Guided Wave Radar vs. Non-Contact Radar Level Measurement Explained

In the world of industrial process control, accuracy is paramount. Precise and reliable level measurement is critical for safety, efficiency, and cost-effectiveness. Whether you’re managing inventory in a massive storage tank, controlling a chemical reaction, or preventing overfills in a wastewater basin, choosing the right level measurement technology is a decision that has significant operational implications. Among the most advanced and versatile level measurement technologies available today are Guided Wave Radar (GWR) and Non-Contact Radar (NCR).

While both technologies leverage the power of radar to determine material levels, they operate on fundamentally different principles and are suited for distinct applications. This comprehensive guide will delve into the working principles, advantages, disadvantages, and ideal applications of both Guided Wave Radar and Non-Contact Radar to help you make an informed decision for your specific needs.

Understanding the Fundamentals: How Radar Level Measurement Works

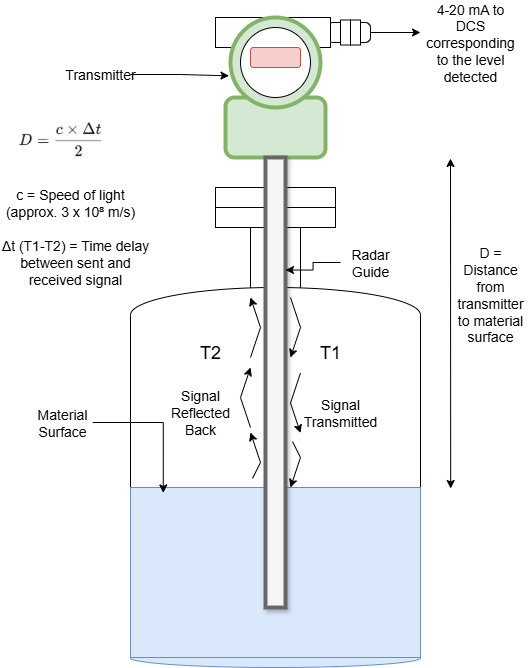

At the heart of both GWR and NCR technology lies the principle of Time of Flight (ToF). This method involves sending a microwave pulse from a transmitter to the surface of the material being measured. The pulse then reflects off the material and returns to the transmitter. The instrument’s sophisticated electronics measure the time it takes for the pulse to travel to the material and back. Since the speed of the microwave pulse is known (it travels at the speed of light), the distance to the material surface can be accurately calculated using the following formula:

Distance=(Speed of Light * Time of Flight)/2

The division by two accounts for the round-trip time of the pulse. Once the distance from the transmitter to the material is known, the actual level can be determined by subtracting this distance from the total height of the tank or vessel.

A crucial factor influencing the effectiveness of radar level measurement is the dielectric constant (E_r) of the material. The dielectric constant is a measure of a substance’s ability to store electrical energy in an electric field. In the context of radar level measurement, a higher dielectric constant results in a stronger reflection of the radar signal. Water, for example, has a high dielectric constant (around 80), making it an excellent reflector of radar waves. Hydrocarbons, on the other hand, have a much lower dielectric constant (typically between 1.9 and 4.0), which can present a challenge for some radar technologies.

What is Guided Wave Radar (GWR)?

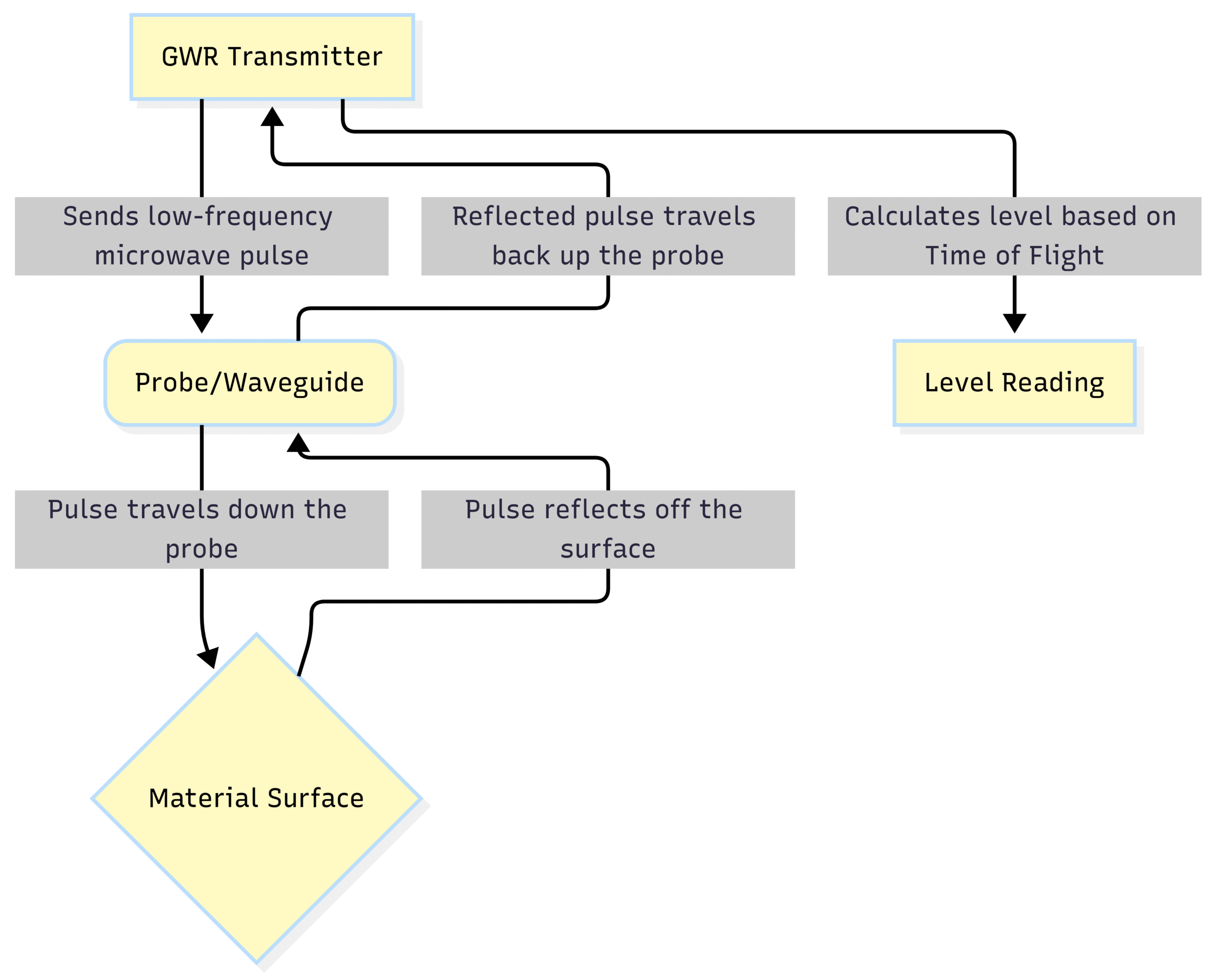

Guided Wave Radar, also known as Time Domain Reflectometry (TDR), is a contact-based level measurement technology. It utilizes a probe, or “waveguide,” that extends from the transmitter at the top of the vessel down to the material being measured.

The Working Principle of GWR

A GWR transmitter sends low-frequency (typically 1-2 GHz) microwave pulses down the length of the probe. This waveguide acts as a concentrated path for the radar signal, ensuring that the energy is focused and travels directly to the material surface. When the pulse encounters a change in the dielectric constant – which occurs at the interface between the air (or vapor space) and the material – a portion of the pulse is reflected back up the probe to the transmitter. The transmitter’s electronics then calculate the level based on the time of flight of this reflected pulse.

GWR probes come in various configurations to suit different applications:

Single Rod Probes: Ideal for applications with high viscosity or a risk of coating, as they have a smaller surface area for material to adhere to.

Twin Rod Probes: Offer a stronger signal and are suitable for a wide range of liquids and solids.

Coaxial Probes: Provide the most focused signal and are excellent for low-dielectric materials, turbulent surfaces, and interface level measurement. They are essentially a rod within a tube.

Flexible Cable Probes: Used for long measurement ranges in tall tanks and silos.

Advantages of Guided Wave Radar

High Accuracy and Reliability: The guided nature of the radar signal makes GWR extremely accurate and reliable, even in challenging process conditions.

Unaffected by Process Conditions: GWR measurements are largely unaffected by changes in material density, conductivity, and dielectric constant.

Superior Performance in Foam and Vapor: The focused signal along the probe allows GWR to effectively cut through foam and heavy vapors that can interfere with other level measurement technologies.

Excellent for Turbulence: The waveguide helps to stabilize the measurement in applications with turbulent or agitated surfaces.

Interface Level Measurement: GWR is the preferred technology for measuring the interface between two immiscible liquids, such as oil and water. The radar pulse will reflect off both the upper and lower liquid surfaces, allowing for the measurement of both levels simultaneously.

Versatile Installation: GWR transmitters can be installed in small tanks and nozzles, and they do not require a clear, unobstructed path to the material surface.

Disadvantages of Guided Wave Radar

Contacting Measurement: As a contacting technology, the probe is in direct contact with the process material. This can be a disadvantage in applications with highly corrosive or abrasive materials that can damage the probe.

Potential for Buildup: In applications with sticky or coating materials, buildup on the probe can potentially affect measurement accuracy. However, modern GWR transmitters have advanced signal processing capabilities to mitigate the effects of buildup.

Limited Measurement Range: The length of the probe limits the measurement range of GWR. For very tall tanks, the weight and cost of the probe can become a factor.

Installation Complexity: The installation of a GWR probe can be more complex than that of a non-contact sensor, especially in tanks with internal obstructions.

What is Non-Contact Radar (NCR)?

Non-Contact Radar, also known as “through-air” or “free-space” radar, is a non-intrusive level measurement technology. As the name suggests, the sensor is mounted at the top of the vessel and measures the level without any physical contact with the material.

The Working Principle of NCR

An NCR transmitter emits high-frequency (typically between 6 and 80 GHz) radar waves from an antenna. These waves travel through the air or vapor space and reflect off the surface of the material below. The reflected waves are then captured by the same antenna, and the level is calculated based on the time of flight.

The frequency and type of antenna used are critical to the performance of an NCR transmitter:

Frequency: Higher frequency radars, such as 80 GHz, have a much narrower beam angle. This focused beam is less likely to be affected by internal tank obstructions and can be more accurately aimed at the material surface. 80 GHz radars are also more effective at penetrating dust and vapors.

Antenna Type:

Horn Antennas: The most common type of antenna, suitable for a wide range of applications.

Parabolic Antennas: Provide a very narrow beam for long-range measurements in large tanks and silos.

Lens Antennas: Offer excellent focusing capabilities and are often used in hygienic applications.

Advantages of Non-Contact Radar

Non-Intrusive Measurement: The primary advantage of NCR is that it does not come into contact with the process material. This makes it the ideal choice for applications involving corrosive, abrasive, sterile, or ultra-pure liquids.

Longer Measuring Ranges: NCR transmitters can measure over much longer distances than GWR, making them suitable for very tall tanks and silos.

Easy Installation: Installation is generally simpler and less expensive than GWR, as there is no probe to install.

Low Maintenance: With no moving parts and no contact with the process material, NCR transmitters are virtually maintenance-free.

Disadvantages of Non-Contact Radar

Susceptibility to Interference: The unguided radar signal of an NCR transmitter can be affected by foam, heavy vapors, and turbulence, which can absorb or scatter the signal and lead to inaccurate readings.

Condensation and Buildup: Condensation or material buildup on the antenna can interfere with the transmission and reception of the radar signal.

Dependence on Dielectric Constant: The performance of an NCR transmitter is more dependent on the dielectric constant of the material than GWR. Low-dielectric materials can result in a weak reflection and a loss of signal.

Requires a Clear Line of Sight: NCR transmitters require a clear, unobstructed path from the antenna to the material surface. Internal tank structures, such as agitators, ladders, or inlet pipes, can create false echoes and interfere with the measurement.

Head-to-Head Comparison: GWR vs. NCR

Feature | Guided Wave Radar (GWR) | Non-Contact Radar (NCR) |

Measurement Principle | Time Domain Reflectometry (TDR) along a probe | Time of Flight (ToF) through the air |

Contact vs. Non-Contact | Contacting | Non-Contacting |

Accuracy | Very high, typically ±2-5 mm | High, typically ±2-10 mm |

Impact of Foam | Excellent performance; can measure through foam | Can be significantly affected by foam |

Impact of Turbulence | Excellent performance; waveguide stabilizes measurement | Can be affected; stilling wells may be required |

Impact of Vapors/Dust | Minimal impact | Can be affected, though higher frequencies improve performance |

Impact of Dielectric Constant | Minimal impact; suitable for low-dielectric materials | More significant impact; challenging with very low dielectrics |

Interface Measurement | Yes, a key advantage | No |

Installation Complexity | More complex due to probe | Simpler |

Maintenance Requirements | Higher due to potential for corrosion and buildup | Very low |

Cost | Generally higher initial cost for complex probes | Generally lower initial cost |

Choosing the Right Technology: Key Application Considerations

The decision between GWR and NCR ultimately comes down to the specific requirements of your application. Here’s a look at how these technologies stack up in various industries:

Chemical Industry

The chemical industry often deals with corrosive and aggressive media. For these applications, NCR is frequently the preferred choice due to its non-contact nature, which eliminates the risk of sensor corrosion. However, for applications with heavy vapors or foam, or for interface level measurement, GWR with a corrosion-resistant probe (e.g., made of Hastelloy or with a PFA lining) is the better option.

Food and Beverage Industry

Hygienic considerations are paramount in the food and beverage industry. NCR is often favored because it has no contact with the product, preventing contamination. Many NCR transmitters are available with hygienic connections and materials that comply with industry standards such as 3-A and EHEDG. For applications in this industry where GWR is necessary (e.g., small tanks or foamy products), hygienic GWR probes are also available.

Water and Wastewater Treatment

Water and wastewater applications can present challenges such as foam, open channel flow, and the presence of debris. In lift stations and open channels, NCR is often a good choice. For clarifiers and digesters where foam is common, GWR can provide a more reliable measurement. The ability of GWR to measure interface levels is also beneficial in applications such as sludge blanket detection.

Oil and Gas Industry

The oil and gas industry has many demanding applications, including high-pressure and high-temperature environments and the need for interface level measurement. GWR is a dominant technology in this sector, particularly for separators where the interface between oil and water needs to be precisely controlled.

Solids and Bulk Materials

Measuring the level of solids and bulk materials in silos can be challenging due to dust, angled surfaces (angle of repose), and low dielectric constants. High-frequency NCR (80 GHz) has proven to be very effective in these applications. The narrow beam angle of an 80 GHz radar can be precisely aimed to avoid internal structures and accurately measure the level of the material, even in dusty conditions.

Installation Best Practices for Optimal Performance

Proper installation is crucial for the performance and reliability of both GWR and NCR transmitters.

GWR Installation

Probe Length: The probe must be the correct length for the measurement range.

Avoid Obstructions: The probe should be installed in a location where it will not come into contact with internal tank structures, such as ladders or agitator blades.

Grounding: Proper grounding is essential for a stable and reliable measurement.

NCR Installation

Nozzle Selection: The sensor should be installed on a nozzle that is as short as possible to minimize signal interference.

Clear Signal Path: Ensure that there are no obstructions in the radar beam’s path to the material surface.

Aiming: For solids applications, the sensor should be aimed at a point on the material surface that is representative of the overall level.

Conclusion

Both Guided Wave Radar and Non-Contact Radar are powerful and versatile level measurement technologies, each with its own set of strengths and weaknesses. The “best” technology is not a one-size-fits-all answer but rather a decision that must be based on a thorough understanding of your specific application and process conditions.

Choose Guided Wave Radar when you need the highest accuracy, have challenging process conditions like foam or turbulence, or require interface level measurement.

Choose Non-Contact Radar when you need a non-intrusive measurement for corrosive or hygienic applications, have a long measurement range, or are measuring solids and bulk materials.

By carefully considering the factors outlined in this guide, you can select the radar level measurement technology that will provide you with accurate, reliable, and cost-effective performance for years to come. For critical applications, it is always recommended to consult with a level measurement expert to ensure you are making the optimal choice.