An Interactive Guide to NAMUR NE 43

Visualize and understand fault signaling in analog 4–20 mA loops.

Interactive Signal Simulator

12.00 mA

Normal Operation

Introduction

In process control, the 4–20 mA analog signal is a cornerstone for transmitting process variables. However, a key challenge is distinguishing between valid process signals and system failures. NAMUR NE 43 provides a standardized solution, using current values outside the normal 4–20 mA range to clearly indicate device faults.

1. What is NAMUR?

NAMUR is an international user association for automation technology in the process industries. Its recommendations (NE) standardize practices to ensure safety and interoperability. NE 43 specifically defines how analog transmitters should signal fault conditions, creating a universal language for device health.

5. NAMUR NE 43 Signal Ranges

| Signal Current | Meaning | Classification |

|---|---|---|

| < 3.6 mA | Device Fault (Low) | Error |

| 3.8–4.0 mA | Below Live Zero (under-range) | Alert |

| 4–20 mA | Normal Measurement Range | Valid |

| 20–20.5 mA | Above Range (over-range) | Alert |

| > 21.0 mA | Device Fault (High) | Error |

7. Key Benefits of NAMUR NE 43

Standardization

Ensures consistency across all manufacturers.

Enhanced Safety

Prevents misinterpretation of faults as process values.

Early Warning

Provides clear alerts for impending device failures.

Improved Diagnostics

Simplifies troubleshooting for technicians.

12. Common Misunderstandings

-

✗

Misconception: “Anything outside 4–20 mA is a process issue.”

-

✓

Clarification: Not always — it may be a device fault.

-

✗

Misconception: “3.5 mA is just a very low measurement.”

-

✓

Clarification: No, it’s a failure signal, not a valid process value.

15. Conclusion

NAMUR NE 43 is a vital standard that brings clarity and safety to analog signaling. By creating a universal method for fault detection, it empowers engineers and technicians to maintain safer, more reliable, and more efficient industrial processes.

Introduction

In the world of process instrumentation and control, the 4–20 mA analog signal remains one of the most widely used methods for transmitting process variables such as temperature, pressure, flow, and level. Despite the rise of digital communication protocols such as HART, Foundation Fieldbus, and Profibus, the 4–20 mA signal remains a backbone due to its simplicity, reliability, and compatibility with existing systems.

However, one challenge with traditional analog loops is how to detect and differentiate between process-related signals and system failures. This is where NAMUR NE 43, a recommendation developed by the NAMUR organization, plays a crucial role. It provides a standardized way to indicate device faults or failures using current values outside the normal 4–20 mA range.

This blog explores NAMUR NE 43 in depth, including its purpose, implementation, significance, and how it supports safety and reliability in industrial automation.

1. What is NAMUR?

NAMUR (originally a German acronym: Normenarbeitsgemeinschaft für Mess- und Regeltechnik in der Chemischen Industrie) is an international user association of automation technology in the process industries. Founded in 1949, NAMUR has developed numerous guidelines and recommendations (called NE – NAMUR Empfehlung) that standardize instrumentation and control practices across industries like oil & gas, chemical, and pharmaceuticals.

One such recommendation is NAMUR NE 43, which specifically addresses how analog transmitters should signal fault conditions.

2. Overview of the 4–20 mA Signal

The 4–20 mA current loop is a standard for transmitting analog signals over long distances in industrial applications. Key characteristics:

-

Live Zero (4 mA): Represents the lower limit of measurement. Not 0 mA, so that circuit integrity can be verified.

-

Span (4–20 mA): Corresponds to the measurement range.

-

Loop-powered Devices: Devices receive both power and signal over the same two wires.

-

Current over Voltage: Less susceptible to noise and resistance over long cable runs.

Despite its robustness, 4–20 mA cannot natively signal device health status or hardware malfunctions — which is why an additional layer, such as NAMUR NE 43, is beneficial.

3. The Need for Fault Signaling

Imagine a pressure transmitter in a refinery that suddenly starts sending 3.5 mA or 22 mA. Is this an abnormal process condition? A short circuit? A blown sensor? Without standardization, interpretation varies across vendors and control systems.

To address this ambiguity, there was a need to define a global, vendor-neutral framework for interpreting current values outside the 4–20 mA range. That’s the foundation of NAMUR NE 43.

4. Introduction to NAMUR NE 43

NAMUR NE 43, titled “Signal levels for the transmission of analog signals from measurement transmitters with digital electronics”, was introduced to define standardized current ranges that indicate normal operation, process limits, and fault conditions in analog 4–20 mA loops.

Its primary goals are:

-

Provide clear signal boundaries for diagnostics.

-

Ensure interoperability between field devices and control systems.

-

Improve plant safety and prevent downtime.

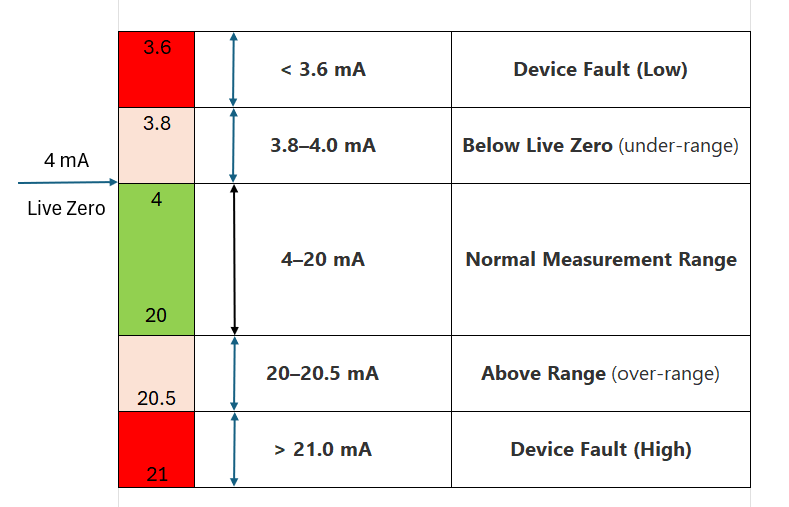

5. NAMUR NE 43 Specification and Signal Ranges

NAMUR NE 43 defines the following signal range categories:

| Signal Current | Meaning | Classification |

|---|---|---|

| < 3.6 mA | Device Fault (Low) | Out-of-range (Error) |

| 3.8–4.0 mA | Below Live Zero (under-range) | Valid but alert condition |

| 4–20 mA | Normal Measurement Range | Valid Signal |

| 20–20.5 mA | Above Range (over-range) | Valid but alert condition |

| > 21.0 mA | Device Fault (High) | Out-of-range (Error) |

6. Fault Conditions and Indication Strategy

Common fault conditions detected using NE 43 include:

-

Sensor failure

-

Internal electronics malfunction

-

Open loop or short circuit

-

Power supply problems

-

Configuration errors

How it works:

-

Instead of the signal simply “dropping to zero” or going undefined, the transmitter forces the current to predefined fault levels.

-

The control system, configured to recognize NE 43 thresholds, triggers alarms or safety actions.

This is especially useful in SIL (Safety Integrity Level) applications, where prompt detection of device faults is critical.

7. Benefits of NAMUR NE 43

-

Standardization across all manufacturers

-

Ensures compatibility with DCS, PLC, SIS, and ESD systems

-

Early warning for impending device failures

-

Enhances safety and availability

-

Prevents nuisance trips caused by false interpretations

-

Supports predictive maintenance

8. NAMUR NE 43 vs Other Standards

| Aspect | NAMUR NE 43 | NE 44 | HART Diagnostic |

|---|---|---|---|

| Focus | Analog 4–20 mA fault signaling | Signal on/off state | Digital diagnostics |

| Signal type | Analog only | Binary | Hybrid (Analog + Digital) |

| Industry Acceptance | Very High | Limited | High, where HART is used |

| Diagnostic Detail | Basic | Binary (on/off) | Detailed |

NE 43 is often combined with HART protocol to add digital layer diagnostics while retaining analog fault signaling.

9. Practical Implementation in Field Instruments

Modern transmitters allow NE 43 configuration via handheld communicators or software tools.

Example (for a temperature transmitter):

-

Configure NE 43 limits: e.g., <3.6 mA for sensor burnout

-

Set action on error: Go to 3.5 mA on sensor open circuit

-

Integrate with control system: Configure alarm at 3.6 mA threshold

10. Use Cases and Industry Applications

Industries where NE 43 is commonly used:

-

Oil & Gas: Shutdown systems, pipeline monitoring

-

Chemical: Reactor temperature control

-

Pharmaceutical: Cleanroom HVAC alarms

-

Power Generation: Boiler safety instrumentation

-

Water Treatment: Pump level safety interlocks

In all these, reliable fault detection using analog signals is vital to prevent damage, downtime, or accidents.

11. Configuration in DCS/PLC/ESD Systems

DCS/PLC:

-

Input modules are configured to recognize 3.6 mA or 21 mA as fault

Alarm logic can trigger local and remote indicators

ESD/SIS:

-

Often used in combination with SIL-rated transmitters

-

NE 43 faults can be treated as safe shutdown conditions

12. Common Misunderstandings

| Misconception | Clarification |

|---|---|

| “Anything outside 4–20 mA is a process issue” | Not always — it may be a device fault |

| “3.5 mA is normal during low measurement” | No, it’s a failure signal, not a valid process value |

| “Fault levels are fixed” | They can be configured in some instruments |

Always check the device manual and ensure the control system understands the same NE 43 levels.

13. Troubleshooting and Diagnostics

When you see signals like 3.5 mA or 22 mA:

-

Check transmitter diagnostics (using HART or DTM tools)

-

Verify loop integrity (wiring, grounding)

-

Inspect sensor condition

-

Cross-check device documentation for error code meaning

NE 43 simplifies troubleshooting by offering unambiguous signal references.

14. Future Outlook: NE 43 in the Era of Smart Instruments

While digital protocols like HART, Profibus, and Ethernet-APL are becoming widespread, NAMUR NE 43 remains relevant because:

-

Many plants still use legacy 4–20 mA systems

NE 43 can coexist with HART and WirelessHART

-

It provides a quick diagnostic method for technicians without requiring specialized tools

Even in smart plants, NE 43 forms a first-line indication of health before deep digital diagnostics.

15. Conclusion

NAMUR NE 43 has become a crucial standard in the instrumentation field, enabling consistent, reliable, and safe interpretation of analog signals — especially when it comes to fault detection.

Its ability to distinguish between process conditions and device failures has made it indispensable for engineers designing or maintaining analog loops in process industries.

By following NE 43, industries can reduce downtime, improve safety, and increase diagnostic efficiency — all while using a signal standard that has stood the test of time.

Final Words

If you’re an instrumentation engineer, control system designer, or maintenance technician, understanding and applying NAMUR NE 43 should be part of your fundamental skillset. As industries evolve, the combination of analog and digital diagnostics — starting with standards like NE 43 — will continue to define the next generation of intelligent automation.