Pipeline Design and Safety in Onshore Facilities: A Comprehensive Guide

In the intricate web of modern industry, onshore pipelines serve as the arteries, transporting vital resources like oil, natural gas, and other chemicals across vast distances. The integrity of this network is paramount, not just for economic efficiency but, more importantly, for the safety of personnel, the public, and the environment. This comprehensive guide delves into the critical aspects of pipeline design and safety in onshore facilities, offering insights into best practices, regulatory landscapes, and the technological advancements shaping the future of this essential sector.

The Foundation: Regulatory Frameworks and Design Principles

The design and operation of onshore pipelines are governed by a stringent set of regulations and industry standards. These frameworks provide a robust foundation for ensuring safety and reliability throughout the pipeline’s lifecycle.

Key Regulatory Bodies and Standards:

ASME B31.3 and B31.4: The American Society of Mechanical Engineers (ASME) provides some of the most widely recognized codes. ASME B31.3 focuses on process piping typically found within the boundaries of a facility, while ASME B31.4 governs liquid and slurry pipeline transportation systems.

API Standards: The American Petroleum Institute (API) publishes a vast array of standards covering all aspects of the oil and gas industry. Standards such as API 5L (Specification for Line Pipe) and API 1104 (Welding of Pipelines and Related Facilities) are fundamental in pipeline construction.

Occupational Safety and Health Administration (OSHA): In the United States, OSHA sets and enforces standards to ensure safe and healthful working conditions.

National and Local Regulations: In addition to international standards, pipeline projects must adhere to the specific regulations of the country and locality in which they are situated.

Core Design Principles:

At its heart, pipeline design is a multi-faceted engineering discipline that balances safety, cost-effectiveness, and environmental responsibility. Key principles include:

Route Selection: The chosen path for a pipeline has profound implications for its safety and cost. A thorough route analysis considers topography, soil conditions, proximity to populated areas, environmental sensitivities, and the presence of other infrastructure.

Material Selection: The material used for the pipeline must be compatible with the fluid it will transport and resistant to corrosion and other forms of degradation. Carbon steel is a common choice, often with specialized coatings and linings for added protection.

Hydraulic Design: This involves determining the optimal pipe diameter and pressure required to transport the fluid at the desired flow rate.

Stress Analysis: Pipelines are subjected to various stresses, including internal pressure, external loads from soil and traffic, and thermal expansion and contraction. A comprehensive stress analysis is crucial to prevent mechanical failures.

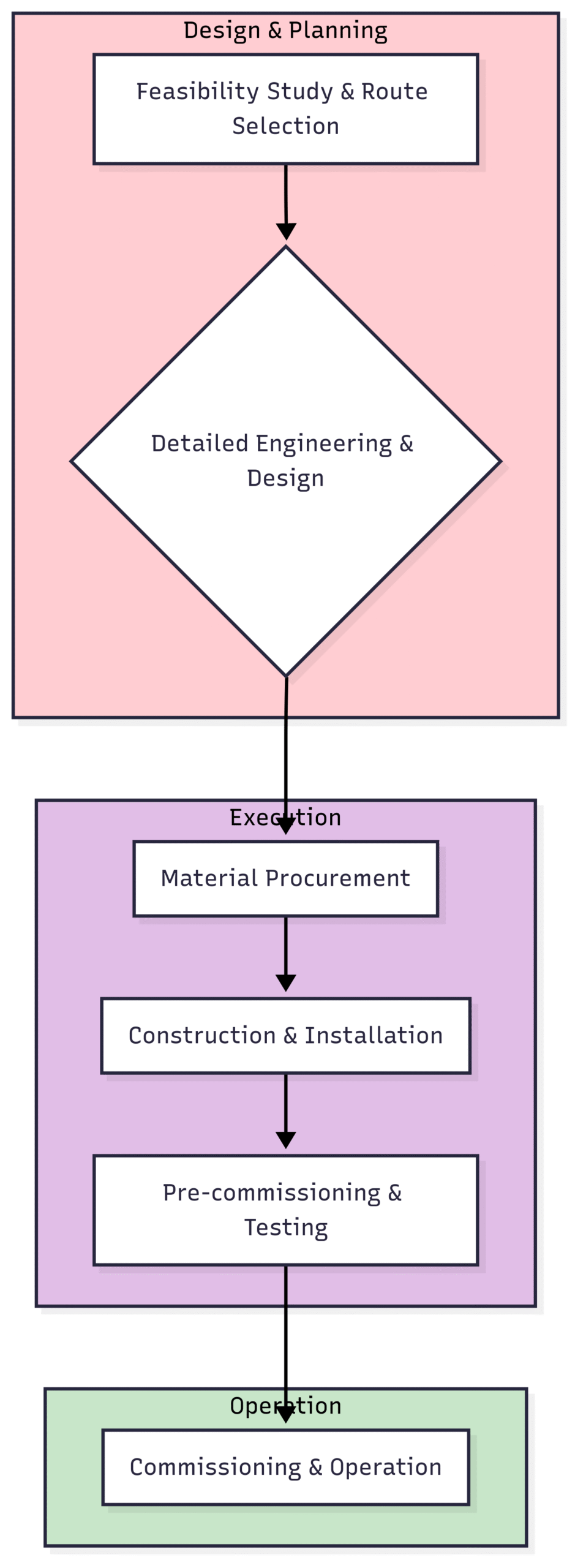

Key Stages of Pipeline Design and Construction

The journey from concept to a fully operational pipeline involves a series of meticulously planned and executed stages. Each stage presents its own set of challenges and safety considerations.

1. Feasibility Study and Route Selection

This initial phase involves a high-level assessment of the project’s viability. Environmental impact assessments, preliminary route surveys, and economic analyses are conducted to determine the project’s feasibility and to identify the most suitable corridor for the pipeline.

2. Detailed Engineering and Design

Once the route is finalized, detailed engineering commences. This stage involves:

Piping and Instrumentation Diagrams (P&IDs): These detailed diagrams illustrate the piping and process equipment along with the instrumentation and control devices.

Isometric Drawings: These three-dimensional drawings provide a clear representation of the pipeline’s layout.

Material Specifications: Detailed specifications for all pipes, fittings, valves, and other components are developed.

3. Material Procurement

The procurement of materials is a critical step that directly impacts the quality and safety of the pipeline. All materials must meet the specified standards and undergo rigorous quality control checks.

4. Construction and Installation

This is the most visible phase of the project and involves a wide range of activities, including:

Right-of-Way (ROW) Preparation: Clearing and grading the land along the pipeline route.

Trenching: Excavating the trench in which the pipeline will be laid.

Pipe Stringing and Bending: Laying out the individual pipe sections and bending them to conform to the terrain.

Welding: Joining the pipe sections together using qualified welders and approved procedures. Non-destructive testing (NDT) methods like radiography and ultrasonic testing are used to ensure the integrity of every weld.

Coating and Lowering: Applying protective coatings to the pipeline and carefully lowering it into the trench.

Backfilling and Restoration: Filling the trench and restoring the right-of-way to its original condition as much as possible.

5. Pre-commissioning and Testing

Before the pipeline is put into service, it undergoes a series of tests to ensure its integrity. The most critical of these is the hydrostatic test, where the pipeline is filled with water and pressurized to a level significantly higher than its maximum operating pressure. This test verifies the strength of the pipe and the quality of the welds.

6. Commissioning and Operation

Once all tests are successfully completed, the pipeline is commissioned and put into operation. This marks the beginning of the operational phase, where a focus on safety and integrity management is paramount.

Ensuring Operational Safety and Integrity

The responsibility for pipeline safety does not end with construction. A robust operational safety and integrity management program is essential to prevent incidents and ensure the long-term reliability of the pipeline.

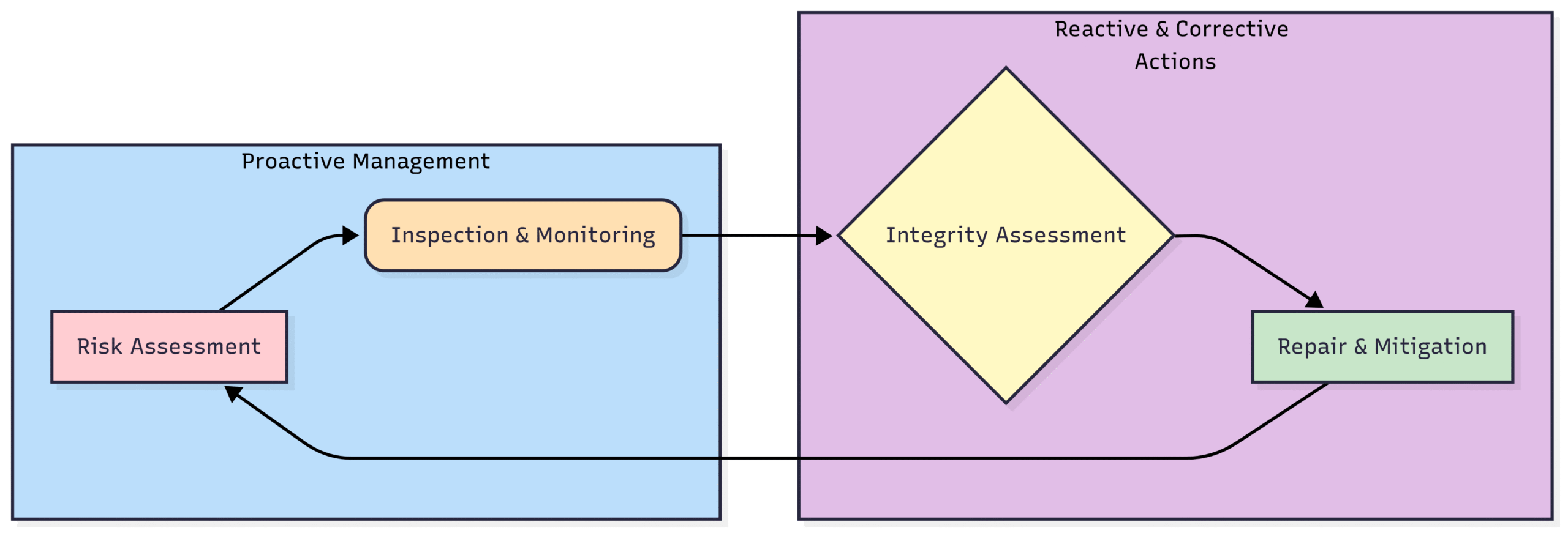

Pipeline Integrity Management (PIM)

PIM is a systematic approach to managing the lifecycle of a pipeline to prevent leaks and ruptures. Key elements of a PIM program include:

Risk Assessment: Identifying and evaluating potential threats to the pipeline’s integrity, such as corrosion, third-party damage, and geotechnical hazards.

Inspection and Monitoring: Regularly inspecting the pipeline using a variety of techniques to detect any signs of degradation. Common inspection methods include:

In-line Inspection (ILI) or “Smart Piggability”: Using sophisticated tools that travel inside the pipeline to detect corrosion, cracks, and other anomalies.

Cathodic Protection Surveys: Monitoring the effectiveness of the cathodic protection system, which is used to control external corrosion.

Aerial and Ground Patrols: Visually inspecting the pipeline right-of-way for any signs of encroachment, leaks, or other issues.

Integrity Assessment: Analyzing the data from inspections to assess the overall condition of the pipeline and to prioritize any necessary repairs.

Repair and Mitigation: Taking corrective actions to address any identified defects or to mitigate potential risks.

Emergency Response Planning

Despite the best efforts to prevent incidents, it is crucial to have a comprehensive emergency response plan in place. This plan should outline the procedures for responding to a leak or rupture, including:

Leak Detection and Shutdown: Procedures for quickly detecting a leak and isolating the affected section of the pipeline.

Emergency Notification: A clear communication plan for notifying emergency responders, regulatory agencies, and the public.

Spill Containment and Cleanup: Strategies for containing any spilled product and for cleaning up the affected area.

Regular Drills and Training: Conducting regular drills and training exercises to ensure that all personnel are familiar with their roles and responsibilities in an emergency.

The Future: Technological Advancements in Pipeline Safety

The pipeline industry is continuously evolving, with new technologies emerging to enhance both design and safety.

Digital Twins: A digital twin is a virtual model of a physical pipeline that is continuously updated with real-time data from sensors. This allows for advanced simulations and predictive analytics to optimize performance and to identify potential issues before they occur.

Advanced Inspection Technologies: The capabilities of “smart pigs” are constantly improving, with higher resolution sensors and more sophisticated data analysis algorithms. The use of drones and satellite imagery for aerial surveillance is also becoming more widespread.

Artificial Intelligence and Machine Learning: AI and machine learning are being used to analyze vast amounts of data from inspections and monitoring systems to identify subtle patterns that may indicate an increased risk of failure.

Improved Materials and Coatings: Research and development efforts are focused on developing new materials and coatings that are more resistant to corrosion and other forms of degradation.

Conclusion: A Commitment to Continuous Improvement

The design and safety of onshore pipelines are intrinsically linked. A robust design, based on sound engineering principles and adherence to stringent regulations, lays the foundation for a safe and reliable pipeline. However, safety is not a one-time achievement; it requires a continuous commitment to integrity management, emergency preparedness, and the adoption of new technologies. As the global demand for energy and other resources continues to grow, the pipeline industry must remain vigilant in its pursuit of excellence in design and safety to protect people, the environment, and our shared future.