ICCS Network Level 3: Site Manufacturing Operations & Control

In the complex architecture of modern industrial automation, every layer plays a crucial role. The Industrial Control and Communication System (ICCS) framework, often aligned with the ISA-95 standard, provides a blueprint for this intricate structure. While the plant floor buzzes with machinery (Levels 0 & 1) and area supervisors monitor specific processes (Level 2), it’s at Level 3: Site Manufacturing Operations & Control where the magic of orchestrating production truly happens. This is the supervisory level that transforms business objectives into tangible manufacturing activities.

Level 3 is the brain of the factory floor. It manages the detailed workflow of production, ensuring that raw materials are converted into finished goods efficiently, consistently, and in compliance with quality standards. It’s the critical link between the corporate business systems (Level 4) and the real-time control systems on the plant floor (Levels 0-2). The key players at this level are Manufacturing Execution Systems (MES), batch management systems, and data historians. These systems work in concert to collect, manage, and execute the detailed information required for minute-by-minute, hour-by-hour production.

This in-depth guide will explore the components, functions, and immense significance of Level 3. We will dissect how MES, batch management, and data historians form the backbone of modern manufacturing, enabling agility, quality, and operational excellence.

The Heart of Production: Manufacturing Execution Systems (MES)

A Manufacturing Execution System (MES) is the central nervous system of Level 3. It’s a comprehensive, dynamic software system that monitors, tracks, documents, and controls the entire process of manufacturing goods from raw materials to finished products. While the Enterprise Resource Planning (ERP) system at Level 4 knows why something needs to be made (customer orders, sales forecasts), the MES knows how to get it done on the factory floor.

The MES provides a layer of real-time visibility and control that is simply not possible with an ERP alone. It closes the loop between planning and execution, providing a granular view of operations that enables rapid decision-making and problem-solving.

Core Functions of an MES

An effective MES encompasses a wide range of functions that can be grouped into several key areas. These functions ensure that production plans are executed precisely and efficiently.

Production Scheduling & Dispatching: The MES takes high-level production orders from the ERP and breaks them down into detailed, machine-specific schedules. It considers resource availability (machines, labor, materials), production constraints, and priorities to create an optimal plan. This detailed schedule is then dispatched to the relevant work centers on the plant floor.

Resource Management & Allocation: This function manages all the resources required for production, including machines, tools, labor, and materials. The MES ensures that the right resources are available at the right time and place, preventing bottlenecks and downtime. It tracks the status and performance of these resources in real time.

Data Collection & Acquisition: The MES is a primary hub for data. It automatically collects data from PLCs, SCADA systems, and sensors at Level 2, as well as manual data entered by operators. This includes production counts, cycle times, machine downtime, and quality measurements.

Quality Management: Integrated quality control is a cornerstone of MES. It enforces quality checks at various stages of the production process, manages non-conformance, and tracks quality data. By embedding quality procedures within the workflow, it helps identify and contain issues before they escalate, ensuring products meet specifications.

Process Management & Control: The MES guides operators through the production process, providing step-by-step instructions, recipes, and standard operating procedures (SOPs). It ensures that the correct process steps are followed in the right sequence, which is critical for consistency and regulatory compliance.

Performance Analysis & OEE: The MES is an invaluable tool for performance monitoring. It calculates key performance indicators (KPIs) like Overall Equipment Effectiveness (OEE), which measures availability, performance, and quality. This analysis helps identify areas for improvement and drives continuous improvement initiatives.

Product Tracking & Genealogy (Traceability): From the moment raw materials enter the plant until a finished product is shipped, the MES tracks every component and process step. This creates a detailed product genealogy or traceability record. This is indispensable for regulatory compliance (e.g., in food & beverage or pharmaceuticals) and for managing recalls efficiently.

Document Control: The MES manages and distributes all necessary production documents, such as work instructions, recipes, drawings, and SOPs. It ensures that operators always have access to the latest approved versions, eliminating errors caused by outdated information.

Below is a diagram illustrating how these core functions interact within the MES environment, bridging the gap between the ERP and the plant floor.

By executing these functions, the MES transforms a manufacturing facility from a reactive environment to a proactive, data-driven operation. It provides the single source of truth for the shop floor, empowering everyone from operators to plant managers with the information they need to perform their jobs effectively.

Precision and Consistency: The Role of Batch Management

In many industries, such as pharmaceuticals, chemicals, food and beverage, and consumer packaged goods, production doesn’t happen in a continuous stream. Instead, products are made in discrete quantities called batches or lots. In these environments, a specialized Batch Management System is a critical component of Level 3.

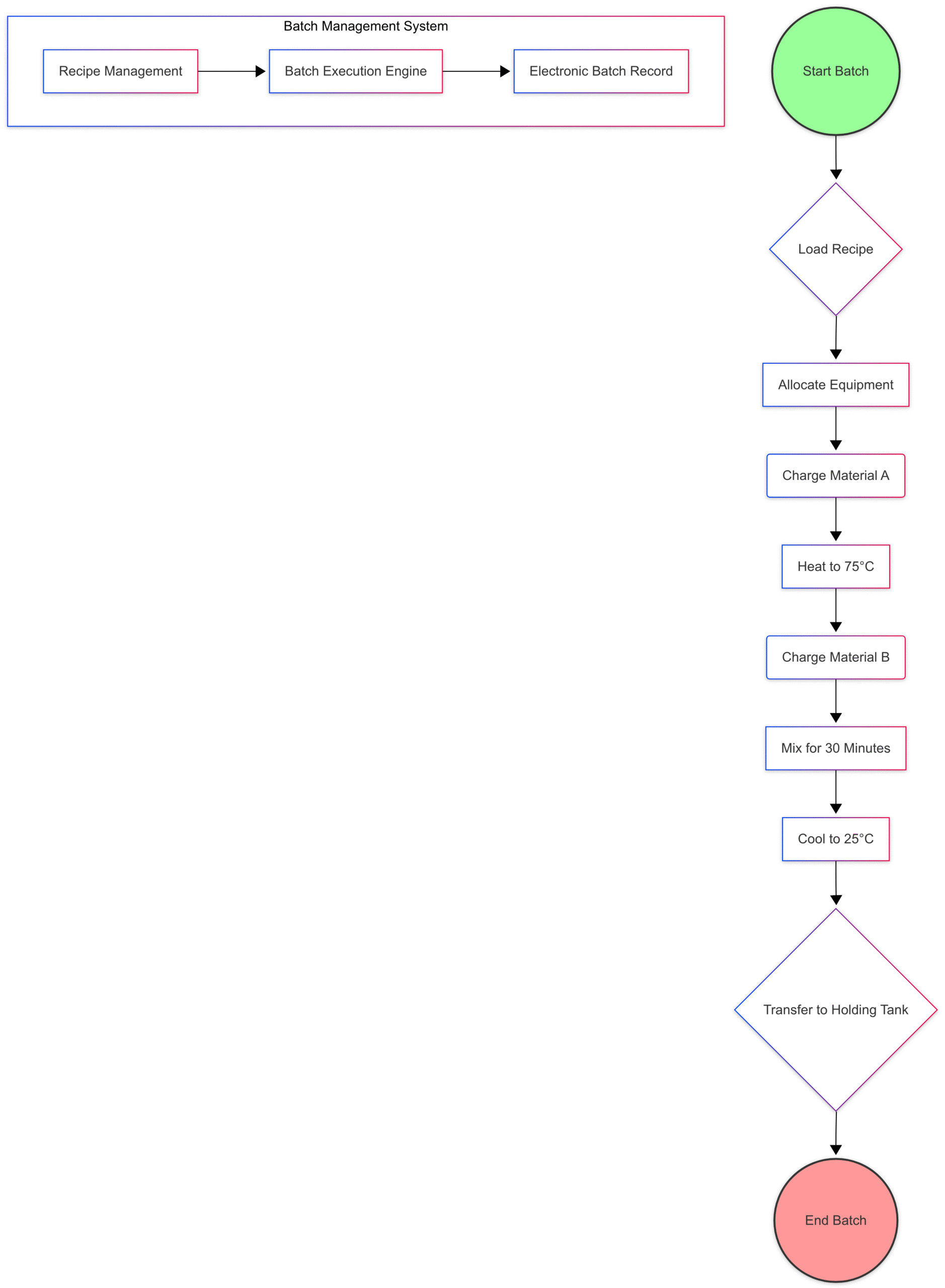

Batch management systems automate the production of batches according to a master recipe, ensuring unparalleled consistency, quality, and compliance. These systems are often designed to comply with the ISA-88 (S88) standard, which provides a universal model for batch control.

Why is Batch Management So Important?

Consistency: A batch system executes a recipe the exact same way every single time, eliminating human error and process variability. This is crucial when even minor deviations can ruin an entire batch, costing thousands or even millions of dollars.

Flexibility: Modern plants need to produce a variety of products on the same equipment. Batch management systems allow manufacturers to easily load different recipes and manage complex production schedules without reconfiguring the underlying control logic.

Regulatory Compliance: In regulated industries like pharmaceuticals, every action, ingredient, and measurement must be documented. Batch systems create a detailed and unalterable Electronic Batch Record (EBR) that captures all process events and data, providing a complete history for regulatory audits (e.g., by the FDA).

Efficiency: By automating recipe execution and transitions between batches, these systems reduce cycle times, minimize waste, and increase throughput.

The ISA-88 Model and Batch Execution

The ISA-88 standard provides a powerful framework for understanding batch processes. It separates the process model (what needs to be done) from the physical model (the equipment used to do it).

The Recipe: At the heart of the system is the recipe, which defines the procedure for making a product. It includes the sequence of operations, the required ingredients, process parameters (e.g., temperature, pressure), and equipment requirements.

Execution: The batch management software takes the master recipe, combines it with a specific production order, and creates a control recipe. It then orchestrates the underlying control systems (PLCs/DCS at Levels 1 & 2) to execute the process steps—adding ingredients, heating, mixing, cooling—while continuously monitoring parameters to ensure they stay within defined limits.

This diagram illustrates a simplified batch workflow managed by a Batch Management System.

This automated, recipe-driven execution is fundamental to modern, flexible manufacturing. It allows companies to respond quickly to changing market demands while guaranteeing product quality and safety.

The Memory of the Plant: Data Historians

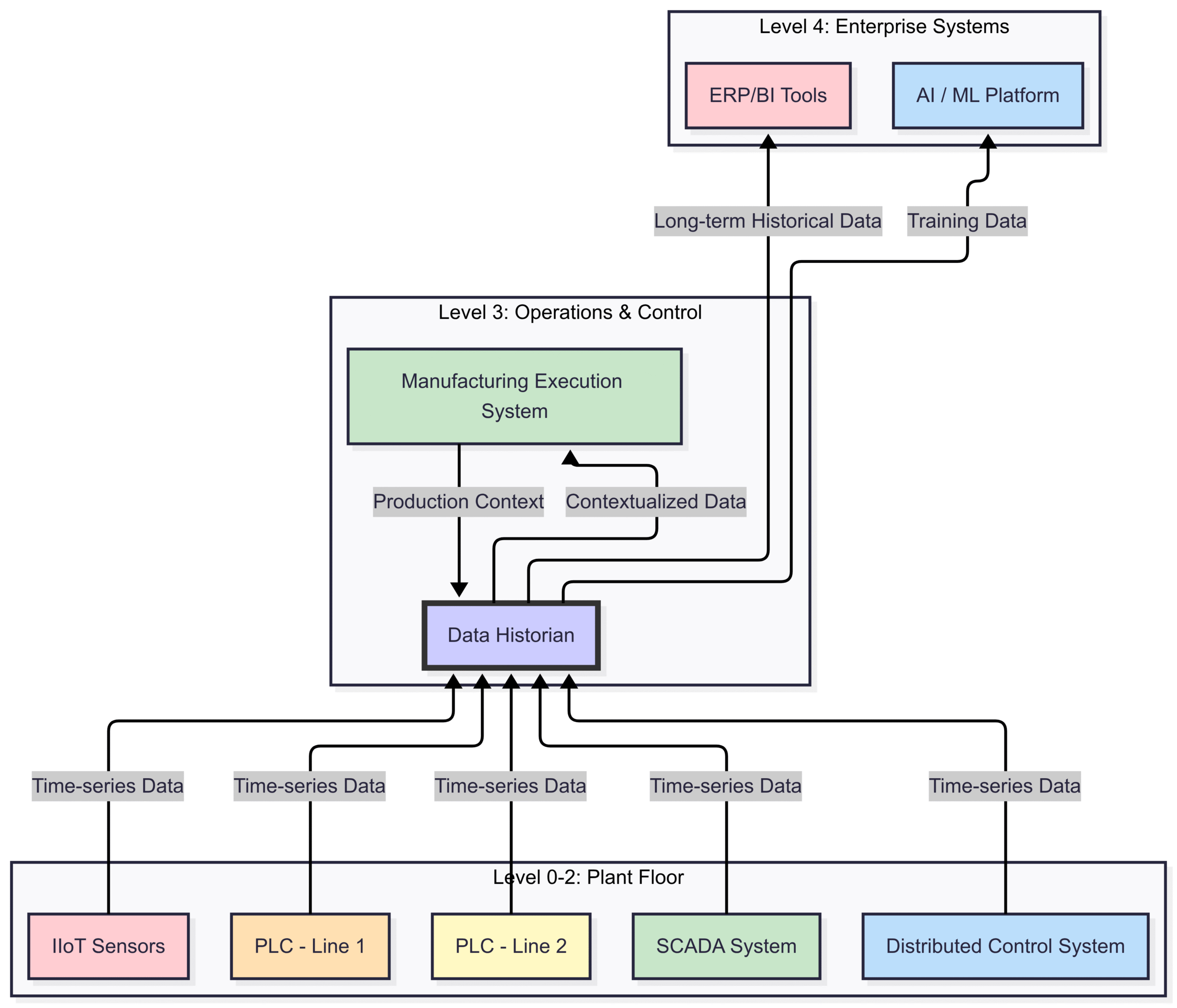

If the MES is the brain of Level 3, the Data Historian is its memory. A data historian, also known as a process historian or operational historian, is a specialized database software application designed to collect and store vast quantities of time-series data from an industrial operation.

While a standard SQL database is good for transactional data (like an inventory record), it’s inefficient at handling the relentless stream of data points generated by a modern factory every second. A historian is optimized for this task, capable of compressing and archiving decades’ worth of operational data efficiently and retrieving it at high speed.

The Function and Value of a Data Historian

The primary job of the historian is simple: collect everything. It connects to SCADA systems, PLCs, DCS, and other data sources across the plant floor and logs thousands, or even millions, of data points (tags) like temperatures, pressures, flow rates, valve positions, and machine states.

So, what is the value of storing all this data?

Process Troubleshooting: When a problem occurs—a batch is off-spec, a machine fails—the historian provides the high-resolution data needed to investigate. Engineers can go back in time to the exact moment the issue started and see what every related sensor was reading. This turns a guessing game into a data-driven analysis, drastically reducing downtime.

Continuous Improvement: By analyzing historical data, teams can identify trends, patterns, and inefficiencies that are invisible in real-time. This is the foundation for process optimization projects that can lead to significant improvements in yield, energy consumption, and quality. For example, by comparing the data from “golden batches” (perfect production runs) with average ones, engineers can pinpoint the exact conditions that lead to optimal results.

Predictive Maintenance: Historical data is the fuel for predictive analytics. By analyzing the performance data of a piece of equipment over time, machine learning models can predict when it is likely to fail. This allows maintenance to be scheduled proactively before a catastrophic breakdown occurs, saving money and preventing unplanned downtime.

Reporting and Compliance: Historians provide the raw data needed for all types of reporting, from daily production summaries for managers to detailed compliance reports for regulatory bodies. They ensure that the data is secure, tamper-proof, and easily accessible for audits.

Feeding Higher-Level Systems: The historian acts as a data buffer and server for other systems. The MES queries the historian for process data to enrich its production context. Business intelligence (BI) tools and AI platforms connect to the historian to perform advanced analytics and generate insights for strategic decision-making at Level 4.

The following diagram shows the central role of a Data Historian in the plant’s data architecture.

Without a robust data historian, a manufacturing facility is flying blind, unable to learn from its past or intelligently predict its future. It is the bedrock of any data-driven manufacturing strategy.

Tying It All Together: The Integrated Level 3

While MES, batch management, and data historians are powerful tools on their own, their true value is unlocked when they are tightly integrated. Level 3 functions as a cohesive unit that synchronizes the entire manufacturing operation.

The information flow is bidirectional:

Top-Down: The ERP system at Level 4 sends a production order to the MES. The MES translates this into a detailed schedule and resource plan. For batch processes, it sends a work order to the Batch Management System, which selects the appropriate recipe. The batch system then sends specific commands (setpoints, phases) down to the PLCs and DCS at Levels 1 and 2.

Bottom-Up: As production runs, sensors and controllers on the plant floor generate a massive amount of real-time data. This data is captured by the Data Historian. The MES and Batch System pull contextual data from the historian to monitor progress, track material consumption, and record quality information. At the end of a shift or batch, the MES aggregates key production data (e.g., units produced, scrap, OEE) and sends a summary back up to the ERP, which then updates inventory, financials, and other business records.

This seamless vertical integration ensures that business goals are perfectly aligned with shop floor execution, and that decision-makers at every level have access to accurate, timely information. This creates a truly agile and responsive manufacturing enterprise.

Challenges and Best Practices for Implementation

Implementing Level 3 systems is a significant undertaking that requires careful planning and execution.

System Selection: Choose solutions that fit your industry and specific operational needs. A system designed for discrete assembly is very different from one designed for chemical batch processing.

Integration Complexity: Integrating Level 3 systems with legacy Level 2 equipment and Level 4 ERP systems can be the most challenging part of the project. A clear data strategy and adherence to standards like ISA-95 are essential.

Data Governance: Establish clear rules for who owns the data, how it is defined, and how it is maintained. Without good data governance, your systems will be fed with unreliable information—”garbage in, garbage out.”

Change Management: Introducing new systems and workflows at Level 3 profoundly impacts the roles of operators, supervisors, and engineers. A comprehensive change management plan that includes training and communication is critical for user adoption and overall success.

Cybersecurity: As Level 3 systems bridge the IT and OT (Operational Technology) networks, they can become a target for cyberattacks. A robust cybersecurity strategy, including network segmentation, access control, and regular patching, is non-negotiable.

Conclusion: The Powerhouse of Modern Manufacturing

Level 3 of the ICCS/ISA-95 model is far more than just a layer in an architectural diagram. It is the powerhouse of the modern factory. Through the combined capabilities of Manufacturing Execution Systems, Batch Management, and Data Historians, it provides the intelligence, control, and memory needed to run a complex manufacturing operation efficiently and effectively.

By orchestrating the entire production workflow, from order to execution to analysis, Level 3 systems enable companies to:

Increase Efficiency and Throughput

Improve Product Quality and Consistency

Ensure Regulatory Compliance and Traceability

Enable Data-Driven Decision Making and Continuous Improvement

Enhance Agility and Responsiveness to Market Changes

In today’s competitive global market, excellence in manufacturing is no longer a choice—it’s a necessity. Investing in and optimizing the systems at Level 3 is one of the most impactful steps a company can take on its journey toward becoming a world-class, smart manufacturing enterprise. It is the critical link that turns strategy into reality, one perfect product at a time.