Top Applications for Ultrasonic Level Instruments in Refineries:

In the complex and demanding environment of a refinery, accurate and reliable level measurement is not just a matter of efficiency; it’s a critical safety imperative. From massive crude oil storage tanks to the intricate processes of wastewater treatment, knowing the precise level of liquids is paramount. Among the various level measurement technologies available, ultrasonic level instruments have carved out a significant niche in the refining industry. Their non-contact nature, cost-effectiveness, and versatility make them a compelling choice for a wide array of applications.

This comprehensive blog post will explore the top applications for ultrasonic level instruments in refineries, delving into the nuances of each use case. We’ll also examine the underlying technology, its inherent advantages, and the crucial limitations to consider in the challenging refinery landscape.

How Ultrasonic Level Instruments Operate

Before we explore their applications, let’s understand the fundamental principle behind ultrasonic level measurement. It’s elegantly simple: the instrument emits a high-frequency sound pulse (an ultrasound) from its transducer, which is typically mounted at the top of a tank or vessel. This sound wave travels down, strikes the surface of the liquid, and reflects as an echo back to the transducer.

The instrument’s sophisticated electronics measure the time it takes for this echo to return—the “time of flight.” Knowing the speed of sound in the vapor space above the liquid, the instrument can then calculate the distance to the liquid surface with remarkable precision. This distance measurement is then converted into a level reading, which can be displayed locally or transmitted to a central control system.

The core formula at play is:

The division by two accounts for the sound wave’s round trip. This non-contact method is a key reason for the popularity of ultrasonic instruments in refineries, as it minimizes the risk of corrosion, contamination, and instrument damage from harsh process fluids.

Top Refinery Applications:

Ultrasonic level instruments are deployed across a refinery for various critical measurements. Let’s explore some of the most prominent applications, complete with Mermaid block diagrams to visualize these processes.

1. Bulk Liquid Storage Tanks: The First Line of Monitoring

Refineries are characterized by their vast tank farms, storing everything from raw crude oil to finished petroleum products like gasoline and diesel. Accurate level measurement in these tanks is crucial for inventory management, preventing costly overfills, and ensuring a steady supply to downstream processing units.

Why Ultrasound?

Non-contact measurement: This is a major advantage when dealing with corrosive or viscous liquids like crude oil. There are no moving parts to get stuck or corrode.

Cost-effectiveness: For large tanks, ultrasonic instruments offer a very economical solution for continuous level monitoring compared to some other non-contact technologies.

Ease of installation: These instruments are typically installed through a nozzle on the tank roof, making installation and maintenance relatively straightforward.

Key Considerations:

Foam: Some crude oils can generate foam, which can absorb the ultrasonic signal and lead to inaccurate readings.

Vapors: The presence of heavy hydrocarbon vapors can affect the speed of sound, potentially requiring temperature compensation for accurate measurement.

Turbulence: During filling operations, the liquid surface can be turbulent, which can scatter the ultrasonic pulse. Stilling wells are often used to mitigate this effect.

2. Chemical and Additive Storage: Precision for Processing

Refineries use a wide variety of chemicals and additives in their processes, from catalysts and corrosion inhibitors to anti-foaming agents. These are often stored in smaller to medium-sized tanks, where accurate dosing is critical for process efficiency and product quality.

Why Ultrasound?

Chemical compatibility: The non-contact nature of ultrasonic sensors means they don’t have to be constructed from exotic materials to withstand corrosive chemicals.

Accuracy: They provide the necessary accuracy for precise inventory control and dosing operations.

Reliability: With no moving parts, they offer long-term, maintenance-free operation.

Key Considerations:

Fuming liquids: Some chemicals, like certain acids, can produce fumes that can affect the performance of the transducer. Proper material selection for the transducer face is crucial.

Small tank challenges: In very narrow tanks, false echoes from the tank walls can be an issue. Instruments with advanced signal processing can help filter these out.

3. Wastewater Treatment: Environmental Compliance and Process Control

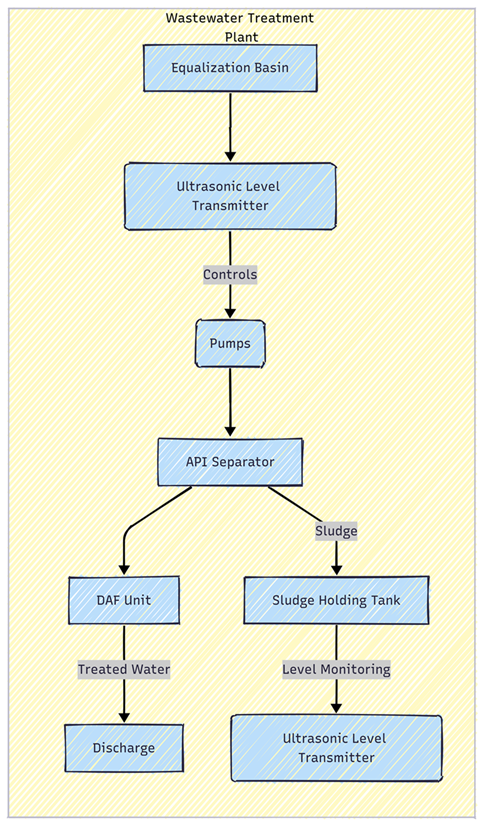

Refinery operations generate significant volumes of wastewater that must be treated before being discharged. This involves a series of tanks and basins for processes like oil-water separation, neutralization, and biological treatment.

Why Ultrasound?

Open channel flow measurement: In wastewater applications, ultrasonic instruments are often used in conjunction with flumes or weirs to measure the flow rate of water.

Sump and pit level monitoring: They are ideal for monitoring the level in collection sumps and pits to control pumps and prevent overflows.

Sludge level detection: In settling tanks, ultrasonic sensors can be used to detect the level of the sludge blanket.

Key Considerations:

Scum and foam: The surface of wastewater can often have a layer of scum or foam, which can be a challenge for ultrasonic measurement.

Environmental conditions: Instruments installed outdoors in wastewater plants need to be robust and weatherproof.

4. Cooling Tower Basins: Ensuring Efficient Heat Exchange

Cooling towers are essential for dissipating the vast amounts of heat generated in a refinery. They rely on a continuous supply of water, and maintaining the correct water level in the cooling tower basin is vital for efficient operation and to prevent damage to pumps.

Why Ultrasound?

Non-intrusive: The non-contact nature of the measurement is beneficial in the turbulent and moist environment of a cooling tower.

Reliable pump control: The continuous level data allows for precise control of the makeup water pumps, preventing the basin from running dry or overflowing.

Cost-effective automation: They provide an affordable way to automate a critical but often overlooked part of the refinery’s utility systems.

Key Considerations:

Steam and mist: The humid environment inside a cooling tower can cause condensation on the transducer face, potentially affecting its performance. Some models have features to mitigate this.

Falling water: The transducer should be positioned away from the direct impact of falling water to avoid interference.

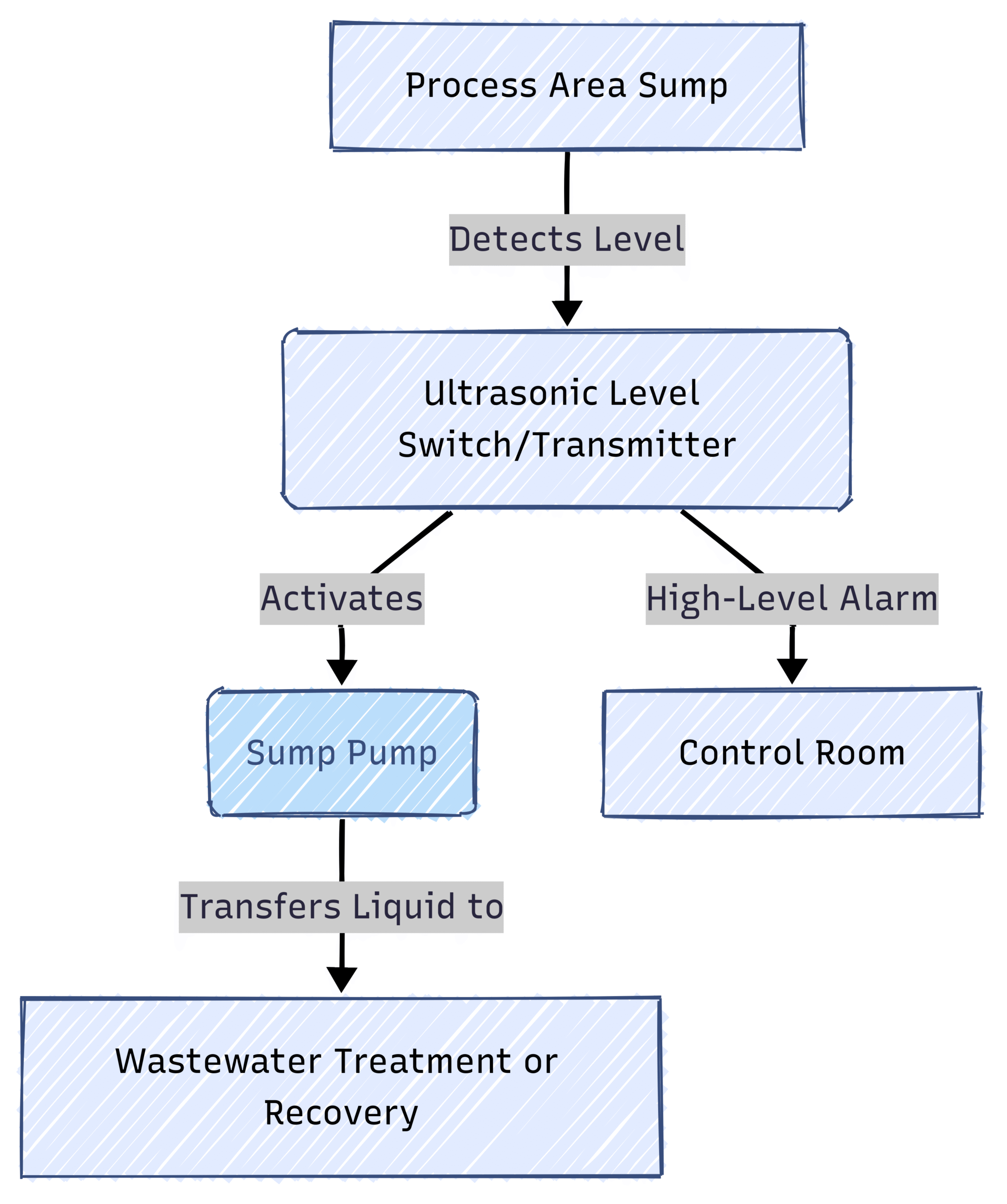

5. Sumps and Pits: Critical for Safety and Environmental Protection

Throughout a refinery, there are numerous sumps and pits designed to collect spills, rainwater, and process drainage. Monitoring the levels in these areas is crucial for preventing environmental contamination and for ensuring the timely removal of collected liquids.

Why Ultrasound?

Versatility: Ultrasonic instruments can be used in a wide variety of sump and pit configurations.

Alarming capabilities: They can be easily configured to trigger alarms at high or low levels, alerting operators to potential issues.

Hazardous area suitability: Many ultrasonic instruments are certified for use in hazardous locations, which is a common requirement in refineries.

Key Considerations:

Debris: Sumps can often contain debris that could potentially block the ultrasonic signal. Proper installation and occasional checks are necessary.

Irregular shapes: The shape of the sump or pit can sometimes create false echoes. Instruments with beam focusing capabilities can be advantageous.

The Double-Edged Sword: Advantages and Limitations in the Refinery Context

While ultrasonic level instruments offer numerous benefits, it’s equally important to understand their limitations to ensure their successful application in a refinery.

Advantages

Non-Contact Measurement: This is the most significant advantage, eliminating issues with corrosion, abrasion, and contamination of the sensor.

Cost-Effectiveness: Generally, ultrasonic instruments provide a lower cost per measurement point compared to technologies like radar, especially for less demanding applications.

Simple Installation and Commissioning: They are relatively easy to install and set up, often without needing to take the vessel out of service.

No Moving Parts: This translates to higher reliability and lower maintenance requirements.

Hazardous Area Ratings: Many models are available with intrinsic safety or explosion-proof certifications, making them suitable for the hazardous environments found in refineries.

Limitations

Influence of Vapors and Gases: The speed of sound changes with the composition and temperature of the gas or vapor in the vessel’s headspace. This can introduce inaccuracies if not compensated for.

Sensitivity to Foam and Turbulence: Foam can absorb the ultrasonic signal, and a turbulent liquid surface can scatter it, leading to a loss of echo or erratic readings.

Temperature and Pressure Effects: Extreme temperatures can affect the transducer, and significant pressure variations can influence the speed of sound. Most ultrasonic instruments are not suitable for high-pressure applications.

Blanking Distance: All ultrasonic instruments have a “blanking distance” or “dead zone” right below the transducer where they cannot make a measurement. This needs to be considered during installation.

Obstructions in the Tank: Internal structures like pipes, ladders, or agitators can create false echoes. Careful positioning and advanced signal processing are needed to overcome this.

Not Suitable for Vacuums: Ultrasonic instruments require a medium (gas or vapor) to transmit the sound waves and therefore cannot work in a vacuum.

Conclusion: A Sound Choice for Smart Refining

Ultrasonic level instruments have firmly established their place in the modern refinery by offering a reliable, cost-effective, and safe solution for a multitude of level measurement tasks. From the vast expanse of crude oil storage tanks to the critical operations of wastewater treatment, their non-contact principle provides a significant advantage in handling the diverse and often challenging liquids found in a refinery.

However, a “one-size-fits-all” approach is never wise in such a complex industrial setting. A thorough understanding of the specific application, including the process conditions and potential interferences like foam, vapor, and turbulence, is essential for selecting and successfully implementing an ultrasonic level instrument. When applied thoughtfully, these silent sentinels play a vital role in optimizing processes, ensuring safety, and protecting the environment in the dynamic world of oil refining. Their continued evolution, with advancements in signal processing and transducer technology, promises to further expand their capabilities and solidify their position as a cornerstone of refinery instrumentation.