Where to Use Displacer Level Instruments in Oil and Gas: A Deep Dive into a Timeless Technology

In the high-stakes world of oil and gas, precision, reliability, and safety are not just operational goals; they are the bedrock of the entire industry. From the wellhead to the refinery, accurately measuring and controlling liquid levels in vessels is a critical task that directly impacts efficiency, product quality, and environmental safety. Amidst a sea of modern digital technologies, one instrument has remained a trusted workhorse for decades: the displacer level instrument.

While newer technologies have their place, the displacer’s robustness and unwavering reliability in extreme conditions make it an indispensable tool in many specific oil and gas applications. This comprehensive guide will explore the inner workings of displacer instruments, their key advantages, and precisely where they are best deployed across the upstream, midstream, and downstream sectors.

How It Works:

At its core, the displacer level instrument operates on a principle discovered by an ancient Greek mathematician: Archimedes’ Principle. This principle states that a body immersed in a fluid is buoyed up by a force equal to the weight of the fluid it displaces.

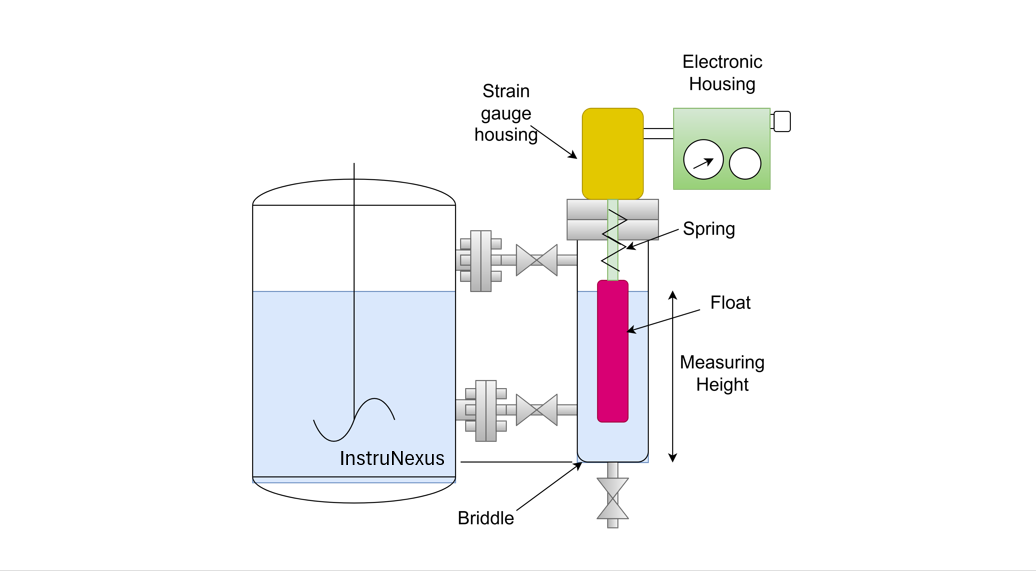

A displacer instrument isn’t a float that rides on the liquid surface. Instead, it’s a weighted cylinder (the displacer) that is fully or partially submerged in the process liquid. This displacer is suspended from a spring or, more commonly in oil and gas, a torque tube.

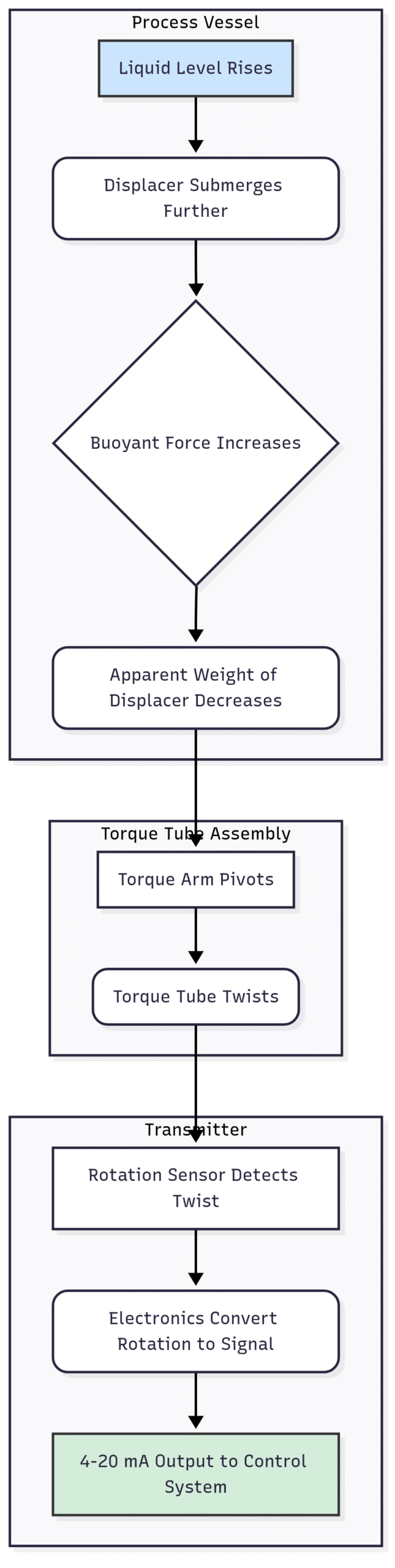

Here’s the step-by-step process:

Apparent Weight Change: As the liquid level rises, it submerges more of the displacer. This creates a greater buoyant force, making the displacer seem lighter. Conversely, as the level falls, the buoyant force decreases, and the displacer’s apparent weight increases.

Torque Tube Action: This change in apparent weight causes a minuscule vertical movement of the displacer. This movement is transferred to a torque tube, a specialized, sealed pipe that twists minutely in direct proportion to the weight change.

Signal Transmission: The twisting motion of the torque tube is detected by a transmitter mounted on the outside of the vessel. This transmitter converts the mechanical rotation into a standard, continuous output signal (e.g., 4-20 mA HART, or FOUNDATION Fieldbus) that is proportional to the liquid level.

This elegant and purely mechanical principle is what makes the displacer so incredibly reliable. It’s not susceptible to many of the interferences that can plague more complex electronic instruments.

Key Advantages: Why Displacers Remain a Go-To Choice

In an industry that demands instruments to perform flawlessly under punishing conditions, displacers offer several compelling advantages.

Unmatched Reliability in Extreme Conditions

Displacer instruments are built to withstand the harshest environments. Their robust, all-mechanical design (on the process side) allows them to operate reliably at extreme temperatures (from cryogenic LNG applications at -196°C to hot refinery processes over 400°C) and high pressures that would damage other types of sensors.

Pinpoint Accuracy and Repeatability

When calibrated correctly for the fluid’s specific gravity, displacers provide highly accurate and repeatable level measurements. This precision is crucial for process control, preventing vessel overflow or dry runs that could damage equipment.

Superior Interface Level Measurement

Perhaps the most significant advantage of displacers is their exceptional ability to measure the interface between two immiscible liquids, such as oil and water. A displacer can be calibrated to sink through the lighter top fluid (e.g., oil) and float on the heavier bottom fluid (e.g., produced water). The buoyant force is then directly proportional to the interface level, allowing for precise control in separation processes. This is a capability where many other technologies struggle.

Resilience to Process Variables

Process conditions inside vessels are rarely calm or clean. Displacers are largely unaffected by:

Foam: Foaming surfaces can confuse radar and ultrasonic sensors, but a displacer measures below the foam.

Vapors and Fumes: Heavy vapors or process gases do not affect the mechanical operation of the displacer.

Turbulence: When installed within a stilling well (a perforated pipe that acts as a calming chamber), displacers provide stable readings even in highly agitated vessels.

Material Versatility

Displacers and their associated wetted parts can be constructed from a wide range of materials, from standard stainless steel to exotic alloys like Hastelloy or Monel, making them suitable for highly corrosive services found in chemical and refining processes.

The Prime Applications: Where Displacers Shine in Oil & Gas

The true value of displacer instruments becomes clear when we look at their specific applications across the industry’s sectors.

Upstream: Exploration & Production

The upstream sector is where raw hydrocarbons are separated from water, gas, and sediment. This is the displacer’s home turf, where reliability is paramount.

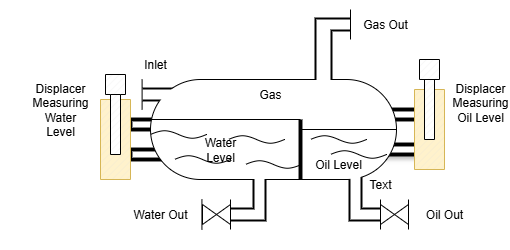

Three-Phase Separators

This is the most critical application for displacers in the oil and gas industry. A three-phase separator divides the well stream into oil, water, and gas. Inaccurate level control can lead to “carryover” (liquid contaminating the gas outlet) or “carryunder” (gas or oil contaminating the water outlet), both of which are costly and inefficient.

Oil/Water Interface Level: A displacer is used to precisely measure and control the boundary between the oil pad and the produced water. This ensures that only water is sent to the water dump valve.

Total Liquid Level: A second displacer or a different technology is often used to control the overall liquid level (the top of the oil pad), which dictates the opening of the oil outlet valve.

Heater Treaters & Free Water Knockouts (FWKOs)

Heater treaters are vessels that use heat to break down stubborn oil/water emulsions. Like separators, they rely on precise interface level control to efficiently remove water. FWKOs are simpler vessels that remove easily separated water before further processing. Displacers provide the reliable measurement needed for both.

Glycol Dehydrators (Contactors)

In natural gas processing, glycol contactors are used to remove water vapor from the gas stream. A displacer measures the level of “rich” glycol at the bottom of the contactor, ensuring a proper seal and efficient dehydration without losing valuable glycol.

Midstream: Transportation & Storage

The midstream sector handles the transportation and storage of hydrocarbons. Here, displacers are used to protect valuable equipment and manage large inventories.

Scrubbers and Knock-out Drums

These vessels are installed upstream of compressors and other rotating equipment. Their job is to “knock out” any liquids that have condensed in pipelines. A displacer provides a simple, robust level measurement to automatically drain these liquids, preventing catastrophic damage to the downstream machinery.

Condensate and NGL Storage

Storage tanks for Natural Gas Liquids (NGLs) and condensate often operate under pressure. Displacers mounted in external cages provide a reliable and easily serviceable method for monitoring inventory levels.

Downstream: Refining & Petrochemicals

The downstream sector involves refining crude oil and producing petrochemicals. The processes here often involve high temperatures, high pressures, and corrosive materials—ideal conditions for displacer instruments.

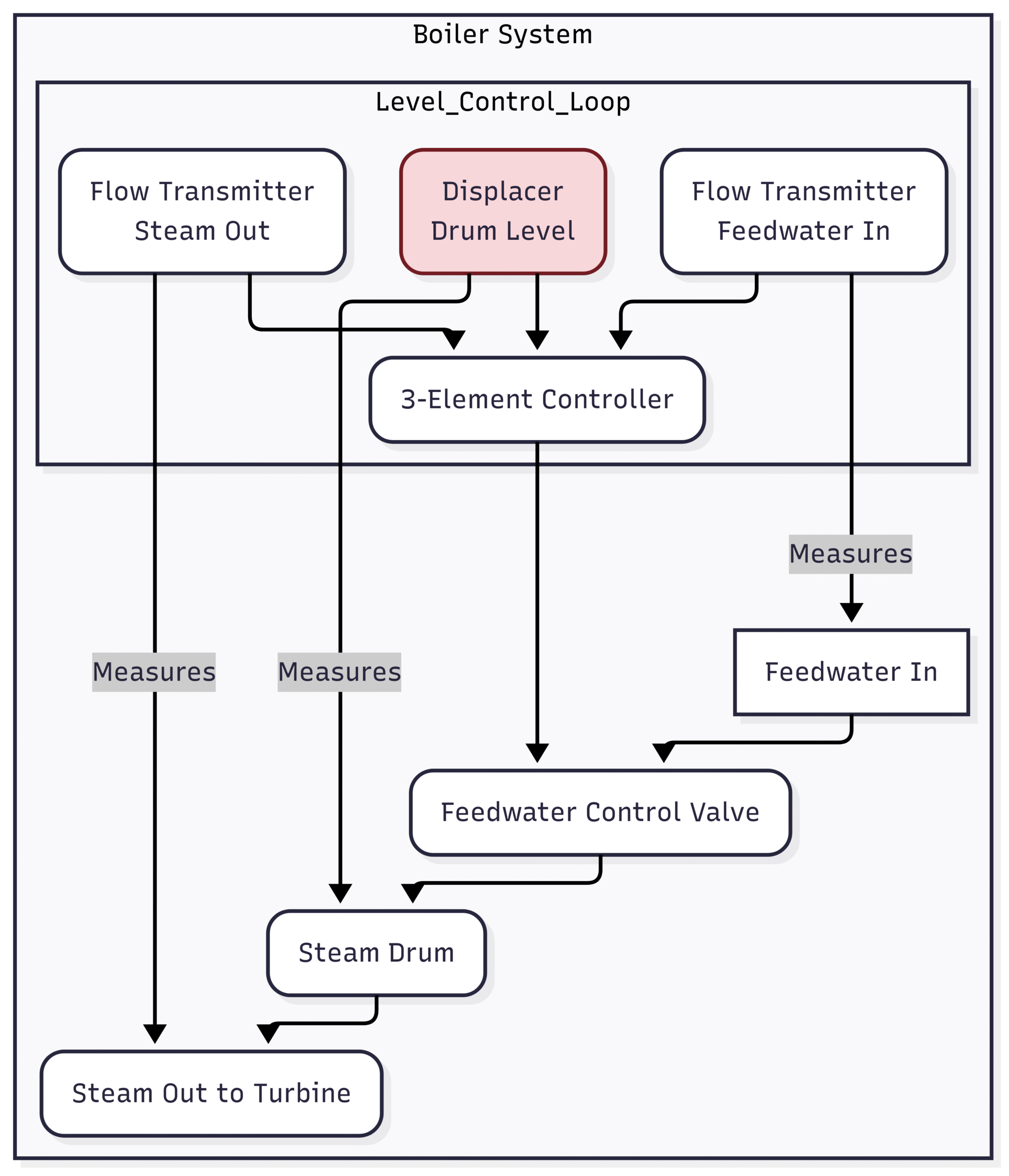

Boiler and Steam Drums

This is a classic safety-critical application. Maintaining the correct water level in a boiler’s steam drum is essential.

Too low a level can expose the boiler tubes, causing them to overheat and rupture catastrophically.

Too high a level can allow water to carry over into the steam system, damaging turbines and other equipment.

Displacers provide the rock-solid reliability required for this “three-element” control application, where level is controlled based on steam flow out, feedwater flow in, and the drum level itself.

Distillation and Fractionation Columns

In refining, distillation columns separate crude oil into different products based on their boiling points. Displacers are frequently used to measure the “bottoms” level—the liquid that collects at the base of the column—ensuring a smooth and efficient separation process.

Feedwater Heaters & Evaporators

Similar to boiler drums, these pieces of equipment require precise level control to operate efficiently and safely. Displacers offer a time-tested solution for managing levels in these high-temperature, high-pressure vessels.

Displacers vs. The Competition: A Comparative Look

While displacers are ideal for many applications, it’s important to understand how they stack up against other common technologies.

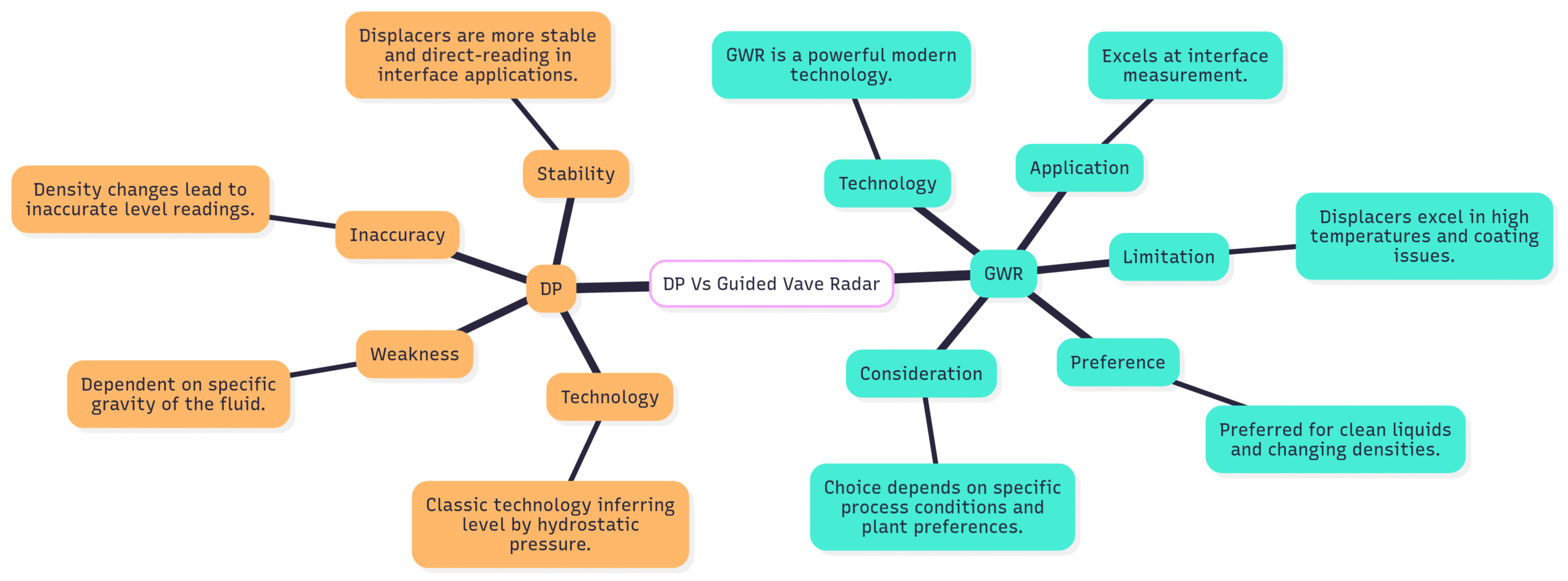

vs. Guided Wave Radar (GWR): GWR is a powerful modern technology that also excels at interface measurement. GWR is often preferred for clean liquids and applications where changing densities might affect a displacer’s calibration. However, displacers often hold the edge in extremely high-temperature services and where heavy coating or buildup on a GWR probe could be an issue. The choice often comes down to the specific process conditions and plant preferences.

vs. Differential Pressure (DP) Transmitters: DP is another classic technology that infers level by measuring hydrostatic pressure. DP’s main weakness is that its output is entirely dependent on the specific gravity of the fluid. If the density changes (due to temperature fluctuations or different product batches), the level reading will be inaccurate without compensation. A displacer is also affected by density but is often more stable and direct-reading in interface applications.

Best Practices for Installation and Maintenance

To get the most out of a displacer instrument, proper installation and maintenance are key.

Calibration is Critical: A displacer must be calibrated for the specific gravity (SG) of the liquid(s) it will be measuring. For interface duty, it must be calibrated for both the upper and lower fluid SGs.

Use Stilling Wells: In any application with turbulence, installing the displacer inside a stilling well is essential for a stable and accurate reading.

External Cages: For many applications, mounting the displacer in an external chamber or “cage” connected to the main vessel is preferred. This allows the instrument to be isolated with block valves for maintenance and calibration without shutting down the entire process.

Routine Inspection: Periodically inspect the displacer element for any signs of coating, buildup, or corrosion that could affect its weight and, therefore, its accuracy.

Conclusion: Legacy of Displacer Instruments

In an era of rapid technological change, the displacer level instrument stands as a testament to the power of a simple, robust design rooted in fundamental physics. Its ability to perform reliably in the most demanding, high-pressure, and high-temperature environments makes it an essential tool, not a legacy one.

From ensuring the efficient separation of oil and water at the wellhead to protecting critical equipment in a complex refinery, displacers provide the trustworthy, continuous level measurement that the oil and gas industry depends on. While newer technologies will continue to find their place, the displacer has earned its position as a go-to instrument for the applications where failure is not an option.