A functional safety engineering certificate is a professional credential that validates an engineer’s expertise in designing and managing systems that prevent harm to people, property, and the environment. For a working engineer, obtaining this certificate involves choosing a certification body (like TÜV or exida), completing a required training course on standards like IEC 61508 or ISO 26262, and passing a rigorous exam. The preparation requires dedicated study of these complex standards and practical application principles. It is absolutely worth getting for engineers in industries like automotive, oil and gas, and automation, as it significantly enhances career prospects, increases earning potential, and demonstrates a high level of competence in a critical engineering discipline.

What is Functional Safety Engineering? A Deep Dive 🛡️

In our increasingly automated world, from the cars we drive to the plants that power our cities, ensuring systems operate safely is not just a priority—it’s an absolute necessity. This is the core domain of functional safety engineering. But what does that term actually mean?

Functional safety is the part of the overall safety of a system or piece of equipment that depends on it operating correctly in response to its inputs. It’s about preventing unacceptable risk due to hazards caused by the malfunctional behavior of electrical, electronic, or programmable electronic (E/E/PE) systems. Think about the anti-lock braking system (ABS) in your car. If the sensors, control unit, or actuators fail, the result could be catastrophic. Functional safety engineering is the discipline that applies engineering principles, processes, and techniques to design these systems so that they predictably fail into a safe state or operate safely even when a fault occurs.

The entire field is built upon a foundation of internationally recognized standards. These standards provide a framework and a set of rigorous requirements for the entire safety lifecycle of a product, from initial concept to decommissioning. The two most foundational standards are:

IEC 61508: Titled “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems,” this is the “umbrella” or basic standard for functional safety. It’s industry-independent and sets out the principles for other industry-specific standards. It introduces key concepts like Safety Integrity Levels (SIL) and defines the required processes for managing, developing, and operating safety-critical systems.

ISO 26262: A derivative of IEC 61508, this standard is specifically for “Road Vehicles – Functional Safety.” With the explosion of complex electronics in modern cars—from advanced driver-assistance systems (ADAS) to autonomous driving features—ISO 26262 has become indispensable for automotive engineers. It introduces concepts like Automotive Safety Integrity Levels (ASIL) to classify the risk associated with potential hazards.

Other industry-specific standards include IEC 61511 for the process industry (oil & gas, chemicals), IEC 62061 for machinery, and EN 50128/50129 for railway applications.

Functional safety isn’t just about adding a redundant sensor or a backup controller. It’s a holistic, systematic approach that permeates the entire engineering lifecycle. It involves:

Hazard and Risk Assessment (HARA): Identifying potential hazards and evaluating the associated risks.

Defining Safety Goals: Specifying what the system must do to be considered safe.

Deriving Safety Requirements: Translating safety goals into concrete, verifiable technical requirements.

System Design and Development: Creating hardware and software architectures that are fault-tolerant and robust.

Verification and Validation: Rigorous testing, analysis, and reviews to ensure the system meets its safety requirements.

Operation and Maintenance: Ensuring the system remains safe throughout its operational life.

A functional safety engineer is the professional who navigates this complex lifecycle, ensuring that every step is executed with precision and adherence to the relevant standards. They are the guardians against systematic failures (flaws in design or process) and random hardware failures that could lead to disaster.

Why is a Functional Safety Certificate Important for Working Engineers? 🚀

In a competitive job market, continuous professional development is key. For engineers in safety-critical domains, a functional safety certificate is more than just another line on a resume; it’s a powerful statement of competence, credibility, and commitment. Here’s why it’s a game-changer for a working engineer.

1. Unmatched Credibility and Trust

A certificate from a reputable body like TÜV Rheinland, TÜV SÜD, or exida acts as an independent, third-party validation of your skills. It tells your employer, clients, and colleagues that your understanding of functional safety isn’t just theoretical—it has been tested and verified against international standards. When you are responsible for designing systems that protect human lives, this level of trust is invaluable. It demonstrates a commitment to the highest standards of engineering practice.

2. Significant Career Advancement and Opportunities

Holding a functional safety certification unlocks doors. Many companies, particularly in the automotive, aerospace, process, and automation industries, now list functional safety certification as a preferred or even mandatory qualification for senior roles. Positions like Functional Safety Manager, Safety Architect, or Senior Systems Safety Engineer often require this credential. It can be the deciding factor that sets you apart from other candidates, fast-tracking your progression from a general engineering role to a specialized, high-demand position.

3. Increased Earning Potential 💰

Specialization pays. Functional safety is a niche, yet critically important, field. The demand for qualified and certified engineers often outstrips the supply, leading to higher salaries. A certified engineer brings verifiable expertise that reduces project risk and potential liability for the company. This value is directly reflected in compensation packages. Investing in a certificate often yields a significant return in the form of a higher salary and better bonuses.

4. Deeper, Structured Knowledge

Even experienced engineers can have knowledge gaps. The structured curriculum of a certification training program forces you to go beyond your day-to-day tasks and learn the entire safety lifecycle in a systematic way. You’ll dive deep into the nuances of the standards, learn the “why” behind the processes you may already be following, and gain a holistic perspective. This comprehensive understanding makes you a more effective and confident engineer. You’ll be better equipped to make critical design decisions, justify them based on the standard, and lead safety-related discussions with authority.

5. Enhanced Project and Company Value

For your employer, having certified engineers on staff is a major asset. It:

Reduces Project Risk: Certified engineers are less likely to make costly errors in design or implementation.

Ensures Compliance: It demonstrates due diligence and compliance with international standards, which is crucial during audits and assessments.

Boosts Client Confidence: When bidding for projects, especially in regulated industries, being able to showcase a team of certified functional safety experts is a powerful competitive advantage.

Fosters a Safety Culture: Having certified experts on the team helps disseminate best practices and elevates the entire organization’s commitment to safety.

In short, a functional safety certificate transforms you from someone who simply works in a safety-related field into a recognized expert in functional safety. It’s an investment in yourself that pays dividends throughout your career.

How to Get a Functional Safety Certificate: A Step-by-Step Guide 🗺️

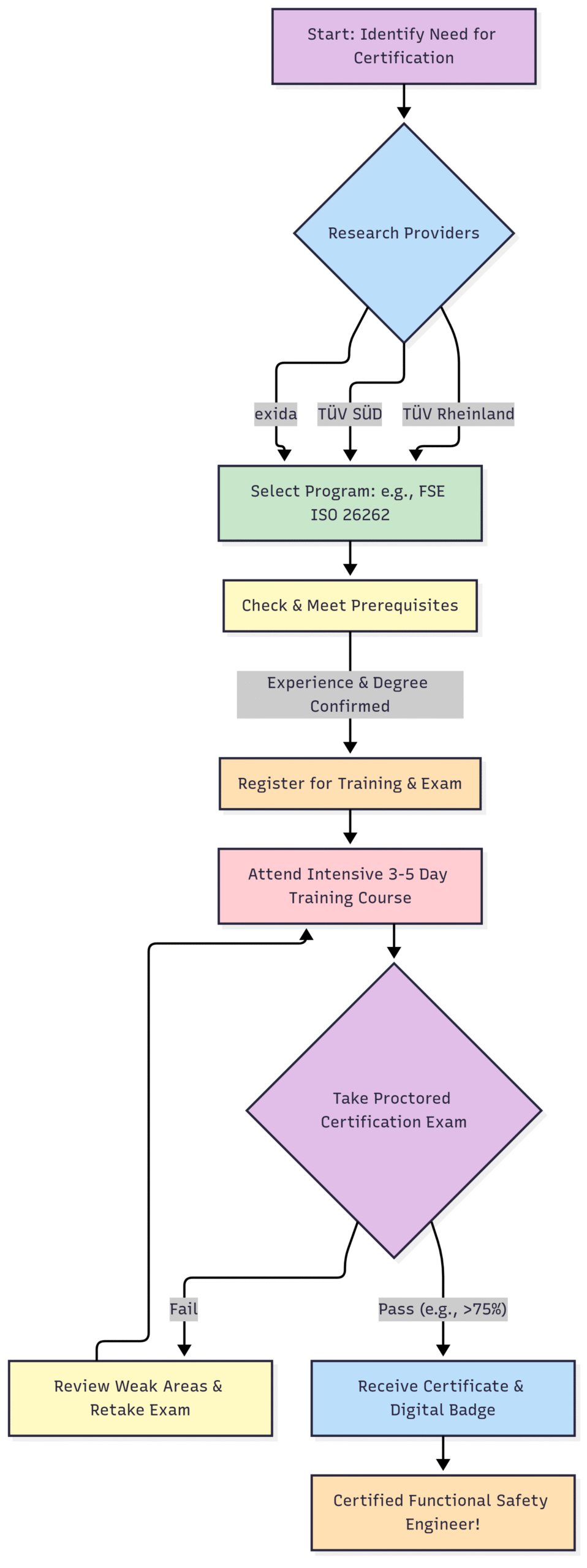

Navigating the path to certification can seem daunting, but it’s a well-defined process. The journey involves research, training, and an exam. Here’s a clear, step-by-step guide to earning your functional safety credential.

Step 1: Research and Select the Right Certification Program

Not all certifications are created equal. Your first step is to choose the program that aligns with your industry and career goals. The main players in this space are globally recognized Technical Inspection Associations (TÜVs) and other specialized safety organizations.

Key Providers:

TÜV Rheinland: Offers the highly respected Functional Safety Engineer (FSE) program, with specializations for different standards like IEC 61508, ISO 26262, etc. Their “FSE (TÜV Rheinland)” credential is one of the most recognized in the world.

TÜV SÜD: Provides a similar range of training and certification programs, also highly regarded, particularly in the European automotive and industrial automation sectors.

exida: A major player founded by former TÜV experts, exida offers the Certified Functional Safety Expert (CFSE) and Certified Functional Safety Professional (CFSP) programs. These are also globally recognized and highly respected.

Key Considerations:

Industry Focus: Are you in automotive (ISO 26262), process industry (IEC 61511), or general systems (IEC 61508)? Choose a program that specializes in the standard most relevant to your work.

Prerequisites: Check the eligibility criteria. Most programs require a certain number of years of professional experience in a related field (typically 2-6 years). Some may also require an engineering degree.

Cost and Location: Training and certification can cost several thousand dollars. Compare prices and consider whether the training is offered online, in-person, or in a hybrid format that suits your schedule.

Step 2: Fulfill Prerequisites and Register

Once you’ve chosen a provider and program, carefully review the prerequisites. You’ll likely need to submit a resume or a detailed application outlining your engineering degree, work history, and specific project experience related to functional safety. This is to ensure that candidates have the foundational knowledge necessary to benefit from the training and succeed in the exam. After your eligibility is confirmed, you can formally register for a training and exam session.

Step 3: Attend the Mandatory Training Course

This is the core of the certification process. These training courses are typically intensive, lasting 3 to 5 full days. They are led by experienced functional safety experts who break down the complex standards into understandable modules. The training will cover:

The philosophy and principles of functional safety.

Detailed walkthroughs of the relevant standard (e.g., ISO 26262).

The safety lifecycle from concept to decommissioning.

Key techniques like Hazard Analysis and Risk Assessment (HARA), Failure Modes and Effects Analysis (FMEA), and Fault Tree Analysis (FTA).

Concepts like SIL/ASIL determination and decomposition.

Requirements for hardware and software development.

Practical examples and workshops.

Pay close attention and ask questions! This training is not just a formality; it’s your primary preparation for the exam.

Step 4: Take and Pass the Certification Exam

The exam is usually held on the last day of the training or shortly after. It’s a rigorous test of your knowledge.

Format: Typically a multiple-choice exam, but it can include short answer or calculation-based questions. It’s almost always a closed-book exam, though you might be allowed to use a clean, unmarked copy of the standard itself.

Content: The questions are designed to test not just rote memorization but your ability to apply the concepts of the standard to practical scenarios. You’ll be tested on definitions, processes, responsibilities, and calculations.

Passing Score: The required passing grade is usually high, often around 75%.

Below is a diagram illustrating the typical journey to certification.

Upon passing the exam, you’ll receive your official certificate, a unique ID number, and often a listing on the provider’s public database of certified professionals. This credential is typically valid for a certain number of years, after which you may need to demonstrate continuing competence to renew it.

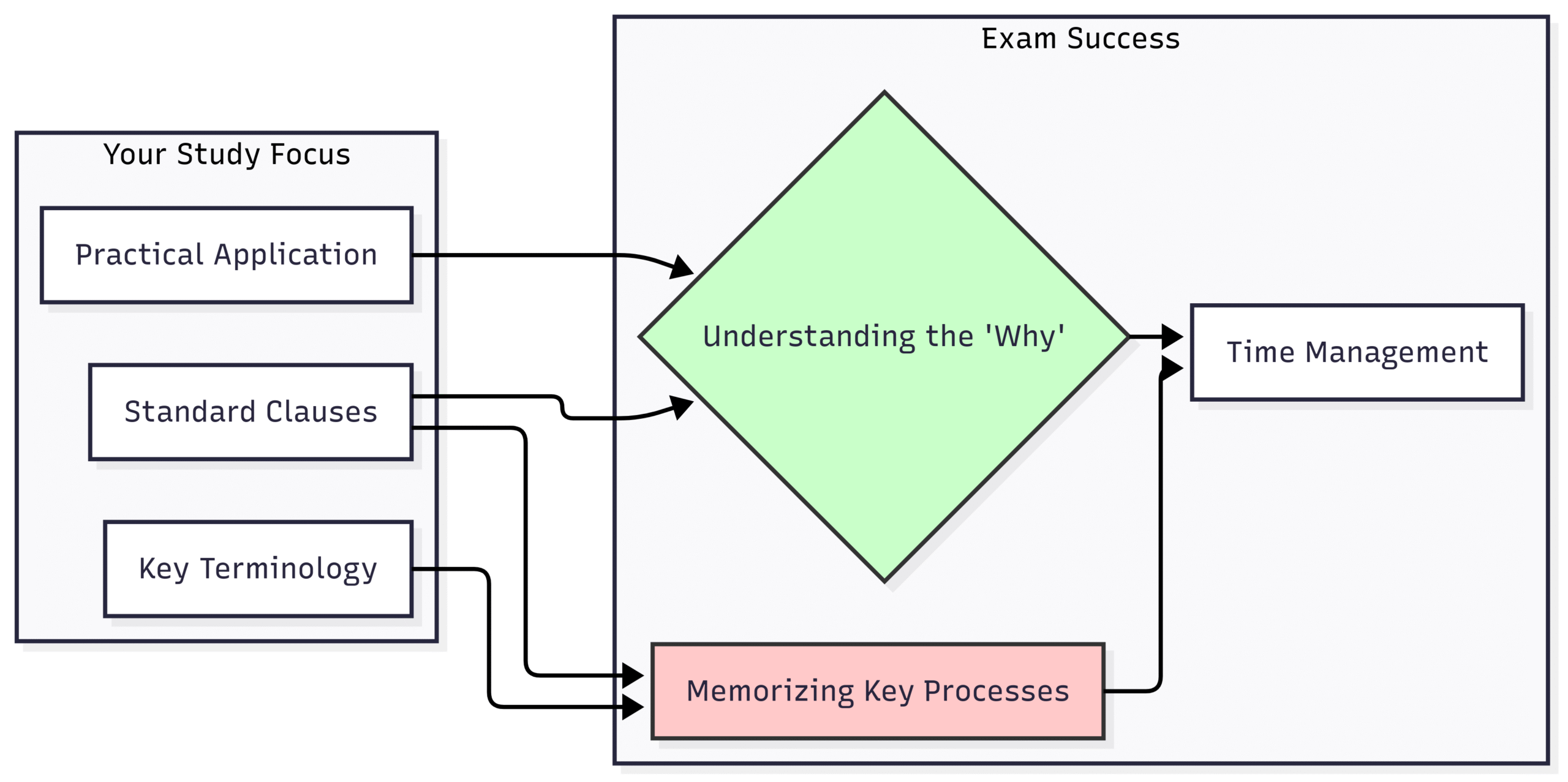

Preparing for the Certification Exam: A Strategy for Success 📚

Passing the functional safety certification exam requires more than just attending the training. It demands dedicated preparation and a strategic approach to studying. The standards are dense, and the exam questions are designed to be tricky. Here’s how to build a solid preparation plan.

1. Pre-Study is Non-Negotiable

Do not walk into the training course cold. The training is fast-paced and assumes a baseline familiarity with engineering concepts. To get the most out of it, you need to do your homework.

Get a Copy of the Standard: Your first and most important step is to purchase and read the relevant standard (e.g., ISO 26262, IEC 61508). Don’t just skim it. Read it cover-to-cover at least once before the training. It will be dense and difficult at first, but this initial pass will familiarize you with the structure, terminology, and key clauses.

Focus on Key Concepts: During your pre-study, pay special attention to foundational concepts:

The V-model for development.

The overall safety lifecycle and its phases.

Definitions: Hazard, Risk, Fault, Error, Failure, Safe State.

The concepts of SIL (Safety Integrity Level) or ASIL (Automotive Safety Integrity Level).

Systematic vs. Random Hardware Failures.

2. Maximize the Training Week

The training course is your single best resource. Treat it like a full-immersion boot camp.

Engage Actively: Don’t be a passive listener. Ask clarifying questions. Participate in the workshops and group discussions. The trainers are experts with real-world experience; tap into their knowledge.

Take Meticulous Notes: Don’t just rely on the provided slides. Annotate them with the trainer’s explanations, examples, and clarifications. If a trainer emphasizes a particular point or says, “This is a common exam topic,” highlight it immediately.

Network with Peers: You are in a room with other engineers facing the same challenge. Discuss difficult concepts during breaks. Explaining a concept to someone else is one of the best ways to solidify your own understanding.

3. Post-Training Consolidation

The real studying happens in the evenings during the training week and in any gap between the training and the exam.

Daily Review: Each evening, spend at least 1-2 hours reviewing the material covered that day. Reread your notes and the corresponding sections of the standard. This repetition is crucial for moving information from short-term to long-term memory.

Practice Questions: If the training provider offers sample questions or mock exams, they are pure gold. Do them under exam-like conditions. This helps you get a feel for the question style, the level of detail required, and how to manage your time.

Focus on Application: The exam isn’t just about definitions. It’s about applying the standard. For any given clause, ask yourself:

Who is responsible for this? (e.g., Safety Manager, Designer, Tester)

What is the required input for this activity?

What is the required output (work product)?

How is this activity confirmed or verified?

The diagram below shows the key relationships between your study efforts and the core components of the standard.

4. Exam Day Strategy

Read Carefully: Read every question and all the options twice before answering. The questions are often worded to catch you out. Look for keywords like “MUST,” “SHALL,” “SHOULD,” “ALWAYS,” or “NEVER.”

Eliminate Wrong Answers: For multiple-choice questions, the process of elimination is your best friend. Even if you aren’t sure of the right answer, you can often identify two or three that are clearly wrong.

Manage Your Time: Don’t get bogged down on a single difficult question. If you’re stuck, make your best guess, flag the question, and move on. You can come back to it later if you have time. It’s better to answer all the questions you know than to run out of time on a few hard ones.

Trust Your Training: You have put in the work. Stay calm, be confident, and apply the knowledge you’ve spent weeks mastering.

By following this structured preparation strategy, you will transform the challenging certification exam from a daunting obstacle into a manageable and achievable goal.

Is a Functional Safety Certificate Worth It? The Verdict ✅

After considering the definition, the process, and the preparation involved, we arrive at the ultimate question: for a working engineer, is investing the time, effort, and money in a functional safety certificate truly worth it?

The short answer is an emphatic yes. For any engineer working on or aspiring to work on safety-critical systems, a functional safety certificate is one of the most valuable professional development investments you can make. Let’s break down the return on investment (ROI).

The Investment

Time: You’ll need to dedicate significant time. This includes several days for the training itself, plus dozens of hours for pre-study and post-training review. For a busy working professional, this is a substantial commitment.

Money: The costs are not trivial. A reputable training and certification package from a provider like TÜV or exida can range from $4,000 to $7,000 USD or more, depending on the program and location. This doesn’t include potential travel and accommodation costs.

Effort: The material is complex and dense. The preparation is mentally taxing, and the exam is designed to be challenging. It requires genuine intellectual effort and discipline.

The Return

Tangible Returns:

Higher Salary: This is the most direct financial return. Certified engineers are specialists in a high-demand field. Data consistently shows that certified professionals command higher salaries than their non-certified peers, often by a margin that allows them to recoup the cost of the certificate within one to two years.

Access to Better Jobs: The certificate is a key that unlocks senior-level and specialized roles that are simply unavailable to non-certified candidates. Positions like Functional Safety Manager, a natural career progression, almost universally require certification.

Job Security: As automation and complexity in systems increase, the need for functional safety experts will only grow. This certification makes you a more valuable and indispensable asset to any technology company, enhancing your job security in a turbulent economy.

Intangible Returns:

Professional Credibility: The certificate is an objective, globally recognized benchmark of your expertise. It instantly establishes your authority in any technical discussion, meeting, or interview related to safety.

Confidence: The deep, structured knowledge gained through the certification process gives you a profound confidence in your own abilities. You will be better equipped to make critical decisions, defend your design choices, and mentor junior engineers, knowing your actions are grounded in international best practices.

A Safety Mindset: Perhaps the most valuable return is the internalization of a “safety culture” mindset. You learn to think systematically about risk and failure, a skill that transcends your specific role and makes you a better, more responsible engineer in all aspects of your work.

The Final Verdict

Think of a functional safety certificate not as an expense, but as an investment in your professional capital. In industries where a single failure can have catastrophic consequences—a malfunctioning airbag, a chemical plant overflow, a railway signal failure—companies are not just looking for engineers; they are looking for verifiable guardians of safety.

While the upfront cost and effort are significant, the long-term benefits to your career trajectory, earning potential, and professional standing are overwhelming. It is the definitive way to signal to the industry that you are a serious, dedicated, and highly competent professional in the critical field of safety engineering. If your career path touches any system where failure is not an option, getting your functional safety certificate isn’t just worth it—it’s essential.