Interface Level Measurement: A Comprehensive Guide to Principles and Technologies

In a vast array of industrial processes, from mammoth oil refineries to intricate chemical plants, the precise measurement and control of liquid levels are paramount. But what happens when you’re not just dealing with a single liquid, but two or more immiscible fluids within the same vessel? This is where the critical discipline of interface level measurement comes into play. Accurately determining the boundary, or interface, between two liquids is not just a matter of efficiency; it’s a cornerstone of safety, product quality, and environmental protection.

This in-depth guide will unravel the complexities of interface level measurement. We’ll explore the fundamental principles that govern this technology, delve into the diverse range of measurement techniques available, and provide the insights you need to select the optimal solution for your specific application.

What is an Interface Level? The Science of Separation

At its core, an interface level is the distinct boundary that forms between two immiscible liquids within a vessel. Immiscible liquids are those that do not mix to form a homogeneous solution, like the classic example of oil and water. Due to differences in their density and specific gravity, the lighter liquid will inevitably float on top of the heavier one, creating a discernible interface.

However, the reality in many industrial settings is far from a clean, sharp line. Often, a third layer, known as an emulsion or “rag layer,” forms between the two primary liquids. This emulsion is a mixture of the two liquids that haven’t fully separated, presenting a significant challenge for many measurement technologies. The thickness and stability of this emulsion layer can vary depending on factors like turbulence, temperature, and the chemical properties of the liquids involved.

Why is Measuring the Interface Level So Important?

The ability to accurately and reliably measure the interface level is crucial across a multitude of industries for several key reasons:

Process Optimization and Efficiency: In separation processes, such as those in the oil and gas industry, precise interface level measurement ensures the efficient separation of oil from water. This maximizes the yield of valuable hydrocarbons and minimizes the amount of oil contaminating the wastewater stream.

Product Quality: In chemical and food processing, preventing the cross-contamination of different liquid phases is essential for maintaining product purity and meeting stringent quality standards. For instance, in a solvent extraction process, accurately measuring the interface between the solvent and the aqueous phase is critical.

Safety and Environmental Compliance: Inaccurate interface level measurement can lead to serious consequences. Overfilling a vessel with a hazardous chemical or accidentally releasing oil into a water treatment system can result in safety hazards, environmental damage, and costly regulatory fines.

Asset Protection: Many industrial processes involve corrosive or abrasive liquids. Ensuring that the correct liquid phase is in contact with the appropriate equipment components can prevent corrosion and extend the lifespan of valuable assets like tanks and pumps.

A Tour of Interface Level Measurement Principles

The market offers a diverse array of technologies for measuring interface levels, each with its own set of operating principles, advantages, and limitations. Understanding these principles is the first step toward selecting the right tool for the job.

1. Guided Wave Radar (GWR): Precision Through Pulses

Guided Wave Radar (GWR) has emerged as one of the most reliable and versatile technologies for interface level measurement. It operates on the principle of time domain reflectometry (TDR).

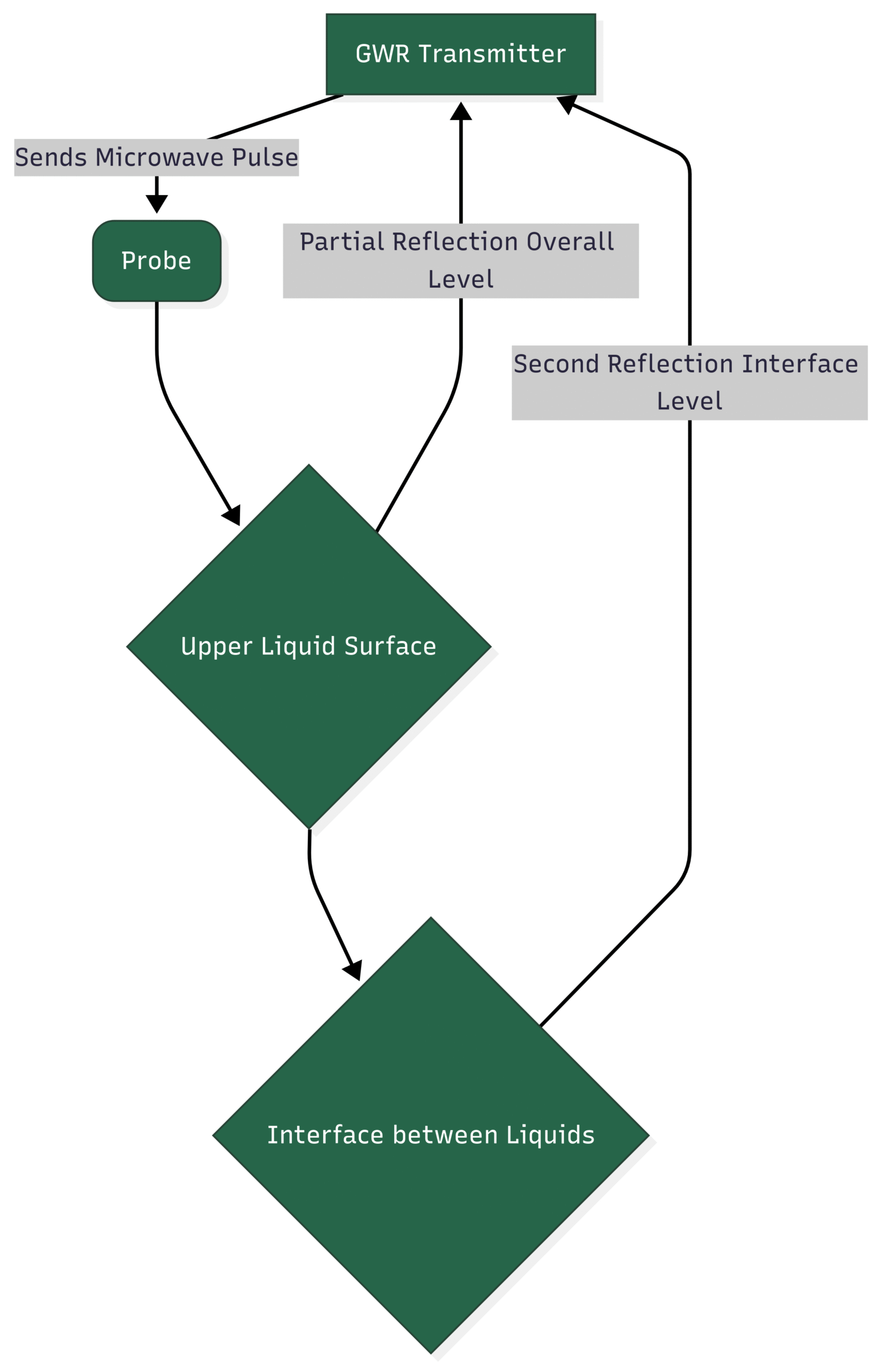

How it Works:

A low-energy microwave pulse is sent down a probe (a rigid rod or flexible cable) that extends into the vessel. When this pulse encounters a change in the dielectric constant (εr) of the medium, a portion of the pulse is reflected back to the transmitter.

The first reflection occurs at the surface of the upper, less dense liquid. The time it takes for this reflection to return is used to calculate the overall level.

The remaining portion of the pulse continues down the probe until it reaches the interface with the lower, denser liquid. Since the two liquids have different dielectric constants, another reflection is generated at this interface. The time delay between the first and second reflections is used to determine the interface level.

Guided Wave Radar Principle

Advantages:

High Accuracy: GWR provides precise and reliable measurements, even in the presence of vapors, temperature and pressure fluctuations, and varying dielectric constants.

Dual Measurement: It can simultaneously measure both the overall level and the interface level with a single instrument.

Unaffected by Density Changes: The measurement is based on dielectric constants, not density, making it robust in applications where densities may vary.

Limitations:

Emulsion Layers: Thick or dense emulsion layers can absorb or scatter the microwave pulse, making it difficult to obtain a clear reflection from the interface.

Low Dielectric Contrast: The difference in the dielectric constants of the two liquids must be significant enough to generate a detectable reflection.

2. Capacitance: Sensing the Dielectric Difference

Capacitance-based level sensors are another popular choice for interface measurement, particularly in applications involving a conductive and a non-conductive liquid.

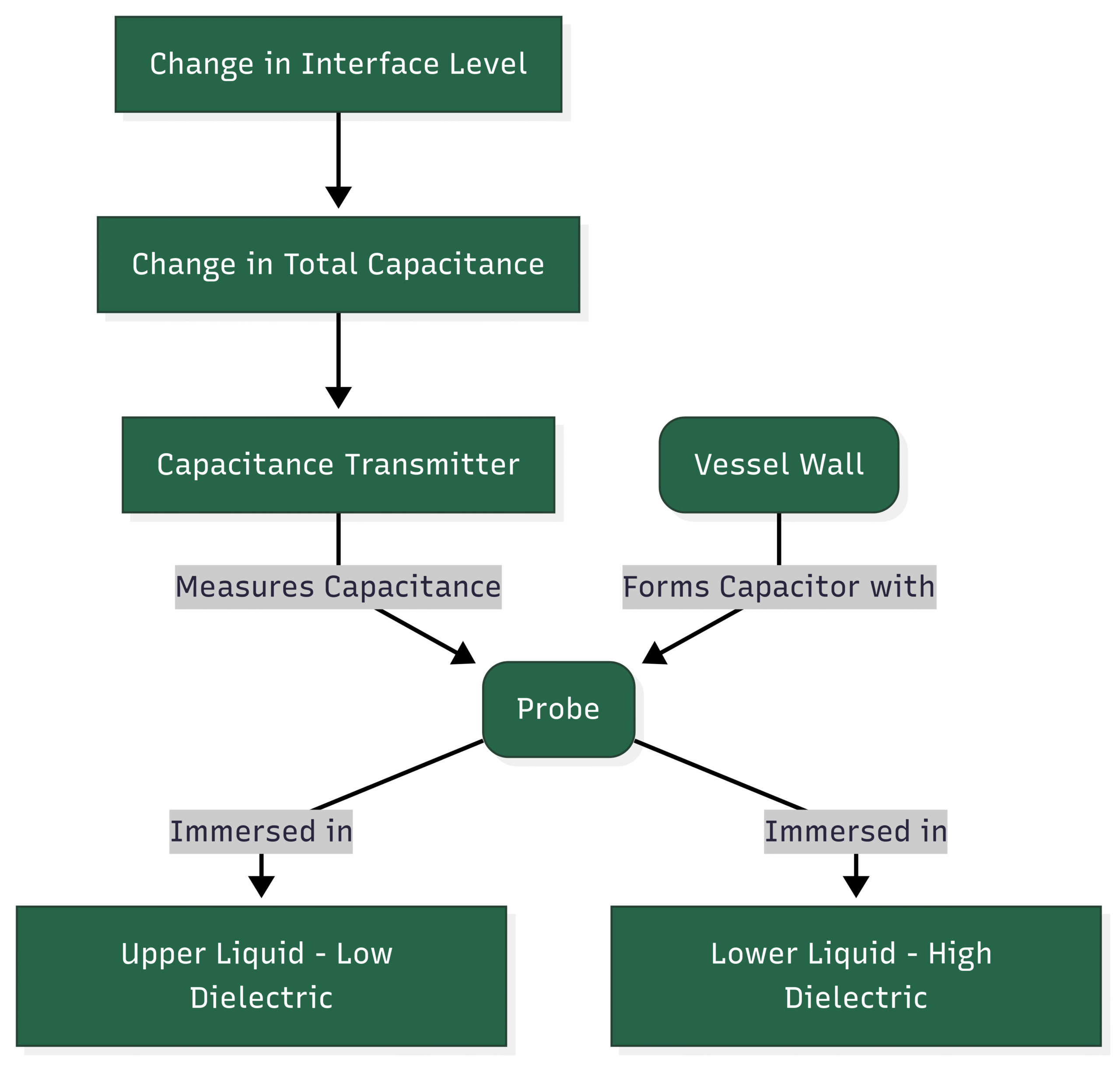

How it Works:

A capacitance probe and the vessel wall (if it’s metallic) act as the two plates of a capacitor. The liquid(s) in the tank serve as the dielectric material between these plates. The capacitance of this setup is dependent on the dielectric constant of the material surrounding the probe.

When measuring an interface, the probe is submerged in both liquids. As the interface level changes, the proportion of the probe surrounded by each liquid changes, resulting in a change in the overall capacitance. This change is then correlated to the interface level. For this to work effectively, one liquid must have a significantly higher dielectric constant than the other (e.g., water, which is conductive and has a high dielectric constant, and oil, which is non-conductive and has a low dielectric constant).

Capacitance Measurement Principle

Advantages:

Cost-Effective: Capacitance sensors can be a more economical solution for certain applications.

No Moving Parts: This leads to lower maintenance requirements.

Handles Emulsions Well: In some cases, capacitance technology can “see through” emulsion layers more effectively than other technologies.

Limitations:

Coating and Buildup: Conductive coatings on the probe can lead to inaccurate readings.

Calibration Required: The sensor needs to be calibrated for the specific liquids being measured. Changes in the dielectric properties of the liquids can affect accuracy.

3. Radiometric (Gamma): Non-Intrusive Measurement for Harsh Environments

Radiometric or gamma-based measurement is a non-contact, non-intrusive technology that is ideal for the most challenging industrial environments, including those with high temperatures, high pressures, and highly corrosive or toxic media.

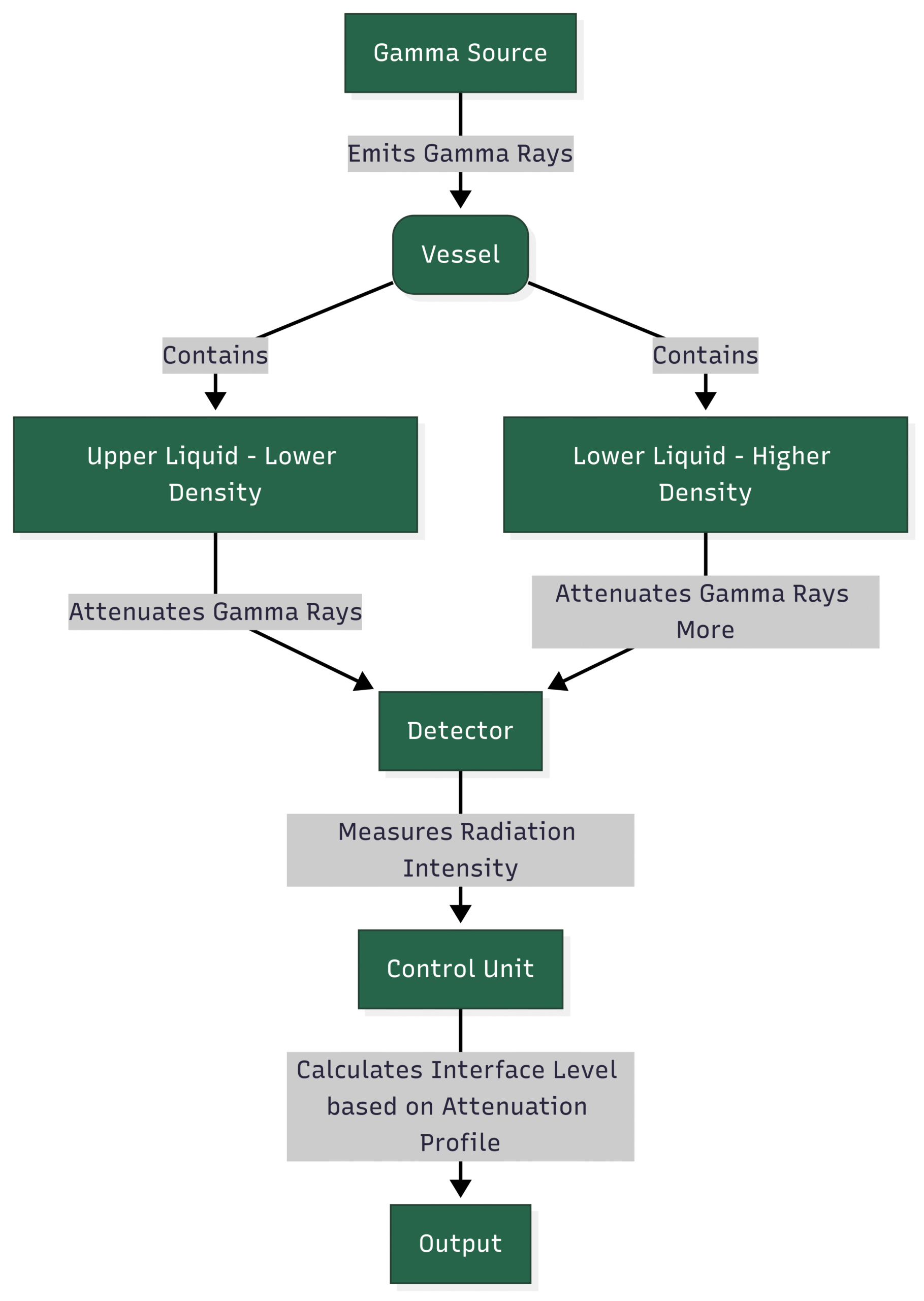

How it Works:

A low-intensity gamma radiation source is mounted on one side of the vessel, and a detector is mounted on the opposite side. The gamma rays pass through the vessel walls and the process liquids. As the radiation travels through the different liquid layers, it is attenuated (weakened) to varying degrees depending on the density of each liquid.

The detector measures the intensity of the received radiation. By analyzing the changes in radiation intensity at different heights, the system can accurately determine the position of the interface, as well as the presence of any emulsion layers.

Radiometric Measurement Principle

Advantages:

Non-Intrusive: No part of the instrument comes into contact with the process media, eliminating concerns about corrosion, abrasion, or sensor damage.

Highly Reliable: Unaffected by process conditions like extreme temperatures, pressures, or the chemical properties of the liquids.

Measures Through Emulsions: Can effectively identify and measure the thickness of emulsion layers.

Limitations:

Regulatory Requirements: The use of a radioactive source is subject to strict licensing and safety regulations.

Higher Initial Cost: Radiometric systems typically have a higher upfront cost compared to other technologies.

4. Magnetostrictive: High Accuracy for Clean Liquids

Magnetostrictive level transmitters are known for their high accuracy and are often used in applications where precise interface measurement of clean, non-coating liquids is required.

How it Works:

A magnetostrictive probe contains a wire made of a magnetostrictive material. One or more floats, each containing a magnet, are designed to float at the interface of the different liquids. A current pulse is sent down the wire, creating a magnetic field along its length.

When this magnetic field interacts with the magnetic field of the float, it generates a torsional strain wave that travels back up the wire to a sensor in the transmitter head. The time it takes for this strain wave to return is precisely measured and converted into a highly accurate level measurement. By using two floats with different densities, both the overall level and the interface level can be measured simultaneously.

Magnetostrictive Measurement Principle

Advantages:

Exceptional Accuracy: Magnetostrictive technology offers very high precision.

Continuous Measurement: Provides a continuous and real-time output of the interface level.

Unaffected by Many Process Variables: The measurement is not affected by changes in pressure, temperature, or dielectric constant.

Limitations:

Moving Parts: The use of floats means there are moving parts that can be affected by turbulence or buildup.

Not Suitable for Dirty or Coating Liquids: The floats can become stuck or coated, leading to inaccurate readings.

5. Other Notable Technologies

While the technologies above are among the most common, several other methods are also used for interface level measurement:

Displacer Level Transmitters: These instruments use a buoyant displacer that is partially submerged in the process liquids. Based on Archimedes’ principle, the buoyant force on the displacer is proportional to the interface level. They are a mature and reliable technology but can be sensitive to density changes.

Ultrasonic Level Sensors: These non-contact sensors emit ultrasonic pulses that reflect off the liquid surfaces. While primarily used for single-liquid level measurement, some advanced ultrasonic systems can be configured for interface detection in certain applications.

Float Switches: A simpler, point-level solution that uses floats of different densities to trigger a switch when the interface reaches a specific point. They are cost-effective for high or low-level alarms but do not provide continuous measurement.

Choosing the Right Technology: A Practical Guide

Selecting the optimal interface level measurement technology is a critical decision that depends on a thorough understanding of your specific application. Here are the key factors to consider:

1. Process Conditions

Temperature and Pressure: Can the instrument withstand the operating temperatures and pressures of your process? Some technologies have limitations in extreme conditions.

Chemical Compatibility: Are the wetted parts of the instrument compatible with the chemicals in your process? Corrosion can lead to sensor failure and safety hazards.

Viscosity: Highly viscous liquids can affect the movement of floats or coat probes, leading to inaccuracies.

2. Liquid Properties

Density Difference: Is there a sufficient difference in the densities of the two liquids for technologies like displacers or floats to work effectively?

Dielectric Constant Contrast: For technologies like GWR and capacitance, is there a significant difference in the dielectric constants of the liquids?

Presence of Emulsions: How thick and stable is the emulsion layer? Some technologies handle emulsions better than others. It may be necessary to conduct a pilot test to determine the best solution.

Foaming and Turbulence: Can the chosen technology handle the presence of foam or turbulence in the vessel? Stilling wells may be required in some cases.

3. Performance Requirements

Accuracy and Repeatability: What level of accuracy is required for your process? Different technologies offer varying levels of precision.

Continuous vs. Point Level: Do you need a continuous measurement of the interface level, or is a simple high/low alarm sufficient?

Response Time: How quickly does the measurement need to respond to changes in the interface level?

4. Installation and Maintenance

Installation Constraints: Are there any physical constraints in the vessel or surrounding area that might limit your choice of technology?

Maintenance Requirements: Consider the long-term maintenance costs and the ease of calibration and repair for each technology.

The Future of Interface Level Measurement: Smarter, Faster, More Reliable

The field of interface level measurement is continually evolving, driven by the increasing demand for greater accuracy, reliability, and ease of use. We are seeing a trend towards multi-parameter transmitters that can measure not only the overall and interface levels but also other process variables like temperature and density.

Furthermore, the integration of advanced diagnostics and digital communication protocols like HART, Foundation Fieldbus, and Profibus is enabling more intelligent and proactive process control. These technologies allow for remote monitoring, configuration, and troubleshooting, reducing downtime and improving overall plant efficiency.

Conclusion: Mastering the Boundary

Interface level measurement is a complex but essential discipline in modern industrial processing. From the oil fields of the world to the pristine environments of pharmaceutical manufacturing, the ability to accurately and reliably determine the boundary between two liquids is fundamental to success.

By understanding the underlying principles of separation, familiarizing yourself with the diverse range of measurement technologies available, and carefully considering the unique requirements of your application, you can confidently select the right solution to optimize your processes, ensure product quality, and maintain a safe and compliant operation. The right interface level measurement strategy is not just an investment in instrumentation; it’s an investment in the long-term health and profitability of your entire enterprise.