In the heart of many industrial processes, from oil and gas refining to chemical production and power generation, lies a critical piece of rotating equipment: the centrifugal compressor. These machines are the workhorses responsible for increasing the pressure of a gas, a fundamental step in numerous applications. However, lurking within their operational envelope is a destructive phenomenon known as surge—a condition that can lead to catastrophic failure if not properly managed. This is where the anti-surge control valve steps in, acting as a vigilant guardian, ensuring the smooth and safe operation of these vital assets.

This comprehensive blog post delves into the critical design considerations and diverse applications of anti-surge control valves, providing a thorough understanding of their role in modern industry. We will explore the intricacies of surge, the specific features that make an anti-surge valve effective, and the various sectors where their application is indispensable, complete with illustrative block diagrams.

What is Compressor Surge?

Before we can appreciate the role of the anti-surge valve, we must first understand the phenomenon it is designed to prevent. A centrifugal compressor operates by converting kinetic energy into pressure energy. Gas enters the compressor’s impeller, where it is accelerated to a high velocity. It then passes through a diffuser, which slows the gas down, converting its velocity into a rise in pressure.

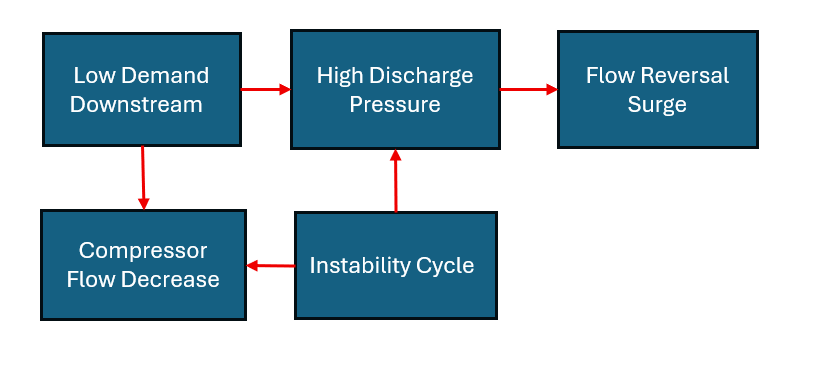

Surge is a condition of flow instability that occurs at low flow rates. When the flow through the compressor drops below a certain point for a given discharge pressure, the compressor is unable to maintain a stable flow. The high-pressure gas downstream of the compressor momentarily flows backward through the machine, leading to a rapid and violent pulsation of flow and pressure. This cycle of flow reversal and correction can occur multiple times per second, subjecting the compressor to severe mechanical stress, high vibrations, and a rapid increase in temperature. The consequences of unchecked surge can range from damage to seals and bearings to complete rotor destruction, resulting in costly downtime and significant safety hazards.

To visualize this, consider the compressor’s performance map, which plots the pressure ratio against the flow rate. The surge line on this map represents the boundary between stable and unstable operation. The primary goal of an anti-surge control system is to keep the compressor’s operating point safely to the right of this surge line.

The Anti-Surge Control System

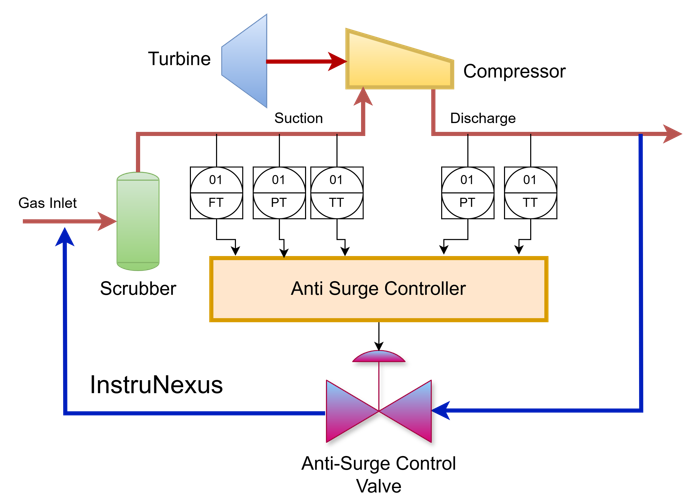

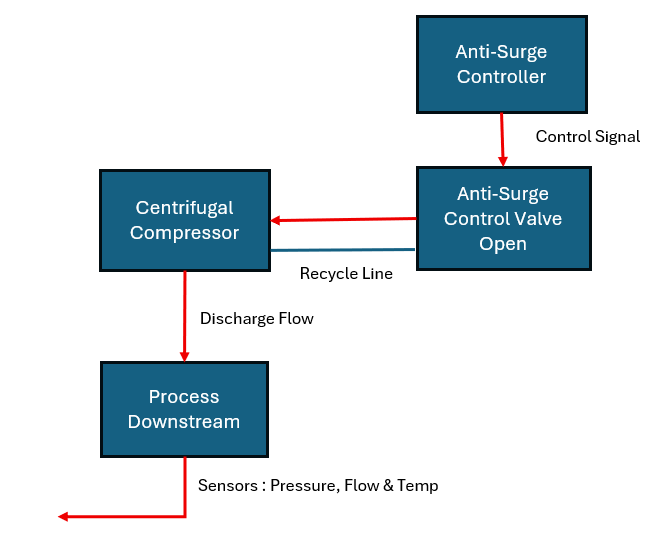

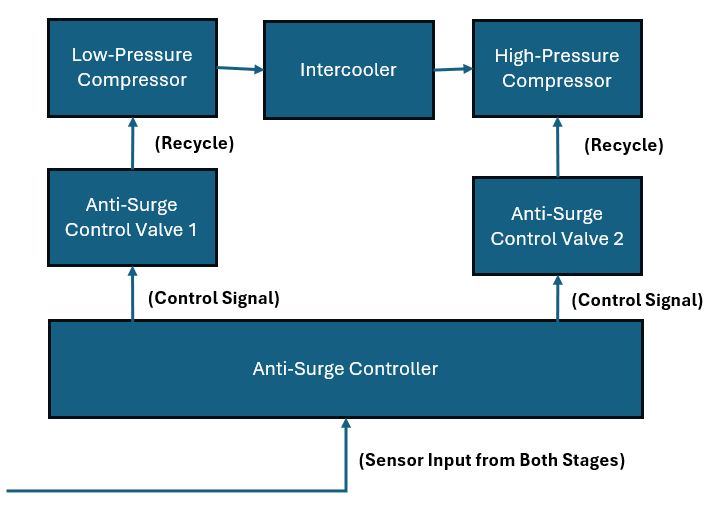

An anti-surge control system is an automated safety loop designed to detect the onset of surge and take immediate corrective action. The system continuously monitors key compressor parameters such as suction flow, suction pressure, discharge pressure, and sometimes temperature and rotational speed. This data is fed into a dedicated anti-surge controller, which calculates the proximity of the operating point to the surge line.

When the controller detects that the operating point is approaching the surge line, it sends a signal to the anti-surge control valve. This valve, typically installed in a recycle line that connects the compressor’s discharge back to its suction, opens rapidly to divert a portion of the high-pressure gas. This recycled flow artificially increases the total flow through the compressor, effectively moving the operating point away from the surge line and back into the stable operating region.

Block Diagram 2: Basic Anti-Surge Control Loop

Key Considerations for Anti-Surge Control Valves

Not all control valves are created equal, and the demanding nature of anti-surge applications necessitates a valve with specific design characteristics. The primary requirement is speed. An anti-surge valve must be able to go from fully closed to the required open position in a matter of seconds, often less than two, to prevent a surge event. This rapid response is critical to outpace the fast-developing instability.

Here are the key design considerations for anti-surge control valves:

-

Actuator Speed and Power: To achieve the necessary stroking speeds, anti-surge valves are equipped with powerful, fast-acting actuators. Pneumatic piston or diaphragm actuators are common, often coupled with volume boosters and quick-exhaust valves to minimize response time. Electro-hydraulic actuators are also employed for their high speed and precise control capabilities. The actuator must be powerful enough to overcome the high-pressure differentials across the valve.

-

Valve Sizing and Flow Characteristic: Sizing an anti-surge valve is a delicate balance. It must be large enough to handle the required recycle flow to move the compressor out of surge, even during a worst-case scenario like an emergency shutdown (ESD). However, an oversized valve can lead to poor control at lower recycle flow rates, causing instability in the control loop. The valve’s flow characteristic is also crucial. A linear characteristic is often preferred as it provides a predictable and proportional relationship between valve travel and flow rate, simplifying control.

-

Trim Design for Noise and Vibration Reduction: The process of recycling high-pressure gas to a lower-pressure suction line can generate significant noise and vibration. This is due to the high-pressure drop and turbulent flow. Modern anti-surge valves often feature specialized trim designs, such as multi-stage or labyrinth-style plugs and cages. This trim breaks down the pressure drop into smaller, more manageable stages, thereby reducing noise levels by as much as 30-40 dBA and minimizing vibration that could damage the valve and surrounding piping.

-

Material Selection and Durability: Anti-surge valves are subjected to demanding conditions, including high-pressure differentials, rapid temperature changes, and potentially corrosive or erosive process fluids. Therefore, robust material selection is paramount. Carbon steel is common for standard applications, while stainless steels and other exotic alloys are used for corrosive services. The trim components, being the most vulnerable to wear, often utilize hardened materials like Stellite.

-

Tight Shut-off and Low Leakage: When the compressor is operating normally, the anti-surge valve remains closed. To prevent the loss of valuable compressed gas and maintain process efficiency, the valve must provide a tight shut-off. This is typically achieved through the use of soft seats or precision-machined metal-to-metal seating surfaces.

-

Reliability and Diagnostics: Given their critical safety function, anti-surge valves must be highly reliable. They are often equipped with advanced diagnostic features, such as smart positioners that continuously monitor the valve’s health and performance. These positioners can detect issues like increased friction, air leaks, or calibration drifts, allowing for proactive maintenance before a failure occurs.

Where the Guardians Stand: Applications of Anti-Surge Control Valves

Anti-surge control valves are ubiquitous in any industry that relies on large centrifugal compressors. Here are some of the key application areas:

-

Oil and Gas Production: In upstream and midstream operations, centrifugal compressors are used for gas gathering, gas lift, and gas injection to enhance oil recovery. The variable nature of gas flows in these applications makes robust anti-surge protection essential.

-

Liquefied Natural Gas (LNG) Plants: The liquefaction of natural gas involves a series of compression and cooling stages. The massive centrifugal compressors used in these “refrigeration trains” are among the largest in the world and represent a significant capital investment. The anti-surge valves in an LNG plant are critical for protecting these multi-million dollar assets.

-

Refining and Petrochemical Industries: Refineries and petrochemical plants utilize centrifugal compressors in a wide range of processes, including hydrocracking, catalytic reforming, and ethylene production. The complex and often fluctuating operating conditions in these plants necessitate reliable anti-surge systems to ensure process stability and safety.

-

Power Generation: In combined-cycle power plants, gas turbines drive centrifugal compressors to pressurize the air for combustion. Anti-surge valves protect these compressors during startup, shutdown, and load changes.

-

Steel Manufacturing: Large centrifugal blowers are used to supply vast quantities of air to blast furnaces. Anti-surge control is crucial to prevent damage to these critical blowers and ensure a continuous supply of air for the steelmaking process.

-

Fertilizer Production: The synthesis of ammonia, a key component of fertilizers, relies on the compression of nitrogen and hydrogen gases. Anti-surge valves are integral to the safe and efficient operation of the synthesis gas compressors.

Block Diagram 3: Anti-Surge Valve in a Multi-Stage Compressor Application

The Final Word: A Critical Component for a Stable Process

The anti-surge control valve is far more than just a piece of hardware; it is a critical safety and operational component that safeguards the heart of many industrial processes. The consequences of a surge event can be severe, leading to costly equipment damage, production losses, and significant safety risks.

By understanding the destructive nature of surge and carefully considering the unique design requirements of anti-surge valves—from lightning-fast actuation to sophisticated noise-reducing trims—engineers can ensure the reliable and efficient operation of centrifugal compressors. As industries continue to push the boundaries of performance and efficiency, the role of the humble yet mighty anti-surge control valve will remain as crucial as ever, a silent guardian standing ready to protect against the ever-present threat of surge.