Actuators for Control Valves: A Detailed Comparison of Pneumatic, Electric, and Hydraulic Options

In the intricate world of industrial process control, the control valve stands as the final control element, the muscle that ultimately implements the decisions of the plant’s control system. But what gives this muscle its power? The answer lies in the actuator, the device responsible for positioning the valve to regulate the flow of fluids. The choice of actuator is as critical as the selection of the valve itself, with each type—pneumatic, electric, and hydraulic—offering a unique set of capabilities and characteristics. This comprehensive guide will delve into the workings, advantages, disadvantages, and ideal applications of each, providing a detailed comparison to aid in the selection of the optimal actuator for your control valve needs.

The Unseen Power: Understanding the Role of a Control Valve Actuator

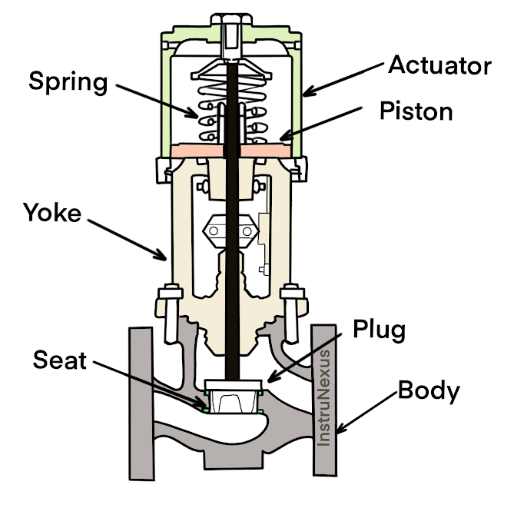

Before we dissect the different actuator technologies, it’s crucial to appreciate their fundamental role. An actuator is a device that converts a source of energy into mechanical motion. In the context of control valves, this motion is typically either linear (for globe, gate, and diaphragm valves) or rotary (for ball, butterfly, and plug valves). The actuator responds to a control signal, precisely positioning the valve’s closure member (e.g., the plug, ball, or disc) to modulate the flow rate and maintain the process variable at the desired setpoint. The performance of the entire control loop hinges on the actuator’s ability to respond accurately, rapidly, and reliably.

The Workhorse of the Industry: Pneumatic Actuators

Pneumatic actuators are the most prevalent type in process industries, and for good reason. They are renowned for their simplicity, reliability, and cost-effectiveness.

Principle of Operation

The operation of a pneumatic actuator is elegantly simple. It utilizes compressed air as its power source. In a typical diaphragm-style actuator, the control signal, often a 3-15 psi (0.2-1.0 bar) pneumatic signal or a 4-20 mA electrical signal converted by a positioner, modulates the air pressure on one side of a flexible diaphragm. This pressure creates a force that counteracts a pre-compressed spring. The resulting movement of the diaphragm is transferred to the valve stem, positioning the valve.

Piston-style pneumatic actuators operate on a similar principle but use a piston within a cylinder, allowing for longer strokes and higher thrust outputs. They can be either single-acting (spring-return) or double-acting (air pressure is used for both opening and closing strokes).

Advantages of Pneumatic Actuators

- Cost-Effective: Pneumatic actuators are generally the most economical option, both in terms of initial purchase price and maintenance costs.

- Simplicity and Reliability: Their straightforward design with fewer components translates to high reliability and ease of maintenance.

- Inherent Fail-Safe Action: Spring-return pneumatic actuators offer a natural and dependable fail-safe mechanism. In the event of a power or air supply failure, the spring will force the valve to a predetermined safe position (either fully open or fully closed).

- Fast Response: They are capable of very fast stroking speeds, which is critical in many process control applications.

- Safety in Hazardous Environments: The use of compressed air as the power source makes them inherently safe for use in explosive or flammable environments where electrical sparks could be catastrophic.

- High Force Output: Piston-style actuators can generate significant thrust, making them suitable for large valves and high-pressure applications.

Disadvantages of Pneumatic Actuators

- Requirement for Compressed Air Infrastructure: Their reliance on compressed air necessitates a dedicated and well-maintained air supply system, which can be a significant investment.

- Lower Efficiency: The generation and transmission of compressed air can be energy-intensive, making them less efficient than electric actuators.

- Sensitivity to Air Quality: The performance and longevity of pneumatic actuators can be affected by the quality of the compressed air. Moisture, oil, and particulates can cause operational issues.

- Limited Precision without a Positioner: For precise throttling control, a positioner is often required to overcome friction and ensure accurate valve positioning in response to the control signal.

Typical Applications

Pneumatic actuators are the go-to choice for a vast array of applications across various industries, including:

- Oil and gas production, refining, and transportation

- Chemical and petrochemical processing

- Power generation

- Water and wastewater treatment

- Pulp and paper manufacturing

- Food and beverage production

The Rise of Precision: Electric Actuators

Electric actuators are increasingly gaining traction in the process control landscape, offering a compelling combination of precision, programmability, and integration capabilities.

Principle of Operation

Electric actuators convert electrical energy into mechanical motion, typically through an electric motor and a gearbox. The motor drives a gear train, which in turn actuates a lead screw or a rack and pinion mechanism to produce linear or rotary motion. Modern electric actuators are sophisticated devices, often incorporating an integrated control unit, position sensors, and diagnostic capabilities.

Advantages of Electric Actuators

- High Precision and Repeatability: Electric actuators offer exceptionally precise positioning and high repeatability, making them ideal for applications requiring tight control.

- Programmability and Integration: They can be easily integrated with digital control systems like DCS (Distributed Control System) and PLC (Programmable Logic Controller), allowing for advanced control strategies and remote diagnostics.

- Energy Efficiency: Electric actuators only consume power when they are moving, making them more energy-efficient than pneumatic systems that require a continuous supply of compressed air.

- No Air Supply Required: Their operation is independent of a compressed air system, simplifying installation and reducing infrastructure costs in facilities where compressed air is not readily available.

- Clean Operation: The absence of air or hydraulic fluid makes them a clean and environmentally friendly option.

- High Torque/Thrust: They can generate very high levels of torque and thrust.

Disadvantages of Electric Actuators

- Higher Initial Cost: The initial purchase price of an electric actuator is generally higher than that of a comparable pneumatic actuator.

- Slower Speed: Traditionally, electric actuators have been slower to stroke than their pneumatic and hydraulic counterparts. However, recent advancements are closing this gap.

- Complex Fail-Safe Mechanisms: Achieving a reliable fail-safe position in the event of a power failure is more complex and often requires a battery backup system or a mechanical spring, adding to the cost and complexity.

- Limited Suitability for Hazardous Environments: Standard electric actuators are not suitable for explosive atmospheres and require expensive and bulky explosion-proof enclosures.

- Heat Generation: The motor can generate heat, which may be a concern in high-temperature environments or applications with high duty cycles.

Typical Applications

The precision and intelligence of electric actuators make them well-suited for a variety of applications, including:

- Building automation (HVAC systems)

- Water and wastewater treatment plants

- Power generation facilities where precise control is paramount

- Remote or unmanned installations where a compressed air supply is not feasible

- Applications requiring frequent and precise positioning changes

The Powerhouse: Hydraulic Actuators

When immense force is the primary requirement, hydraulic actuators reign supreme. They are the heavy-lifters of the actuator world, capable of generating unparalleled levels of thrust and torque.

Principle of Operation

Hydraulic actuators operate on the principle of Pascal’s Law, utilizing an incompressible fluid (typically oil) under high pressure to generate force. A hydraulic power unit (HPU) supplies pressurized fluid to a cylinder, where it acts on a piston to produce linear motion. For rotary motion, a hydraulic motor or a vane-type actuator is used. The flow of hydraulic fluid is controlled by servo or proportional valves, allowing for precise control over the actuator’s movement.

Advantages of Hydraulic Actuators

- Unmatched Force and Torque: Hydraulic actuators can generate extremely high forces and torques, making them the only viable option for very large valves and high-pressure, high-flow applications.

- High Power-to-Size Ratio: They offer a very high power-to-size ratio, meaning they can produce a large amount of force from a relatively compact package.

- Stiffness and Stability: The incompressibility of the hydraulic fluid provides a high degree of stiffness, resulting in stable and precise positioning even under fluctuating load conditions.

- Fast Response: Hydraulic actuators are capable of very fast and smooth stroking speeds.

Disadvantages of Hydraulic Actuators

- High Cost and Complexity: Hydraulic systems, including the actuator, HPU, and associated piping, are the most expensive option. They are also complex to install and maintain.

- Requirement for a Hydraulic Power Unit: They necessitate a dedicated HPU, which adds to the initial investment and ongoing maintenance requirements.

- Potential for Leaks: The use of hydraulic fluid introduces the risk of leaks, which can be a safety hazard and an environmental concern.

- Fluid Maintenance: The hydraulic fluid must be kept clean and at the proper temperature to ensure optimal performance and prevent damage to the system.

- Lower Efficiency: Like pneumatic systems, hydraulic systems can be less energy-efficient due to pressure drops and the continuous operation of the HPU.

Typical Applications

The immense power of hydraulic actuators makes them indispensable in a range of demanding applications, such as:

- Large-scale water control projects (dams, large water mains)

- Power generation (turbine control, large steam valves)

- Steel mills and other heavy industrial processes

- Offshore oil and gas platforms

- Mining operations

A Head-to-Head Comparison: Pneumatic vs. Electric vs. Hydraulic

| Feature | Pneumatic Actuator | Electric Actuator | Hydraulic Actuator |

|---|---|---|---|

| Power Source | Compressed Air | Electricity | Hydraulic Fluid (Oil) |

| Thrust/Torque | Moderate to High | Low to Very High | Very High |

| Speed of Operation | Fast | Moderate to Fast | Very Fast |

| Control Precision | Good (with positioner) | Excellent | Excellent |

| Fail-Safe | Simple & Inherent (Spring-Return) | Complex (Battery/Spring) | Can be complex |

| Initial Cost | Low | High | Very High |

| Operating Cost | Moderate (Air Generation) | Low | High (Fluid, Maintenance) |

| Maintenance | Low | Low to Moderate | High |

| Hazardous Areas | Excellent (Intrinsically Safe) | Poor (Requires Explosion-Proofing) | Good (with proper design) |

| Complexity | Low | Moderate | High |

| Environmental Impact | Low (Air Leaks) | Very Low | Moderate (Fluid Leaks) |

Making the Right Choice: Key Selection Criteria

The selection of the appropriate actuator is a multi-faceted decision that requires a thorough evaluation of the specific application requirements. Here are the key factors to consider:

- Valve Type and Size: The type of valve (linear or rotary) and its size will dictate the required motion and the amount of thrust or torque needed.

- Power Source Availability: The availability and reliability of a compressed air supply, electricity, or a hydraulic power unit will be a primary determinant.

- Fail-Safe Requirement: The criticality of the process will determine the need for a fail-safe mechanism and the preferred fail position (open, closed, or last position).

- Control Requirements: The need for precise throttling control, fast response times, or integration with a digital control system will influence the choice.

- Environmental Conditions: The ambient temperature, presence of corrosive or explosive materials, and other environmental factors must be considered.

- Total Cost of Ownership: This includes not only the initial purchase price but also the installation, operating, and maintenance costs over the lifetime of the actuator.

Conclusion: The Right Actuator for the Right Job

There is no single “best” actuator for all control valve applications. Each type—pneumatic, electric, and hydraulic—presents a unique set of strengths and weaknesses. The ubiquitous pneumatic actuator remains the workhorse of the process industries due to its simplicity, reliability, and cost-effectiveness. The intelligent and precise electric actuator is rapidly gaining ground, particularly in applications demanding high accuracy and digital integration. And for sheer power, the hydraulic actuator stands in a class of its own.

Ultimately, a well-informed decision based on a comprehensive understanding of the process requirements and the distinct characteristics of each actuator type will lead to the selection of a solution that ensures optimal performance, reliability, and safety for your control valve and the entire process it governs. By carefully weighing the factors of power, precision, safety, and cost, you can empower your control valves with the right muscle to get the job done effectively and efficiently for years to come.