Introduction

Thermal Mass Flow Meters (TMFMs), also known as thermal dispersion or thermal flow meters, are specialized instruments used primarily for the measurement of mass flow rates of gases. Unlike other flow meters that infer mass flow from volumetric flow and density, thermal mass flow meters measure the mass flow directly based on the principles of heat transfer.

These meters are widely used in industries such as oil & gas, chemical, semiconductor, HVAC, and biotech due to their high accuracy, no moving parts, low pressure drop, and ability to measure low flow rates.

Working Principle

Thermal Mass Flow Meters operate based on the principle of heat transfer between a heated element and the flowing gas. The amount of heat carried away by the gas is directly proportional to the mass flow rate.

There are two common types of thermal mass flow meters:

-

Capillary Tube Type (used for clean, low-flow gas applications)

-

Insertion or Inline Thermal Dispersion Type (used for industrial gas flow)

1. Capillary Tube Type (Used in Labs and OEMs)

Components:

-

Capillary tube (narrow tube through which gas flows)

-

Two temperature sensors

-

One heater (typically placed between the two sensors)

Working Mechanism:

-

A portion of the gas is diverted through a small capillary bypass tube.

-

A constant power heater is placed between two precision temperature sensors.

-

As gas flows through the tube, it absorbs heat from the heater and transfers it downstream.

-

The upstream sensor detects a drop in temperature, and the downstream sensor detects a rise in temperature.

-

The temperature differential between the sensors is directly proportional to the mass flow rate.

-

A feedback loop in the electronics keeps the temperature difference constant and calculates the mass flow from the power required.

This design provides very high accuracy and is commonly used for gas blending, leak testing, and analytical instruments.

2. Insertion / Inline Thermal Dispersion Type (Industrial Applications)

Components:

-

Flow probe or inline pipe section

-

Two temperature sensors (RTDs – Resistance Temperature Detectors)

-

One sensor is heated (active), the other remains at gas temperature (reference)

Working Mechanism:

-

One RTD (sensor) is self-heated, while the second one measures the ambient gas temperature.

-

As the gas flows across the probe, it removes heat from the heated sensor.

-

The rate of heat loss depends on the mass velocity of the gas.

-

The meter measures the power required to maintain a constant temperature difference (ΔT) between the two RTDs.

-

The greater the mass flow, the more power is required to maintain this temperature difference.

-

This power input is converted to a mass flow rate signal, typically in kg/hr, Nm³/hr, or SCFM.

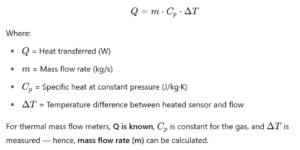

Heat Transfer Fundamentals

The fundamental equation governing heat loss is:

Key Features and Advantages

-

Direct mass flow measurement without pressure or temperature compensation

-

No moving parts – low maintenance

-

Ideal for low flow or leak detection

-

Good rangeability (typically 100:1)

-

Can measure very low velocity gases (as low as 0.1 m/s)

-

Available in insertion and in-line models

Limitations

-

Mostly suitable for clean, dry gases – dust, moisture, and corrosive gases may affect accuracy

-

Not ideal for liquids – due to different thermal conductivities and heat capacities

-

Gas composition dependency – calibration is gas-specific; changing gas type requires recalibration

-

Response time can be slower in larger pipe sizes or fluctuating flow conditions

Typical Applications

-

Air and Nitrogen flow in compressors and pneumatic systems

-

Natural Gas monitoring and consumption metering

-

Flare gas and vent gas flow measurement

-

HVAC – air handling systems

-

Process gas flow monitoring (e.g., Oxygen, Hydrogen, Argon)

Conclusion

Thermal Mass Flow Meters provide reliable, accurate, and direct mass flow measurement for gas applications without the need for additional temperature and pressure compensation. Their versatile design, low maintenance, and wide turndown ratio make them an ideal choice for a variety of industries, particularly where gas flow monitoring is critical.

When selecting a TMFM, it is important to consider the gas composition, operating pressure and temperature, and whether the application suits capillary or insertion style meters.