DP Level Instruments vs. Radar: Which Is Right for Your Process?

Process level measurement is a critical aspect of many industrial operations in Doha, Qatar, ensuring efficient control, safety, and optimized production. Selecting the right level measurement technology is paramount, and two common contenders are Differential Pressure (DP) Level Instruments and Radar Level Instruments. While both serve the fundamental purpose of determining liquid or solid levels within a vessel, they operate on vastly different principles and offer distinct advantages and limitations. Understanding these nuances is crucial for making an informed decision that aligns with your specific process requirements and operational environment in Qatar’s demanding industrial landscape.

This comprehensive blog post will delve into the intricacies of both DP level instruments and radar level instruments, providing a detailed comparison to help you determine which technology is the right fit for your application. We will explore their working principles, highlight their pros and cons, and discuss critical factors to consider during the selection process. To enhance clarity and understanding, we will incorporate mermaid block diagrams to visually represent the operational mechanisms of each instrument type.

Understanding Differential Pressure (DP) Level Instruments

DP level instruments are a well-established and widely used technology for level measurement. They operate based on the principle that the pressure at the bottom of a liquid-filled vessel is directly proportional to the height (level) of the liquid and its specific gravity.

Working Principle:

A DP level transmitter typically utilizes two pressure sensors:

High-Pressure (HP) Port: This port is connected to the bottom of the vessel, measuring the hydrostatic pressure exerted by the liquid column plus any superimposed pressure above the liquid surface.

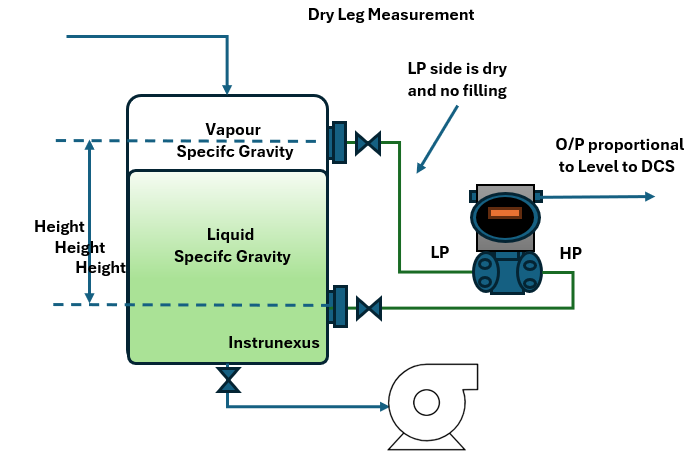

Low-Pressure (LP) Port: This port is typically open to the atmosphere (for open tanks) or connected to the vapor space above the liquid (for closed tanks), measuring the reference pressure.

The DP transmitter measures the difference between these two pressures (HP – LP). This differential pressure is directly proportional to the liquid level in the vessel, provided the liquid density remains constant. The transmitter then converts this pressure difference into a standard electrical signal (e.g., 4-20 mA) or a digital communication signal for transmission to a control system.

Block Diagram:

Advantages of DP Level Instruments:

Cost-Effective: DP level transmitters are generally less expensive than radar level instruments, making them an attractive option for budget-conscious applications.

Simple Technology: The underlying principle of DP measurement is relatively simple and well-understood, leading to easier installation and maintenance in some cases.

Versatile Applications: DP level instruments can be used for a wide range of liquids and in various tank configurations, including open and closed vessels.

Reliable Performance: When properly installed and maintained, DP level instruments can provide reliable and accurate level measurements.

Suitable for High Pressure and Temperature: Many DP transmitters are designed to withstand high process pressures and temperatures commonly found in Qatar’s industrial facilities.

Disadvantages of DP Level Instruments:

Density Dependence: The accuracy of DP level measurement is directly affected by changes in the liquid density. If the density varies significantly due to temperature fluctuations, composition changes, or aeration, the level reading will be inaccurate. This can be a significant challenge in processes with variable fluid properties common in the petrochemical industry.

Potential for Clogging: The impulse lines connecting the transmitter to the vessel can become clogged with process media, especially in viscous or particulate-laden liquids, leading to inaccurate readings or instrument failure. Regular maintenance and purging of these lines are often required, which can increase operational overhead.

Requires Wet Legs or Dry Legs: In closed tank applications, maintaining stable reference columns (wet legs or dry legs) can be challenging and require careful installation and insulation to prevent errors due to condensation or vaporization, particularly in Qatar’s hot climate.

Indirect Measurement: DP level measurement is an indirect method, inferring the level from pressure readings. This indirectness can introduce potential sources of error.

Sensitivity to Superimposed Pressure Changes: In closed tanks, significant fluctuations in the vapor pressure above the liquid can affect the DP reading and require compensation.

Exploring Radar Level Instruments

Radar level instruments utilize electromagnetic waves to measure the distance to the liquid or solid surface, providing a direct and non-contact level measurement. This technology has gained significant popularity due to its accuracy and reliability in various challenging applications.

Working Principle:

Radar level transmitters emit microwave signals towards the material surface. These signals are reflected back to the instrument, and the time-of-flight (the time it takes for the signal to travel to the surface and return) is measured. Since the speed of the microwave signal (the speed of light) is known, the distance to the surface can be precisely calculated. Knowing the total height of the tank, the level of the material can then be determined.

There are two main types of radar level instruments:

Pulsed Radar (Time Domain Reflectometry – TDR): These instruments emit short pulses of microwave energy. The time taken for the reflected pulse to return is measured to determine the distance.

Frequency Modulated Continuous Wave (FMCW) Radar: These instruments emit a continuous microwave signal with a constantly increasing (or decreasing) frequency. The difference in frequency between the emitted and received signals is proportional to the distance to the surface.

Generic Radar:

Advantages of Radar Level Instruments:

Unaffected by Density Changes: Radar level measurement is a direct measurement and is not affected by changes in the density, conductivity, temperature, or pressure of the process medium. This is a significant advantage in applications with variable fluid properties.

Non-Contact Measurement: As a non-contact technology, radar level instruments are not susceptible to issues like clogging, corrosion, or mechanical wear caused by direct contact with the process medium. This reduces maintenance requirements and increases reliability, especially in harsh environments in Qatar.

Accurate Measurement: Radar level instruments offer high accuracy and repeatability, providing reliable level readings for critical process control.

Suitable for Turbulent Surfaces and Foam: Advanced radar technologies, particularly FMCW, can often perform reliably even with turbulent liquid surfaces or the presence of foam, which can be challenging for other level measurement technologies.

Minimal Maintenance: Due to their non-contact nature, radar level instruments typically require very little maintenance.

Disadvantages of Radar Level Instruments:

Higher Initial Cost: Radar level transmitters generally have a higher initial purchase cost compared to DP level transmitters.

Performance Can Be Affected by Certain Conditions: While generally robust, the performance of radar level instruments can be affected by extreme conditions such as heavy condensation, very dusty environments (for solids), or significant build-up on the antenna.

Dielectric Constant Sensitivity (for some applications): The reflectivity of the microwave signal depends on the dielectric constant of the process medium. Very low dielectric constant materials might provide a weak reflected signal, although advancements in radar technology have mitigated this issue in many cases.

Tank Obstructions: Internal tank structures or obstructions can sometimes cause false reflections, requiring careful installation and potentially mapping of the tank to ensure accurate readings.

Factors to Consider When Choosing Between DP and Radar Level Instruments

Selecting the most appropriate level measurement technology requires a careful evaluation of several factors specific to your process and operational environment in Qatar. Here’s a comprehensive checklist to guide your decision:

Process Medium Properties:

Density Variations: If the density of your liquid varies significantly, radar is generally the better choice as it is unaffected by density changes. DP level instruments will require compensation or may provide inaccurate readings.

Viscosity and Particulates: For viscous liquids or those containing suspended solids that could clog impulse lines, radar’s non-contact nature is a significant advantage.

Corrosiveness: If the process medium is highly corrosive, radar can eliminate the risk of corrosion to wetted parts associated with DP transmitters.

Foaming: Radar instruments, especially FMCW types, often handle foam better than DP instruments, which can experience pressure fluctuations due to foam.

Dielectric Constant: For radar, ensure the dielectric constant of the liquid is sufficient for reliable reflection. Consult the manufacturer’s specifications.

Process Conditions:

Temperature and Pressure: Both DP and radar transmitters are available for a wide range of temperature and pressure conditions. Ensure the selected instrument is rated for your specific process requirements.

Turbulence: Radar generally performs better with turbulent liquid surfaces.

Vapor Space Conditions: Significant changes in vapor pressure in closed tanks can affect DP readings and may require compensation. Radar is less susceptible to these changes.

Dust (for Solids): In dusty environments for solid level measurement, non-contact radar can be advantageous as it avoids issues with sensor contamination.

Tank Characteristics:

Tank Height and Geometry: Consider the range and beam angle of radar transmitters in relation to the tank size and shape.

Internal Obstructions: Internal tank structures can affect radar signals, requiring careful placement or mapping. DP level is generally not affected by internal obstructions (below the tapping point).

Open vs. Closed Tank: DP level instruments require different reference configurations for open and closed tanks. Radar works similarly in both types.

Accuracy Requirements:

Determine the required accuracy for your level measurement. Both DP and radar instruments can offer high accuracy, but radar often provides slightly better accuracy, especially in challenging conditions.

Installation and Maintenance:

Installation Complexity: DP level installation involves tapping points, impulse lines, and potentially wet or dry legs, which can be more complex than installing a radar transmitter on the top of the tank.

Maintenance Requirements: DP level instruments require periodic inspection and cleaning of impulse lines and calibration. Radar instruments generally require less maintenance due to their non-contact nature. Consider the accessibility of the installation location for maintenance in your plant.

Cost Considerations:

Initial Purchase Cost: DP level instruments typically have a lower initial cost.

Installation Costs: Consider the cost of impulse lines, fittings, and labor for DP level installation compared to the potentially simpler installation of radar.

Maintenance Costs: Factor in the long-term maintenance costs associated with each technology. Radar’s lower maintenance requirements can lead to cost savings over time.

Communication and Integration:

Ensure the selected level instrument is compatible with your existing control system and supports the necessary communication protocols (e.g., 4-20 mA, HART, Foundation Fieldbus, Profibus). Both DP and radar instruments offer a variety of communication options.

Making the Right Choice for Your Process in Qatar

The decision between DP level instruments and radar level instruments ultimately depends on the specific requirements of your process.

Choose DP Level Instruments if:

Your application involves liquids with relatively stable densities.

The process medium is clean and non-viscous, minimizing the risk of clogging impulse lines.

Cost is a primary concern and the accuracy requirements are not extremely stringent.

The process conditions (temperature and pressure) are within the capabilities of standard DP transmitters.

Choose Radar Level Instruments if:

Your application involves significant variations in liquid density.

The process medium is viscous, contains particulates, or is corrosive.

Accurate and reliable level measurement is critical.

You need a non-contact solution to avoid maintenance issues related to direct contact with the process medium.

The presence of foam or turbulent surfaces poses challenges for other technologies.

Long-term cost savings through reduced maintenance are a priority.

In many industrial facilities in Qatar, a combination of both technologies might be used, with each applied in situations where it offers the most significant advantages. For instance, DP level instruments might be used for basic level indication in simple storage tanks, while radar level instruments could be employed for critical control applications in reactors or distillation columns where accuracy and reliability are paramount, and fluid properties may vary.

By carefully considering the factors outlined in this blog post and understanding the working principles of both DP and radar level instruments (as illustrated by the mermaid block diagrams), you can make an informed decision that optimizes the performance, safety, and efficiency of your process level measurement in Doha, Qatar. Always consult with experienced instrumentation professionals and refer to manufacturer specifications to ensure the correct selection and application of these vital instruments.