Selecting the Right Instrument for Oil-Water Interface Detection: A Comprehensive Guide

The precise detection of the oil-water interface is a critical operational parameter in numerous industries, most notably in oil and gas production, refining, and petrochemical processing. Effective interface detection prevents process upsets, ensures product quality, and safeguards against environmental contamination. With a multitude of technologies available, selecting the right instrument can be a daunting task. This comprehensive guide will delve into the various methods for oil-water interface detection, their principles of operation, and the key factors to consider when making your selection.

Why is Accurate Oil-Water Interface Detection So Important?

In the oil and gas industry, separators are fundamental in processing well stream fluids. These vessels separate the mixture into its constituent components: oil, water, and gas. The efficiency of this separation process hinges on the accurate measurement of the interface level between the oil and the produced water.

Imprecise interface level control can lead to several detrimental consequences:

Process Upsets: If the oil level is too high, it can carry over into the water outlet, leading to oil contamination in the produced water treatment system. This not only reduces the efficiency of the treatment process but can also result in non-compliance with environmental discharge regulations.

Reduced Product Quality: Conversely, if the water level is too high, water can be carried over into the oil outlet. This is known as “water in oil” and can lead to significant issues downstream, including corrosion in pipelines and processing equipment, and will ultimately require further separation, increasing operational costs.

Equipment Damage: Poor interface control can lead to the formation of emulsions, which are difficult to separate and can cause operational problems in downstream equipment.

Production Losses: Inefficient separation results in lost hydrocarbons, directly impacting the profitability of the operation.

Given these significant implications, the selection of a reliable and accurate oil-water interface detection instrument is paramount.

Technologies for Oil-Water Interface Detection

A variety of technologies are employed for oil-water interface detection, each with its own set of advantages and disadvantages. The choice of technology is often dictated by the specific application, the properties of the fluids, and the operating conditions.

1. Guided Wave Radar (GWR)

Guided Wave Radar (GWR) has emerged as a leading technology for interface measurement. It is a time-domain reflectometry (TDR) based measurement that provides a direct reading of both the total level and the interface level.

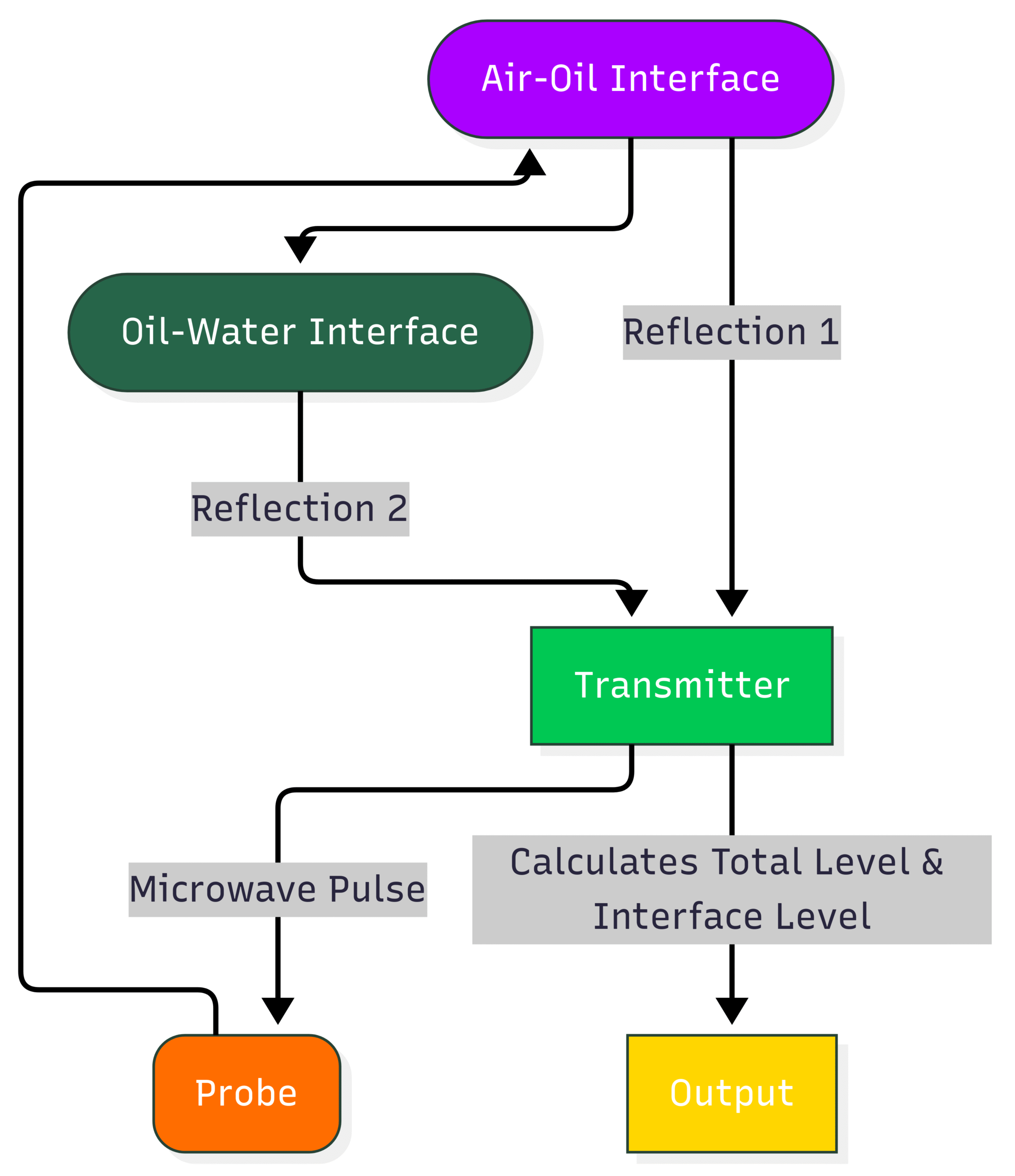

Principle of Operation:

A low-energy microwave pulse is guided down a probe. When the pulse reaches a liquid surface, a portion of the energy is reflected back to the transmitter. The time it takes for the pulse to travel to the liquid surface and back is used to calculate the distance to the surface.

In an oil-water interface application, two reflections occur: one from the upper liquid surface (the air-oil interface) and one from the lower liquid surface (the oil-water interface). The difference in the dielectric constant between the oil and water creates the reflection at the interface.

Advantages:

High Accuracy: GWR provides highly accurate and repeatable measurements.

Unaffected by Process Conditions: The measurement is largely unaffected by changes in density, temperature, pressure, and viscosity.

No Moving Parts: This results in low maintenance requirements.

Direct Measurement: It directly measures the interface, eliminating the need for complex calculations or inferences.

Handles Emulsions: Advanced GWR instruments can often detect and measure through emulsion layers.

Disadvantages:

Probe Coating: The probe can be susceptible to coating in applications with heavy, sticky crude oils, which can attenuate the signal.

Cost: GWR instruments can have a higher initial cost compared to some other technologies.

Dielectric Constant Difference: A sufficient difference in the dielectric constants of the two liquids is required for a clear reflection at the interface.

2. Capacitance Probes

Capacitance probes are a well-established and cost-effective method for interface detection. They work by measuring the change in capacitance between a probe and the vessel wall.

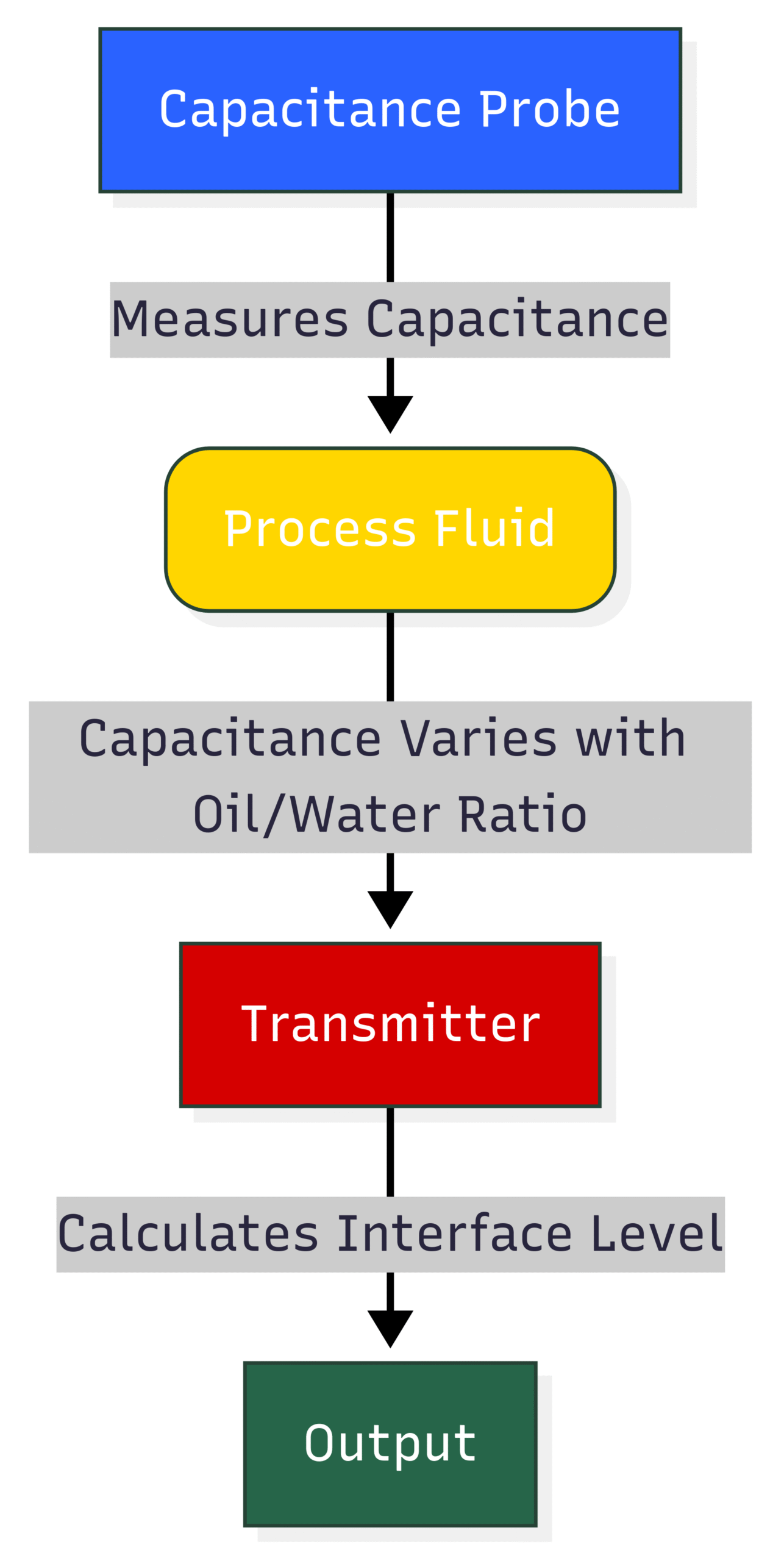

Principle of Operation:

The probe and the vessel wall act as the two plates of a capacitor. The process fluid between them acts as the dielectric. As the interface level changes, the overall capacitance of the system changes because oil and water have different dielectric constants. This change in capacitance is measured and correlated to the interface level.

Advantages:

Cost-Effective: Capacitance probes are generally less expensive than GWR instruments.

Simple Installation: They are relatively easy to install.

Good for Clean Applications: They perform well in applications with clean, well-defined interfaces.

Disadvantages:

Susceptible to Coating: Coating on the probe can significantly affect the accuracy of the measurement.

Affected by Process Variations: Changes in the dielectric constant of either the oil or water due to temperature or composition variations can lead to errors.

Calibration Required: They often require calibration with the actual process fluids.

Not Ideal for Emulsions: The presence of an emulsion layer can make it difficult to obtain a distinct interface measurement.

3. Vibrating Fork (Tuning Fork)

Vibrating fork, or tuning fork, level switches are simple, robust, and reliable point level detection devices. They can be used to detect the presence or absence of a liquid at a specific point, making them suitable for high or low-level alarms in interface applications.

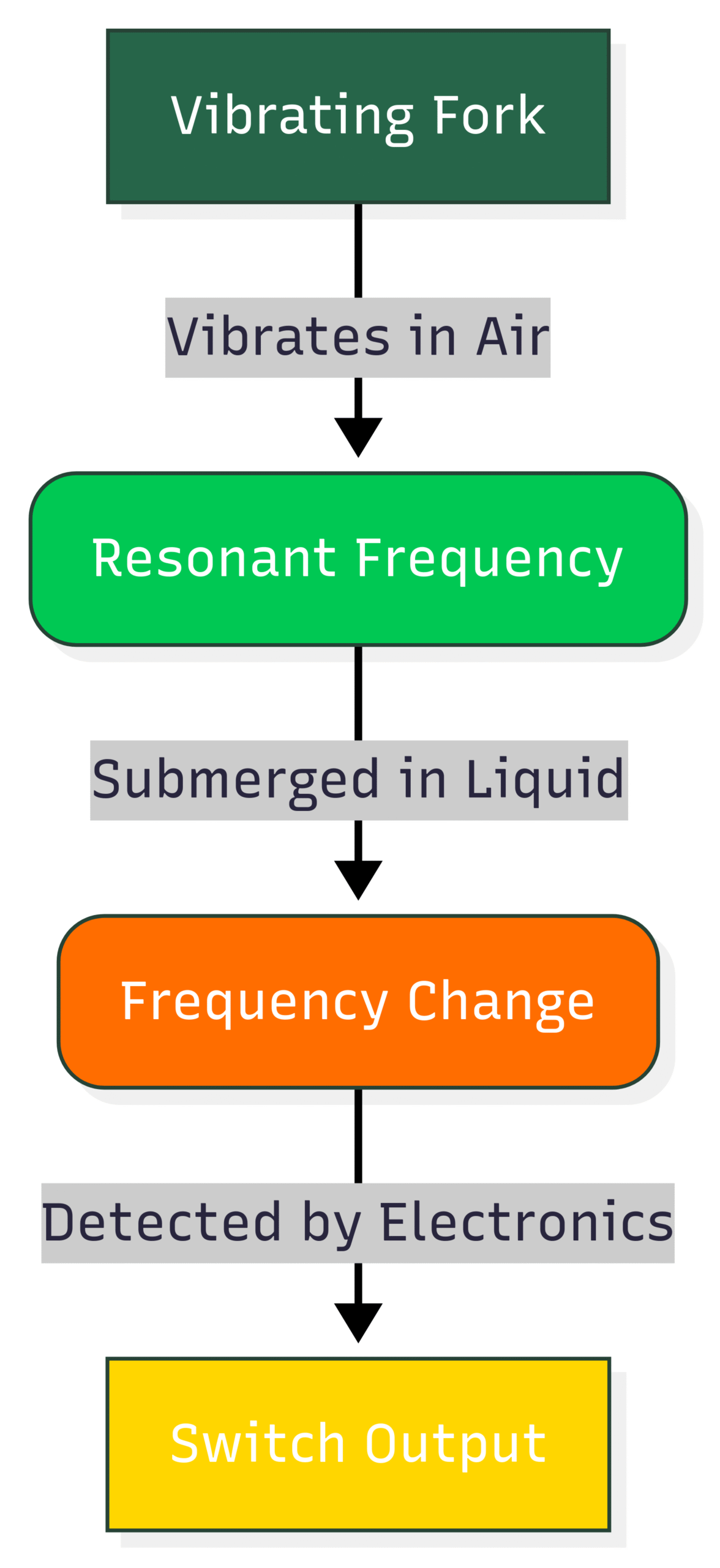

Principle of Operation:

A piezoelectric crystal causes the tines of the fork to vibrate at their natural resonant frequency in air. When the tines come into contact with a liquid, the frequency of vibration changes. This change is detected by the electronics and used to switch a relay.

In an interface application, a vibrating fork can be installed at a specific height. When the denser liquid (water) reaches the fork, the change in vibration is detected.

Advantages:

High Reliability: Vibrating forks are very reliable and have a long service life.

Low Maintenance: They have no moving parts and are not affected by coating.

Unaffected by Process Conditions: Their operation is not significantly impacted by changes in conductivity, dielectric constant, pressure, or temperature.

Self-Cleaning: The vibration of the tines can help to prevent buildup.

Disadvantages:

Point Level Detection Only: They only provide a point level measurement, not a continuous level. Multiple switches would be needed for continuous monitoring.

Can be Affected by High Viscosity: In very viscous fluids, the vibration can be dampened, leading to false readings.

4. Magnetostrictive Level Transmitters

Magnetostrictive level transmitters are highly accurate and are often used in applications where precise level control is critical.

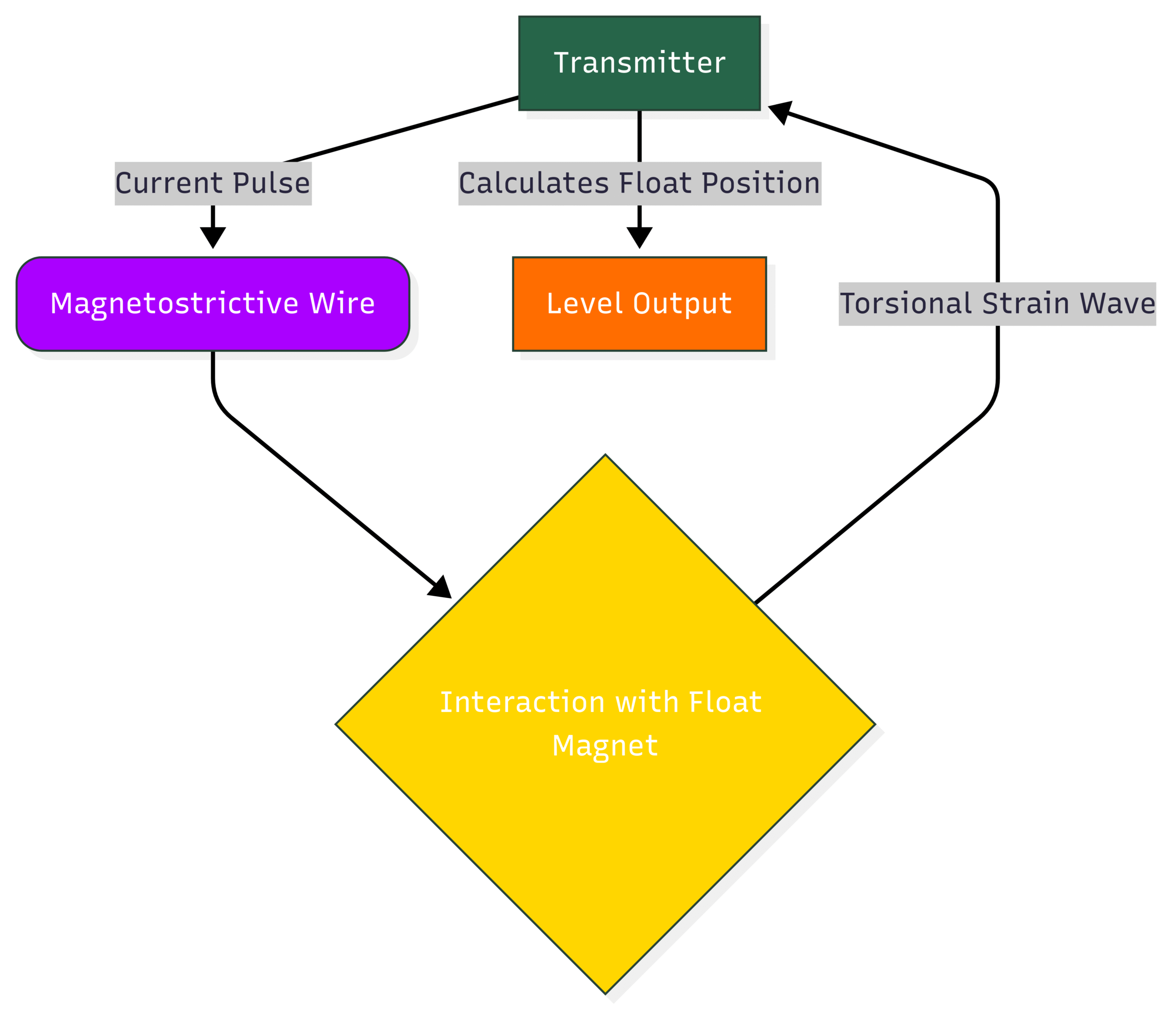

Principle of Operation:

A magnetostrictive transmitter uses a float containing a magnet that moves up and down a rigid probe. A current pulse is sent down a magnetostrictive wire inside the probe. The interaction of the magnetic field from the float and the magnetic field generated by the current pulse creates a torsional strain wave that travels back up the wire. The time it takes for this wave to travel determines the position of the float.

For interface applications, two floats with different densities are used. The upper float rests on the top liquid (oil), and the lower float rests on the interface.

Advantages:

High Accuracy and Resolution: They provide very precise and repeatable measurements.

Unaffected by Most Process Variables: The measurement is not affected by changes in density, dielectric constant, or pressure.

Can Measure Total and Interface Level: The use of two floats allows for the measurement of both the total level and the interface level.

Disadvantages:

Moving Parts: The use of floats means there are moving parts that can be subject to wear or sticking.

Potential for Buildup: The floats and the probe can be susceptible to buildup, which can impede movement.

Cost: Magnetostrictive transmitters can be more expensive than some other technologies.

5. Nuclear (Gamma) Profilers

Nuclear, or gamma, profilers are a non-contacting and non-intrusive method for interface detection. They are often used in harsh process environments where other technologies may fail.

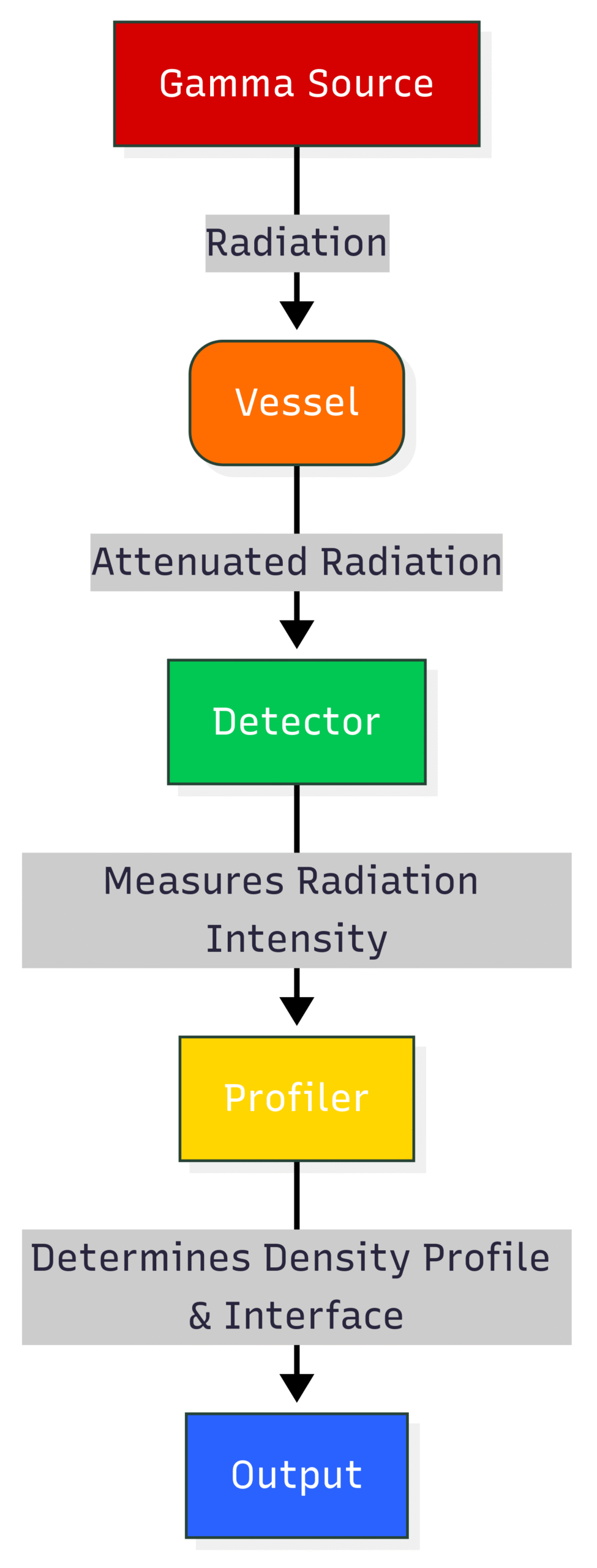

Principle of Operation:

A gamma radiation source is mounted on one side of the vessel, and a detector is mounted on the other. The gamma radiation passes through the vessel and its contents. The amount of radiation that reaches the detector is dependent on the density of the material it passes through. Since oil and water have different densities, the amount of radiation absorbed will change as the interface level changes.

By using a profiler with multiple detectors, a density profile of the vessel can be created, allowing for the precise determination of the oil-water interface, as well as any emulsion layers.

Advantages:

Non-Contacting and Non-Intrusive: The instrument is mounted entirely outside the vessel, so it is not affected by corrosive or abrasive process fluids.

Highly Reliable: With no moving parts and no contact with the process, nuclear profilers are extremely reliable and require minimal maintenance.

Handles Severe Conditions: They are ideal for high-temperature, high-pressure applications and can handle heavy buildup and emulsions.

Provides a Density Profile: They can measure the thickness and density of emulsion layers.

Disadvantages:

Regulatory Requirements: The use of a radioactive source requires licensing and adherence to strict safety regulations.

High Initial Cost: Nuclear profilers have a high initial capital cost.

Specialized Personnel: Handling and maintenance require trained and certified personnel.

Key Factors to Consider When Selecting an Instrument

Choosing the right instrument for your oil-water interface detection application requires a thorough evaluation of several factors.

1. Fluid Properties

Dielectric Constant: For GWR and capacitance probes, a significant difference in the dielectric constants of the oil and water is crucial for a strong, detectable signal at the interface.

Density: The difference in density between the oil and water is the primary operating principle for nuclear profilers and is also important for magnetostrictive transmitters that use floats.

Viscosity: High viscosity fluids can be problematic for vibrating forks and can cause buildup on probes and floats.

Conductivity: Highly conductive fluids can interfere with some capacitance probes.

Presence of Emulsions: The presence, thickness, and characteristics of an emulsion layer are critical considerations. Some technologies, like advanced GWR and nuclear profilers, can measure through or quantify emulsion layers, while others will provide inaccurate readings.

2. Operating Conditions

Temperature and Pressure: The selected instrument must be rated for the operating temperature and pressure of the process vessel. High temperatures and pressures can limit the choice of materials and technologies.

Vibration: High levels of vibration can affect the performance of some instruments, particularly those with moving parts.

Presence of Solids or Paraffins: The potential for buildup of solids, waxes, or paraffins on probes or floats must be considered. This can lead to inaccurate measurements and increased maintenance.

3. Installation and Maintenance

Vessel Geometry: The size and shape of the vessel, as well as the location of nozzles and other internal structures, will influence the choice of instrument and its installation.

Accessibility: Consider the ease of access for installation, calibration, and maintenance.

Maintenance Requirements: Evaluate the long-term maintenance needs of the instrument. Technologies with no moving parts, like GWR and nuclear profilers, generally require less maintenance.

4. Performance Requirements

Accuracy and Repeatability: The required accuracy of the interface measurement will depend on the specific application. Tighter process control requires more accurate instrumentation.

Response Time: The speed at which the instrument can respond to changes in the interface level is important for dynamic processes.

Continuous vs. Point Level: Determine whether you need a continuous measurement of the interface level or if point level detection for high or low alarms is sufficient.

5. Cost

Initial Purchase Price: The capital cost of the instrument is a significant factor.

Installation Costs: Consider the costs associated with installation, including any necessary vessel modifications.

Operating and Maintenance Costs: Factor in the long-term costs of operation, including power consumption, calibration, and routine maintenance.

Total Cost of Ownership: A comprehensive evaluation should consider the total cost of ownership over the life of the instrument, not just the initial purchase price. A more expensive but highly reliable and low-maintenance instrument may have a lower total cost of ownership in the long run.

Comparison of Oil-Water Interface Detection Technologies

| Technology | Principle of Operation | Advantages | Disadvantages | Best Suited For |

| Guided Wave Radar (GWR) | Microwave pulse reflection | High accuracy, unaffected by most process conditions, no moving parts, handles emulsions | Probe coating, higher cost, requires dielectric difference | A wide range of applications, including those with changing process conditions and emulsions. |

| Capacitance Probes | Change in capacitance | Cost-effective, simple installation | Susceptible to coating, affected by process variations, requires calibration | Clean applications with stable fluid properties and a well-defined interface. |

| Vibrating Fork | Change in resonant frequency | High reliability, low maintenance, unaffected by most process conditions | Point level only, can be affected by high viscosity | High or low-level alarms, simple interface detection where a single point is sufficient. |

| Magnetostrictive | Float position measurement | High accuracy, unaffected by most process variables, measures total and interface level | Moving parts, potential for buildup, higher cost | Applications requiring very high accuracy and where the process fluids are relatively clean. |

| Nuclear (Gamma) Profiler | Gamma radiation absorption | Non-contacting, non-intrusive, highly reliable, handles severe conditions, provides density profile | Regulatory requirements, high initial cost, specialized personnel | Harsh process environments, high-temperature/pressure applications, and when a detailed profile of the interface and emulsions is needed. |

Conclusion: Making the Right Choice for Your Application

Selecting the right instrument for oil-water interface detection is a critical decision that can have a significant impact on the efficiency, safety, and profitability of your operations. There is no one-size-fits-all solution. A thorough understanding of the available technologies, combined with a detailed assessment of your specific process requirements, is essential for making an informed choice.

For most standard oil and gas separation applications, Guided Wave Radar (GWR) has become the technology of choice due to its high accuracy, reliability, and ability to handle a wide range of process conditions, including the presence of emulsion layers.

However, for less demanding applications with clean fluids and stable properties, a capacitance probe may offer a more cost-effective solution. For simple high or low-level alarms, a vibrating fork provides a robust and reliable option. In applications where the highest accuracy is paramount and the process fluids are clean, a magnetostrictive transmitter may be the best choice. Finally, for the most challenging process environments with high temperatures, high pressures, and heavy buildup, a nuclear profiler offers a non-contacting and highly reliable solution, albeit with a higher initial cost and regulatory considerations.

By carefully considering the factors outlined in this guide – fluid properties, operating conditions, installation and maintenance requirements, performance needs, and cost – you can select the instrument that will provide reliable and accurate oil-water interface detection for years to come, ensuring optimal process control and maximizing the efficiency of your operations.