Mastering the Flow: Best Practices for Optimizing Onshore Oil and Gas Production

In the dynamic and ever-evolving landscape of the oil and gas industry, the quest for production optimization is a constant endeavor. For onshore operations, maximizing recovery, minimizing costs, and ensuring safe and sustainable practices are paramount. This comprehensive guide delves into the best practices for optimizing onshore oil and gas production, exploring a synergistic approach that integrates advanced technologies, robust reservoir management, and streamlined operational workflows. From the reservoir to the sales point, every stage of the production lifecycle presents opportunities for enhancement. This blog will navigate through these critical areas, providing actionable insights and illustrative diagrams to illuminate the path toward peak production efficiency.

The Foundation: Proactive Reservoir Management

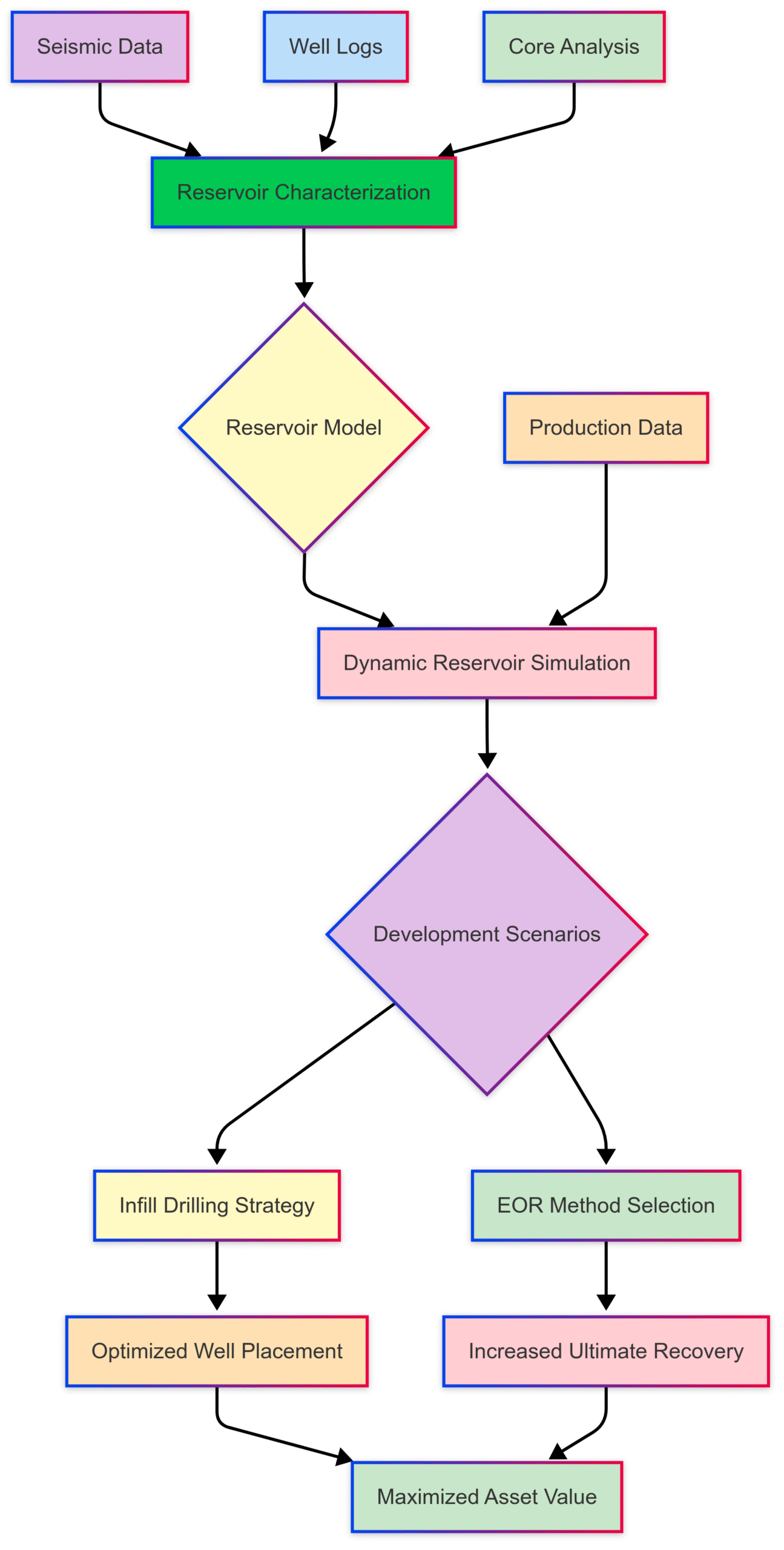

Effective production optimization begins deep within the earth, in the hydrocarbon-bearing reservoirs. A thorough understanding and proactive management of the reservoir are the bedrock upon which all other optimization strategies are built. The primary goal is to maximize the ultimate recovery of hydrocarbons in the most economically viable manner.

A key aspect of modern reservoir management is the integration of static and dynamic data to build a comprehensive reservoir model. This model is not a one-time creation but a living entity, continuously updated with new data from drilling, production, and surveillance activities.

Key Practices in Reservoir Management:

Comprehensive Characterization: This involves a detailed analysis of the reservoir’s geological and fluid properties. Techniques include 3D seismic imaging to understand the reservoir structure and stratigraphy, core analysis to determine rock properties like porosity and permeability, and fluid analysis to understand the behavior of the oil and gas.

Dynamic Reservoir Simulation: Advanced simulation software uses the reservoir model to predict fluid flow and forecast production under various operating scenarios. This allows engineers to evaluate different development strategies, such as well placement, completion design, and injection schemes, to identify the optimal path forward.

Infill Drilling and Well Placement: Strategic placement of new wells, known as infill drilling, can access previously untapped or poorly drained areas of the reservoir. Reservoir simulation plays a crucial role in identifying the most promising locations for these new wells to maximize incremental recovery without causing detrimental interference with existing wells.

Enhanced Oil Recovery (EOR): In mature fields, primary and secondary recovery methods often leave a significant amount of oil behind. EOR techniques, such as waterflooding, gas injection (like CO2 injection), and chemical injection (polymers, surfactants), can be employed to alter the fluid properties and improve sweep efficiency, thereby recovering additional barrels of oil. The selection of the appropriate EOR method depends on a thorough evaluation of the reservoir characteristics and economic feasibility.

Lifting Production: The Art and Science of Artificial Lift Optimization

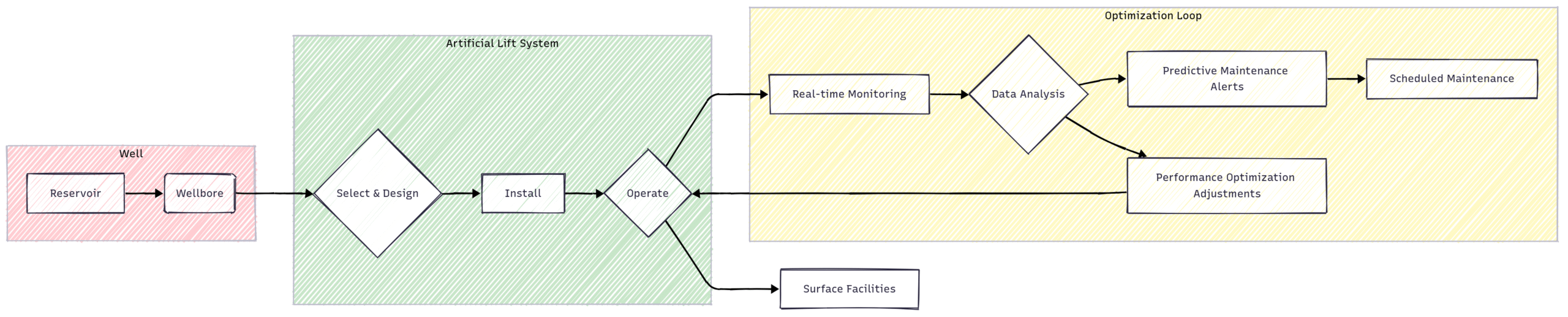

As reservoir pressure naturally declines over the life of a well, the natural flow of hydrocarbons to the surface diminishes. Artificial lift systems are then employed to provide the necessary energy to bring the fluids to the surface. The selection and optimization of these systems are critical for maintaining and enhancing production rates.

Choosing the right artificial lift method depends on various factors, including the well’s production rate, fluid properties (oil viscosity, gas-to-oil ratio, water cut), and operating conditions. Common artificial lift systems include sucker rod pumps, electric submersible pumps (ESPs), gas lift, and progressing cavity pumps (PCPs).

Best Practices for Artificial Lift Optimization:

System Selection and Design: A thorough analysis of the well’s inflow performance and the characteristics of the produced fluids is essential for selecting the most appropriate artificial lift system. Proper design and sizing of the equipment are crucial to ensure efficient operation and longevity.

Real-Time Monitoring and Control: Modern artificial lift systems are increasingly equipped with sensors and telemetry that provide real-time data on key performance parameters. This data can be transmitted to a central control room, allowing operators to monitor the system’s health, identify potential issues early, and make timely adjustments to optimize performance.

Predictive Maintenance: By analyzing the real-time data from the artificial lift equipment, operators can implement predictive maintenance strategies. Machine learning algorithms can identify subtle changes in operating parameters that may indicate an impending failure, allowing maintenance to be scheduled proactively before a costly breakdown occurs. This minimizes downtime and lost production.

Energy Efficiency: Artificial lift systems can be significant consumers of energy. Optimizing their operation to match the well’s production potential not only reduces operating costs but also lowers the carbon footprint of the operation. Variable speed drives (VSDs) on ESPs, for example, allow for precise control of the pump’s speed to match the well’s inflow, leading to substantial energy savings.

Streamlining the Surface: Optimizing Production Facilities

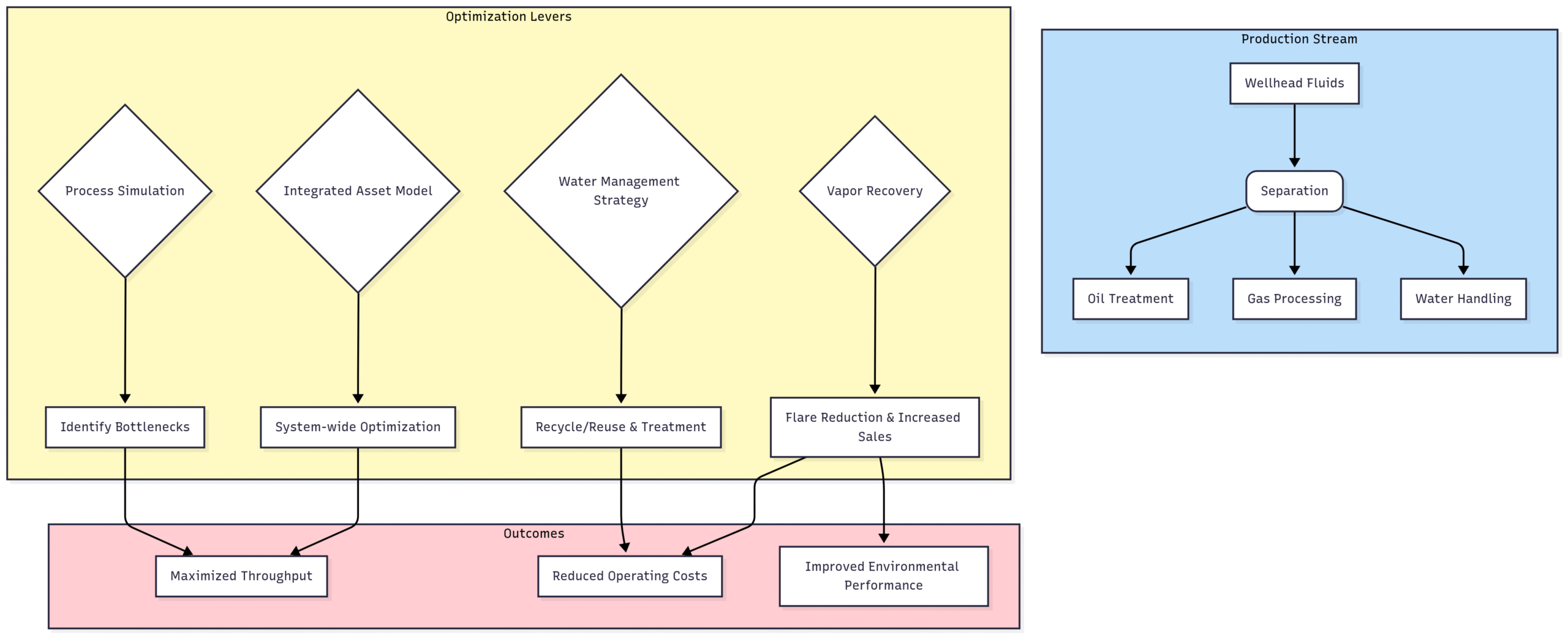

Once the hydrocarbons reach the surface, they enter the production facilities, where they are separated, treated, and prepared for transportation. The efficiency and reliability of these surface facilities have a direct impact on production uptime and operating costs.

The goal of surface facility optimization is to maximize throughput, minimize processing costs, and ensure compliance with environmental regulations. This requires a holistic view of the entire production system, from the wellhead to the sales pipeline.

Key Strategies for Surface Facility Optimization:

Process Simulation and Debottlenecking: Process simulation software can be used to model the entire surface facility, from separators and treaters to compressors and pipelines. This allows engineers to identify bottlenecks in the system that may be restricting production. By analyzing the model, they can evaluate various debottlenecking options, such as equipment upgrades or process modifications, to increase the facility’s capacity.

Integrated Asset Modeling: An integrated asset model (IAM) connects the reservoir model with the surface facility model. This powerful tool allows for a system-wide optimization approach, where the impact of changes in one part of the system (e.g., bringing a new well online) on the entire production network can be evaluated.

Effective Water Management: Onshore production often generates large volumes of produced water. Managing this water efficiently is a major operational challenge and cost driver. Optimization strategies include recycling and reusing the water for injection or other operational purposes, as well as employing advanced water treatment technologies to meet discharge standards.

Flare Reduction and Vapor Recovery: Flaring of associated gas is not only a waste of a valuable resource but also a source of greenhouse gas emissions. Installing vapor recovery units (VRUs) on storage tanks and other equipment can capture these vapors and redirect them into the sales gas pipeline, increasing revenue and reducing the environmental impact.

The Digital Transformation: Leveraging Data and Analytics

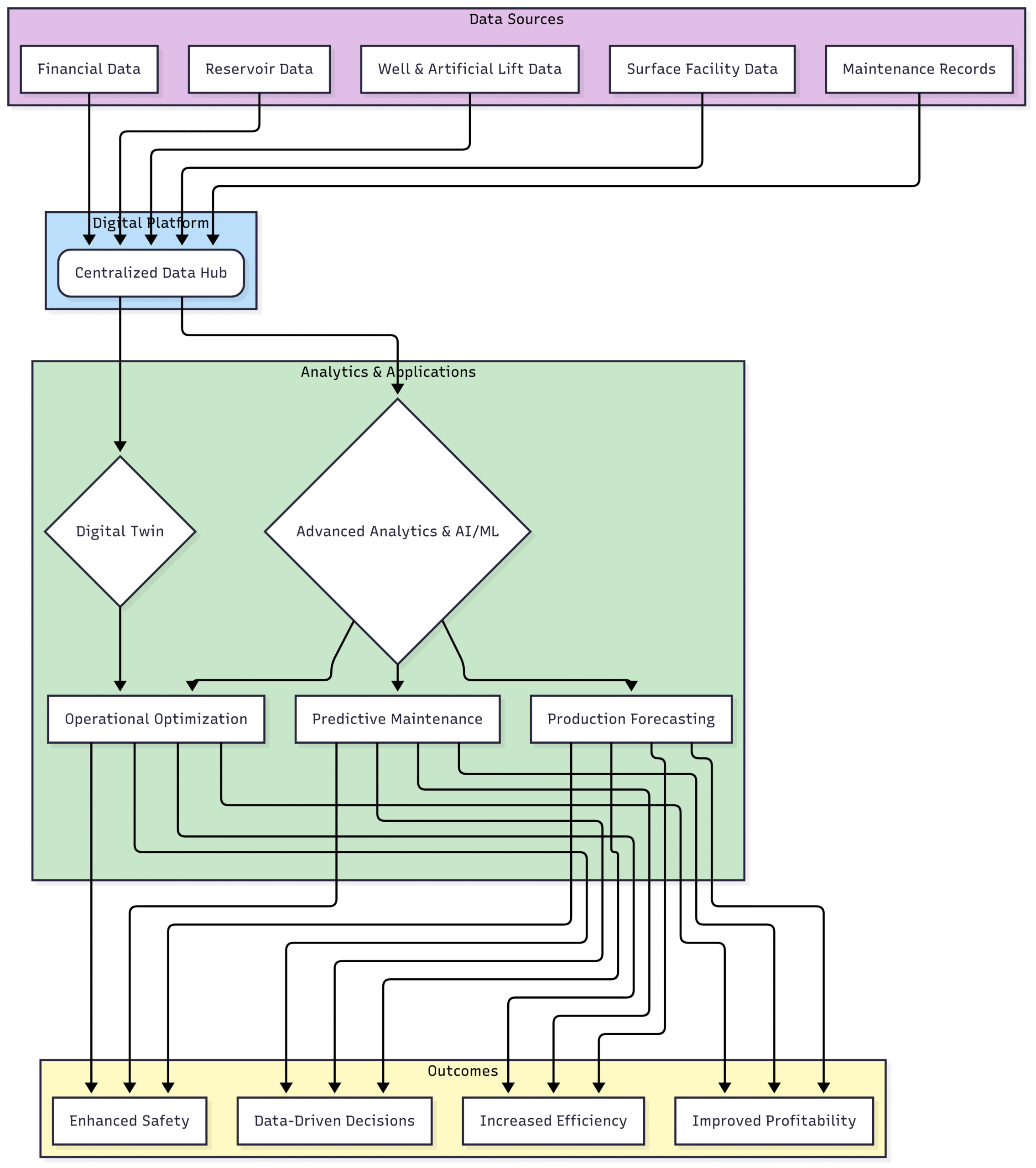

The oil and gas industry is undergoing a profound digital transformation, and onshore production is at the forefront of this revolution. The proliferation of sensors, the availability of high-speed connectivity, and the power of cloud computing and data analytics are unlocking new levels of efficiency and performance.

A “digital oilfield” approach integrates data from all aspects of the operation—from downhole sensors to surface facilities and financial systems—into a single, unified platform. This provides a comprehensive, real-time view of the entire production system, enabling data-driven decision-making at all levels.

Harnessing the Power of Data:

Centralized Data Platforms: The foundation of the digital oilfield is a centralized data platform that can ingest, store, and process vast amounts of data from various sources. This “single source of truth” eliminates data silos and ensures that everyone in the organization is working with the same information.

Advanced Analytics and Machine Learning: With a centralized data platform in place, advanced analytics and machine learning algorithms can be applied to uncover hidden patterns and insights in the data. This can be used for a wide range of applications, including production forecasting, predictive maintenance, and optimizing operational parameters.

Remote Operations and Automation: The digital oilfield enables a shift towards remote operations, where many tasks that traditionally required personnel to be in the field can now be performed from a central control room. This improves safety, reduces costs, and allows for more efficient management of a large number of wells. Automation of routine tasks further enhances efficiency and frees up personnel to focus on more complex challenges.

Digital Twins: A digital twin is a virtual model of a physical asset, such as a well or a production facility. It is continuously updated with real-time data from the physical asset, allowing for detailed analysis and simulation of its performance. Digital twins can be used to test different operating scenarios, optimize performance, and predict the impact of maintenance activities without affecting the actual operation.

Conclusion: A Continuous Cycle of Improvement

Optimizing onshore oil and gas production is not a one-time project but a continuous cycle of improvement. It requires a holistic and integrated approach that combines deep domain expertise with the power of modern technology. By focusing on proactive reservoir management, optimizing artificial lift systems, streamlining surface facilities, and embracing the digital transformation, operators can unlock the full potential of their assets. The journey towards production excellence is ongoing, and those who embrace these best practices will be well-positioned to thrive in the competitive and ever-changing energy landscape.