MODBUS RS485 vs. TCP/IP: A Deep Dive into Industrial Protocols

In the sprawling world of industrial automation, communication is king. The ability for devices to seamlessly talk to each other forms the bedrock of modern manufacturing, process control, and building automation. For decades, one protocol has stood out for its simplicity, reliability, and widespread adoption: MODBUS. However, as technology has evolved, so too has MODBUS, branching into different variants to meet the changing demands of the industry. Two of the most prevalent versions are MODBUS RS485 and MODBUS TCP/IP.

While they share a common linguistic ancestor, their underlying structures and capabilities are vastly different, akin to two dialects that have evolved in separate geographical regions. Understanding these differences is not just an academic exercise; it’s a critical decision-making factor for engineers, system integrators, and IT professionals designing and maintaining industrial networks. Choosing the right protocol can significantly impact a system’s performance, scalability, cost, and ease of integration.

This in-depth guide will explore the nuances of both MODBUS RS485 and MODBUS TCP/IP. We will dissect their technical specifications, compare their strengths and weaknesses, and provide clear guidance on when to use each protocol. Whether you are a seasoned automation expert or new to the field, this article will equip you with the knowledge to navigate the complexities of industrial communication and make informed decisions for your specific application.

What is MODBUS? A Brief Refresher

Before we delve into the specifics of RS485 and TCP/IP, let’s quickly recap what MODBUS is. Developed by Modicon (now Schneider Electric) in 1979, MODBUS is an open, royalty-free serial communication protocol. Its primary purpose is to facilitate communication between electronic devices in a master-slave (or more recently, client-server) relationship. A master device can initiate requests (queries) to read or write data to slave devices. The slave devices then respond to these requests.

The beauty of MODBUS lies in its simplicity. The data model is straightforward, consisting of four primary data types:

Coils: Single-bit read/write values (e.g., turning a relay on or off).

Discrete Inputs: Single-bit read-only values (e.g., the status of a switch).

Input Registers: 16-bit read-only values (e.g., a temperature reading).

Holding Registers: 16-bit read/write values (e.g., a setpoint for a motor).

This simple structure has allowed MODBUS to be implemented on a wide range of devices, from simple sensors to complex programmable logic controllers (PLCs).

MODBUS RS485: The Workhorse of the Field

MODBUS RS485, often referred to as MODBUS RTU (Remote Terminal Unit) or MODBUS ASCII, is the original serial implementation of the protocol. It operates on the physical layer defined by the TIA/EIA-485 standard, more commonly known as RS485. This physical layer is what gives MODBUS RS485 its unique characteristics.

The Physical Layer: RS485

RS485 is a robust, differential signaling standard designed for long-distance communication in electrically noisy environments. Here’s what that means:

Differential Signaling: Instead of sending a signal over a single wire referenced to ground, RS485 uses a twisted pair of wires (A and B). The data is represented by the voltage difference between these two wires. This makes the communication highly resistant to common-mode noise, which is prevalent in industrial settings.

Multi-Drop Capability: A single RS485 network can support multiple devices (up to 32 standard devices, and more with repeaters or high-impedance transceivers) on the same bus. This “multi-drop” capability allows for a daisy-chain wiring configuration, which is cost-effective and simplifies installation.

Half-Duplex Communication: In a standard two-wire RS485 network, communication is half-duplex, meaning devices can either transmit or receive, but not both simultaneously. This requires a mechanism to control the direction of data flow, which is handled by the master device.

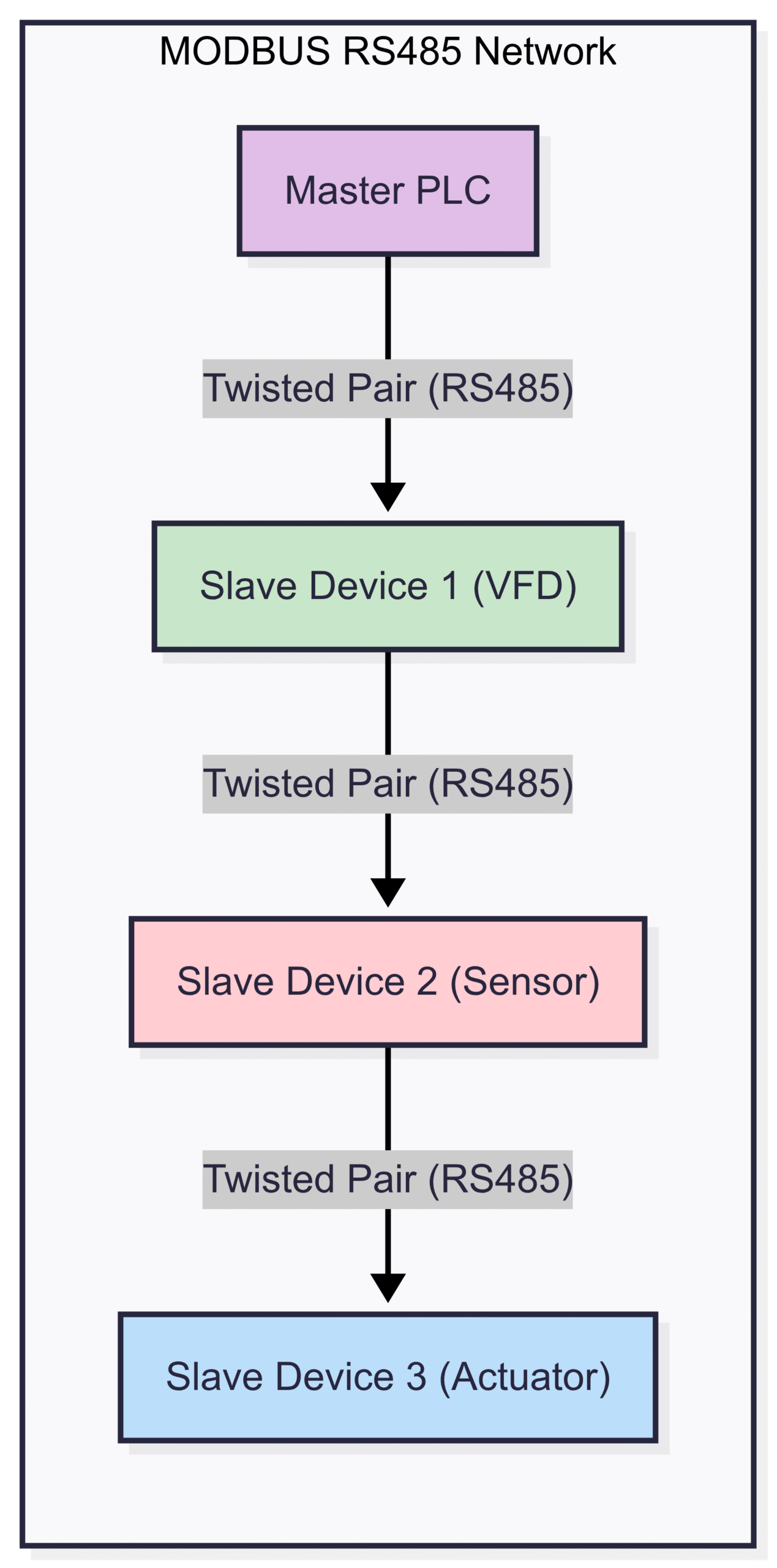

MODBUS RS485 Network Architecture

A typical MODBUS RS485 network consists of a single master and one or more slave devices connected in a daisy-chain fashion.

In this architecture, the master initiates all communication. It sends a request to a specific slave device by including the slave’s unique address in the message frame. Only the addressed slave will respond to the request. All other slaves on the bus will ignore the message.

Data Framing: RTU vs. ASCII

MODBUS RS485 can use two different data framing modes:

MODBUS RTU: This is the more common mode and is known for its efficiency. Data is transmitted in a compact binary format. Each byte in the message contains two 4-bit hexadecimal characters. The end of a message is determined by a silent interval of at least 3.5 character times.

MODBUS ASCII: This mode uses ASCII characters to represent the data. Each byte of information is sent as two ASCII characters. While this makes the data more human-readable for debugging purposes, it is less efficient than RTU and requires twice the number of bytes to transmit the same amount of information.

Advantages of MODBUS RS485

Robustness: The differential signaling of RS485 makes it highly immune to electrical noise, a critical feature in industrial environments.

Long Distance: RS485 networks can span long distances, up to 1200 meters (4000 feet) at lower baud rates.

Cost-Effective: The simple two-wire, multi-drop cabling is inexpensive to install and maintain.

Low Power Consumption: RS485 transceivers generally have low power requirements.

Wide Adoption: A vast number of legacy and new devices support MODBUS RS485.

Limitations of MODBUS RS485

Limited Speed: Compared to modern Ethernet-based protocols, the data rates of RS485 are relatively slow, typically ranging from 9600 bps to 115.2 kbps.

Limited Number of Devices: A standard RS485 segment is limited to 32 devices. While this can be extended with repeaters, it adds complexity to the network.

Master-Slave Architecture: The strict master-slave hierarchy can be a bottleneck, as all communication must be initiated by the master. Slaves cannot initiate communication with the master or with each other.

Configuration Complexity: Setting up an RS485 network requires careful attention to details like baud rate, parity, stop bits, and termination resistors.

Lack of Standardization: While the MODBUS protocol itself is standardized, the physical implementation (connectors, pinouts) can vary between manufacturers.

MODBUS TCP/IP: Bridging the Gap to Modern IT

As industrial automation systems became more complex and the need for higher bandwidth and seamless integration with enterprise-level systems grew, a new flavor of MODBUS emerged: MODBUS TCP/IP. This protocol takes the familiar MODBUS data structure and encapsulates it within a TCP/IP packet, allowing it to be transmitted over standard Ethernet networks.

The Physical Layer: Ethernet

MODBUS TCP/IP leverages the ubiquitous Ethernet standard (IEEE 802.3) as its physical layer. This opens up a world of possibilities and addresses many of the limitations of RS485.

High Speed: Ethernet offers significantly higher data rates than RS485, with common speeds of 10/100 Mbps and even 1 Gbps.

Full-Duplex Communication: Ethernet is a full-duplex medium, meaning devices can transmit and receive data simultaneously.

Standardized Infrastructure: Ethernet uses standard networking hardware, such as switches, routers, and cables (Cat5e, Cat6), which are readily available and well-understood by IT professionals.

Scalability: Ethernet networks are highly scalable and can support a virtually unlimited number of devices.

MODBUS TCP/IP Network Architecture

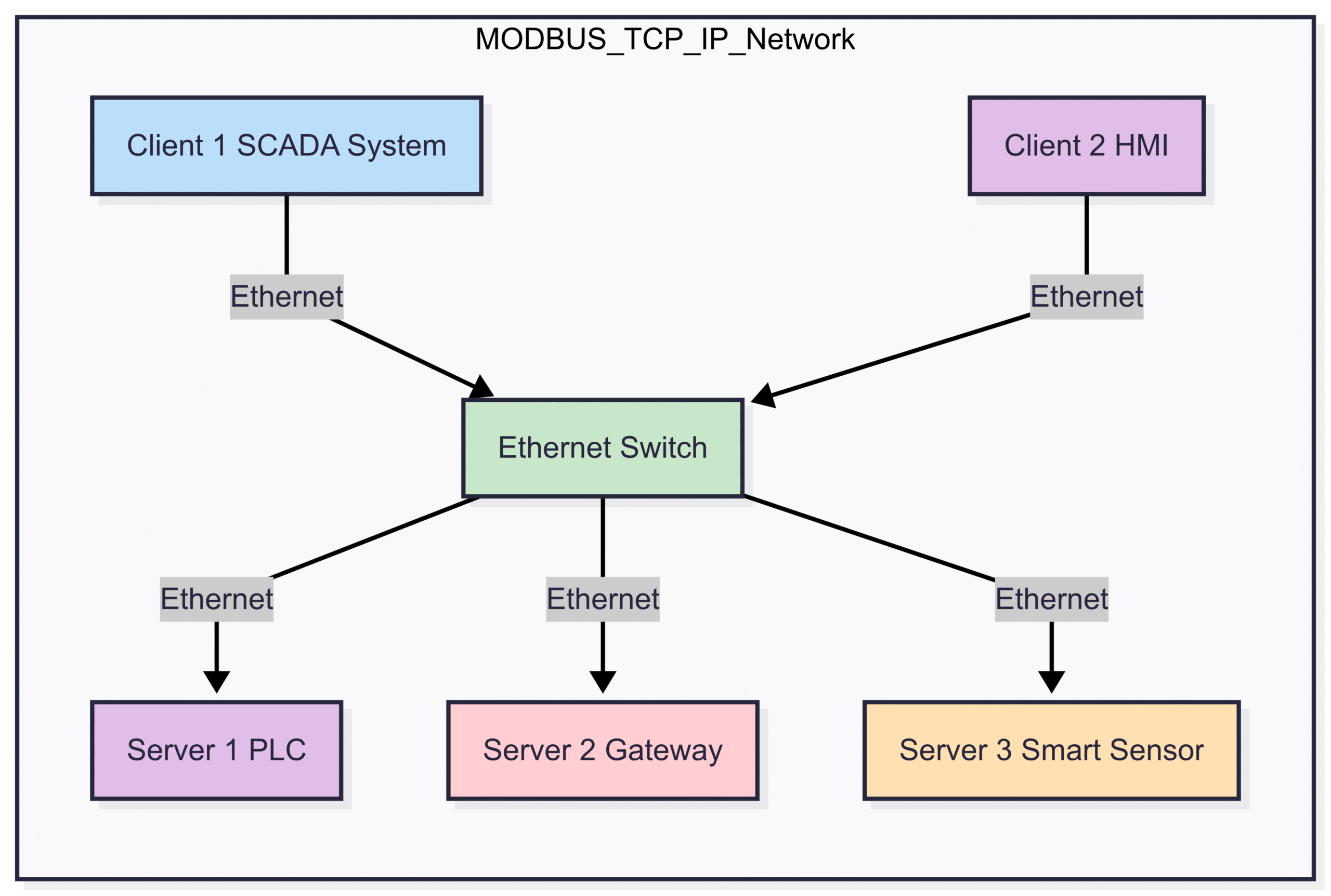

A MODBUS TCP/IP network is built on a standard client-server model, which is a more flexible and powerful paradigm than the master-slave architecture of RS485.

In this architecture:

Clients: These are the devices that initiate communication (equivalent to the master in RS485).

Servers: These are the devices that respond to requests from clients (equivalent to the slaves in RS485).

The key difference is that multiple clients can communicate with multiple servers simultaneously. The Ethernet switch manages the traffic, ensuring that messages are delivered to the correct destination.

Data Framing: The MBAP Header

MODBUS TCP/IP introduces a new header called the MODBUS Application Protocol (MBAP) header. This 7-byte header is prepended to the standard MODBUS Protocol Data Unit (PDU) and contains the following fields:

Transaction Identifier (2 bytes): A unique number assigned by the client to pair requests with responses. This allows multiple transactions to be in progress simultaneously.

Protocol Identifier (2 bytes): Always 0 for MODBUS.

Length (2 bytes): The number of bytes that follow in the message.

Unit Identifier (1 byte): This field is used for routing messages through gateways to underlying serial MODBUS networks. In a pure TCP/IP network, it is often ignored.

The use of the MBAP header and the underlying TCP/IP stack eliminates the need for the slave address and CRC (Cyclic Redundancy Check) that are present in the MODBUS RTU frame. TCP/IP provides its own error-checking mechanisms.

Advantages of MODBUS TCP/IP

High Speed and Bandwidth: The high data rates of Ethernet allow for much faster communication and the transmission of larger amounts of data.

Scalability: Ethernet networks can easily accommodate a large number of devices and can be expanded as needed.

Flexibility: The client-server model allows for more flexible and distributed control architectures. Multiple clients can access data from multiple servers simultaneously.

Integration with IT Systems: MODBUS TCP/IP uses the same infrastructure as standard IT networks, making it easy to integrate plant floor data with enterprise-level systems like MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning).

Remote Access: The use of TCP/IP enables remote access and monitoring of industrial devices over the internet or a corporate intranet.

Standardization: Ethernet hardware and cabling are highly standardized, reducing compatibility issues.

Limitations of MODBUS TCP/IP

Cost: The initial cost of Ethernet hardware (switches, routers, network interface cards) can be higher than that of RS485.

Complexity: Setting up and managing an Ethernet network requires IT expertise. Concepts like IP addressing, subnets, and firewalls need to be understood.

Security: As with any IP-based network, security is a major concern. MODBUS TCP/IP itself does not have built-in security features, so measures like firewalls, VPNs, and access control lists must be implemented to protect the network from unauthorized access.

Overhead: The TCP/IP stack adds some overhead to the communication, which can be a consideration in very time-critical applications.

Head-to-Head Comparison: MODBUS RS485 vs. MODBUS TCP/IP

Now that we have a solid understanding of both protocols, let’s put them side-by-side for a direct comparison.

Feature | MODBUS RS485 | MODBUS TCP/IP |

|---|---|---|

Physical Layer | TIA/EIA-485 (RS485) | Ethernet (IEEE 802.3) |

Cabling | Twisted pair (2-wire or 4-wire) | Cat5e, Cat6, Fiber Optic |

Network Topology | Daisy-chain (bus) | Star, Tree, Mesh |

Communication Model | Master-Slave | Client-Server |

Communication Type | Half-duplex (2-wire) or Full-duplex (4-wire) | Full-duplex |

Data Rate | 9600 bps – 115.2 kbps (typically) | 10/100 Mbps, 1 Gbps |

Max. Devices | 32 per segment (standard) | Virtually unlimited |

Max. Distance | 1200 meters (4000 feet) | 100 meters per segment (copper), longer with fiber |

Addressing | Slave Address (1-247) | IP Address |

Error Checking | CRC (Cyclic Redundancy Check) | TCP/IP checksum |

Cost | Low | Higher initial cost |

Ease of Integration | Good for field-level devices | Excellent for enterprise integration |

Security | Physically secure, but no built-in protocol security | Requires robust network security measures |

Choosing the Right Protocol: A Practical Guide

The choice between MODBUS RS485 and MODBUS TCP/IP is not about which one is “better” in an absolute sense, but rather which one is the best fit for your specific application. Here are some key factors to consider:

When to Choose MODBUS RS485

Existing Infrastructure: If you have a large installed base of legacy devices that only support serial communication, sticking with RS485 may be the most cost-effective solution.

Simple, Localized Control: For small-scale applications with a limited number of devices in a localized area, the simplicity and low cost of RS485 are hard to beat.

Long-Distance Point-to-Point: When you need to connect devices over long distances (up to 1200 meters) without the need for high bandwidth, RS485 is an excellent choice.

Harsh Electrical Environments: The noise immunity of RS485 makes it well-suited for environments with high levels of electromagnetic interference.

Low Power Applications: In battery-powered or other power-constrained applications, the low power consumption of RS485 can be a significant advantage.

When to Choose MODBUS TCP/IP

High-Performance Applications: When you need high-speed data acquisition, real-time control, or the transfer of large amounts of data, MODBUS TCP/IP is the clear winner.

Large-Scale Systems: For complex systems with a large number of devices distributed over a wide area, the scalability of Ethernet is essential.

Integration with Enterprise Systems: If you need to connect your plant floor data with MES, ERP, or other business-level systems, MODBUS TCP/IP provides a seamless path for integration.

Remote Monitoring and Control: The ability to access and control devices remotely over an IP network is a powerful feature that is only possible with MODBUS TCP/IP.

Future-Proofing: As the Industrial Internet of Things (IIoT) continues to grow, Ethernet-based protocols like MODBUS TCP/IP are becoming the de facto standard. Choosing TCP/IP today will ensure that your system is ready for the future.

The Hybrid Approach: Gateways and Converters

It’s important to note that the choice between RS485 and TCP/IP is not always an either/or proposition. In many cases, a hybrid approach is the most practical solution. MODBUS gateways and converters can be used to bridge the gap between serial and Ethernet networks.

In this example, a MODBUS gateway allows a modern SCADA system (running on an Ethernet network) to communicate with legacy RS485 devices. The gateway acts as a translator, converting MODBUS TCP/IP messages into MODBUS RTU messages and vice versa. This allows you to leverage the benefits of both protocols within the same system.

Conclusion: The Enduring Legacy of MODBUS

For over four decades, MODBUS has been a cornerstone of industrial communication. Its evolution from a simple serial protocol to a modern Ethernet-based solution is a testament to its enduring design and adaptability. While MODBUS RS485 remains a reliable and cost-effective choice for many field-level applications, MODBUS TCP/IP has emerged as the clear path forward for high-performance, large-scale systems that require seamless integration with the broader IT landscape.

By understanding the fundamental differences between these two protocols, you can make informed decisions that will optimize the performance, scalability, and cost-effectiveness of your industrial automation systems. Whether you are building a new system from the ground up or upgrading an existing one, the choice between MODBUS RS485 and MODBUS TCP/IP will be a critical one. And now, you have the knowledge to make that choice with confidence.

This is explanatory, nice one.