Ultrasonic vs. Radar Level Measurement in Oil & Gas Industries: The Definitive Guide

In the high-stakes world of the oil and gas industry, precision is not just a preference; it’s a prerequisite for safety, efficiency, and profitability. From sprawling tank farms holding millions of barrels of crude oil to complex separators operating under extreme pressures, accurately measuring the level of liquids and solids is a critical operational function. For decades, two non-contact technologies have been at the forefront of this task: Ultrasonic and Radar.

Choosing between them is more than a simple technical preference. It’s a decision that impacts process control, inventory management, and, most importantly, operational safety. While both technologies operate on a similar time-of-flight principle, their fundamental differences in physical media—sound waves vs. electromagnetic waves—create a world of difference in the demanding environments of the oil and gas sector.

This in-depth guide will explore the working principles, strengths, and weaknesses of both ultrasonic and radar level measurement. We will conduct a head-to-head comparison, analyze their performance under the harsh conditions specific to the oil and gas industry, and provide clear guidance on selecting the optimal technology for your application.

The Critical Role of Level Measurement in Oil & Gas

Before diving into the technology, it’s essential to understand why level measurement is so crucial. Virtually every stage of the oil and gas value chain—upstream, midstream, and downstream—relies on accurate level data for:

Inventory Management: Knowing the precise quantity of crude oil, refined products, or LNG in storage tanks is fundamental for financial accounting, logistics, and supply chain management.

Custody Transfer: When ownership of a product changes hands, from a pipeline to a tanker or from a refinery to a distributor, the level measurement must be impeccably accurate and certified for fiscal purposes.

Process Control: In reactors, separators, and distillation columns, maintaining levels within a specific range is vital for ensuring product quality and process efficiency. Deviations can lead to off-spec products or costly shutdowns.

Safety and Environmental Protection: Overfill prevention is a paramount safety concern. A failed level sensor can lead to dangerous spills, resulting in catastrophic environmental damage, significant financial losses, and potential harm to personnel. High- and low-level alarms, driven by reliable sensors, are the first line of defense.

Given these high stakes, the reliability of a level measurement device is its most important attribute.

Understanding Ultrasonic Level Measurement

Ultrasonic level transmitters have been a popular choice for level measurement for many years, primarily due to their simplicity and attractive price point.

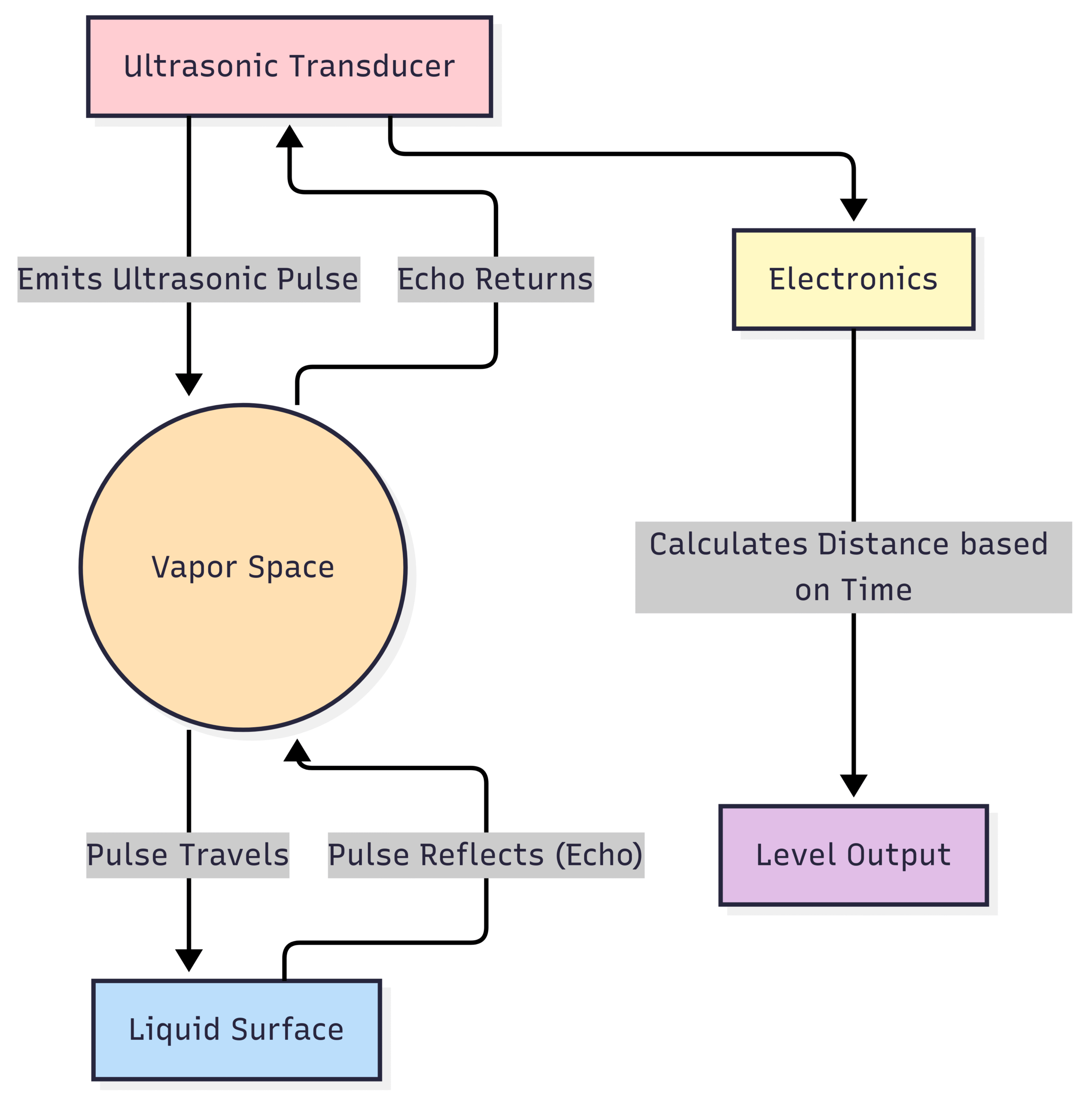

The “How-To”: The Principle of Sound

Ultrasonic sensors operate by using the Time-of-Flight (ToF) principle. The sensor, mounted at the top of a tank, emits a short burst of high-frequency sound waves (typically in the 20-200 kHz range) towards the surface of the material being measured. These sound waves travel through the gas or vapor in the tank, reflect off the liquid surface, and return as an echo to the sensor.

The instrument’s electronics measure the time it takes for the pulse to travel from the sensor to the surface and back. Knowing the speed of sound in the vapor space, the sensor calculates the distance.

Distance = (Speed of Sound x Time Delay) / 2

The level is then determined by subtracting this distance from the total height of the tank.

Mermaid Diagram: Ultrasonic Working Principle

The Achilles’ Heel: Limitations in Oil & Gas

While effective in simple applications like water tanks, ultrasonic technology faces significant challenges in the complex and dynamic conditions of the oil and gas industry. Its reliance on a mechanical wave (sound) traveling through a medium (vapor) makes it highly susceptible to process variables.

Vapor and Gas Composition: This is the single greatest limitation. The speed of sound changes significantly with the composition, temperature, and pressure of the gas it’s traveling through. The vapor space in hydrocarbon tanks is rarely just air; it’s a mixture of methane, propane, butane, and other volatile organic compounds (VOCs). As the tank is filled or emptied, or as ambient temperatures change, this vapor composition fluctuates, altering the speed of sound and leading to inaccurate measurements.

Temperature and Pressure: A change in process temperature or pressure directly impacts the density of the vapor, which in turn changes the speed of sound. While some sensors have built-in temperature compensation, they cannot account for pressure changes or stratification (temperature gradients) within the tank.

Foam, Turbulence, and Dust: Foam is a very poor reflector of sound waves; it absorbs them, often resulting in a complete loss of signal. Similarly, heavy turbulence on the liquid surface can scatter the sound pulse, preventing a clear echo from returning to the sensor.

Condensation and Buildup: The face of the ultrasonic transducer is a sensitive diaphragm. In humid or vapor-rich environments, condensation can form on the transducer face, muffling the signal and impeding its ability to transmit and receive sound waves effectively.

Tank Obstructions: The sound pulse from an ultrasonic sensor spreads out in a cone shape. Any internal tank obstructions, such as pipes, ladders, or agitators, can create false echoes, leading to incorrect level readings.

The Rise of Radar Level Measurement

Radar level measurement, once considered a high-end specialty technology, has become the industry standard for demanding applications, particularly in oil and gas. It overcomes nearly all the limitations that challenge ultrasonic sensors.

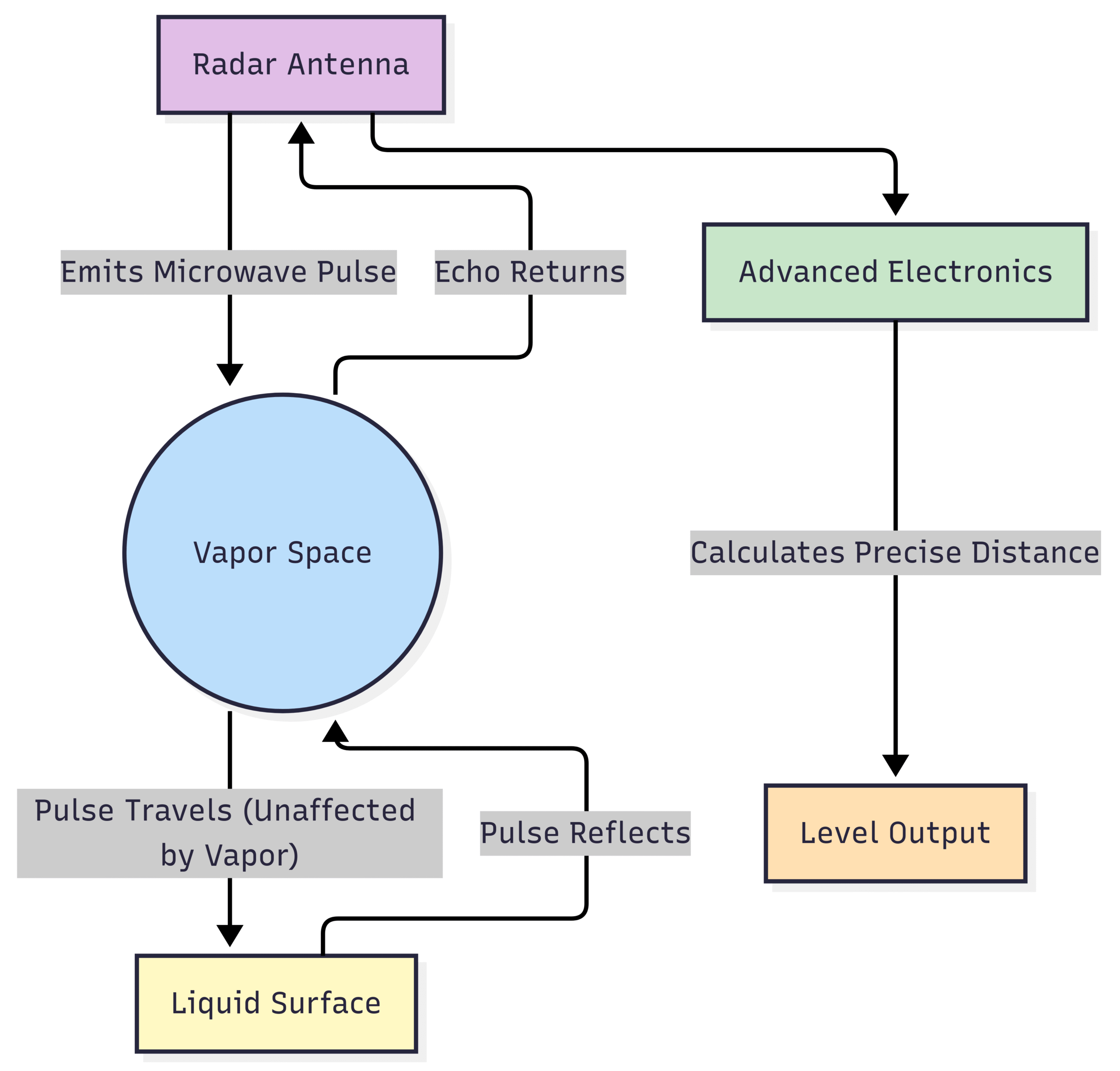

The Principle of Microwaves

Like ultrasonic sensors, radar transmitters also operate on the Time-of-Flight (ToF) principle. However, instead of sound waves, they emit short pulses of microwaves (a type of electromagnetic energy) from an antenna.

These microwave pulses travel at the speed of light towards the liquid surface, reflect, and are detected by the antenna. The instrument’s high-speed electronics measure the transit time and calculate the distance.

Distance = (Speed of Light x Time Delay) / 2

The crucial difference is that electromagnetic waves are virtually unaffected by the properties of the vapor space they travel through.

Radar Working Principle

Types of Radar Technology

Non-Contact Radar: This is the most common type. It uses an antenna mounted on top of the tank. There are two main variants:

Pulsed Radar: Sends out discrete pulses of energy. It is robust and cost-effective.

Frequency Modulated Continuous Wave (FMCW): Transmits a continuous signal with a constantly changing frequency. FMCW radars offer higher accuracy and better signal processing capabilities, making them ideal for the most demanding applications.

Guided Wave Radar (GWR): GWR uses a rigid or flexible probe (a “waveguide”) that extends from the sensor housing down into the tank. A low-energy microwave pulse is guided down this probe. This focuses the energy, making GWR extremely reliable and unaffected by tank obstructions or low-dielectric materials. It is also the go-to technology for measuring the interface between two liquids, such as oil and water.

Why Radar Excels in Oil & Gas

Radar’s use of electromagnetic waves gives it a distinct and decisive advantage:

Immunity to Process Conditions: The speed of light is constant and is not affected by changes in vapor composition, temperature, pressure, or dust. This ensures that radar provides consistently accurate and reliable measurements regardless of the conditions inside the tank.

Superior Performance in Foam and Turbulence: Microwaves can penetrate through most types of foam and are largely unaffected by surface turbulence. Advanced algorithms in modern radar sensors can filter out any spurious signals to focus on the true liquid level.

Unaffected by Condensation: Condensation on the radar’s antenna has a negligible effect on the measurement, ensuring high reliability in humid and vapor-heavy environments.

High Accuracy and Reliability: Modern FMCW radar sensors can achieve accuracy down to the millimeter, making them suitable for critical custody transfer applications that must meet API standards. Their reliability significantly reduces the need for maintenance and manual checks (tank dipping).

The Ultimate Head-to-Head Comparison: Ultrasonic vs. Radar

Feature | Ultrasonic Level Measurement | Radar Level Measurement | Winner (for Oil & Gas) |

Physical Principle | Sound Waves (Mechanical) | Microwaves (Electromagnetic) | Radar |

Accuracy | Moderate (±0.25% of range) | High to Very High (down to ±1 mm) | Radar |

Effect of Vapor | Severe. Changes in gas composition, pressure, and temp alter the speed of sound, causing errors. | Negligible. Speed of light is constant in all vapor spaces. | Radar |

Effect of Foam | Poor. Sound waves are absorbed by foam, leading to signal loss. | Excellent. Microwaves penetrate most foams. | Radar |

Effect of Turbulence | Poor. Surface disturbance scatters the sound signal. | Excellent. Unaffected by most turbulence. | Radar |

Effect of Condensation | Can be an issue, muffling the transducer. | Negligible effect on the antenna. | Radar |

Application Range | Typically up to 15 meters (50 ft). | Up to 100 meters (330 ft) or more. | Radar |

Initial Cost | Low | Medium to High | Ultrasonic |

Total Cost of Ownership | Higher due to potential for failure, inaccuracy, and maintenance. | Lower due to high reliability, low maintenance, and process uptime. | Radar |

Best For | Simple, non-critical, atmospheric applications (e.g., water tank). | Virtually all Oil & Gas applications. | Radar |

Application Spotlight: Choosing the Right Tool for the Job

The choice between ultrasonic and radar becomes clear when we look at specific applications within the oil and gas industry.

When to Consider Ultrasonic

While largely unsuitable for hydrocarbon applications, ultrasonic sensors can be a cost-effective choice for non-critical, ancillary processes, such as:

Water and wastewater storage tanks.

Storage of non-volatile chemicals in atmospheric tanks.

Open-air sumps and pits in stable weather conditions.

In these simple cases, where the vapor space is just air at atmospheric pressure and temperature swings are moderate, an ultrasonic sensor can perform adequately.

Where Radar is Non-Negotiable

For the core processes in oil and gas, radar’s robustness makes it the only viable choice.

Crude Oil Storage Tanks (inc. Floating Roofs): These tanks contain a cocktail of volatile hydrocarbons. The vapor space is constantly changing, making ultrasonic measurement unreliable. Radar provides the necessary accuracy for inventory control and custody transfer.

Separators: These vessels operate under pressure and often have a foam layer and an oil/water interface. Non-contact radar can measure the primary level, while Guided Wave Radar is perfect for reliably measuring the crucial oil/water interface to optimize the separation process.

Refining Processes (Distillation Columns, Reactors): These involve high temperatures, high pressures, and aggressive chemicals. Radar’s immunity to these conditions ensures the tight process control needed for product quality and safety.

LNG and LPG Storage: These cryogenic applications involve extremely low temperatures and vapours that would instantly render an ultrasonic sensor useless. Specially designed radar sensors are the industry standard for LNG tank gauging.

Mermaid Diagram: Complex Application Scenario

This diagram illustrates why radar is superior in a challenging vessel like a separator.

The Final Verdict: An Investment in Reliability

While ultrasonic level transmitters have a lower initial purchase price, the oil and gas industry has overwhelmingly standardized on radar technology for a simple reason: Total Cost of Ownership (TCO) and reliability.

An inaccurate reading can lead to process inefficiencies that cost thousands of dollars per day. A missed reading or failure can lead to a dangerous overfill or a costly shutdown. The higher initial investment in a radar device is easily justified by its unparalleled reliability, accuracy, and peace of mind. It requires less maintenance, suffers from far less downtime, and delivers trustworthy data day in and day out, regardless of the challenging process conditions.

In the final analysis, the debate of ultrasonic vs. radar in the oil and gas industry is largely settled. For any application involving hydrocarbons, pressure, temperature, or any process-critical function, radar is the superior and safer technology. Choosing radar is not just a technical decision; it’s a strategic investment in the safety, efficiency, and long-term profitability of your operation.