Maintenance Tips for Displacer Level Instruments in Hydrocarbon Liquids

Displacer level instruments are a stalwart technology in the oil and gas industry, providing reliable level measurements in a variety of applications. However, the unique properties of hydrocarbon liquids can present challenges to the accuracy and longevity of these instruments. This comprehensive guide will delve into the maintenance best practices for displacer level instruments in hydrocarbon service, ensuring optimal performance and safety. We’ll explore everything from the fundamental working principles to advanced troubleshooting, and even provide some handy checklists to streamline your maintenance routines.

Understanding Displacer Level Instruments

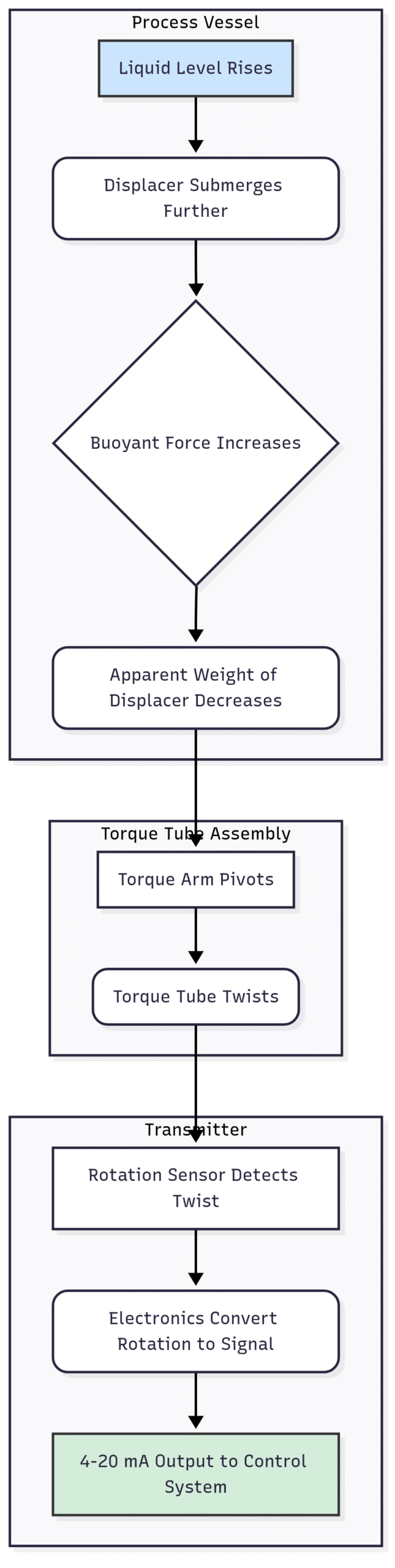

Before we dive into maintenance, let’s establish a firm understanding of how displacer level instruments work. At their core, these instruments operate on Archimedes’ Principle, which states that the buoyant force exerted on a submerged object is equal to the weight of the fluid it displaces.

A displacer instrument consists of a weighted cylinder (the displacer) suspended in the process fluid. As the liquid level rises, more of the displacer is submerged, and the buoyant force increases. This makes the displacer appear lighter to the instrument’s sensing mechanism, which can be a torque tube or a spring. The instrument then translates this change in apparent weight into a proportional output signal, typically 4-20 mA, which corresponds to the liquid level.

Working Principle of a Displacer Level Instrument

The Challenges of Hydrocarbon Service

Hydrocarbon liquids, ranging from crude oil to refined products, introduce a unique set of challenges for displacer level instruments:

Varying Densities: The density of hydrocarbons can fluctuate significantly with temperature and composition. Since the buoyant force is directly related to the fluid density, any change will affect the accuracy of the level measurement.

Emulsion Layers: In separation processes, an emulsion layer (or “rag layer”) can form between the hydrocarbon and water phases. This layer has a different density from either of the two main liquids, which can lead to measurement inaccuracies.

Coating and Buildup: Hydrocarbons can be viscous and contain suspended solids, which can coat the displacer and the chamber walls. This buildup alters the displacer’s weight and volume, leading to calibration drift.

Corrosion: Some hydrocarbons, particularly those containing sulfur compounds, can be corrosive to the instrument’s materials of construction.

High Pressures and Temperatures: Many hydrocarbon applications involve high pressures and temperatures, which can affect the mechanical integrity of the instrument and the accuracy of the measurement.

A Comprehensive Maintenance Program

A well-structured maintenance program is essential for ensuring the reliability and accuracy of displacer level instruments in hydrocarbon service. This program should include a combination of preventive, corrective, and predictive maintenance activities.

Preventive Maintenance

Preventive maintenance (PM) is the cornerstone of a reliable instrumentation system. A good PM program can help you identify and address potential issues before they lead to a failure. Here’s a checklist of PM tasks for displacer level instruments:

Visual Inspection:

Check for any signs of external damage to the instrument housing, chamber, and connections.

Look for leaks at the process connections, gaskets, and seals.

Inspect the wiring and conduit for any signs of damage or corrosion.

Calibration Verification:

Regularly verify the instrument’s calibration using a known standard. This is especially important in applications where the hydrocarbon density is known to vary.

The calibration should be checked at several points across the instrument’s range (e.g., 0%, 25%, 50%, 75%, and 100%).

Cleaning:

Periodically clean the displacer and the chamber to remove any buildup of solids or coating. The frequency of cleaning will depend on the severity of the service.

Use a solvent that is compatible with the process fluid and the instrument’s materials of construction.

Torque Tube/Spring Inspection:

Inspect the torque tube or spring for any signs of corrosion, fatigue, or damage.

Ensure that the torque tube is properly lubricated (if required by the manufacturer).

Corrective Maintenance

Corrective maintenance is performed to restore an instrument to its normal operating condition after a failure has occurred. Here are some common corrective maintenance tasks for displacer level instruments:

Troubleshooting Inaccurate Readings:

If the instrument is providing inaccurate readings, the first step is to verify the calibration.

If the calibration is correct, check for any changes in the process conditions (e.g., density, temperature, pressure).

Inspect the displacer and chamber for any buildup or coating.

Repairing Leaks:

If a leak is found, the instrument should be isolated from the process and depressurized before any repairs are attempted.

Replace any damaged gaskets or seals.

If the leak is from a crack in the chamber or a weld, the instrument may need to be replaced.

Replacing Damaged Components:

Replace any damaged components, such as the displacer, torque tube, or transmitter.

Ensure that the replacement components are of the correct size and material for the application.

Predictive Maintenance

Predictive maintenance (PdM) uses data analysis and condition monitoring to predict when an instrument is likely to fail. This allows you to schedule maintenance before a failure occurs, reducing downtime and maintenance costs. Here are some PdM techniques that can be used with displacer level instruments:

HART Diagnostics: Many modern displacer level transmitters are equipped with HART (Highway Addressable Remote Transducer) communication protocol. HART diagnostics can provide valuable information about the health of the instrument, such as the status of the sensor, the electronics, and the loop.

Statistical Process Control (SPC): SPC can be used to monitor the output of the instrument over time. Any sudden changes or trends in the output can be an indication of a developing problem.

Vibration Analysis: Vibration analysis can be used to detect mechanical problems with the torque tube or spring.

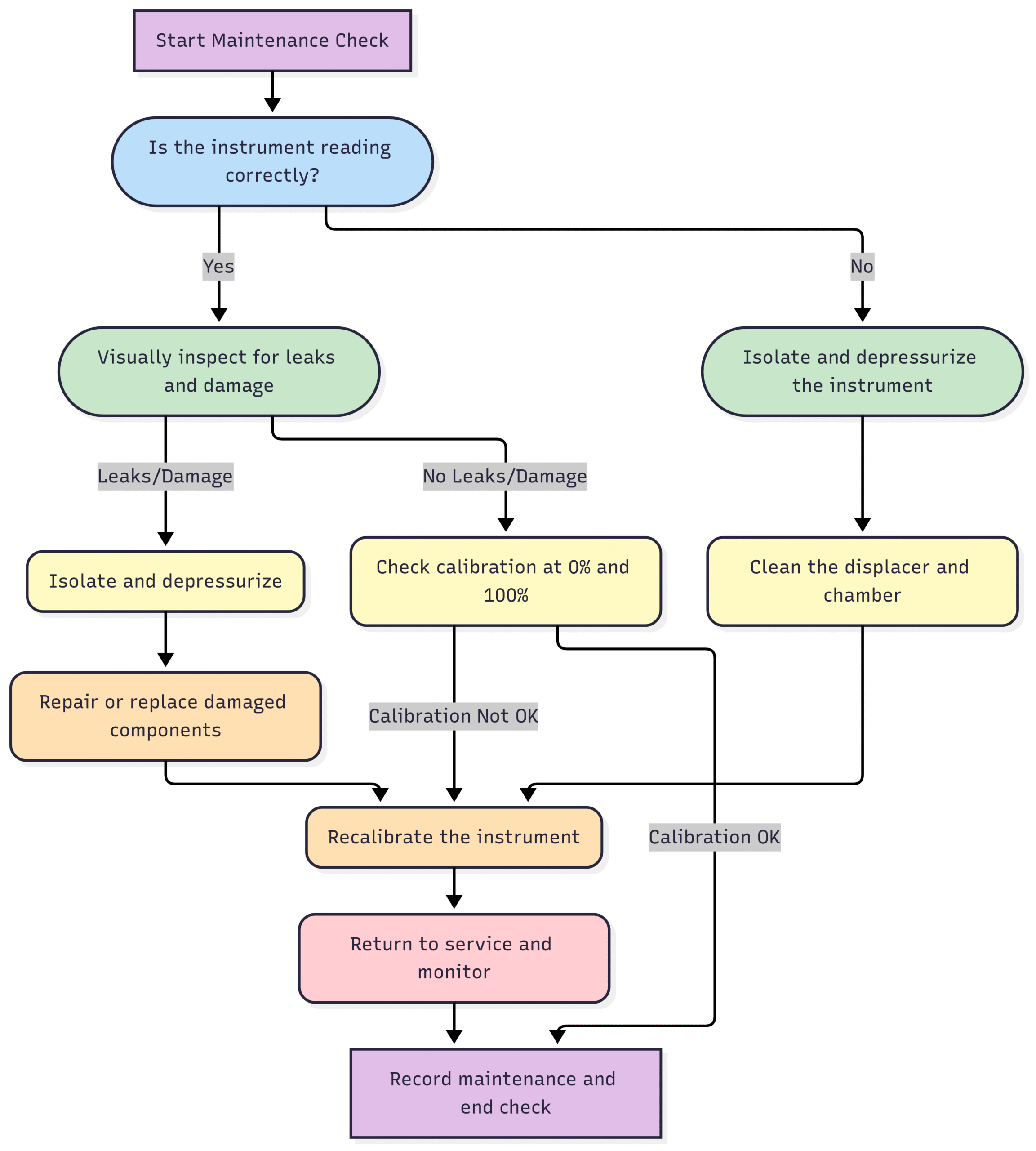

Routine Maintenance Check Flowchart

Here is a simple flowchart that can be used as a guide for routine maintenance checks:

Safety First!

Working with hydrocarbons presents a number of safety hazards, including flammability, toxicity, and high pressures. It is essential to follow all safety procedures when performing maintenance on displacer level instruments in hydrocarbon service.

Permit-to-Work: Always obtain a permit-to-work before starting any maintenance activity.

Personal Protective Equipment (PPE): Wear the appropriate PPE, including safety glasses, gloves, and flame-retardant clothing.

Lockout/Tagout (LOTO): Isolate and de-energize all sources of energy to the instrument before starting any work.

Ventilation: Ensure that the work area is well-ventilated to prevent the buildup of flammable or toxic vapors.

Confined Space Entry: If it is necessary to enter a confined space to perform maintenance, follow all confined space entry procedures.

Conclusion

Displacer level instruments are a reliable and accurate technology for measuring the level of hydrocarbon liquids. However, to ensure their continued performance and safety, it is essential to have a comprehensive maintenance program in place. By following the tips and best practices outlined in this guide, you can maximize the life of your displacer level instruments and minimize the risk of costly downtime. Remember, a proactive approach to maintenance is always better than a reactive one.