An excellent choice for a wide range of industrial applications, Differential Pressure (DP) level measurement stands as a time-tested and robust method for determining the level of liquids in tanks and vessels. While newer technologies have emerged, DP level measurement remains a popular and reliable solution due to its accuracy, versatility, and cost-effectiveness. This comprehensive guide will delve into the intricacies of DP level measurement, exploring its fundamental principles, significant advantages, inherent limitations, and best-suited applications. By understanding these aspects, you can make an informed decision about whether DP level measurement is the right choice for your specific process needs.

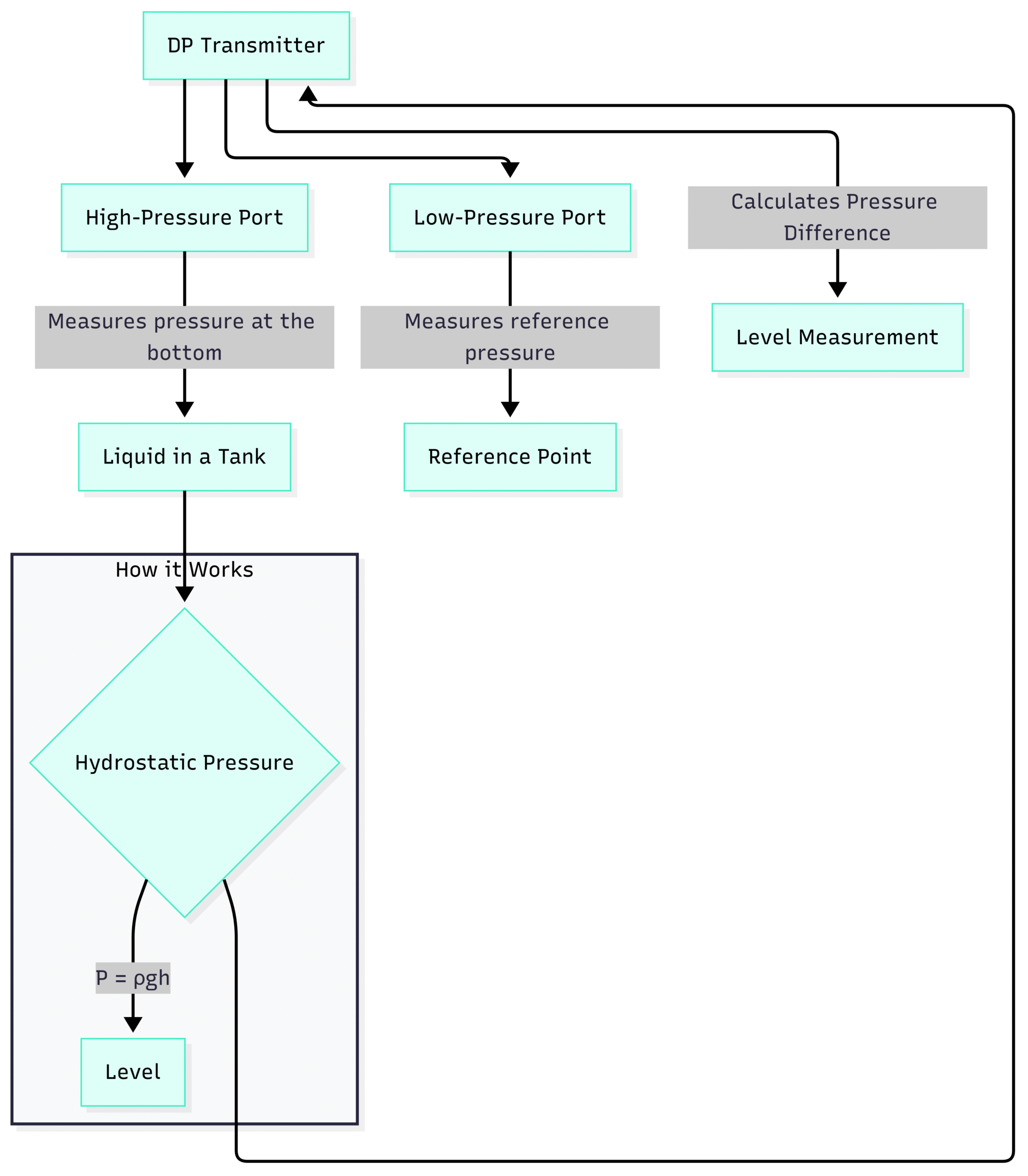

Understanding the Principle of DP Level Measurement

At its core, DP level measurement is ingeniously simple. It operates on the fundamental principle of hydrostatic pressure. In any vessel containing a liquid, the downward force exerted by the liquid due to gravity creates pressure. This pressure, known as hydrostatic pressure, is directly proportional to the height (or level) of the liquid, its density, and the gravitational force. The relationship is elegantly expressed by the formula:

P=ρgh

Where:

P is the hydrostatic pressure

ρ (rho) is the density of the liquid

g is the acceleration due to gravity

h is the height of the liquid column

A DP transmitter is the key component in this measurement system. It features two pressure ports: a high-pressure (HP) port and a low-pressure (LP) port. By measuring the pressure difference between these two points, the transmitter can accurately infer the liquid level. The high-pressure port is typically connected to the bottom of the tank, where it senses the total pressure exerted by the liquid column. The low-pressure port is connected to a reference point, which varies depending on whether the tank is open to the atmosphere or enclosed.

The accuracy of DP level measurement is intrinsically linked to the density of the process fluid. Since the calculation relies on a known density, any variations in this parameter, often caused by changes in temperature or fluid composition, can introduce errors in the level reading. Therefore, for applications where density is not constant, some form of density compensation is crucial for maintaining accuracy.

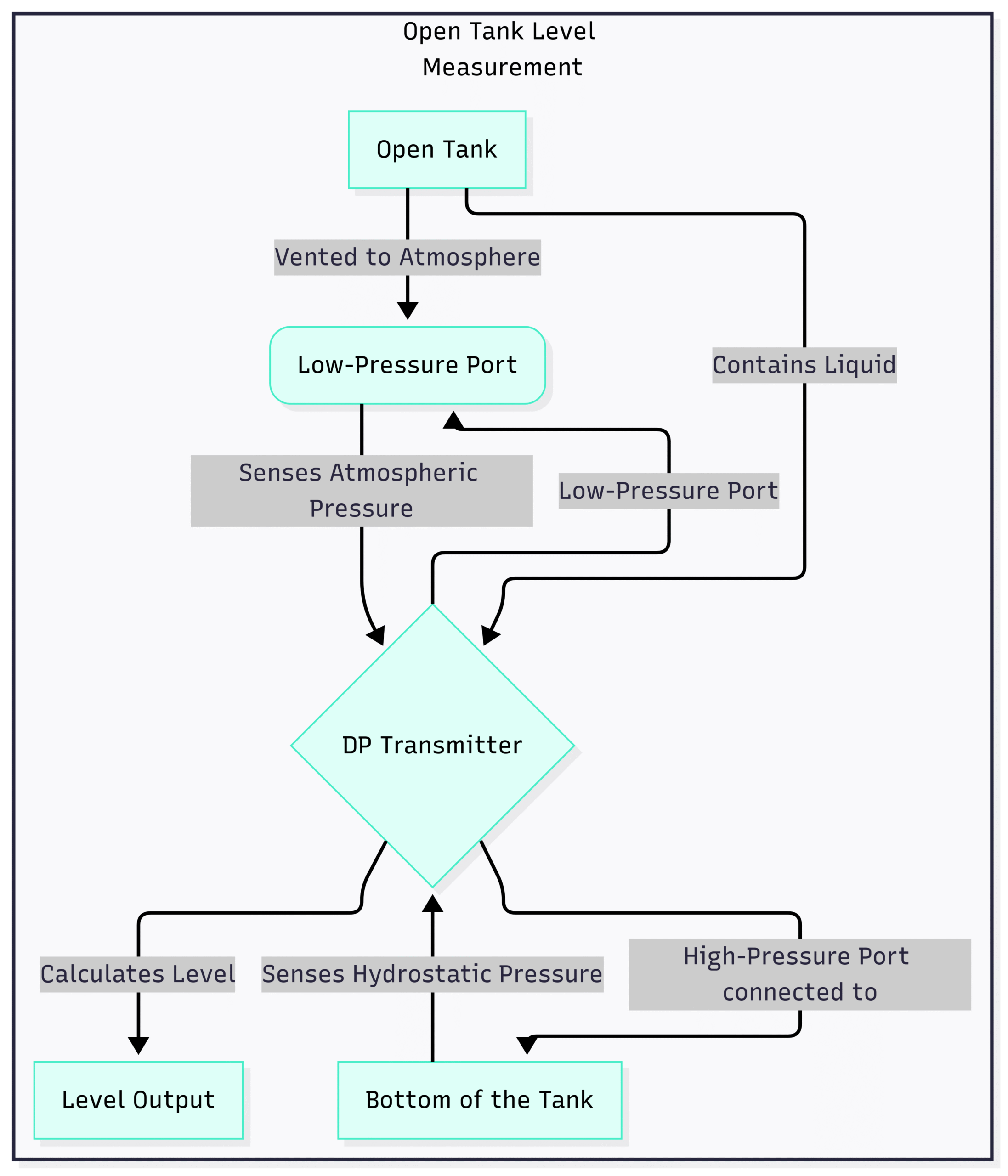

Measuring Levels in Open Tanks: A Straightforward Approach

For applications involving open tanks or vessels that are vented to the atmosphere, DP level measurement is particularly straightforward. In this setup, the high-pressure port of the DP transmitter is connected to the bottom of the tank, while the low-pressure port is left open to the atmosphere.

Here’s a step-by-step breakdown of how it works:

The high-pressure port senses the combined pressure of the liquid column (hydrostatic pressure) and the atmospheric pressure acting on the surface of the liquid.

The low-pressure port senses only the atmospheric pressure.

The DP transmitter then calculates the difference between these two pressures. Since the atmospheric pressure is present on both sides, it is effectively canceled out.

The resulting differential pressure is directly proportional to the hydrostatic pressure of the liquid, which in turn corresponds to the liquid level.

This method is commonly used for applications such as water reservoirs, storage tanks for non-volatile liquids, and sump pits. Its simplicity and reliability make it a popular choice in numerous industries.

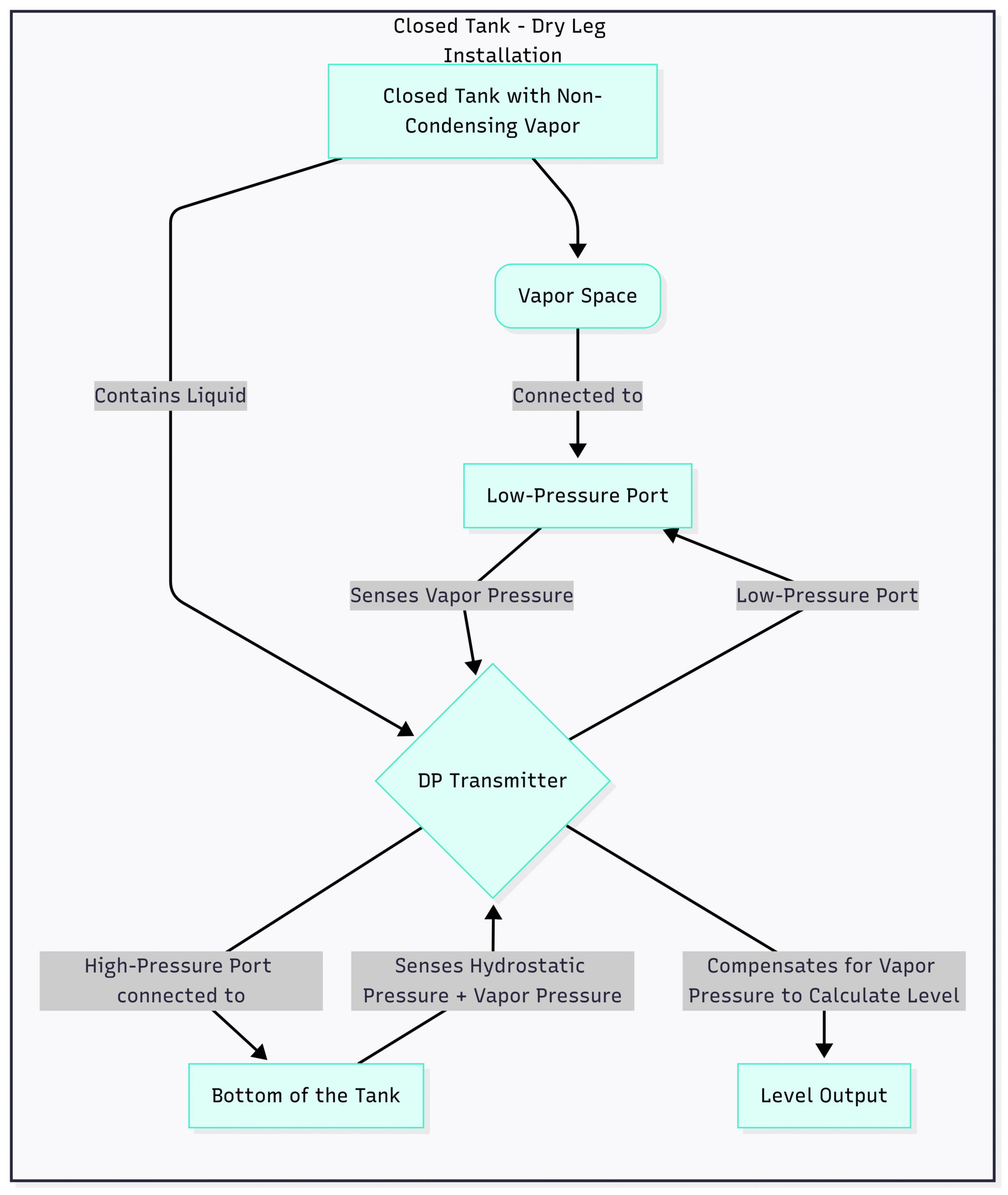

Tackling the Challenge of Closed Tanks: Wet Legs, Dry Legs, and Sealed Systems

Measuring liquid levels in closed or pressurized tanks presents an additional challenge: the pressure of the gas or vapor in the space above the liquid, often referred to as the blanket pressure. This vapor pressure adds to the hydrostatic pressure, and if not accounted for, will lead to inaccurate level readings. DP level measurement systems overcome this challenge through two primary installation methods: dry leg and wet leg installations.

Dry Leg Installation: For Non-Condensing Vapors

A dry leg installation is the preferred method when the vapor in the tank is non-condensing. In this configuration, the high-pressure port is connected to the bottom of the tank, and the low-pressure port is connected to the vapor space at the top of the tank via an impulse pipe.

The principle is as follows:

The high-pressure port measures the sum of the hydrostatic pressure and the vapor pressure.

The low-pressure port measures only the vapor pressure.

The DP transmitter subtracts the low-pressure reading from the high-pressure reading, effectively canceling out the effect of the vapor pressure and leaving only the hydrostatic pressure, which is then used to calculate the level.

A critical consideration for dry leg systems is to prevent any condensation from forming in the impulse line connected to the low-pressure port. If liquid accumulates in this “dry” leg, it will introduce a pressure that leads to an erroneous level reading.

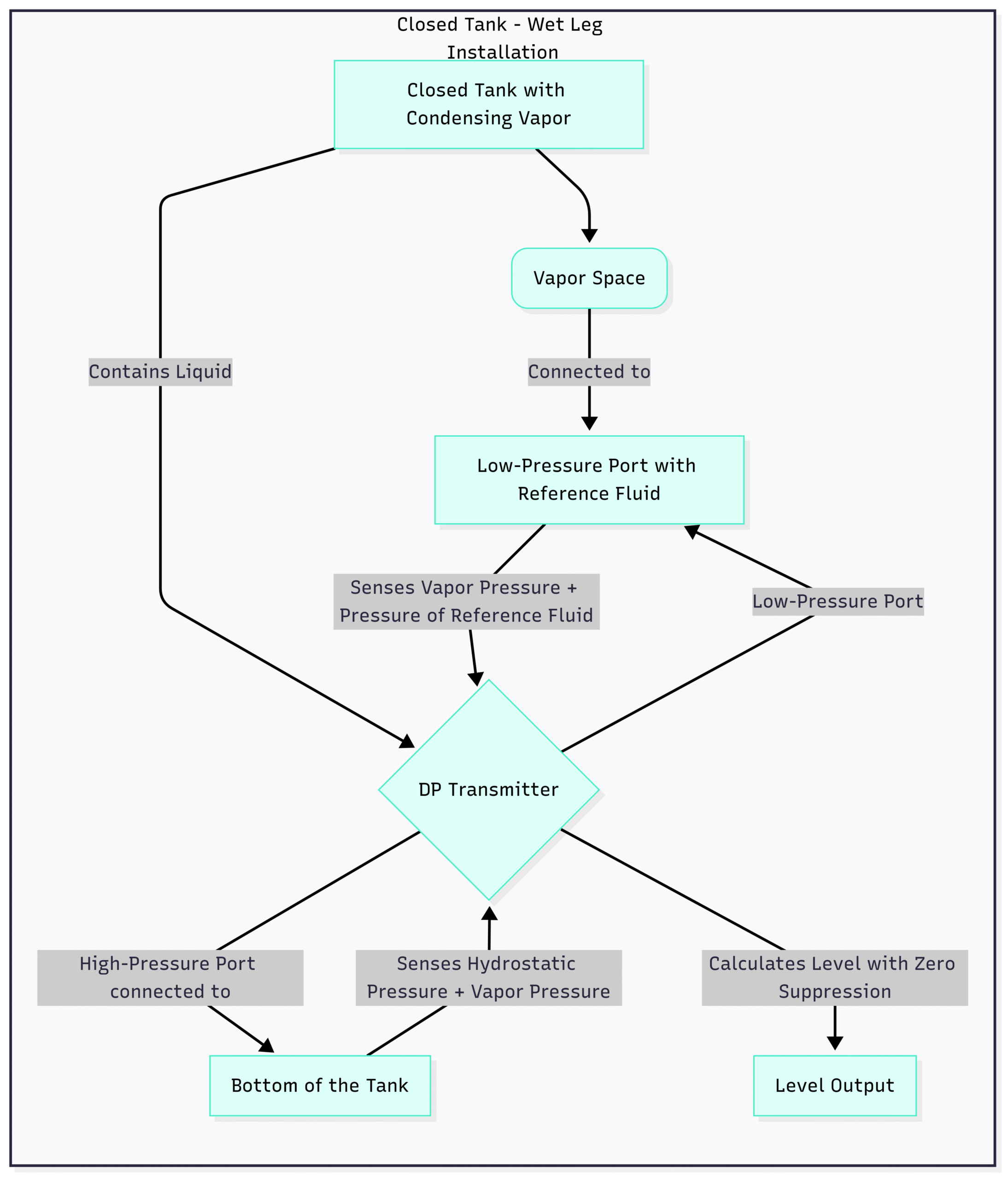

Wet Leg Installation: The Solution for Condensing Vapors

When dealing with processes that involve condensing vapors, a wet leg installation is the necessary approach. In this setup, the impulse line connecting the low-pressure port to the top of the tank is intentionally filled with a reference fluid that is compatible with the process fluid.

Here’s how it operates:

The high-pressure port measures the hydrostatic pressure of the process liquid plus the vapor pressure.

The low-pressure port measures the pressure of the reference fluid column in the wet leg plus the vapor pressure.

The DP transmitter is calibrated with a zero suppression. This means that when the tank is empty, the transmitter is set to read zero level, accounting for the constant pressure exerted by the wet leg. As the liquid level in the tank rises, the differential pressure changes, and the transmitter provides an accurate level reading.

The primary advantage of a wet leg is that it provides a stable and predictable pressure on the low-pressure side, unaffected by the condensation of process vapors.

Sealed Capillary Systems: An Advanced Alternative

For applications where impulse piping is undesirable due to the risk of leaks, clogging, or freezing, sealed capillary systems offer a robust alternative. In these systems, the DP transmitter is connected to diaphragm seals via oil-filled capillaries. The diaphragm seals are mounted directly onto the tank, isolating the transmitter from the process fluid. This design eliminates many of the common problems associated with traditional impulse lines.

The Upside: Key Advantages of DP Level Measurement

DP level measurement has remained a cornerstone of industrial process control for several compelling reasons:

Cost-Effectiveness: Compared to more advanced level measurement technologies, DP transmitters often provide a more economical solution, especially for large tanks.

Versatility: This technology is suitable for a wide range of liquids and can be adapted to handle high temperatures and pressures, making it applicable in diverse and demanding process environments.

Reliability and Accuracy: When installed and calibrated correctly, DP level measurement is a highly reliable and accurate method, providing consistent and repeatable results.

External Installation: The ability to mount the transmitter externally to the vessel is a significant advantage. It allows for easy access for maintenance, calibration, and replacement without the need to shut down the process or empty the tank.

Well-Established Technology: As a mature and widely understood technology, most technicians and engineers are familiar with its principles of operation, making troubleshooting and maintenance more straightforward.

The Downside: Limitations and Important Considerations

Despite its numerous advantages, DP level measurement is not without its limitations. It’s crucial to be aware of these to ensure its successful implementation:

Density Dependence: This is the most significant limitation. As the level calculation is directly tied to the liquid’s density, any changes in temperature or composition that alter the density will result in measurement errors. For applications with fluctuating densities, density compensation is a must.

Clogging of Impulse Lines: In processes involving slurries, viscous fluids, or liquids with suspended solids, the impulse lines are susceptible to clogging. This can block the pressure from reaching the transmitter, leading to false readings. The use of diaphragm seals can mitigate this issue.

Not Ideal for All Materials: DP level measurement can be challenging for highly viscous liquids, materials that can solidify, and bulk solids.

Installation Complexity: The accuracy of DP level measurement is highly dependent on proper installation. Incorrectly installed wet or dry legs, for instance, can lead to significant and persistent errors.

Potential for Leaks: The use of impulse piping and fittings introduces potential leak points in the system, which can be a concern, especially when dealing with hazardous or corrosive materials.

Where DP Level Measurement Shines: Best Applications

The versatility of DP level measurement makes it a suitable choice for a vast array of industries and applications. Here are some of the areas where it is most commonly and effectively used:

Water and Wastewater Treatment: From monitoring the levels in large storage tanks and reservoirs to controlling the levels in treatment basins and clarifiers, DP level measurement is a reliable workhorse in this sector.

Oil and Gas Industry: This industry relies heavily on DP level measurement for a variety of applications, including measuring levels in separators to monitor the interface between oil, water, and gas, as well as in storage tanks and distillation columns.

Chemical Processing: In chemical plants, DP level measurement is used for level control in reactors, mixing vessels, and storage tanks for a wide range of chemicals. Material compatibility of the transmitter’s wetted parts is a critical consideration in these applications.

Power Generation: One of the most critical applications for DP level measurement is in power plants for monitoring the water level in boiler drums. Maintaining the correct level is essential for the safe and efficient operation of the boiler.

Food and Beverage: DP level measurement is used to monitor the levels of ingredients, intermediate products, and finished goods in storage and processing tanks. Hygienic design considerations are paramount in this industry.

Pulp and Paper: The papermaking process involves numerous stages where level measurement is critical, and DP technology is often employed to monitor levels in pulp chests, storage tanks, and white water tanks.

A Quick Look at the Alternatives

While DP level measurement is a powerful tool, it’s essential to be aware of other available technologies to make the best choice for your application. Here’s a brief comparison:

Ultrasonic Level Transmitters: These are non-contact devices that measure level by emitting a sound wave and measuring the time it takes for the echo to return. They are a good choice for applications where contact with the process fluid is undesirable, but their accuracy can be affected by foam, vapor, turbulence, and changes in temperature.

Radar Level Transmitters: Both non-contacting and guided wave radar (GWR) transmitters use microwaves to measure level. They are highly accurate, largely unaffected by changes in density, temperature, or pressure, and can handle a wide range of process conditions. However, they typically come at a higher initial cost.

Capacitance Level Transmitters: These sensors measure the change in capacitance between a probe and the tank wall as the liquid level changes. They are suitable for a variety of liquids but can be affected by changes in the material’s dielectric constant.

Hydrostatic Level Transmitters (Submersible): These are simple and cost-effective sensors that are submerged in the liquid to measure the hydrostatic pressure at the bottom of the tank. They are ideal for open tank applications but require direct contact with the process fluid.

In conclusion, DP level measurement is a robust, reliable, and versatile technology that has earned its place as a staple in industrial process control. Its advantages of cost-effectiveness, accuracy, and applicability to a wide range of conditions make it an excellent choice for many applications. However, it’s crucial to understand its limitations, particularly its dependence on liquid density and the potential for installation-related issues. By carefully considering the principles of operation, the specific requirements of your process, and the available alternatives, you can confidently determine if DP level measurement is the optimal solution to your level measurement challenges.