The Definitive Guide to Heat Detection Technology: A Comparative Analysis of Fixed Temperature, Rate-of-Rise, and Rate-Compensated Detectors

Introduction: Beyond Smoke Detection – The Critical Role of Heat Detectors in a Layered Fire Safety Strategy

In the comprehensive field of fire safety, heat detectors represent the oldest and one of the most reliable forms of automatic fire detection. While smoke detectors are often the first line of defense, particularly for life safety, heat detectors serve a distinct and critical purpose. They are engineered to respond to the convective thermal energy released by a fire, triggering an alarm when a significant temperature change occurs. Their primary role has traditionally been focused on property protection, a mission subtly but significantly different from the life-safety focus of smoke alarms.

However, this slower response is a deliberate trade-off for unparalleled resilience. Heat detectors are indispensable in environments where smoke detectors would be impractical or prone to false alarms. These include areas with high levels of dust, humidity, steam, fumes, or routine temperature extremes, such as commercial kitchens, boiler rooms, attics, and industrial facilities. In these challenging conditions, a heat detector provides robust and reliable fire detection without the nuisance alarms that can lead to system complacency.

Section 1: The Foundations of Heat Detection

Before comparing specific detector models, it is crucial to understand the fundamental scientific principles and industry classifications that govern all heat detection technologies.

1.1 The Physics of Fire and Detection

Fires release energy primarily through radiation and convection. Heat detectors are designed to sense the convective heat. As a fire burns, it heats the surrounding air, causing it to become less dense and rise. This column of hot gas, known as a thermal plume, carries significant heat energy upward to the ceiling, where detectors are strategically placed to intercept it.

1.2 The Concept of Thermal Lag

The single greatest challenge for any heat detector is thermal lag. This is the inherent delay between the moment the air surrounding a detector reaches a critical temperature and the moment the internal heat-sensitive element absorbs enough energy to reach that same temperature and trigger an alarm. This lag is influenced by the detector’s thermal mass and conductivity; a larger, less conductive element will heat up more slowly. Nearly all advancements in heat detection technology, from rate-of-rise to rate-compensation, are fundamentally attempts to overcome or mitigate the effects of thermal lag.

1.3 Core Detector Classifications

Heat detectors are categorized based on their monitoring area and their state after activation:

Spot vs. Line Type: This report focuses on spot-type detectors, which monitor heat at a single, specific location. Line-type detectors, by contrast, use a heat-sensitive cable or tube to monitor temperature along a continuous path, making them suitable for applications like cable trays or large warehouses.

Restorable vs. Non-Restorable: This distinction has significant implications for testing, maintenance, and the total cost of ownership.

Restorable detectors, such as most rate-of-rise and bimetallic types, can be tested with a heat source and will automatically reset to their normal state once cooled.

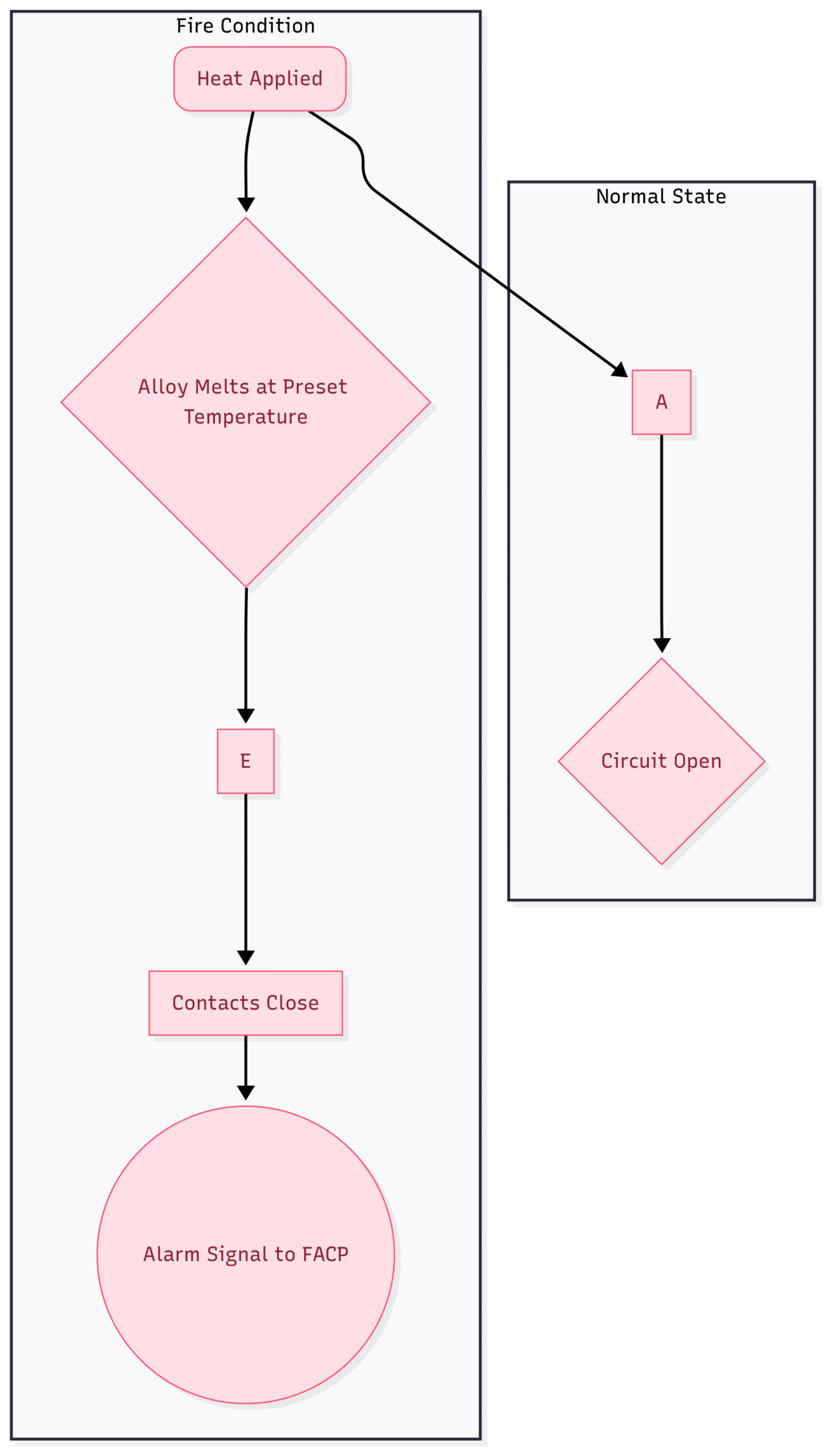

Non-restorable detectors, like those using a fusible alloy, are destroyed upon activation or during a heat test and must be replaced. This single-use nature introduces a considerable, often overlooked, lifecycle cost. While their initial purchase price may be lower, NFPA 72 mandates that these devices either be replaced 15 years after installation or be subject to a costly laboratory testing protocol for a representative sample every five years thereafter. This transforms the choice from a simple technical decision into a long-term financial and logistical one, where a more expensive restorable detector may offer a significantly lower total cost of ownership over the system’s life.

1.4 System Architecture

Heat detectors are components of a larger fire alarm system and communicate with a central Fire Alarm Control Panel (FACP) in one of two ways:

Conventional Systems: Detectors are wired together in groups called zones. If any detector in a zone activates, the FACP will indicate an alarm in that general zone but cannot identify the specific device. This is a simpler, less expensive approach suitable for smaller buildings.

Addressable Systems: Each detector on the circuit has a unique digital address. When a detector activates, it sends a signal to the FACP that pinpoints its exact location. This precise information is invaluable for first responders, enabling a much faster and more targeted response. Most modern addressable heat detectors are sophisticated devices, often combining multiple sensing technologies.

Section 2: Fixed Temperature Heat Detectors

Fixed temperature detectors are the most common and straightforward type of heat detector. Their operation is based on a simple, unambiguous principle: they trigger an alarm only when their internal sensing element reaches a specific, factory-preset temperature. Common activation points are 135°F (57°C) for ordinary applications and higher ratings like 190°F or 194°F (88°C or 90°C) for areas with naturally high ambient temperatures. This simple threshold makes them exceptionally resistant to false alarms caused by transient heat sources.

2.1 Mechanisms of Activation

Fixed temperature detection is achieved through several proven mechanisms:

The Fusible Link: This classic mechanical design employs a eutectic alloy, which is a mixture of two or more metals engineered to melt at a very precise and consistent temperature that is lower than the melting point of the individual metals. This alloy holds a spring-loaded electrical contact in an open position. When the ambient temperature heats the alloy to its melting point, it changes from solid to liquid, releasing the spring and allowing the contacts to close, which completes the alarm circuit. These devices are highly reliable and cost-effective but are non-restorable and must be replaced after activation.

The Bimetallic Strip: This mechanism uses a strip composed of two different metals (e.g., steel and brass) that are bonded together. Because the metals have different coefficients of thermal expansion, the strip bends when heated. This physical bending action is harnessed to push two electrical contacts together, completing the alarm circuit. Most bimetallic detectors are self-restoring; the strip returns to its original shape as it cools, opening the circuit.

The Bimetallic Strip: This mechanism uses a strip composed of two different metals (e.g., steel and brass) that are bonded together. Because the metals have different coefficients of thermal expansion, the strip bends when heated. This physical bending action is harnessed to push two electrical contacts together, completing the alarm circuit. Most bimetallic detectors are self-restoring; the strip returns to its original shape as it cools, opening the circuit. Modern Electronic Sensing (Thermistor): Many contemporary detectors utilize a thermistor, which is a type of resistor whose electrical resistance changes predictably with temperature. At lower temperatures, the thermistor has high resistance, allowing little current to flow. As it heats up, its resistance drops significantly. An onboard microcontroller continuously monitors this resistance. When the resistance falls to a level that corresponds to the alarm temperature, the circuit triggers an alarm. This electronic method offers greater accuracy and responsiveness compared to older mechanical types.

2.2 Analysis

Strengths: The primary advantages of fixed temperature detectors are their high reliability and exceptional immunity to false alarms, making them the ideal choice for environments with normal, dramatic, but non-fire-related heat fluctuations. They are also low-cost and perform well in dusty or dirty conditions where smoke detectors would fail.

Weaknesses: Their main drawback is their slow response speed, a direct result of thermal lag. In a rapidly growing fire, the room temperature may far exceed the detector’s rating before the device itself gets hot enough to activate. This makes them generally unsuitable for life-safety applications and ineffective for detecting slow, smoldering fires that may not generate enough heat to reach the fixed threshold in a timely manner.

Section 3: Rate-of-Rise (ROR) Heat Detectors

Rate-of-Rise (ROR) heat detectors were developed specifically to overcome the inherent slowness of fixed temperature devices. Instead of waiting for a specific temperature to be reached, an ROR detector triggers an alarm when the ambient temperature increases at an abnormally fast rate, typically 12°F to 15°F (6.7°C to 8.3°C) per minute. This allows it to respond to a fast-developing, flaming fire much more quickly than a fixed temperature detector, regardless of the initial starting temperature.

3.1 Mechanisms of Activation

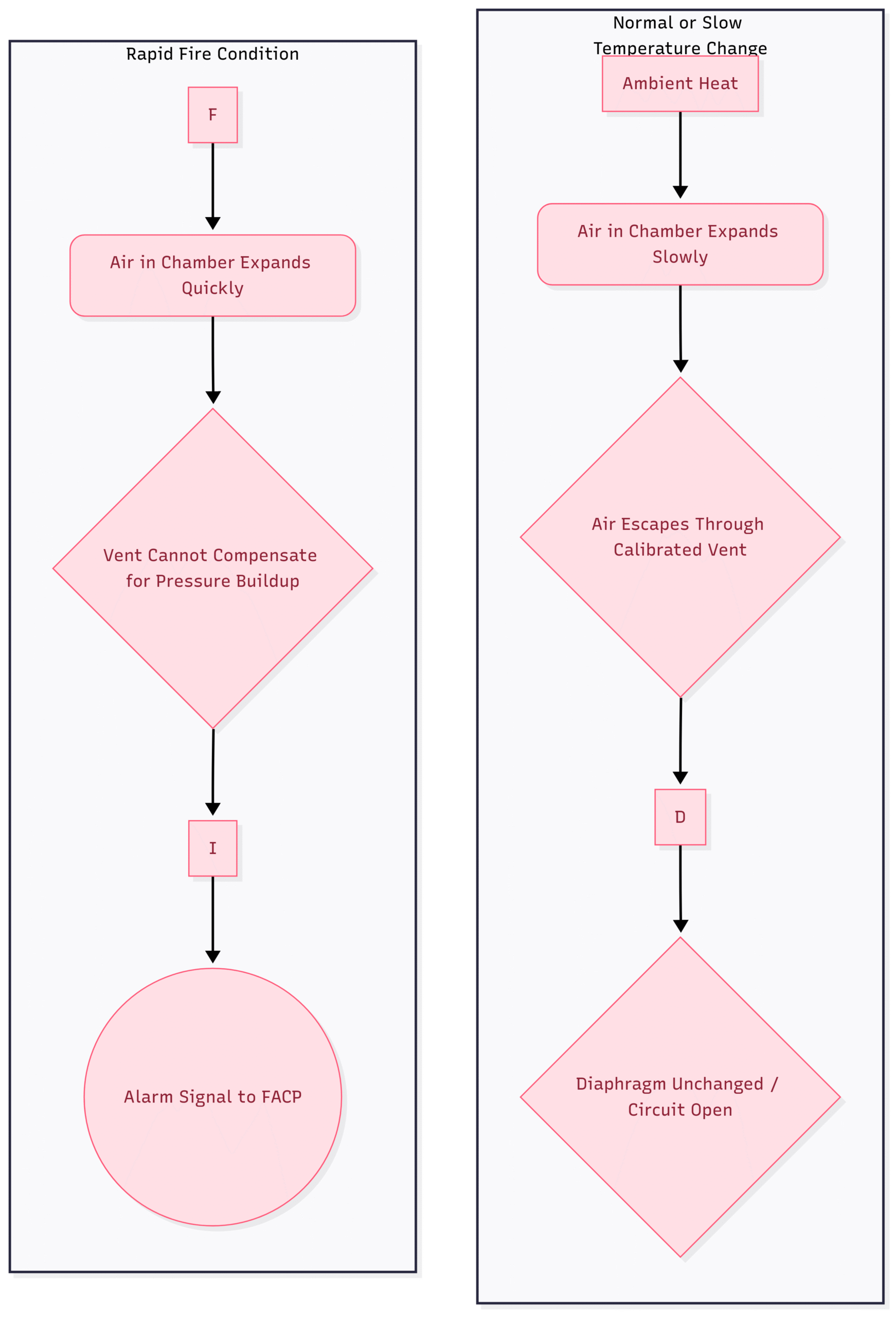

The Pneumatic Principle: The most common mechanical ROR design relies on the physics of air expansion. The detector contains a sealed air chamber connected to the outside air by a very small, calibrated vent or leak. A flexible diaphragm separates this chamber from a set of electrical contacts.

During normal temperature changes (e.g., from a heating system turning on), the air inside the chamber expands slowly. This excess air pressure has time to bleed out through the calibrated vent, so the diaphragm does not move.

During a fire, the temperature rises rapidly. The air inside the chamber expands much faster than it can escape through the vent. This rapid pressure buildup forces the diaphragm to flex and close the alarm contacts.

Electronic ROR (Dual Thermistors): An electronic approach uses two separate thermistors. One thermistor is exposed to the ambient air to measure temperature changes quickly. The second is partially insulated or shielded, causing it to react more slowly to temperature changes. The detector’s circuitry constantly compares the temperatures of the two thermistors. A normal, slow temperature change will affect both nearly equally. However, a rapid temperature increase from a fire will create a large and sudden difference between the two readings, which triggers the alarm.

3.2 Analysis

The weaknesses of a “pure” ROR detector—its inability to detect slow-building fires and its susceptibility to false alarms—have driven a crucial evolution in the market. A fire that builds heat steadily but just below the 15°F-per-minute threshold could grow to a dangerous size without ever triggering a pure ROR alarm. Conversely, a legitimate process like opening a large industrial oven could cause a nuisance alarm every time.

To solve this, manufacturers integrated a fixed temperature element as a fail-safe backup. This has created the Combination ROR/Fixed Temperature Detector, which has become the modern industry standard. This hybrid device offers the speed of ROR for fast-flaming fires while ensuring that even a slow-smoldering fire will eventually be detected when its heat builds to the fixed temperature threshold. For practical purposes, when a fire protection professional specifies an “ROR detector” today, they are almost invariably referring to a combination ROR/Fixed Temperature model.

Strengths: Faster response to rapidly growing fires compared to fixed-only models. Like other heat detectors, they are unaffected by dust and dirt.

Weaknesses: A pure ROR detector may not respond to slow-developing fires. They are highly susceptible to false alarms in environments with legitimate, rapid temperature fluctuations, making them unsuitable for placement near HVAC vents, large ovens, or in boiler rooms without careful consideration.

Section 4: Rate-Compensated Heat Detectors

The rate-compensated heat detector is the most sophisticated of the three spot-type technologies, representing a clever engineering solution to the problem of thermal lag. Unlike a simple combination detector that has two separate operating modes, a rate-compensated detector uses a single, integrated mechanism designed to respond accurately when the air surrounding the device reaches a predetermined temperature, regardless of how quickly that temperature was reached. Its primary goal is to anticipate and actively compensate for thermal lag, ensuring it triggers precisely at its rated temperature even during a fast-developing fire.

4.1 Mechanism of Activation: The Engineering of Differential Expansion

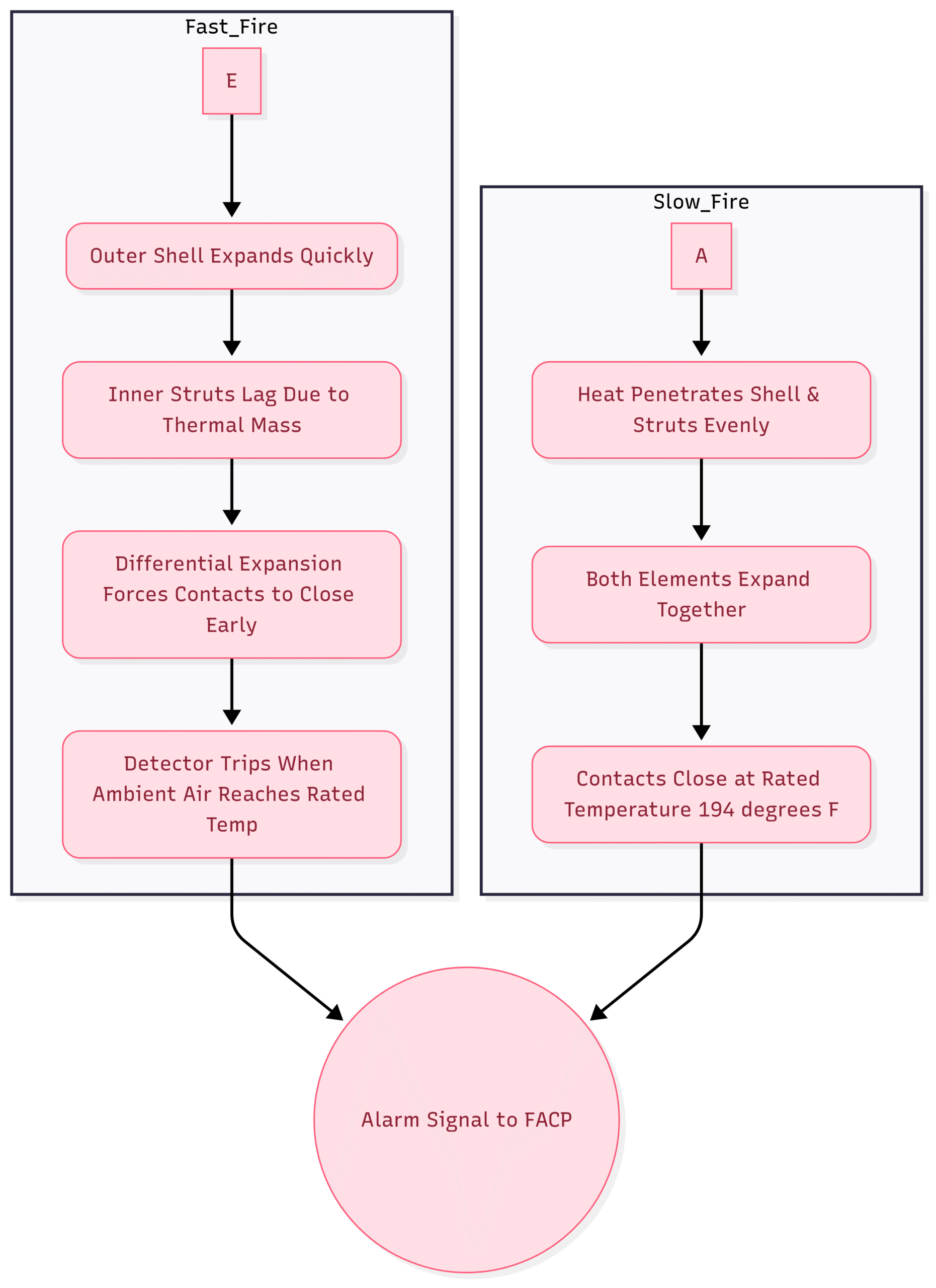

The genius of the rate-compensated detector lies in its physical construction. It consists of a sealed, highly conductive outer metallic tube or shell. Housed inside this shell are internal support struts made from a different metal alloy with a lower coefficient of thermal expansion. These two components work in opposition to control a set of electrical contacts.

During a slow temperature rise: Heat has sufficient time to penetrate the entire detector assembly. The outer shell and the inner struts heat up and expand at a relatively similar pace. In this scenario, the device acts like a high-quality fixed temperature detector, closing its contacts only when the entire unit has been heated to its rated alarm temperature (e.g., 135°F or 194°F).

During a rapid temperature rise: The highly conductive outer shell heats up and expands very quickly. The inner struts, with their greater thermal mass and lower expansion rate, lag behind, remaining cooler and shorter. This large differential in expansion between the outer shell and inner struts forces the contacts to close much earlier. The detector is engineered so that this early activation corresponds precisely to the moment the surrounding air has reached the rated alarm temperature, effectively eliminating thermal lag.

4.2 The “Virtual Set Point”

This unique mechanism creates what is known as a “virtual set point”. The actual internal temperature at which the detector trips is dynamic and self-adjusts based on the rate of temperature rise. This is not a dual-element system like a combo ROR/Fixed detector; it is a single, elegant mechanical system designed for one purpose: achieving unparalleled accuracy across all fire growth scenarios.

4.3 Analysis

Rate-compensated detectors effectively combine the best attributes of the other two types. They offer the speed of an ROR detector for fast-flaming fires and the stability of a fixed temperature detector for slow-building fires, all while actively mitigating the primary weakness of thermal lag. This makes them exceptionally reliable and well-suited for high-value or demanding industrial applications where precise and dependable detection is paramount.

Section 5: A Professional’s Guide to Selection and Placement

Selecting the correct heat detector is not a one-size-fits-all decision. It requires a careful analysis of the environment, the potential fire hazards, and the primary protection goal.

5.1 Key Selection Criteria

Ambient Environment: Consider the normal operating temperature range, the potential for rapid but non-fire-related temperature changes, and the presence of environmental contaminants like dust, moisture, or corrosive agents.

Expected Fire Type: Evaluate whether a fast, high-heat flaming fire (e.g., from flammable liquids) or a slow, smoldering fire is the more likely risk in the space.

Regulatory Mandates: All installations must comply with the requirements of NFPA 72, National Fire Alarm and Signaling Code, as well as all local and state building codes.

Life Safety vs. Property Protection: As established, this is the primary strategic driver. If the main goal is to protect human life, a smoke detector is almost always the required and superior choice. If the goal is to protect the asset in a harsh environment, a heat detector is appropriate.

5.2 Application-Specific Recommendations

The following table provides guidance for selecting the appropriate heat detector for common challenging environments.

| Application / Location | Primary Hazard/Concern | Recommended Detector Type | Rationale & Key Considerations |

| Commercial Kitchen | High ambient heat, steam, grease, rapid temperature changes from cooking appliances. | Fixed Temperature (High Temp Rating, e.g., 190°F/88°C or higher) | Must be rated well above the maximum expected ceiling temperature during cooking to prevent false alarms. A rate-of-rise detector is highly unsuitable due to the rapid heat changes from ovens, grills, and fryers. |

| Boiler Room / Furnace Room | High ambient heat, dust, potential for rapid temperature fluctuations when equipment cycles on and off. | Fixed Temperature (High Temp Rating) or Rate-Compensated | A high-temperature fixed detector provides excellent stability against normal operational heat spikes. A rate-compensated detector offers faster, more reliable detection if a true fire develops, justifying its use in protecting critical equipment. |

| Attic / Unconditioned Space | Extreme temperature swings (solar heating in summer, cold in winter), high levels of dust. | Fixed Temperature (High Temp Rating, e.g., 190°F/88°C or higher) | Smoke detectors are prone to false alarms from dust and temperature extremes. A high-temperature fixed detector will not trigger from normal solar heating but will reliably detect the heat from a fire. |

| Garage (Residential/Commercial) | Vehicle exhaust fumes, dust, wide temperature fluctuations, potential for fast-developing fuel fires. | Combination Rate-of-Rise/Fixed Temperature or Rate-Compensated | Exhaust fumes make smoke detectors unreliable. A combination ROR/Fixed detector provides a faster response to a potential vehicle fire than a fixed-only model, with the fixed element serving as a backup. |

| Loading Dock / Parking Structure | Vehicle exhaust fumes, exposure to weather and drafts, potential for vehicle fires. | Combination Rate-of-Rise/Fixed Temperature | Smoke detectors are completely unsuitable due to constant exhaust fumes. The ROR element is critical for providing the earliest possible warning of a rapidly growing vehicle fire. |

| Storage Rooms (with Combustibles) | Risk of rapidly developing, high-heat fires from stored materials like paper, wood, or plastics. | Combination Rate-of-Rise/Fixed Temperature or Rate-Compensated | The rate-of-rise sensing capability is crucial for providing timely warning of a fast-flaming fire involving highly combustible materials, allowing for a quicker response to suppress the fire. |

| Data Centers / Telecom Rooms | High-value equipment, high airflow from cooling systems that can dilute heat and smoke. | (Note: Primarily uses VESDA/Air-Sampling Smoke Detection). If heat detection is supplemental: Rate-Compensated | High airflow makes standard spot detectors slow to respond. A rate-compensated detector offers the best performance by mitigating thermal lag. However, point heat detectors are generally not the primary method of protection in these critical environments. |

5.3 Environments Where Heat Detectors Are Contraindicated

It is equally important to know where not to use heat detectors as the primary means of detection.

Life-Safety Areas: In sleeping areas (bedrooms), hallways outside sleeping areas, living rooms, and office spaces, smoke detectors are mandated by code and are essential for providing early warning necessary for safe evacuation.

Spaces with High Ceilings: In areas with very high ceilings (typically exceeding the manufacturer’s listed limits, e.g., >30 feet), the hot air from a fire may cool and stratify below the ceiling, never reaching a spot-type detector with enough intensity to trigger an alarm. NFPA 72 provides specific rules and height limitations that must be followed.

Section 6: Installation and Maintenance per NFPA 72

Proper selection is only half the battle; compliant installation and maintenance are critical for ensuring a heat detector will perform as intended during a fire. All design and maintenance must adhere to NFPA 72, National Fire Alarm and Signaling Code.

6.1 Spacing and Placement

Listed Spacing: Every heat detector has a “listed spacing” determined by its manufacturer during testing (e.g., 30 ft x 30 ft or 50 ft x 50 ft). This represents the maximum square area a single detector can cover on a smooth, flat ceiling.

The “Point Seven” (0.7S) Rule: To ensure there are no gaps in coverage, NFPA 72 requires that all points on the ceiling must be within a distance of 0.7 times the listed spacing (S) of the nearest detector. For a detector with a 30-foot spacing, this means no point on the ceiling can be more than 21 feet ( 0.7×30=21) from a detector.

Wall Placement: To ensure coverage near the edges of a room, detectors must be placed within one-half of their listed spacing from all walls or partitions. For a 30-foot spaced detector, this is 15 feet.

Ceiling Obstructions: NFPA 72 provides extensive rules for reducing spacing based on ceiling height, slopes, and obstructions like beams or joists, which can impede the flow of heat.

6.2 Temperature Ratings

To prevent nuisance alarms, the fixed temperature rating of a detector must be at least 20°F (11°C) above the highest normally expected ambient ceiling temperature in that space.

6.3 Testing and Maintenance Protocols

Annual Testing: Restorable heat detectors (ROR, rate-compensated, bimetallic) must be tested annually. This test must be performed using a heat source that is listed and labeled for that purpose. Using unlisted heat guns, lighters, or torches is prohibited as it can damage the detector or produce inaccurate results.

Non-Restorable Detector Maintenance: As noted previously, fixed-temperature, non-restorable spot-type detectors cannot be heat tested in the field. Per NFPA 72, they must either be replaced 15 years from their date of manufacture, or a minimum of two detectors per 100 must be removed and sent to a certified testing laboratory for analysis, with this process repeated every five years thereafter.

Conclusion: Synthesizing a Risk-Based Approach to Heat Detection

The choice between fixed temperature, rate-of-rise, and rate-compensated heat detectors is a critical decision in the design of a comprehensive fire protection system. The selection process must move beyond simple preference to a nuanced, risk-based analysis grounded in engineering principles and regulatory compliance.

The core trade-offs are clear:

Fixed Temperature detectors offer the ultimate in stability and false alarm immunity, making them the workhorse for environments with high ambient heat. This reliability comes at the cost of response speed.

Rate-of-Rise detectors, which in modern practice are almost always combination ROR/Fixed Temperature devices, provide superior speed for fast-developing, flaming fires. This makes them ideal for protecting areas with combustible materials, but they require careful placement to avoid nuisance alarms from legitimate heat sources.

Rate-Compensated detectors represent a sophisticated engineered solution, providing both speed and stability by actively designing for and mitigating the effects of thermal lag. They are the premium choice for high-value or challenging industrial applications where performance cannot be compromised.

Ultimately, the selection of a heat detector should never be arbitrary. It must be a deliberate process that begins with a thorough analysis of the protected space: its normal environmental conditions, the most likely fire scenarios, and the overarching protection goal. By layering this analysis with a strict adherence to the installation, spacing, and maintenance requirements of NFPA 72, a fire protection professional can design a system that is not just compliant, but truly effective in safeguarding property from the devastating effects of fire.