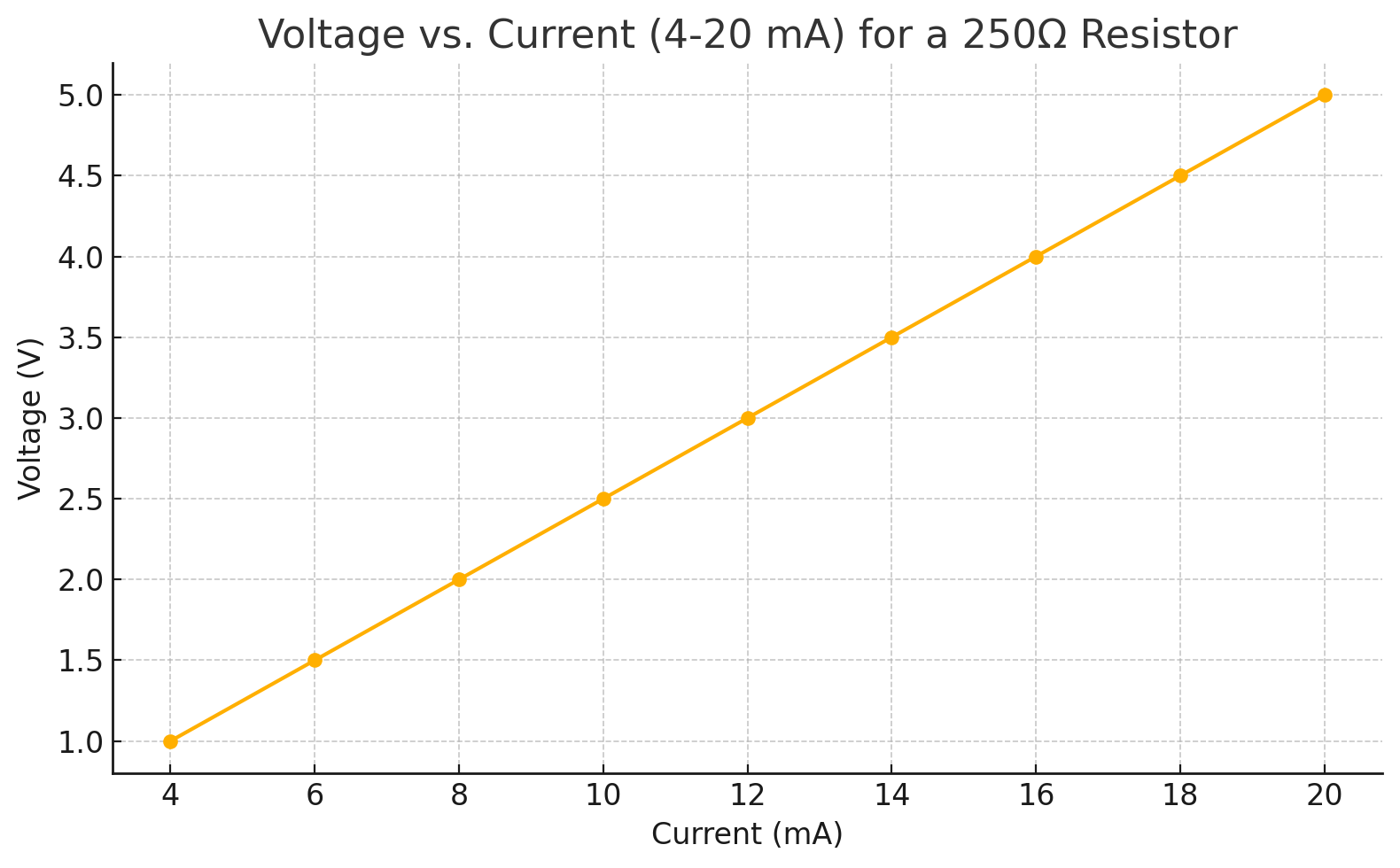

The 4-20 mA Loop & The 250-Ohm Resistor

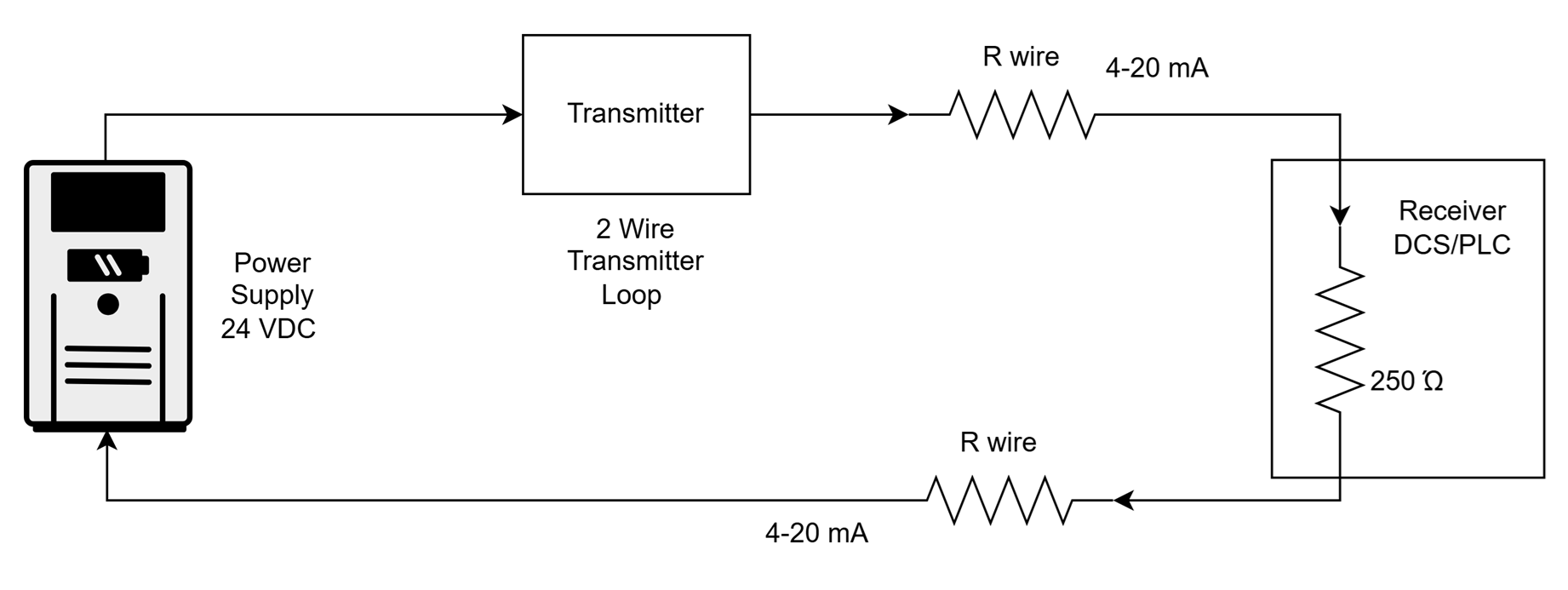

The entire system forms a simple series circuit known as the current loop. It consists of a power supply (typically 24V DC), the transmitter, the signal wiring, and the receiving device (like a PLC or DCS input card).

The Role of the 250Ω Resistor

Many controller input cards are designed to read voltage, not current. The 250-ohm precision resistor is a simple and effective way to bridge this gap. By placing it across the input terminals of the PLC/DCS, the 4-20 mA current is converted into a 1-5V signal according to Ohm's Law ($V = I \times R$).

At minimum signal (4 mA): 0.004 A * 250 Ω = 1 V

At maximum signal (20 mA): 0.020 A * 250 Ω = 5 V

This allows a standard voltage-input device to accurately read the signal from a current loop.

Power Supply Considerations

The loop's 24V DC power supply must have enough voltage to overcome all the voltage drops in the series circuit, including the transmitter's internal electronics, the wire resistance, and the 250Ω receiver resistor. A 24V supply typically provides a safe margin for most applications.

Conclusion: Robust & Reliable

The 4-20 mA current loop remains a cornerstone of industrial instrumentation due to its inherent simplicity, robustness against electrical noise, and built-in fault detection capabilities. Understanding how a transmitter converts a physical process variable into a proportional current signal is fundamental for any instrumentation or control systems engineer. By mastering these concepts, engineers can effectively design, troubleshoot, and maintain the systems that ensure accurate and reliable process control.

In industrial automation, accurate and reliable transmission of process data is critical. One of the most widely used methods for transmitting analog signals in process control systems is the 4-20 mA current loop. This article will provide an in-depth explanation of how a process variable, such as pressure, temperature, level, or flow, is converted into a 4-20 mA signal. It will also explore the electronics involved in a transmitter and the role of a 250-ohm resistor in this setup.

- Introduction to Process Variables

A process variable (PV) is a measurable condition of a process, such as:

- Pressure (in bar, psi, etc.)

- Temperature (in °C, °F)

- Flow (in m3/hr, LPM)

- Level (in %, meters)

In process plants, sensors measure these variables, and the measured signal is converted into a standardized analog signal, most commonly 4-20 mA.

- Why Use 4-20 mA Instead of Voltage?

Advantages:

- Less noise interference: Current is less susceptible to signal loss and electromagnetic interference.

- Long distance transmission: Signals can travel hundreds of meters without degradation.

- Live zero: 4 mA (not 0 mA) represents the minimum measurement, allowing for sensor fault detection.

- Simplicity: Loop-powered devices can be powered and controlled with just two wires.

- Anatomy of a Transmitter

A transmitter is an electronic device that converts the output from a sensor (such as a thermocouple, RTD, strain gauge, or differential pressure sensor) into a standard current output signal (4-20 mA).

Typical Transmitter Architecture:

- Sensing Element

- Signal Conditioning Circuitry

- Analog-to-Digital Converter (ADC) (in smart transmitters)

- Microcontroller or Microprocessor

- Digital-to-Analog Converter (DAC)

- Current Driver Circuit

- Step-by-Step Conversion Process

Step 1: Sensor Measures the Process Variable

A sensor (e.g., RTD or strain gauge) generates a small analog voltage or resistance change based on the process variable.

Step 2: Signal Conditioning

The sensor output is often very small or nonlinear. The signal conditioning circuit amplifies and linearizes the signal:

- Amplification to increase signal strength

- Filtering to remove noise

- Linearization to correct non-linear sensor outputs

Step 3: Analog to Digital Conversion (if smart transmitter)

An ADC converts the conditioned analog signal into a digital value for microcontroller processing.

Step 4: Microcontroller Processing

The microcontroller compares the signal against calibrated range:

For example:

- 0 to 100 °C = 4 to 20 mA

- If sensed value is 50 °C, then the equivalent output should be:

Step 5: Digital to Analog Conversion

A DAC converts the calculated digital signal into a voltage which is then used to control the current driver.

Step 6: Current Driver Circuit

This circuit converts the DAC voltage into a regulated current source. The design ensures the loop current matches the desired signal (4-20 mA) regardless of load impedance within permissible limits.

- 4-20 mA Loop Configuration

Basic Loop Elements:

- Power Supply (typically 24V DC)

- Transmitter (loop-powered or 2-wire)

- Signal wire (twisted pair cable)

- Receiving device (PLC/Controller or DCS input card)

- 250-ohm resistor (if voltage input is required)

- Role of 250-Ohm Resistor

The 250-ohm resistor is often used in analog input cards of PLCs or DCS where the input is voltage-based (1-5V) rather than current-based. Since:

A 4-20 mA current passing through a 250-ohm resistor will generate:

- 4 mA * 250 ohm = 1 V

- 20 mA * 250 ohm = 5 V

Thus, the voltage across the resistor represents the current level and hence the process variable.

This allows current-loop signals to be read by voltage-input analog devices.

- Transmitter Power Supply Considerations

The power supply must provide:

- Enough voltage to overcome the voltage drops due to:

- Transmitter internal electronics

- Wire resistance

- Any resistors or input impedances

Voltage budget calculation:

- Transmitter drop = 10 V typical

- Input impedance = 250 ohms = 5V max

- Cable drop = minimal (~1V)

- Total = 16V

- Supply = 24V provides a safe margin

- Fault Detection and Live Zero

Using 4 mA instead of 0 mA for the lowest signal (live zero) allows systems to:

- Detect open loop (0 mA = fault)

- Differentiate between signal failure and low measurement

- Support diagnostics (NAMUR NE43 uses <3.6 mA or >21 mA for fault indication)

- Loop Calibration and Ranging

Ranging:

Configure the transmitter to interpret:

- 0% PV = 4 mA

- 100% PV = 20 mA

This is set using HART communicator, DIP switches, or software.

Calibration:

Ensure actual output matches expected current for given PV using:

- Calibration source (e.g., pressure calibrator)

- Multimeter or loop calibrator

- Conclusion

The 4-20 mA current loop remains the backbone of industrial instrumentation due to its simplicity, robustness, and ability to operate in electrically noisy environments. Understanding how the process variable is sensed, conditioned, digitized, and converted into a proportional 4-20 mA signal enables engineers to design and troubleshoot systems effectively.

The 250-ohm resistor plays a crucial role in interfacing current loops with voltage-input devices. By mastering these fundamentals, instrumentation engineers can ensure accurate and reliable data transmission across all stages of process control.