Control Valve Trims

Understanding the Core Differences Between Balanced and Unbalanced Designs

What is Valve Trim?

Control valves are essential components in process industries, regulating the flow of fluids. One of the most critical internal features of a control valve is its **trim**—the internal parts that are directly responsible for modulating the flow.

The term "valve trim" refers to all internal parts of a valve that are in contact with the process fluid and directly affect flow control. This includes:

The design of the trim determines the flow characteristics, capacity, shutoff capability, and pressure balancing of the valve.

Unbalanced Trim

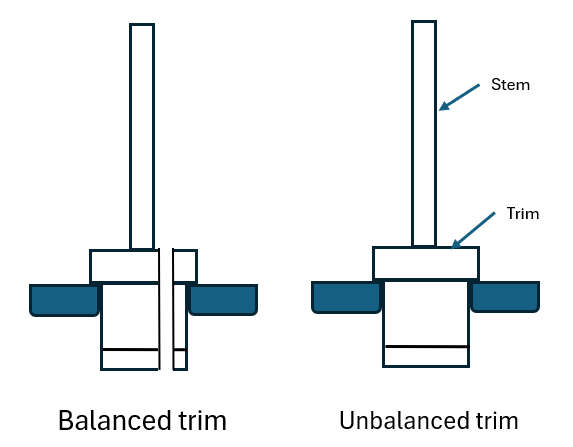

In an unbalanced trim, the process fluid pressure acts directly on the full area of the plug, creating a significant force that the actuator must overcome.

Advantages

- ✔ Simple and robust construction

- ✔ Provides effective, tight shutoff

- ✔ Lower initial cost

- ✔ Ideal for low-pressure drop applications

Disadvantages

- ✖ Requires high thrust from the actuator

- ✖ Needs larger, more expensive actuators

- ✖ Unsuitable for high-pressure systems

- ✖ Potential for plug instability

Balanced Trim

A balanced trim is engineered to reduce the net force on the plug by equalizing pressure on both sides, often using balancing holes and seals.

Advantages

- ✔ Requires significantly lower actuator thrust

- ✔ Allows for smaller, less costly actuators

- ✔ Excellent for high-pressure & high-flow

- ✔ Provides more stable plug movement

Disadvantages

- ✖ More complex design and construction

- ✖ Higher initial cost

- ✖ Seals and O-rings can wear and fail

- ✖ Not suitable for dirty or slurry service

Key Design Features Compared

| Feature | Unbalanced Trim | Balanced Trim |

|---|---|---|

| Force Requirement | High | Low |

| Actuator Size | Large | Smaller |

| Cost | Lower | Higher |

| Maintenance | Lower, simpler | Higher, due to seals |

| Applications | Low-pressure, clean service | High-pressure, high-flow |

| Shutoff Capability | Very tight | Good (seal dependent) |

| Susceptibility to Wear | Low | High (seal wear) |

| Design Complexity | Simple | Complex |

Selecting the Right Trim Type

Pressure Drop

High pressure drops (> 100 psi) often demand a balanced trim, while low-pressure drops work well with unbalanced designs.

Shutoff Requirement

For bubble-tight shutoff in low-pressure systems, unbalanced trim is ideal. Balanced trims can also achieve good shutoff with proper sealing.

Fluid Cleanliness

Unbalanced trims are more tolerant of particulates. The seals in balanced trims can wear quickly in dirty or slurry applications.

Valve Size & Actuator Limits

For larger valves (6”+) or when actuator size is limited, a balanced trim becomes essential to make the valve operable.

Conclusion: A Critical Choice

The choice between balanced and unbalanced trim directly impacts valve performance, operational efficiency, and system reliability. Choose **unbalanced trim** for simplicity and reliability in clean, low-pressure services. Opt for **balanced trim** in high-pressure, high-flow, or actuator-constrained environments, but be prepared for the required maintenance.

Control valves are essential components in process industries, regulating the flow of fluids—liquids, gases, or slurries—by varying the size of the flow passage. One of the most critical internal features of a control valve is its trim—the internal parts such as the plug, seat, and stem that are directly responsible for modulating the flow.

Control valve trims can be categorized into two major types: Balanced Trim and Unbalanced Trim. The selection between these two depends on process conditions such as pressure drop, flow rate, service fluid, actuator size, and required precision. This article explores the fundamental differences, operating principles, advantages, limitations, and selection criteria of balanced vs. unbalanced trim designs.

What is Valve Trim?

Before diving into the types, let’s clarify what we mean by trim. The term “valve trim” refers to all internal parts of a valve that are in contact with the process fluid and that directly affect flow control. This includes:

- Valve plug

- Seat ring

- Stem

- Guide bushings

- Cage (in cage-guided designs)

The design of the trim determines the flow characteristics, capacity, shutoff capability, and pressure balancing of the valve.

Unbalanced Trim – Overview

In an unbalanced trim, the process fluid pressure acts directly on the full area of the plug or disc. This results in a significant hydrodynamic force acting in the direction opposite to the stem movement.

Working Principle:

The plug is exposed to high pressure on one side and low pressure on the other. Because the plug does not have any design features (like balancing holes or seals) to counteract the pressure force, the stem and actuator must provide enough force to overcome this pressure imbalance.

Example:

In a globe valve with an unbalanced trim, the actuator must push the plug against the full line pressure to achieve tight shutoff. This is often feasible in low-pressure applications but can be problematic in high-pressure systems.

Advantages:

- Simple construction

- Robust and effective shutoff

- Lower cost

- Suitable for low-pressure drop applications

Disadvantages:

- High thrust force required from the actuator

- Larger actuator sizes needed

- Not suitable for high-pressure applications

- Potential for plug instability due to pressure forces

Balanced Trim – Overview

In contrast, a balanced trim is designed to reduce the net force acting on the plug by equalizing the pressure on both sides. This is accomplished using:

- Pressure balancing holes or slots in the plug

- O-rings or piston rings for sealing

- Double-seated or cage-guided designs

Working Principle:

Balanced trim uses engineering design features to cancel out pressure forces. In globe valves, this is often achieved with a hollow plug having pressure-balancing holes that allow fluid to enter from both sides of the plug, equalizing the pressure. Seals prevent leakage across the plug, ensuring that only the desired flow passes through.

Example:

In a high-pressure steam line, a balanced plug reduces the actuator thrust requirements significantly, allowing the use of smaller and less expensive actuators.

Advantages:

- Requires lower actuator thrust

- Smaller actuator sizes

- Suitable for high-pressure and high-flow applications

- More stable plug movement

Disadvantages:

- Complex design

- Higher cost

- Seals and O-rings may wear and require maintenance

- Not suitable for dirty or slurry service (due to seal wear)

Key Design Features Compared

| Feature | Unbalanced Trim | Balanced Trim |

| Force Requirement | High (direct pressure load on plug) | Low (pressure force balanced) |

| Actuator Size | Large | Smaller |

| Cost | Lower | Higher |

| Maintenance | Lower, simple design | Higher, due to seals/O-rings |

| Applications | Low-pressure, clean service | High-pressure, high-flow, critical service |

| Shutoff Capability | Very tight shutoff | Good, but depends on seal integrity |

| Susceptibility to Wear | Low | High (seal wear in dirty fluids) |

| Design Complexity | Simple | Complex (holes, seals, guides) |

Application Examples

Unbalanced Trim Applications:

- Cooling water control valves in HVAC systems

- Fuel gas control at low pressures

- Utility service lines

- Low-pressure steam or condensate return systems

Balanced Trim Applications:

- High-pressure steam control

- Gas transmission pipelines

- Boiler feedwater systems

- Hydrocarbon service in refineries

- Severe service valves in chemical reactors

Selecting the Right Trim Type

When selecting between balanced and unbalanced trim, engineers must consider several process and design factors:

- Pressure Drop Across the Valve

- High pressure drops (> 100 psi) often demand a balanced trim.

- Low-pressure drops can work well with unbalanced trim.

- Shutoff Requirement

- For bubble-tight shutoff in low-pressure systems, unbalanced trim is ideal.

- In high-pressure systems, balanced trims with proper sealing also achieve good shutoff.

- Actuator Limitations

- If actuator size and thrust are limited due to space or cost, a balanced trim can make the valve operable.

- Fluid Cleanliness

- Balanced trims use seals and O-rings that can wear out quickly in dirty or slurry applications.

- Unbalanced trims are more tolerant of particulates.

- Valve Size

- For larger valves (6” and above), the required force on an unbalanced plug becomes excessive; balanced trim becomes essential.

Maintenance Considerations

Balanced trims, due to their additional components (seals, rings, and ports), may require more frequent maintenance, especially in critical service. Any damage to the seal can compromise the performance and leak tightness. Periodic inspection and replacement of seals are required to maintain reliability.

Unbalanced trims, being simpler, are easier to inspect, maintain, and clean—especially important in remote or less accessible installations.

Innovations and Trends

Recent advancements in control valve design have focused on improving the reliability of balanced trims through:

- Improved materials for seals (e.g., PTFE blends, elastomers for high temperatures)

- Self-adjusting seals

- Better guide designs to reduce plug instability

- Multi-stage pressure drop trim designs for severe service

Some modern designs use hybrid approaches where the valve operates as unbalanced in normal conditions and switches to a balanced mode under high-pressure differentials.

Conclusion

The choice between balanced and unbalanced trim in control valves is not merely a design preference—it directly impacts valve performance, operational efficiency, maintenance requirements, and overall system reliability.

- Choose unbalanced trim for simplicity, reliability in clean low-pressure services, and lower cost.

- Opt for balanced trim in high-pressure, high-flow, or actuator-constrained environments, but ensure good maintenance practices to address potential seal issues.

An in-depth understanding of these trim types allows instrumentation and control engineers to make informed decisions that enhance plant safety, efficiency, and uptime.