An Introduction to Oil and Gas Process Operations: From Wellhead to Refinery

The journey of oil and gas from deep within the earth to the fuels that power our cars and the materials that make up countless everyday products is a complex and fascinating odyssey of engineering, chemistry, and logistics. This intricate process, known as oil and gas process operations, is the lifeblood of our modern world. In this comprehensive guide, we will embark on a journey from the wellhead, where the raw hydrocarbons are first extracted, through the intricate network of pipelines and processing facilities, to the final destination – the refinery, where crude oil is transformed into a myriad of valuable products.

Upstream Operations at the Wellhead

The story begins in he upstream sector of the oil and gas industry, which is primarily concerned with exploration and production. Geologists and geophysicists identify potential reservoirs of oil and gas trapped in porous rock formations deep underground. Once a promising site is located, the process of drilling a well commences.

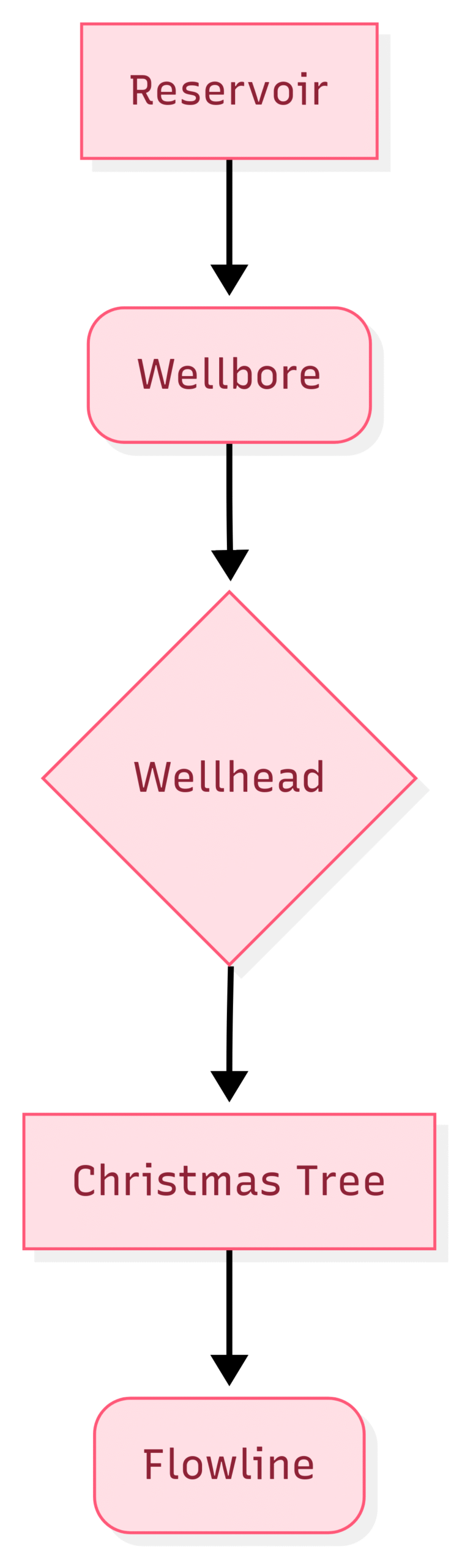

At the surface of a completed well sits the wellhead, a critical piece of equipment that serves as the interface between the reservoir and the surface facilities. It’s a complex assembly of valves, spools, and fittings that control the pressure and flow of hydrocarbons from the well. The wellhead is the first point of control and safety in the entire oil and gas process.

A key component of the wellhead is the “Christmas Tree,” a collection of valves that control the flow of oil and gas. This allows operators to manage the well’s production rate and to shut it in for maintenance or in case of an emergency. The wellhead and its associated components are designed to withstand immense pressures and harsh environmental conditions, ensuring the safe and efficient extraction of resources.

From Reservoir to Surface: The Initial Extraction

The natural pressure within the reservoir often provides the initial force to push the oil and gas to the surface. This mixture, known as crude oil, is rarely pure. It’s a complex emulsion containing a mixture of hydrocarbons, water, dissolved gases, and various impurities like sand, salt, and carbon dioxide. The composition of this raw fluid varies significantly from one reservoir to another.

As the reservoir pressure declines over time, artificial lift methods are employed to maintain production. These can include techniques like gas lift, where gas is injected into the well to reduce the density of the fluid column, or the use of downhole pumps.

The Midstream Journey: Separation, Treatment, and Transportation

Once the crude oil and gas mixture reaches the surface, it enters the midstream sector. This segment of the industry is responsible for the processing, storing, and transportation of the raw hydrocarbons. The primary goal of the initial midstream operations is to separate the valuable hydrocarbons from the unwanted components.

The Crucial First Step: Three-Phase Separation

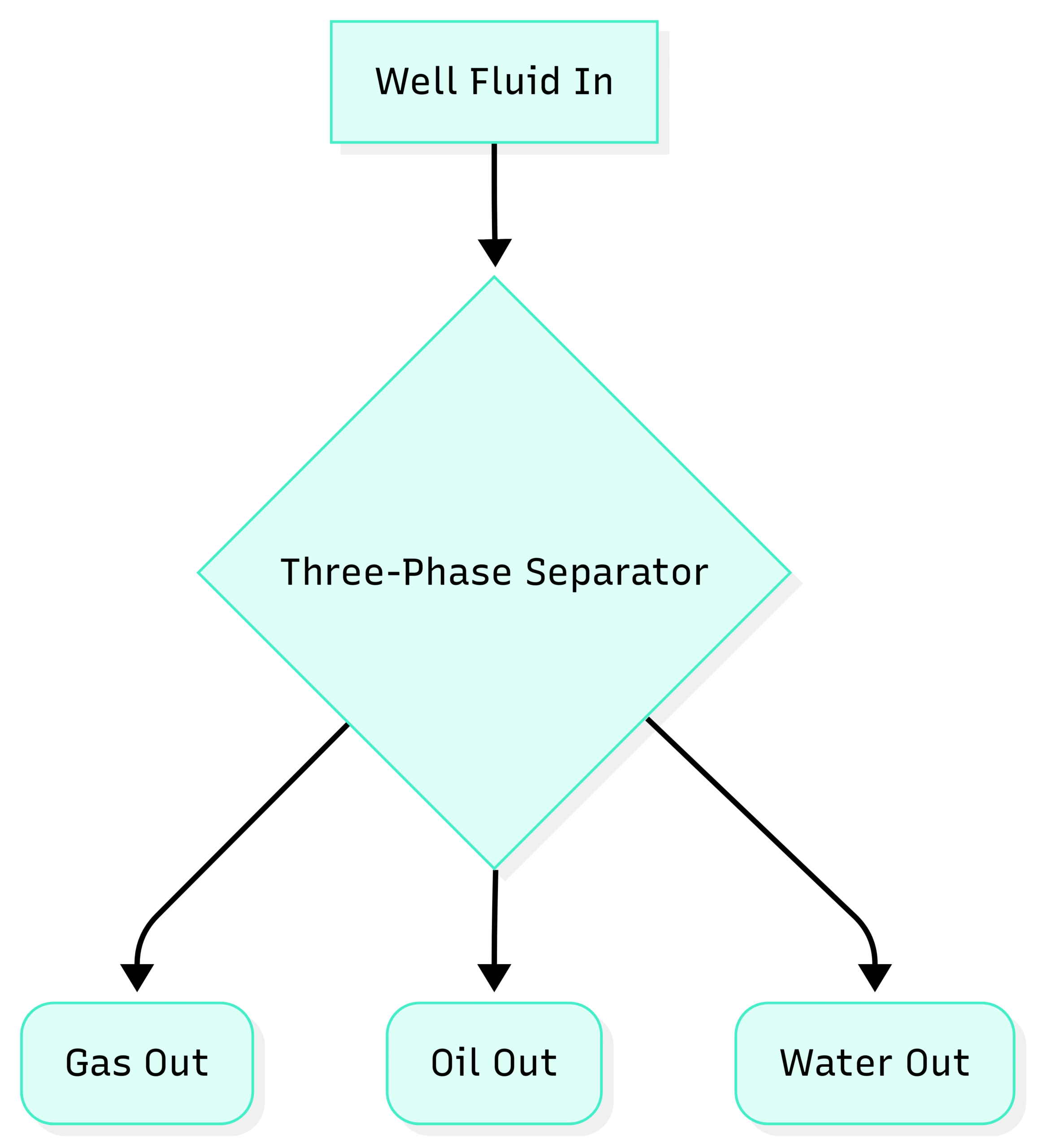

The raw fluid from the wellhead is directed to a separator, a large vessel designed to separate the oil, gas, and water based on their different densities. This process, known as three-phase separation, is a fundamental step in oil and gas processing.

Inside the separator, the mixture is allowed to settle. The free gas, being the lightest component, rises to the top and is drawn off. The water, being the densest, settles at the bottom and is drained away. The oil, with a density between that of gas and water, forms a layer in the middle and is collected.

The separated water, often referred to as produced water, is typically treated to remove any residual oil and then either re-injected into the reservoir to maintain pressure or disposed of in an environmentally responsible manner.

Treating the Hydrocarbons: Preparing for Transport

The separated oil and gas are still not ready for transportation or refining. They require further treatment to remove impurities that could cause corrosion in pipelines or interfere with the refining process.

Oil Treatment: The crude oil from the separator may still contain emulsified water and dissolved salt. These are removed through a process called dehydration and desalting. This often involves heating the oil and applying an electric field to coalesce the water droplets, allowing them to settle out.

Gas Treatment: The natural gas separated from the oil is known as associated gas. It typically contains water vapor, acid gases like hydrogen sulfide (H_2S) and carbon dioxide (CO_2), and heavier hydrocarbons known as natural gas liquids (NGLs).

Dehydration: Water vapor is removed to prevent the formation of solid hydrates, which can plug pipelines.

Acid Gas Removal (Sweetening): Hydrogen sulfide and carbon dioxide are removed as they are corrosive and, in the case of H_2S, highly toxic. This process is often referred to as “sweetening” the gas.

NGL Recovery: The valuable NGLs, such as propane and butane, are separated from the methane, the primary component of natural gas. These NGLs have their own markets and applications.

The Arteries of the Industry: Transportation

Once treated, the oil and gas are ready to be transported to their next destination. The primary modes of transportation in the midstream sector are pipelines, tankers, and in some cases, rail and trucks.

Pipelines: This is the most common and efficient method for transporting large volumes of oil and gas over land. A vast network of pipelines crisscrosses the globe, connecting production fields to processing plants and refineries.

Tankers: For long-distance transportation across oceans, massive oil tankers and specialized liquefied natural gas (LNG) carriers are used. To transport natural gas by sea, it is cooled to approximately -162°C (-260°F), at which point it becomes a liquid, reducing its volume by a factor of 600.

Rail and Truck: While less common for long-haul transportation of crude oil, rail and trucks play a vital role in transporting refined products to end-users and in areas where pipeline infrastructure is not available.

The Transformation: Downstream Operations at the Refinery

The final stage of the journey takes place in the downstream sector, which encompasses the refining of crude oil and the processing and purification of raw natural gas. The centerpiece of the downstream sector is the oil refinery, a sprawling industrial complex where crude oil is transformed into a wide range of valuable products.

The refining process is a highly complex series of chemical and physical operations designed to separate the different hydrocarbon components of crude oil and convert them into finished products.

The Heart of the Refinery: Crude Distillation

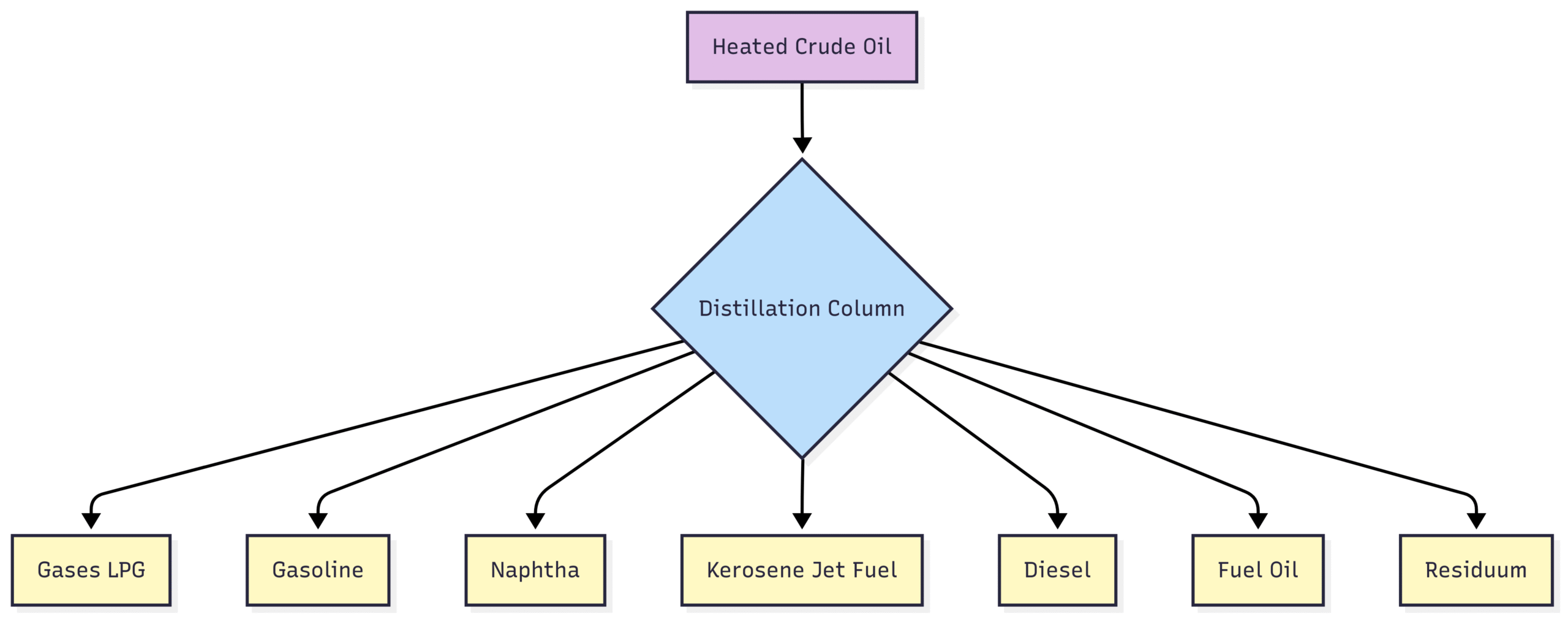

The first and most fundamental step in refining is fractional distillation. The crude oil is heated to high temperatures (around 400°C or 752°F) in a furnace, causing most of it to vaporize. This hot vapor-liquid mixture is then fed into the bottom of a tall distillation column (or fractionating tower).

Inside the column, the hot vapors rise and cool. As they cool, different hydrocarbon components condense back into liquids at different temperatures and are collected on trays at various levels of the column.

Lighter fractions with lower boiling points, such as gasoline and naphtha, rise higher up the column before condensing.

Heavier fractions with higher boiling points, such as kerosene, diesel, and fuel oil, condense at lower levels.

The heaviest components, known as residuum, do not vaporize and remain at the bottom of the column.

Enhancing Value: Conversion and Treatment Processes

The initial products from the distillation column, known as straight-run products, are often not suitable for direct use. They require further processing to improve their quality and to convert lower-value heavy hydrocarbons into higher-value lighter products like gasoline.

Some of the key conversion processes include:

Cracking: This process breaks down large, heavy hydrocarbon molecules into smaller, more valuable ones. There are several types of cracking, including thermal cracking, catalytic cracking, and hydrocracking.

Reforming: This process is used to rearrange the molecular structure of naphtha to produce high-octane gasoline components.

Alkylation: This process combines smaller hydrocarbon molecules to create larger ones, which are also high-quality gasoline components.

Following conversion, the various product streams undergo further treatment to remove any remaining impurities, such as sulfur. This is crucial for meeting environmental regulations and for ensuring the quality and stability of the final products.

The Final Products: A Myriad of Uses

The output of a refinery is a diverse range of products that are essential to our modern way of life. These include:

Fuels: Gasoline, diesel, jet fuel, and heating oil.

Petrochemical Feedstocks: Naphtha and other streams are used as raw materials for the production of plastics, synthetic fibers, and other chemicals.

Other Products: Lubricating oils, waxes, asphalt for paving roads, and petroleum coke used as a fuel.

Conclusion: A Symphony of Processes

The journey of oil and gas from the wellhead to the refinery is a testament to human ingenuity and technological advancement. It is a complex and interconnected series of processes that require a deep understanding of geology, chemistry, and engineering. From the initial extraction in the upstream sector, through the crucial separation and transportation in the midstream, to the final transformation in the downstream, each stage plays a vital role in delivering the energy and materials that fuel our world. As technology continues to evolve and the demand for energy shifts, the oil and gas process operations will undoubtedly continue to adapt and innovate, ensuring a reliable and efficient supply of these vital resources for years to come.