Interface Level Measurement Challenges and How to Overcome Them

Interface level measurement, the detection of the boundary between two immiscible liquids, is a cornerstone of process control in countless industries. From optimizing separation in oil and gas to ensuring product purity in chemical manufacturing and managing effluent quality in wastewater treatment, accurate interface detection is not just a metric—it’s a critical driver of efficiency, safety, and profitability.

However, measuring this seemingly simple boundary is one of the most persistent and complex challenges in industrial instrumentation. Unlike single-fluid level measurement, the interface is rarely a perfect, calm line. It’s often a dynamic, messy, and unpredictable zone influenced by the chemical and physical properties of the liquids themselves.

This in-depth guide explores the most significant challenges operators face in interface level measurement. We will dissect the problems, from the dreaded emulsion layers to the complexities of process conditions, and provide a clear roadmap of modern technologies and strategies to overcome them, ensuring your process runs smoothly and efficiently.

What is Interface Level Measurement and Why is it Critical?

At its core, interface level measurement is the process of identifying and tracking the point of separation between two liquids that do not mix, such as oil and water, a solvent and an aqueous solution, or two different chemicals. These liquids typically have different densities and other physical properties, which allows them to separate naturally over time in vessels like settlers, decanters, and separators.

The “level” being measured is this boundary. Knowing its precise location is vital for several key reasons:

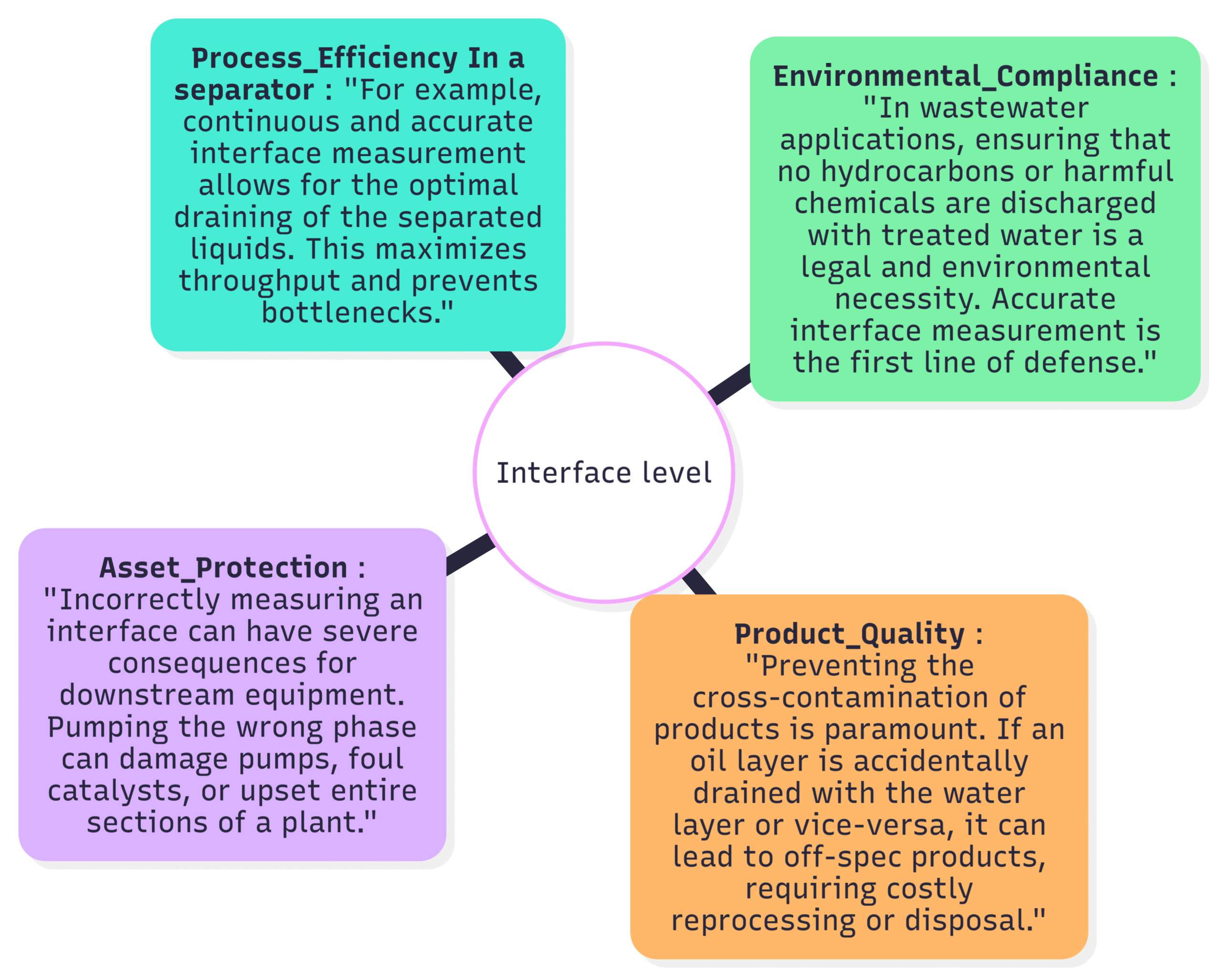

Process Efficiency: In a separator, for example, continuous and accurate interface measurement allows for the optimal draining of the separated liquids. This maximizes throughput and prevents bottlenecks.

Product Quality: Preventing the cross-contamination of products is paramount. If an oil layer is accidentally drained with the water layer (or vice-versa), it can lead to off-spec products, requiring costly reprocessing or disposal.

Asset Protection: Incorrectly measuring an interface can have severe consequences for downstream equipment. Pumping the wrong phase can damage pumps, foul catalysts, or upset entire sections of a plant.

Environmental Compliance: In wastewater applications, ensuring that no hydrocarbons or harmful chemicals are discharged with treated water is a legal and environmental necessity. Accurate interface measurement is the first line of defense.

Without reliable interface measurement, plants are forced to rely on manual sampling or operate with wide margins of error, leading to inefficiency, waste, and increased operational risk.

The Top 5 Challenges in Interface Level Measurement

While the goal is simple, the reality is fraught with challenges that can baffle even the most robust measurement technologies. Understanding these specific problems is the first step toward solving them.

Challenge 1: The Dreaded Emulsion Layer (Rag Layer)

By far the most common and difficult challenge is the presence of an emulsion layer, often called a “rag layer.” This is not a clean, sharp interface but a third, indistinct phase where the two liquids are partially mixed, often contaminated with solids, surfactants, and paraffins.

What it is: An emulsion is a stable mixture of liquids that are normally immiscible. In separators, this layer can vary in thickness from a few centimeters to several meters.

Why it’s a problem: Most level sensors are designed to find a distinct change in fluid properties. An emulsion presents a gradual change, creating a “ghost” or “smear” in the measurement signal. The sensor might read the top of the emulsion, the bottom, or an arbitrary point in the middle, leading to highly unreliable data.

The Impact: Poor rag layer management leads directly to inefficient separation. Valuable product can be lost in the waste stream, or contaminants can be carried forward, disrupting downstream processes.

Challenge 2: Similar or Varying Liquid Properties

Many measurement technologies rely on a significant difference between the physical properties of the two liquids. This creates two potential failure points:

Similar Properties: If the densities or dielectric constants of the two liquids are too close, technologies like displacers or capacitance probes cannot distinguish between them. The sensor effectively becomes “blind” to the interface.

Varying Properties: In many real-world applications, the properties of the liquids are not constant. Temperature and pressure fluctuations can alter density and dielectric values. Changes in feedstock or upstream processes can introduce new chemical compositions. When a sensor is calibrated for one set of properties, it will provide inaccurate readings as soon as those properties change.

Challenge 3: Extreme Process Conditions

Industrial processes rarely occur at room temperature and atmospheric pressure. Interface measurement must often be performed in environments that are hostile to instrumentation.

High Temperature and Pressure: These conditions place immense physical stress on sensor probes and seals. Electronics must often be mounted remotely to avoid failure. The choice of materials becomes critical to prevent corrosion and ensure mechanical integrity.

Corrosive and Abrasive Fluids: Highly acidic, caustic, or abrasive materials can quickly degrade and destroy sensor components that are in direct contact with the process fluids, leading to frequent and costly replacements.

Challenge 4: Buildup, Coatings, and Fouling

When liquids are sticky, viscous, or contain suspended solids, they can coat the surface of any instrument probe inserted into the vessel. This is a persistent issue for contact-based technologies.

How it happens: Paraffins in crude oil, sludge in wastewater, or polymerizing materials can adhere to probes.

The Impact: For a capacitance probe, a conductive coating can short-circuit the sensor, while any buildup will change the capacitance and cause a measurement error. For guided wave radar, a thick coating can weaken the signal to the point of being unusable. For displacers, buildup changes the effective weight and volume of the element, rendering Archimedes’ principle moot.

Challenge 5: Turbulence and Agitation

Processes involving mixing, agitation, or high-velocity fluid inlets create a chaotic environment for level measurement.

The Problem: A turbulent surface does not provide a clear target for non-contact technologies like radar or ultrasonic sensors, leading to scattered signals and fluctuating readings.

The Impact: For contact probes, the turbulence can cause mechanical vibration and stress. In all cases, the result is an unstable and unreliable measurement, making it difficult for control systems to maintain a steady state.

Choosing the Right Technology: A Deep Dive into Solutions

Overcoming these challenges requires matching the right measurement technology to the specific application. There is no one-size-fits-all solution. Here’s a breakdown of the leading technologies, their operational principles, and how they tackle these problems.

Guided Wave Radar (GWR)

Guided Wave Radar has become a dominant technology for interface measurement due to its versatility and accuracy in a wide range of applications.

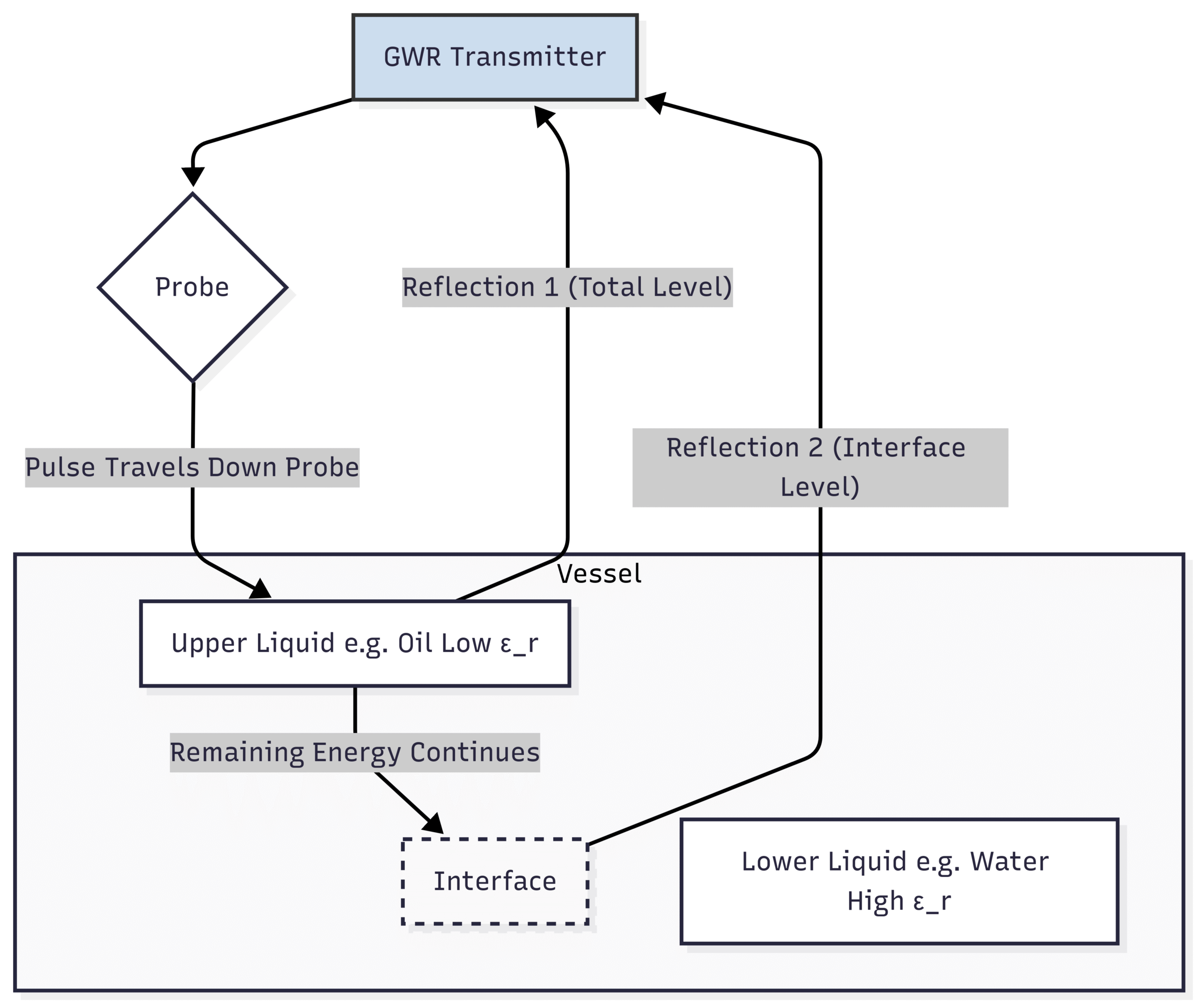

How it Works: A low-energy microwave pulse is sent down a rigid or flexible probe. A portion of this pulse reflects from the surface of the upper liquid (measuring the total level). The remaining energy continues through the upper liquid until it hits the interface with the lower liquid, which has a different dielectric constant (epsilon_r), causing a second reflection. The transmitter’s electronics analyze the time-of-flight for both reflections to determine the total level and the interface level.

Solving the Challenges:

Varying Properties: GWR is largely immune to changes in density, pressure, and temperature. The primary requirement is a difference in the dielectric constants of the two liquids.

Emulsion Layers: This is where advanced GWR shines. While a basic GWR might struggle, modern transmitters use sophisticated signal processing algorithms. They can analyze the entire echo profile, not just the strongest reflection. This allows them to distinguish the weak reflection from the true interface at the bottom of the emulsion layer, rather than being fooled by the noisy signal from the emulsion itself.

Turbulence: The probe acts as a guide, focusing the energy and making GWR far more resistant to turbulence than through-air radar.

Capacitance Probes – The Dielectric Differentiator

Capacitance technology is a proven and cost-effective solution for clean interface applications where the fluid properties are well-understood and stable.

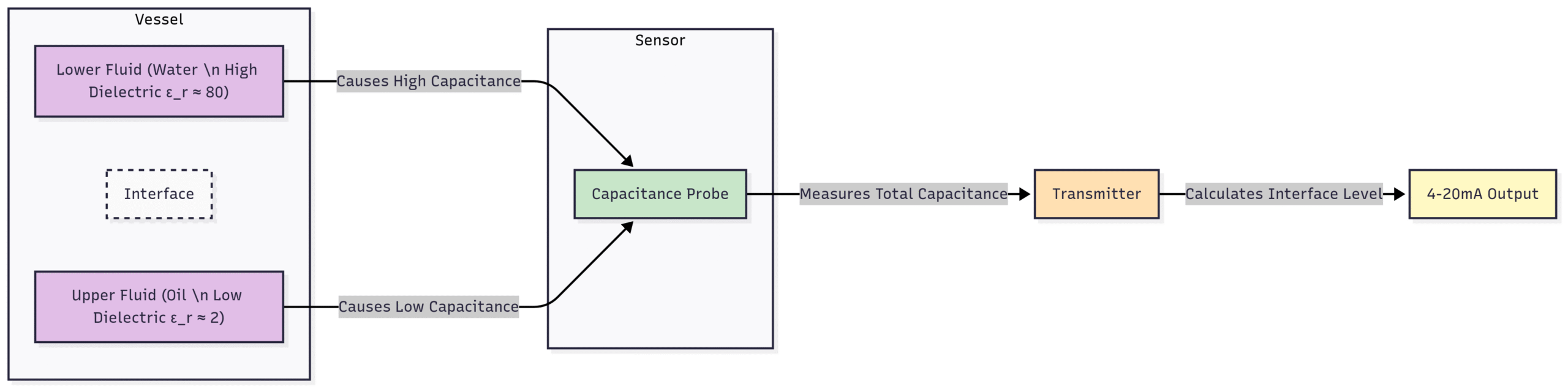

How it Works: The sensor’s probe and the vessel wall (or a second concentric probe) form a capacitor. The capacitance of this setup depends on the dielectric constant of the material between them. Since oil (epsilon_rapprox2−3) and water (epsilon_rapprox80) have vastly different dielectric constants, the total capacitance measured by the probe changes predictably as the oil-water interface moves up or down.

Solving the Challenges:

Ideal Applications: Best suited for applications with a large, stable difference in dielectric constants and no emulsion.

Weaknesses: Highly susceptible to buildup and coatings, as any foreign material on the probe will alter the capacitance and cause measurement errors. They are also easily confused by emulsion layers, which present a gradual change in dielectric constant rather than a sharp one.

Displacers and Servo Gauges – The Density Detectives

This technology is based on Archimedes’ principle of buoyancy and directly measures the buoyant force on an element suspended in the process fluids.

How it Works: A “displacer” element with a known weight and volume is hung from a sensor. As the interface level of two different density liquids rises and falls along the length of the displacer, the buoyant force changes. This change is measured by the sensor and correlated to a precise interface level.

Solving the Challenges:

Direct Measurement: It’s a direct measurement of the physical property (density) that causes the separation in the first place.

Weaknesses: Displacers have moving parts that can wear or become stuck. They are extremely sensitive to density changes in either fluid; if a fluid’s density changes, the entire calibration is thrown off. They are also notoriously poor at handling emulsion layers, as the emulsion’s “average” density provides a completely false reading of the interface position.

Nuclear / Gamma Radiometric – The Non-Contact Powerhouse

For the most difficult applications where no other technology will work, radiometric measurement provides a powerful, non-invasive solution.

How it Works: A low-strength gamma radiation source is mounted on one side of the vessel, and a highly sensitive detector is mounted on the opposite side. The gamma rays pass through the vessel and the process fluids. Because the upper and lower liquids have different densities, they absorb the radiation differently. The detector measures the strength of the radiation that passes through, and any change corresponds to a movement in the interface level.

Solving the Challenges:

Completely Non-Contact: The system is mounted entirely outside the vessel. It is completely unaffected by extreme temperatures/pressures, corrosive fluids, buildup, or turbulence inside.

Emulsion Layers: A key advantage is its ability to “profile” the vessel. By using a continuous detector or multiple detectors, it can accurately measure the thickness and position of all three layers (upper fluid, emulsion, and lower fluid) simultaneously, providing unparalleled insight into the separation process.

Considerations: The primary drawbacks are higher initial cost and the regulatory requirements and safety protocols associated with a nuclear source.

Advanced Strategies to Conquer Interface Challenges

Beyond selecting the right sensor, several strategic approaches can dramatically improve measurement reliability.

1. Smart Diagnostics and Signal Processing

Do not underestimate the power of the transmitter’s “brain.” Modern instruments, particularly GWR, incorporate powerful microprocessors that run sophisticated software.

Echo Profile Analysis: Instead of just looking for the biggest “blip,” these devices record the entire signal profile. Algorithms can then filter out false echoes from internal obstructions and, most importantly, identify the characteristic signal shapes of an emulsion versus a true liquid-liquid interface. This allows the device to ignore the emulsion and report the true interface level, a game-changer for separator control.

2. Proper Installation and Stilling Wells

How and where a sensor is installed is just as important as the sensor itself.

Stilling Wells: For applications with significant turbulence or internal agitation, installing the sensor inside a stilling well (or bypass chamber) is a highly effective solution. A stilling well is a pipe mounted parallel to the vessel, with connections at the top and bottom. The liquid inside the well is calm and free of turbulence, yet perfectly represents the level in the main tank, providing an ideal, stable environment for the measurement probe.

3. Meticulous Calibration

For any technology, proper calibration is non-negotiable. For interface applications, a “three-point calibration” is essential.

Step 1 (Lower Fluid): Calibrate the 0% point with the vessel filled only with the heavier, lower fluid.

Step 2 (Upper Fluid): Calibrate the 100% point with the vessel filled only with the lighter, upper fluid.

Step 3 (Known Interface): If possible, establish a known interface point to verify the linearity and accuracy of the sensor’s response between the two extremes.

This process ensures the instrument is precisely tuned to the specific properties of the liquids it will be measuring.

Conclusion: Turning a Challenge into a Competitive Advantage

Interface level measurement is undeniably complex. The presence of emulsion layers, fluctuating fluid properties, harsh process conditions, and turbulence can make reliable measurement seem like an impossible goal.

However, the solution lies in a methodical approach. By first thoroughly understanding the specific challenges of your application and then matching those challenges with the right technology, you can achieve accurate and repeatable control. Modern tools like Guided Wave Radar with advanced signal processing can solve the emulsion problem, while non-contact radiometric systems can handle the most extreme and difficult applications.

Ultimately, mastering interface level measurement is not just about solving an instrumentation problem. It’s about unlocking a higher level of process control, improving product quality, reducing waste, and enhancing operational safety. It’s about turning one of the toughest measurement challenges into a significant competitive advantage.