Introduction

Flow measurement in hazardous areas—such as oil refineries, chemical plants, offshore platforms, and mining operations—demands special consideration. These environments often contain flammable gases, vapors, or combustible dusts that pose risks of ignition. Selecting the right flow meter in such applications is not just about accuracy and performance; safety certification and protection methodology are paramount.

Two commonly used safety protection techniques are Intrinsically Safe (IS) and Explosion-Proof (XP) designs. This blog post explores the fundamental differences between them, explains how to select flow meters accordingly, and provides practical insights into making the right decision.

Table of Contents

What Are Hazardous Areas?

Why Safety Ratings Matter in Flow Meter Selection

Intrinsically Safe vs. Explosion-Proof: A Side-by-Side Comparison

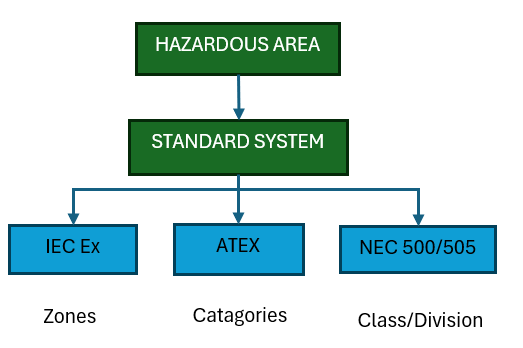

Standards and Certifications (IECEx, ATEX, NEC, etc.)

Types of Flow Meters for Hazardous Areas

Choosing Between IS and XP for Flow Meters

Installation, Maintenance, and Cost Factors

Real-World Examples & Applications

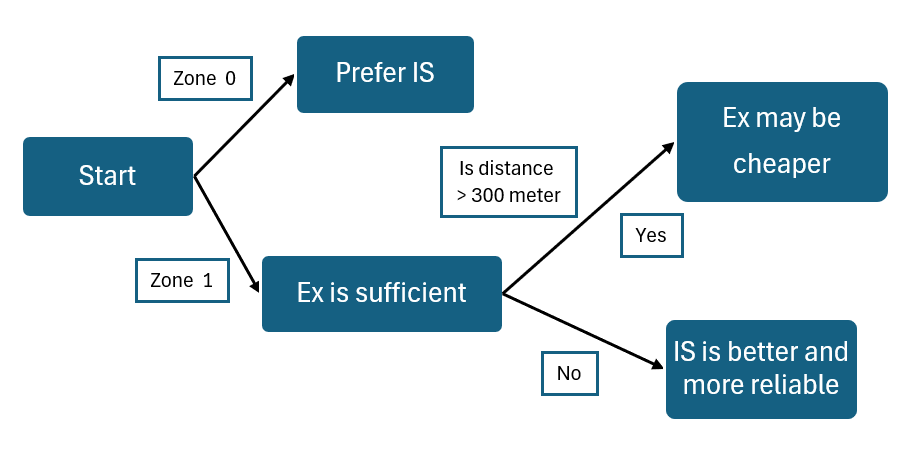

Decision-Making Flowchart

Conclusion

Downloadable Resources

1. What Are Hazardous Areas?

Hazardous areas are classified based on the presence of flammable substances:

Zone 0 (or Class I, Div 1) – Explosive atmosphere is present continuously or for long periods.

Zone 1 (or Class I, Div 1) – Explosive atmosphere is likely to occur under normal operation.

Zone 2 (or Class I, Div 2) – Explosive atmosphere is not likely, but may occur occasionally.

These classifications help determine the appropriate protective techniques for instrumentation.

2. Why Safety Ratings Matter in Flow Meter Selection

Flow meters used in hazardous areas must not ignite the surrounding atmosphere under any circumstances. This includes normal operation and fault conditions. Therefore, your flow meter selection must adhere to safety standards such as:

ATEX (Europe)

IECEx (International)

NEC 500/505 (North America)

Failing to comply with these standards can lead to fires, explosions, and legal liabilities.

3. Intrinsically Safe vs. Explosion-Proof: A Side-by-Side Comparison

| Feature | Intrinsically Safe (IS) | Explosion-Proof (XP) |

|---|---|---|

| Principle | Limits energy (voltage/current) to prevent ignition | Encloses potential spark-producing devices in flame-proof enclosures |

| Zone Usage | Preferred in Zone 0 and 1 | Suitable for Zone 1 and 2 |

| Certification | Requires IS barriers and certified devices | Requires heavy-duty flameproof enclosures |

| Maintenance | Easier, no need to shut down area | Requires opening enclosures with permit |

| Wiring | Uses low-energy signal wiring | Standard wiring; more robust cabling |

| Cost | Lower cost for wiring; higher for IS barriers | Higher cost for enclosures; lower for devices |

| Safety Level | Higher intrinsic safety; safe even during faults | Contains explosion but may allow pressure escape |

| Space | Compact | Bulky installation |

| Field Modifications | Easier | More regulated and restricted |

4. Standards and Certifications

🔹 ATEX (Europe)

Directive 2014/34/EU

Two zones: Group I (mining), Group II (surface industries)

Equipment Category 1, 2, or 3 depending on zone

🔹 IECEx (International)

Follows IEC standards (IEC 60079 series)

Recognized globally (except USA)

🔹 NEC 500/505 (USA)

Class I (gases), Class II (dust), Class III (fibers)

Division and Zone systems

Block Diagram: Certification Mapping

5. Types of Flow Meters for Hazardous Areas

| Flow Meter Type | Suitable for Hazardous Areas? | IS/XP Availability |

|---|---|---|

| Coriolis | Yes | IS & XP options |

| Magnetic | Yes | IS & XP options |

| Ultrasonic | Yes | IS (non-invasive) |

| Turbine | Yes | XP preferred |

| Vortex | Yes | IS & XP |

| DP Flow (Orifice, Venturi) | Yes | IS & XP |

💡Note:

Choose non-invasive ultrasonic flow meters for zero risk in high-hazard zones.

6. Choosing Between IS and XP for Flow Meters

Here’s a simplified flowchart for decision-making:

Flowchart: Intrinsically Safe vs. Explosion-Proof Selection

Decision Factors

Zone Classification – IS is mandatory for Zone 0.

Distance to Control Room – Long cables cause signal loss for IS.

Serviceability – XP systems require permits for maintenance.

Environmental Factors – Dust, heat, vibration may influence enclosure design.

Cost of Barrier vs. Enclosure – Evaluate project-specific cost balance.

7. Installation, Maintenance, and Cost Factors

| Parameter | Intrinsically Safe | Explosion-Proof |

|---|---|---|

| Installation | Simpler wiring but needs barriers | Requires thick cables and sealed enclosures |

| Maintenance | Can be serviced live (Zone 1/2) | Needs shutdown for opening enclosure |

| Training Required | Lower | Higher (Explosion-proof procedures) |

| Overall Cost | Lower over lifecycle | Higher initial cost |

8. Real-World Examples & Applications

🛢️ Oil Refinery

Coriolis IS Flow Meter for metering hydrocarbons in Zone 0

XP Vortex Flow Meter in Zone 2 for utility gases

🧪 Chemical Plant

Magnetic Flow Meter (IS) in Zone 1 for acidic liquids

Ultrasonic IS Meter for non-intrusive flow monitoring

🚀 Offshore Platform

XP-rated Turbine Flow Meter for high-pressure natural gas

IS-rated DP Flow Meter for fuel consumption measurement

9. Final Tips for Selection

Consult with Hazardous Area Classification Engineer

Ensure compatibility of barriers, transmitters, and power supplies

Verify temperature ratings and IP/NEMA enclosure ratings

Match process fluid with wetted materials of flow meter

Consider certified third-party audits for high-SIL/SIS applications

10. Conclusion

Selecting the right flow meter for hazardous areas requires balancing safety, performance, and cost. Intrinsically Safe designs are compact, low-energy, and ideal for sensitive or space-constrained areas like Zone 0. Explosion-Proof designs are robust and widely used in rugged industrial environments.

Understanding the trade-offs between the two helps make informed choices. Partner with certified instrumentation vendors and prioritize safety above all.