Slash Costs, Not Accuracy: The Ultimate Guide to Cost-Effective Flow Meters for Water & Wastewater

The Great Divide: Open Channels vs. Closed Pipes

Before we dive into specific meter types, it’s crucial to understand the two primary environments for flow measurement in this industry:

- Closed Pipe Flow: This refers to water or wastewater flowing through a full, pressurized pipe. This is common in water distribution networks, treatment plant piping, and force mains.

- Open Channel Flow: This involves fluid flowing in a channel where the surface is open to the atmosphere. Think of rivers, irrigation canals, and the gravity-fed channels within a wastewater treatment plant.

The technology and cost-effectiveness of a flow meter are heavily dependent on which of these two environments it’s designed for.

Cost-Effective Champions for Closed Pipe Applications

For pressurized pipes, several technologies offer a fantastic balance of performance and affordability. Let’s explore the top contenders.

1. Magnetic Flow Meters (Magmeters): The Wastewater Workhorse

If there’s one flow meter that has become synonymous with water and wastewater treatment, it’s the magnetic flow meter, or “magmeter.” Their popularity is well-earned, especially when dealing with the challenging nature of wastewater.

Working Principle:

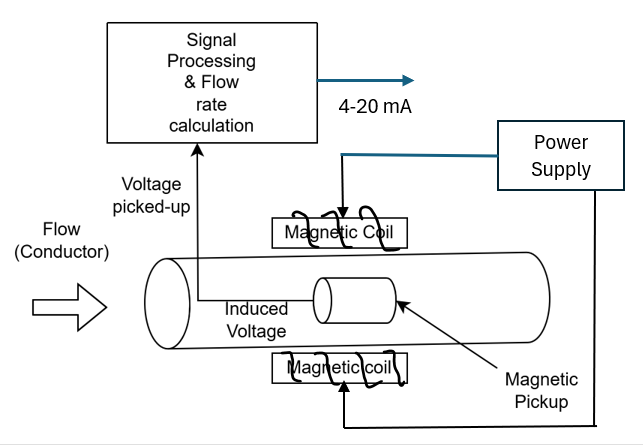

Magmeters operate on Faraday’s Law of Electromagnetic Induction. This law states that a voltage will be induced when a conductor moves through a magnetic field. In a magmeter, the “conductor” is the water itself.

- Magnetic Field Generation: A set of coils outside the pipe generates a magnetic field perpendicular to the direction of flow.

- Voltage Induction: As the conductive water (even wastewater has enough ions to be conductive) flows through this magnetic field, a small voltage is induced.

- Sensing and Calculation: Two electrodes mounted on the inside wall of the meter detect this voltage. The magnitude of the voltage is directly proportional to the velocity of the water. The meter’s transmitter then converts this voltage into a flow rate.

Block Diagram of a Magnetic Flow Meter:

Cost-Effectiveness Analysis:

- Initial Cost: The upfront cost of a full-bore magmeter can be moderate. However, for larger pipe sizes, the cost can increase significantly. This is where insertion-style magmeters become highly cost-effective, as their price is not dependent on the pipe diameter.

- Installation: Installation is relatively straightforward, but it does require cutting the pipe for a full-bore meter. They often require a certain length of straight pipe upstream and downstream to ensure an accurate reading.

- Maintenance: This is where magmeters truly shine in cost-effectiveness. With no moving parts, there is virtually no mechanical wear and tear. This translates to very low maintenance costs over the meter’s long lifespan. The primary maintenance consideration is ensuring the electrodes don’t get coated in grease or scale, which can be mitigated with periodic cleaning or by choosing models with automatic cleaning functions.

- Lifespan: Magmeters are incredibly durable and can last for decades with minimal attention.

Ideal Applications:

- Wastewater (raw sewage, activated sludge)

- Slurries

- Any conductive liquid

- Water treatment chemicals

Pros and Cons:

| Pros | Cons |

|---|---|

| No moving parts, low maintenance | Requires a conductive fluid |

| Obstructionless design, no pressure drop | Can be expensive for very large pipes (full-bore) |

| High accuracy | Electrodes can become coated in greasy applications |

| Unaffected by most solids in wastewater | Higher initial cost than mechanical meters |

| Bi-directional flow measurement |

2. Propeller Meters: The Economical Choice for Clean Water

Propeller meters, a type of turbine meter, have been a staple in the water industry for decades, particularly in agriculture and for raw water intake. They offer a simple, mechanical, and low-cost way to measure flow.

Working Principle:

The principle is straightforward and analogous to a windmill.

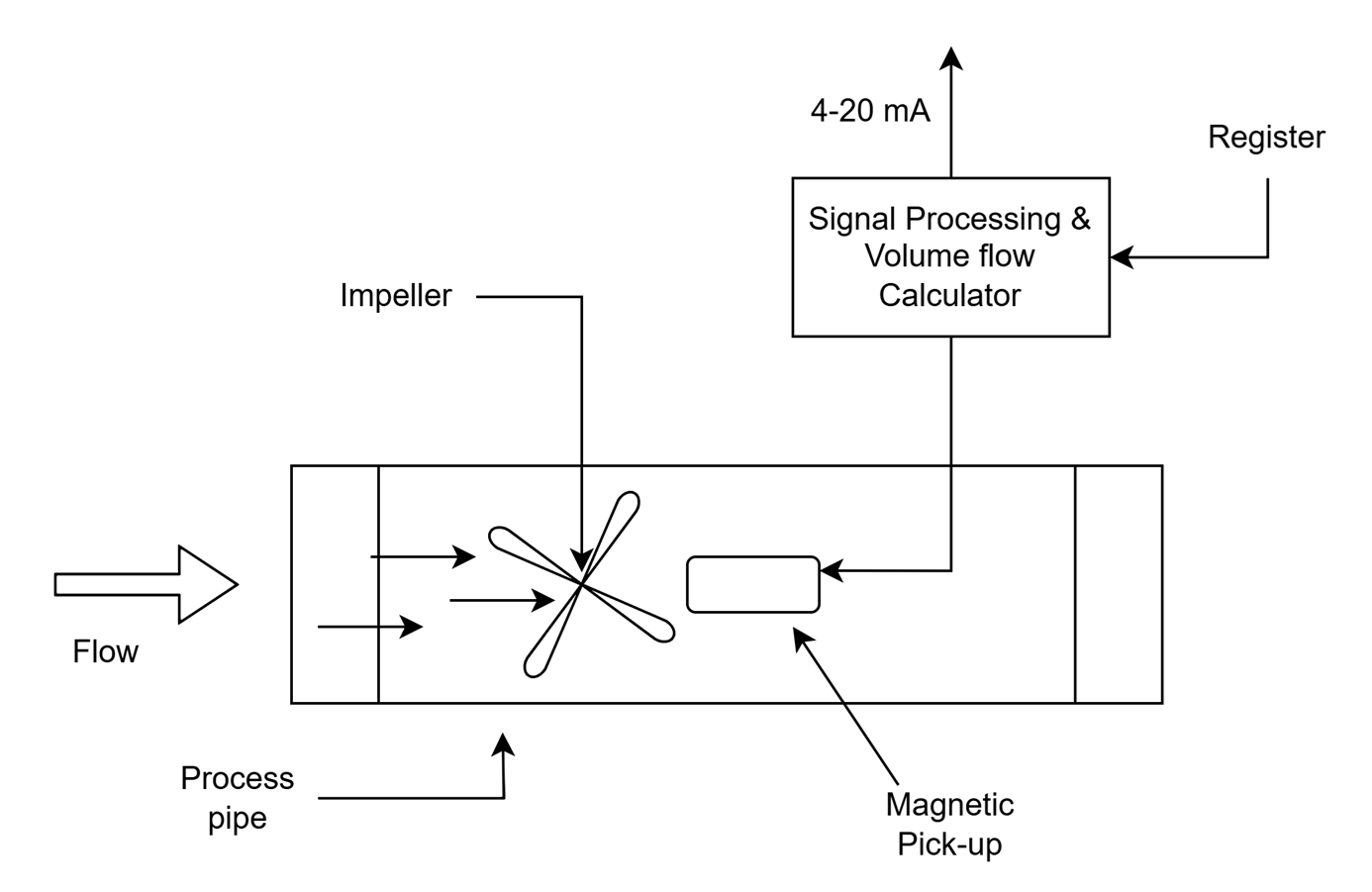

- Propeller Rotation: A propeller (or impeller) is placed in the path of the fluid flow.

- Direct Proportionality: The speed at which the propeller rotates is directly proportional to the velocity of the water.

- Measurement: The rotation is mechanically or magnetically linked to a register on the top of the meter, which displays the total volume of water that has passed through and the current flow rate.

Block Diagram of a Propeller Meter:

Cost-Effectiveness Analysis:

- Initial Cost: Propeller meters generally have a lower initial purchase price compared to magmeters and ultrasonic meters, making them a very attractive option for budget-conscious projects.

- Installation: Installation is similar to other inline meters, requiring the pipe to be cut.

- Maintenance: This is the primary trade-off. Because they have moving parts (the propeller and bearings), they are subject to wear and tear, especially in water with high sediment or grit. Regular inspection and periodic replacement of bearings or the propeller itself are necessary, which adds to the long-term cost of ownership.

- Lifespan: With proper maintenance, propeller meters can have a long service life. However, in poor quality water, their lifespan will be shorter than a magmeter’s.

Ideal Applications:

- Clean water distribution

- Irrigation

- Well water monitoring

- Raw water intake from rivers or reservoirs (with appropriate screening)

Pros and Cons:

| Pros | Cons |

|---|---|

| Low initial cost | Moving parts require maintenance and can wear out |

| No power required for mechanical versions | Prone to damage from debris and solids |

| Easy to read and understand | Creates a pressure drop in the pipe |

| High turndown ratio (can measure a wide range of flows) | Less accurate than magmeters |

3. Clamp-On Ultrasonic Flow Meters: The Non-Invasive Innovator

Ultrasonic flow meters represent a significant leap in technology, offering the ability to measure flow from outside the pipe. This non-invasive nature provides unique cost-saving advantages.

Working Principle:

Clamp-on ultrasonic meters use the “transit-time” method.

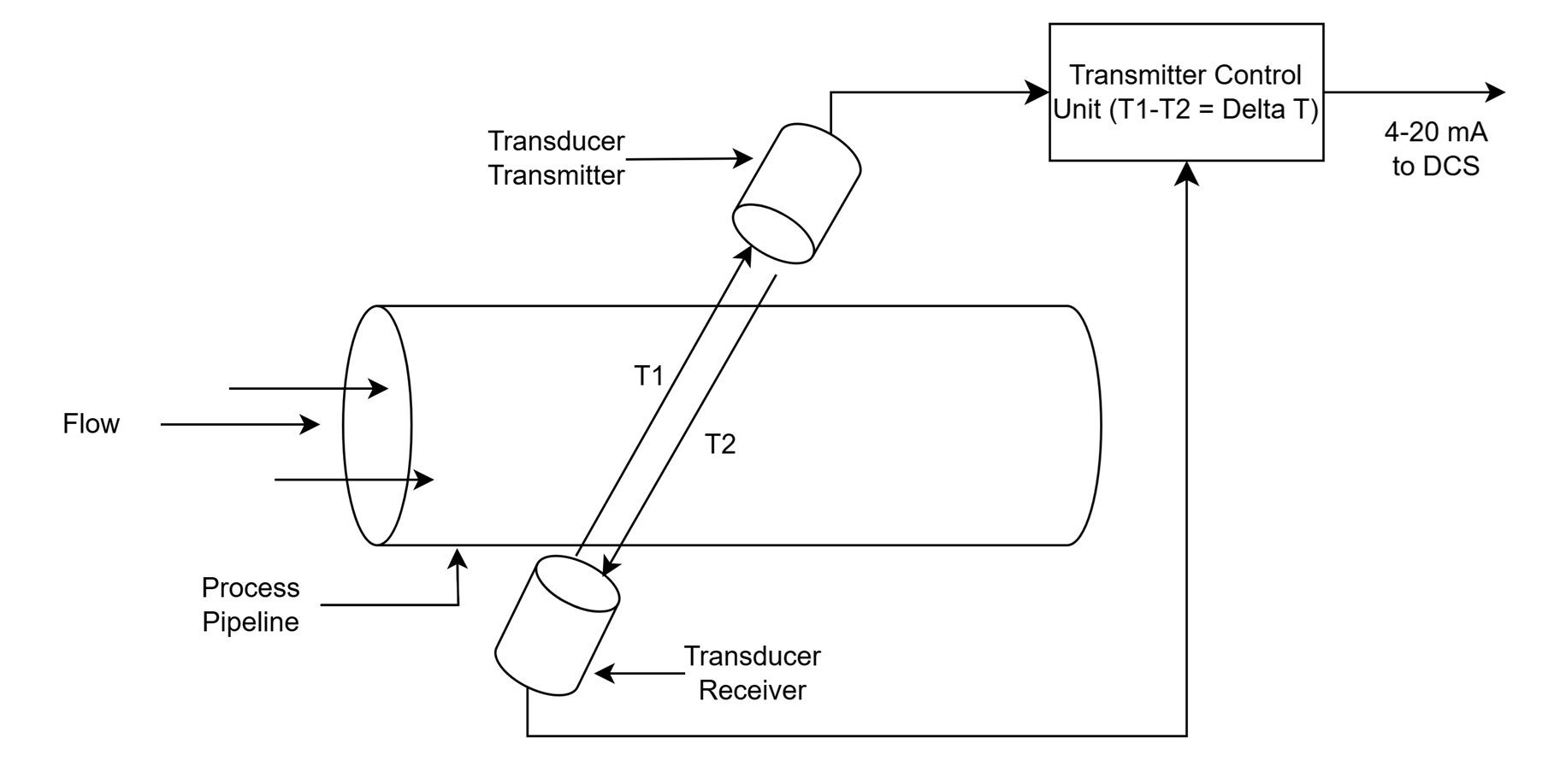

- Transducer Pair: Two transducers are strapped to the outside of the pipe. They act as both transmitters and receivers of ultrasonic pulses.

- Signal Transmission: One transducer sends a sound pulse through the pipe wall and the water to the second transducer. This is done both with and against the direction of flow.

- Time Difference: The pulse traveling with the flow will arrive slightly faster than the pulse traveling against the flow.

- Flow Calculation: The meter measures this tiny time difference (Delta t). This difference is directly proportional to the velocity of the fluid. The meter uses this, along with the pipe’s dimensions, to calculate the flow rate.

Block Diagram of a Clamp-On Ultrasonic Flow Meter:

Cost-Effectiveness Analysis:

- Initial Cost: The initial cost of an ultrasonic meter can be higher than a propeller meter but is often competitive with, or even cheaper than, a large-diameter magmeter.

- Installation: This is the standout feature for cost savings. Installation is incredibly cheap and fast. There is no need to cut the pipe, weld flanges, or shut down the process. This eliminates the costs associated with labor, heavy equipment, and downtime.

- Maintenance: With no moving parts and no contact with the fluid, maintenance is very low. There is no risk of corrosion or wear.

- Lifespan: The electronic components are robust, and the lack of physical interaction with the process fluid gives them a very long potential lifespan.

Ideal Applications:

- Retrofitting on existing pipelines where shutdown is difficult or expensive.

- Large diameter pipes where other meter types are prohibitively expensive.

- Clean to moderately dirty water (high levels of solids or bubbles can interfere with the signal).

- System audits and temporary flow measurement.

Pros and Cons:

| Pros | Cons |

|---|---|

| No pipe cutting, no process shutdown for installation | Less accurate on water with high solids/bubbles |

| No pressure drop | Accuracy is highly dependent on correct installation and pipe conditions |

| No contact with the fluid, no corrosion or wear | Can be more expensive initially than mechanical meters |

| Portable versions are available for spot-checking | Pipe wall condition (corrosion, lining) can affect the signal |

Cost-Effective Solutions for Open Channel Flow

Measuring flow in open channels like canals or effluent troughs requires a different approach. Here, cost-effectiveness is often found in pairing a primary device with a level sensor.

1. Weirs and Flumes with Ultrasonic Level Sensors: The Classic Combo

This is the most common and cost-effective method for open channel measurement. It’s a two-part system.

Primary Device (Weir or Flume): A specifically shaped obstruction is placed in the channel.

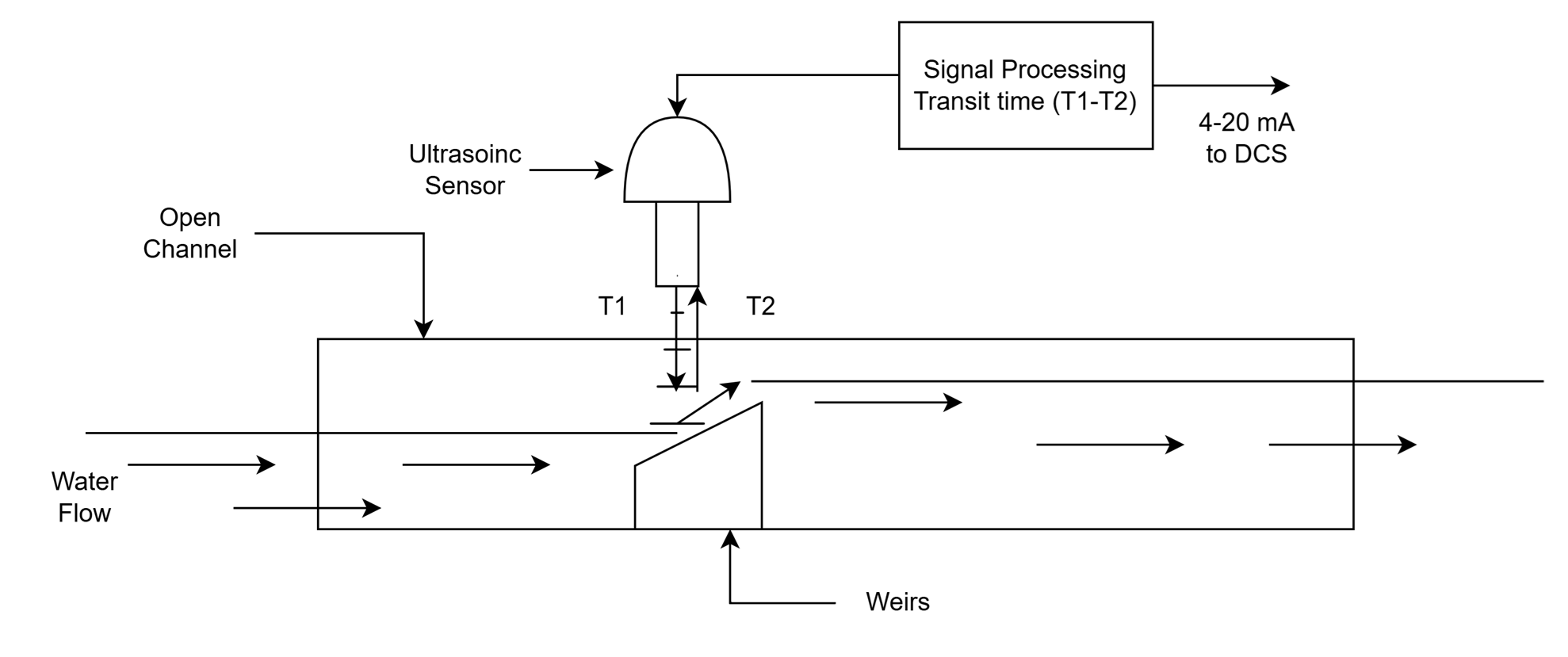

- Weirs: A dam-like structure with a notch of a specific shape (V-notch, rectangular) through which the water flows.

- Flumes: A specially shaped section of the channel that constricts the flow (e.g., Parshall flume, Palmer-Bowlus flume). The key principle is that for a given shape of weir or flume, the height (or “head”) of the water flowing over it has a known, non-linear relationship to the flow rate.

Ultrasonic Level Sensor: A non-contacting sensor is mounted above the water surface, upstream of the primary device. It emits an ultrasonic pulse down to the water surface and measures the time it takes for the echo to return. This time is used to calculate the precise level of the water.

The flow measurement system then takes the level reading from the sensor and applies the known mathematical formula for the specific weir or flume to calculate the flow rate.

Block Diagram of a Weir/Flume with Ultrasonic Sensor:

Cost-Effectiveness Analysis:

- Initial Cost: The cost of the ultrasonic level sensor and transmitter is relatively low. The main cost can be the construction and installation of the weir or flume, which can vary greatly depending on the size of the channel and the material used (concrete, fiberglass, etc.). However, for many treatment plants that already have these structures in place, the cost is simply that of the instrumentation.

- Installation: Installing the sensor is simple. Installing the primary device can be a significant civil works project.

- Maintenance: The ultrasonic sensor itself is non-contact and requires very little maintenance. The weir or flume may require periodic cleaning to remove debris or algae that could affect its hydraulic properties.

- Lifespan: Both the primary devices (if well-built) and the sensors are extremely durable and can last for many years.

Ideal Applications:

- Wastewater treatment plant effluent

- Stormwater monitoring

- Irrigation canals

- Industrial discharge monitoring

Pros and Cons:

| Pros | Cons |

|---|---|

| Highly reliable and accurate when properly installed | Installation of a weir or flume can be expensive |

| Non-contact measurement (sensor) means low maintenance | Weirs can cause solids to accumulate upstream |

| Relatively low cost for the electronic components | Flumes are better with solids but can still have issues |

| Widely accepted for regulatory reporting | Requires a fixed, known channel shape |

Making the Right Choice: Factors to Consider

Selecting the most cost-effective flow meter is not just about the sticker price. Consider the total cost of ownership by asking these questions:

- Fluid Properties: Is the water clean or full of solids? Is it conductive? The nature of the fluid will immediately rule out some technologies.

- Installation Requirements: Can you afford to shut down the line for installation? Do you have enough straight pipe? Clamp-on ultrasonic meters excel where installation is a major cost driver.

- Accuracy Needs: What level of accuracy is required? While all these meters are reliable, magmeters generally offer higher accuracy than propeller meters.

- Maintenance Capacity: Do you have the personnel for regular mechanical maintenance? If not, a zero-maintenance option like a magmeter or ultrasonic meter is a more cost-effective long-term solution.

- Pipe Size: For very large pipes, clamp-on ultrasonic or insertion magmeters are almost always more cost-effective than full-bore meters.

Conclusion: Smart Spending for Superior Flow Data

The journey to cost-effective flow measurement is about smart, informed decisions, not just finding the cheapest hardware. For the abrasive and challenging world of wastewater, the magnetic flow meter stands out as the long-term cost champion due to its “fit and forget” nature. For clean water applications where initial budget is the primary driver, the propeller meter remains a viable and economical choice, provided maintenance is factored in.

When installation costs and process downtime are major concerns, or when dealing with large and existing pipelines, the clamp-on ultrasonic meter offers unparalleled value and flexibility. And for the vast networks of open channels, the tried-and-true combination of a weir or flume with an ultrasonic level sensor continues to provide a reliable and affordable solution.

By carefully evaluating your specific application, considering the total cost of ownership, and leveraging the strengths of these cost-effective technologies, you can implement a flow measurement strategy that delivers the accuracy you need and the budget you can afford.