How PLCs Revolutionize Industrial Automation

In the heart of every modern factory, processing plant, or automated warehouse, there’s an unsung hero working tirelessly behind the scenes. This digital workhorse is the Programmable Logic Controller (PLC), the brain of industrial automation. While it might not have the futuristic glamour of a humanoid robot, the PLC is arguably the single most important innovation that has propelled industries into the 21st century. It’s the silent conductor of a complex orchestra of machines, sensors, and actuators, ensuring everything operates with precision, reliability, and unparalleled efficiency.

But what exactly is a PLC, and why has it become so utterly indispensable? Before the advent of PLCs, industrial control was a chaotic maze of electromechanical relays, timers, and counters. Every logical sequence was hardwired, making the system incredibly rigid, difficult to troubleshoot, and a nightmare to modify. A single change in the production process could mean days or even weeks of painstaking rewiring. The PLC changed everything by replacing this physical labyrinth with software-based logic.

This blog post will dive deep into the world of PLCs, exploring the transformative benefits they bring to industrial automation. We’ll uncover how these robust computers have slashed costs, boosted productivity, and enhanced safety across countless sectors. From their rugged design to their incredible flexibility, we will dissect the key advantages that have cemented the PLC’s status as a cornerstone of modern manufacturing and process control. We’ll also look at real-world applications and peek into the future of this foundational technology.

What is a Programmable Logic Controller (PLC)?

At its core, a Programmable Logic Controller (PLC) is a specialized industrial computer designed and built to withstand the harsh environments often found in manufacturing facilities. Unlike a standard desktop or laptop, a PLC is engineered to tolerate extreme temperatures, humidity, electrical noise, and vibrations. Its primary function is to automate industrial processes by continuously monitoring inputs from devices like sensors and switches, making decisions based on a custom program, and controlling output devices like motors, valves, and lights.

The logic inside a PLC is not hardwired. Instead, it’s programmed using specialized languages, with Ladder Logic being the most common due to its resemblance to the electrical relay diagrams it replaced. This programmability is the PLC’s superpower.

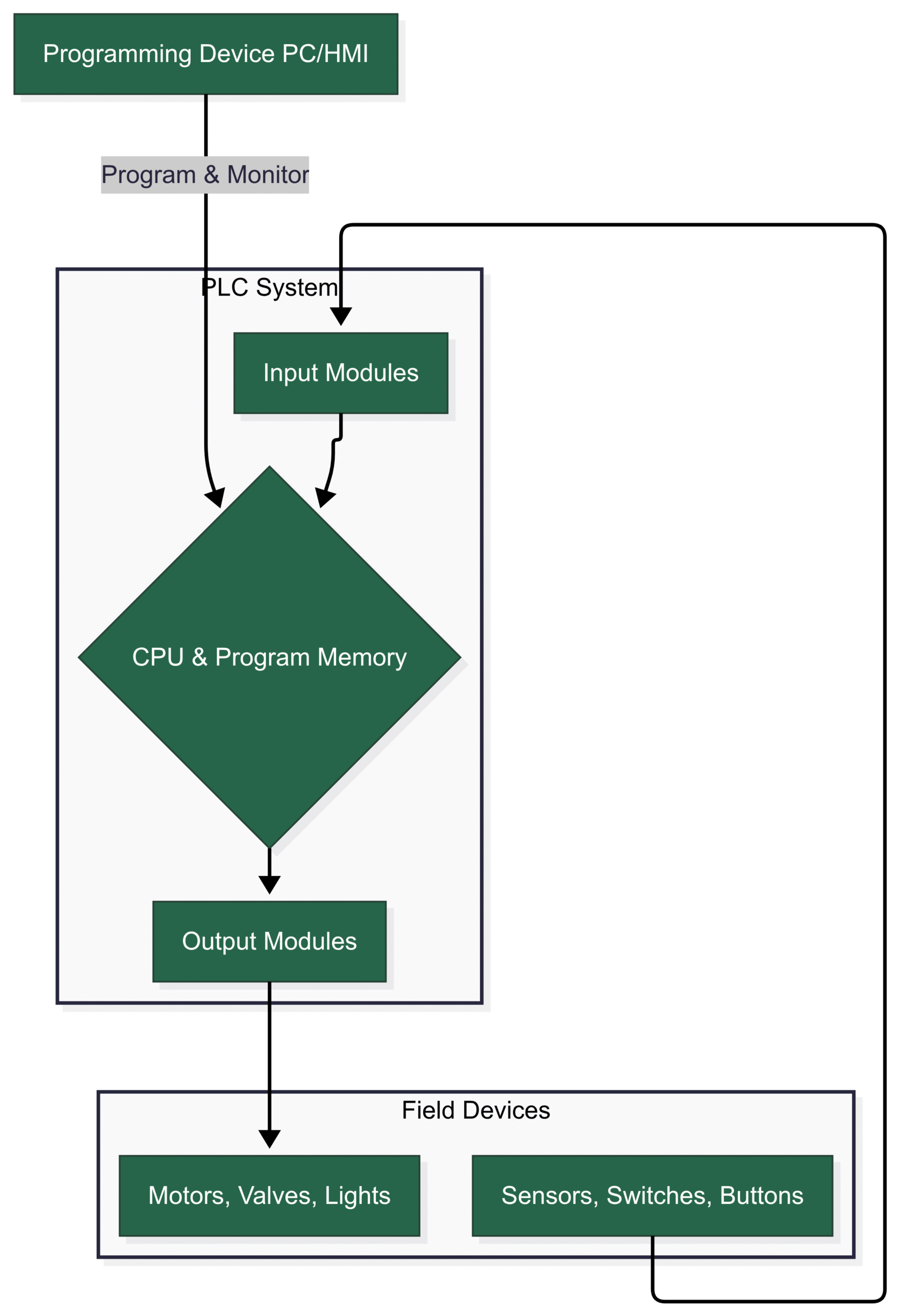

A typical PLC system consists of several key components:

Central Processing Unit (CPU): The brain of the PLC, which executes the control program, performs logical operations, and manages communication.

Input Modules: These modules connect the PLC to the outside world by receiving signals from input devices like buttons, sensors (e.g., proximity, temperature, pressure), and switches. They convert these real-world signals into digital data the CPU can understand.

Output Modules: These modules send control signals from the PLC to output devices (actuators) like motors, solenoids, relays, and indicator lights, turning them on or off as dictated by the program logic.

Power Supply: Provides the necessary electrical power to the CPU and the input/output modules.

Programming Device: A PC or a dedicated handheld device used to write, edit, and download the control program to the PLC’s memory.

Here’s a simplified view of how these components interact:

The operational cycle of a PLC, known as a scan cycle, is a continuous loop:

Input Scan: The PLC reads the status of all connected input devices.

Program Execution: The CPU executes the user-written program logic, instruction by instruction.

Output Scan: Based on the program’s results, the PLC updates the status of all connected output devices.

Housekeeping: The PLC performs internal diagnostics and communications tasks.

This cycle repeats thousands of times per second, allowing for near-instantaneous control over complex machinery.

1. Unmatched Reliability and Durability

The number one reason PLCs dominate the industrial landscape is their rock-solid reliability. Industrial environments are unforgiving. They are often hot, dusty, subject to constant vibrations, and plagued with electrical interference. A standard computer would fail within hours under such conditions.

PLCs, however, are purpose-built for this world. They are solid-state devices with no moving parts like hard drives or fans that can fail. Their internal components are selected for their resilience and are housed in rugged, protective enclosures. This robust design ensures they can operate continuously, 24/7, for years on end with minimal maintenance. This high Mean Time Between Failures (MTBF) is critical in industries where downtime can cost thousands or even millions of dollars per hour.

The shift from electromechanical relays to PLCs was a quantum leap in reliability. Relays, being mechanical devices, suffer from wear and tear. Their contacts can arc, stick, and eventually fail. Troubleshooting a complex relay panel was a detective story involving tracing wires through a dense, confusing web. A PLC replaces hundreds of these individual failure points with a single, highly reliable solid-state controller.

This diagram illustrates the simplification and consolidation of control hardware, which directly translates to increased system reliability. When a PLC does encounter an issue, its built-in diagnostics and status indicators make identifying the problem far simpler than hunting for a failed relay in a cabinet of hundreds.2. Incredible Flexibility and Reusability

Imagine you need to change a production sequence in a system controlled by relay logic. You’d have to halt production, call in electricians, and spend hours, if not days, physically rewiring the control panel. With a PLC, the same change can often be accomplished in minutes.

This flexibility is a game-changer. An engineer can simply connect a laptop to the PLC, modify the software logic, and upload the new program. The physical wiring remains untouched. This allows manufacturers to:

Adapt to Market Demands: Quickly change product lines or modify recipes without significant downtime or capital expense.

Improve Processes: Easily tweak timings, sequences, and parameters to optimize efficiency and product quality based on real-world performance data.

Prototype and Test: Develop and test new control strategies in a simulated environment before deploying them to the factory floor, minimizing risk.

Furthermore, PLC programs are reusable. The logic developed for one machine can be adapted and deployed on a similar machine elsewhere in the plant or even in a different factory. Modules of code for common tasks, like controlling a conveyor belt or a mixing tank, can be saved in libraries and reused across multiple projects. This “copy and paste” capability drastically reduces engineering and development time, saving immense costs and accelerating project timelines. This modular approach ensures consistency and reduces the chances of human error in programming from scratch.

3. Significant Cost-Effectiveness

While the initial purchase price of a PLC might be higher than the individual relays and timers it replaces for a very simple task, the overall cost-effectiveness becomes overwhelmingly clear as system complexity increases. The true savings are realized across the entire lifecycle of the system.

Here’s a breakdown of the cost savings:

Reduced Hardware Costs: A single PLC can replace hundreds of relays, timers, and counters. This not only saves on the cost of the components themselves but also reduces the size of the required control cabinets, saving valuable floor space.

Lower Installation Costs: Wiring a PLC system is far simpler and faster than wiring a relay-based panel. Instead of point-to-point wiring for every logical connection, you simply wire the I/O devices to the PLC’s input and output modules. The “control wiring” is all done in software. This reduces labor, material costs (less wire), and the potential for wiring errors.

Minimized Operational Costs: PLCs consume significantly less power than a large bank of energized relays. Over the life of the system, this energy saving can be substantial.

Reduced Downtime Costs: As mentioned, the reliability of PLCs and their advanced diagnostics mean less downtime. Troubleshooting is faster, getting the production line back up and running much more quickly. A technician can plug into the PLC and see exactly which sensor has failed or which part of the logic is holding up the process, rather than manually testing dozens of physical components.

Lower Modification Costs: The software-based nature of PLCs makes modifications cheap and fast compared to the labor-intensive process of rewiring hardwired panels.

When you factor in the entire Total Cost of Ownership (TCO)—including design, installation, operation, maintenance, and modification—the PLC is the undisputed economic champion for nearly all industrial automation applications.

4. Enhanced Scalability and Powerful Communication

Industrial needs are not static; they grow and evolve. A key benefit of PLCs is their inherent scalability. PLC systems are modular by design. If you need to add more sensors or control more motors as your production line expands, you don’t need to replace the entire system. You can simply add more I/O modules to the existing PLC rack or network additional PLCs together. This “pay-as-you-go” approach allows a control system to grow in lockstep with the facility it controls.

Beyond simple scalability, PLCs are powerful communication hubs. Modern PLCs are equipped with a wide array of communication protocols, such as Ethernet/IP, Profinet, Modbus, and more. This enables them to seamlessly integrate with other essential industrial systems.

This integration creates a cohesive, plant-wide automation ecosystem.

Human-Machine Interfaces (HMIs): These are the graphical touchscreens that allow operators to visualize the process, monitor machine status, adjust setpoints, and receive alarms. The PLC feeds real-time data to the HMI, providing an intuitive window into the automated process.

Supervisory Control and Data Acquisition (SCADA) Systems: For larger operations, SCADA systems collect data from multiple PLCs across the plant. This provides a high-level, centralized view of the entire facility, enabling managers to track production KPIs, analyze trends, and make informed business decisions.

Manufacturing Execution Systems (MES): PLCs can feed production data directly into MES platforms, which manage and track work orders, resource allocation, and product genealogy from raw materials to finished goods.

This powerful communication capability transforms the PLC from a simple machine controller into a vital data source for enterprise-level planning and optimization, paving the way for Smart Factory and Industry 4.0 initiatives.

5. Ease of Troubleshooting and Visual Diagnostics

When a machine on a production line stops, the clock starts ticking. Every second of downtime costs money. This is where the ease of troubleshooting with PLCs provides immense value.

Unlike the black box of a hardwired relay panel, a PLC offers a transparent view into its own operation. A technician can connect a laptop and use the programming software to monitor the program logic in real-time. This is often called “online monitoring.” The software visually highlights which contacts are open or closed, which timers are running, and what values are stored in counters and registers.

Visual Logic Flow: In Ladder Logic, the virtual “power” flow is shown on the screen. The technician can see exactly where the logic sequence is being interrupted. They can instantly tell if a specific input sensor isn’t activating or if a certain permissive condition hasn’t been met.

Forcing I/O: For testing purposes, a technician can “force” inputs or outputs on or off directly from the software. This allows them to test the logic or verify the functionality of an output device (like a solenoid) without needing the physical input to be present. For example, they can force an output to fire a valve to confirm the valve itself is working, isolating the problem to either the physical device or the control logic.

Built-in Diagnostics: PLCs continuously run self-diagnostics. They have indicator lights on the CPU and I/O modules that can immediately signal issues like a loss of power, a communication fault, a module failure, or a low battery. Error codes are generated that pinpoint the exact nature of the problem, drastically reducing the time spent on diagnosis.

This ability to “see” inside the machine’s brain turns troubleshooting from a guessing game into a methodical, efficient process, getting valuable equipment back online in a fraction of the time.

Real-World Applications Across Industries

The benefits of PLCs are not theoretical; they are proven daily in nearly every industrial sector imaginable.

Manufacturing: In automotive plants, PLCs control robotic welding and painting arms, manage conveyor systems that move car bodies through the assembly line, and conduct quality control checks with machine vision systems.

Food and Beverage: PLCs are crucial for batching and mixing processes, ensuring recipe accuracy and consistency. They control pasteurization temperatures, manage bottling and packaging lines, and oversee clean-in-place (CIP) systems to maintain hygiene.

Energy and Utilities: In power plants, PLCs manage boiler controls and safety interlocks. In water treatment facilities, they control pumps, valves, and chemical dosing systems to ensure safe and efficient water distribution.

Pharmaceuticals: Precision and documentation are paramount. PLCs control highly sensitive processes like pill manufacturing and packaging, while also logging data to comply with strict regulatory standards from bodies like the FDA.

Logistics and Warehousing: The massive automated sorting systems used by companies like Amazon and FedEx rely heavily on PLCs to read barcodes, divert packages, and track inventory in real-time.

The Future is Bright: PLCs and Industry 4.0

The role of the PLC is evolving. It’s no longer just a standalone controller but a key enabler of the Industrial Internet of Things (IIoT) and Industry 4.0. The future of PLCs is focused on even greater connectivity, intelligence, and security.

IIoT Integration: Newer PLCs are being designed with native support for protocols like MQTT and OPC UA, making it easier than ever to push data directly to cloud platforms for advanced analytics, machine learning, and predictive maintenance.

Enhanced Cybersecurity: As PLCs become more connected, securing them from cyber threats is a top priority. Manufacturers are building in more robust security features, such as user authentication, encrypted communications, and firmware integrity checks.

Edge Computing: More powerful PLC processors are allowing them to perform data processing and analysis at the “edge” (right at the machine level) instead of sending all raw data to the cloud. This reduces latency for critical decisions and lessens the load on the network.

Integrated Motion and Safety: Modern PLC platforms, often called Programmable Automation Controllers (PACs), are integrating advanced motion control for robotics and sophisticated safety functions into a single controller, simplifying machine design and programming.

Conclusion: The Indispensable Core of Modern Industry

The Programmable Logic Controller is more than just a piece of hardware; it’s the foundation upon which modern industrial efficiency is built. By replacing antiquated, inflexible relay panels with intelligent, software-based control, PLCs have delivered a powerful combination of reliability, flexibility, scalability, and cost-effectiveness. They have made our factories safer, our products better, and our industries more competitive.

From controlling a single machine to orchestrating an entire plant-wide network of automated systems, the PLC has proven to be one of the most resilient and adaptable technologies of the industrial age. As we move further into the era of Industry 4.0 and the IIoT, the PLC is not being replaced; it’s evolving. It’s becoming smarter, more connected, and more secure, cementing its role as the indispensable brain and central nervous system of industrial automation for decades to come. Any industry looking to modernize, optimize, and thrive in the competitive global market must start with this unseen, yet all-important, titan of technology.