In the world of fluid dynamics and process control, valves are the gatekeepers, directing the flow of liquids and gases that are the lifeblood of countless industries. From chemical plants and refineries to the systems within power generation and water treatment facilities, the precise management of fluid flow is paramount. At the heart of this control are two fundamental types of valves: the control valve and the on-off valve. While both regulate flow, their purposes and operational philosophies are worlds apart. For any engineer involved in process design, operation, or maintenance, understanding the key differences between these two is not just academic—it’s fundamental to safety, efficiency, and profitability.

This comprehensive guide will delve deep into the world of control valves and on-off valves, exploring their core principles, design variations, and critical applications. We will dissect their key differences in a head-to-head comparison and provide practical guidance on selecting the right valve for your specific engineering challenge.

What is an On-Off Valve?

As its name aptly suggests, an on-off valve, also known as a shut-off or isolation valve, has a binary mission: to either completely allow or completely stop the flow of a fluid. Think of it as a light switch for your piping system—it’s either fully on or fully off, with no middle ground. Their primary role is to isolate equipment, redirect flow, or provide a positive shut-off for safety and maintenance purposes.

Principle of Operation

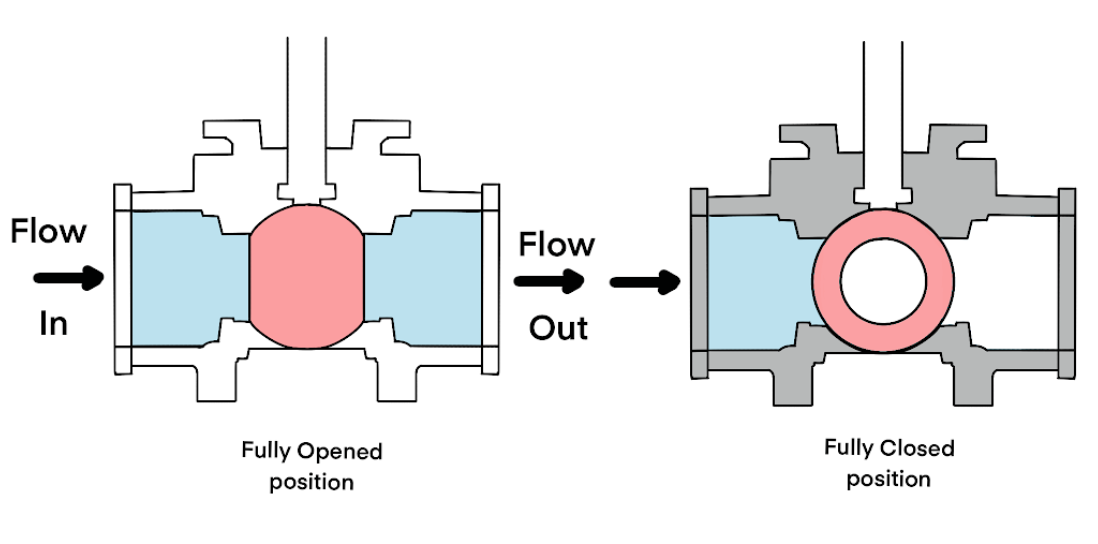

The operation of an on-off valve is straightforward. It moves a closure element, such as a ball, gate, or disc, perpendicular to the flow path. When fully open, the closure element is moved out of the flow stream, offering minimal resistance. When closed, it forms a tight seal against the valve seat, effectively blocking the flow. The actuation of these valves is typically rapid, moving from fully open to fully closed in a short period.

Common Types of On-Off Valves

On-off valves come in various designs, each suited for different applications:

Ball Valves: These are one of the most common types of on-off valves. They feature a spherical closure element with a bore through the center. A quarter-turn of the valve stem aligns the bore with the pipe for full flow or positions it perpendicularly to block the flow. They offer excellent shut-off capabilities and are known for their durability and simplicity.

Gate Valves: These valves use a flat gate-like disc that slides into the flow stream to stop the fluid. When fully open, the gate is completely withdrawn, resulting in a straight, unobstructed flow path and minimal pressure drop. They are ideal for applications where a full, unimpeded flow is required.

Plug Valves: Similar to ball valves, plug valves use a cylindrical or tapered plug with a bore. A quarter-turn of the stem rotates the plug to align or block the flow path. They are robust and can handle slurries and high-pressure applications.

Butterfly Valves: These valves feature a disc mounted on a rotating shaft. A quarter-turn of the disc moves it from a position parallel to the flow (fully open) to perpendicular to the flow (fully closed). They are lightweight, cost-effective, and suitable for large-diameter pipes.

Applications of On-Off Valves

On-off valves are the workhorses of fluid isolation and are found in a vast array of applications, including:

- Isolation of equipment: To safely perform maintenance or repairs on a pump, vessel, or other piece of equipment.

- Emergency shutdown systems (ESD): To quickly halt the flow of hazardous materials in an emergency.

- Blending and mixing operations: To start or stop the flow of different ingredients into a mixing tank.

- Pipeline pigging operations: To launch and receive pipeline inspection gauges (pigs).

- General purpose shut-off: In utility lines for water, air, or steam.

What is a Control Valve? The Master of Modulation

In stark contrast to the binary nature of on-off valves, the control valve is a sophisticated instrument designed for precision and finesse. Its purpose is to modulate or regulate the flow of a fluid, maintaining a desired process variable such as pressure, temperature, flow rate, or liquid level. It achieves this by precisely positioning its closure element at any point between fully open and fully closed, based on a control signal.

Principle of Operation

A control valve operates as the final control element in a control loop. This loop typically consists of a sensor, a controller, and the control valve itself.

- Sensor: Measures the process variable (e.g., a pressure transmitter measuring the pressure in a pipe).

- Controller: Compares the measured value from the sensor to a desired setpoint. If there is a difference (error), the controller calculates a corrective action.

- Control Valve: Receives a signal from the controller (typically a 4-20 mA electrical signal or a 3-15 psi pneumatic signal) and adjusts the position of its closure element to change the flow rate, thereby bringing the process variable back to the setpoint.

The heart of a control valve’s ability to modulate flow lies in its trim. The trim consists of the valve plug (or disc), seat, and stem, which are engineered to provide a specific flow characteristic.

Common Types of Control Valves

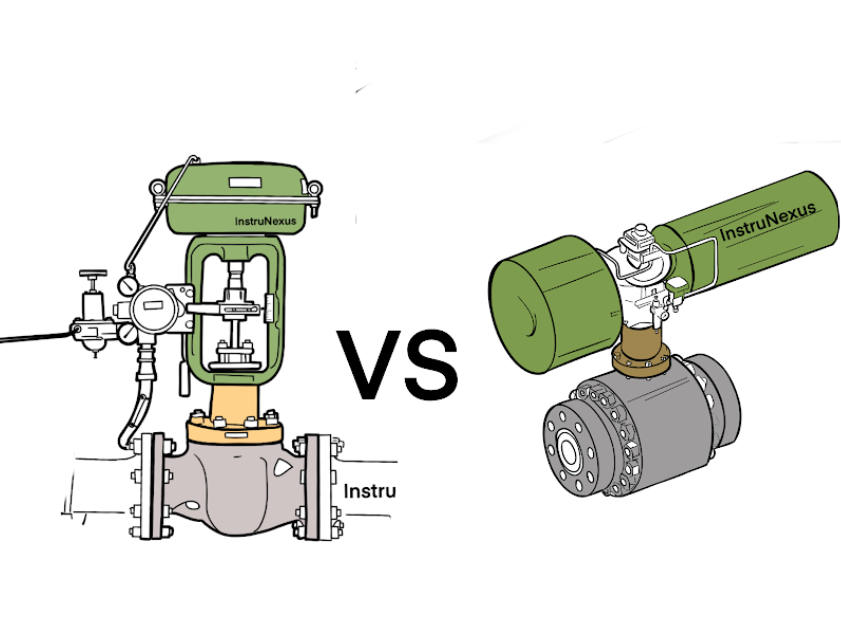

While some valve types like globe and butterfly valves can be used for both on-off and control applications, certain designs are specifically optimized for throttling and precise control:

Globe Valves: These are the most common type of control valve. They feature a globular body and a movable plug that moves perpendicular to the seat. The design of the plug and seat can be contoured to achieve specific flow characteristics (e.g., linear, equal percentage, or quick opening), making them ideal for throttling applications.

Angle Valves: A variation of the globe valve where the inlet and outlet ports are at a 90-degree angle. This design can be advantageous for certain piping configurations and can handle flashing and erosive services.

Diaphragm Valves: These valves use a flexible diaphragm to control the flow. The diaphragm is pressed against a weir or a seat to restrict or stop the flow. They are excellent for handling corrosive, viscous, and sanitary fluids as the fluid is isolated from the valve’s operating mechanism.

Segmented Ball Valves & High-Performance Butterfly Valves: While standard ball and butterfly valves are primarily for on-off service, specialized designs like V-notch ball valves and high-performance butterfly valves are engineered for throttling control. They offer better flow characteristics and can handle more demanding control applications than their on-off counterparts.

Applications of Control Valves

Control valves are critical components in any automated process control system. Their applications are vast and varied:

- Pressure control: Maintaining a constant pressure in a vessel or pipeline.

- Flow control: Regulating the flow rate of a reactant into a chemical reactor.

- Temperature control: Controlling the flow of steam to a heat exchanger to maintain a specific product temperature.

- Level control: Maintaining a constant liquid level in a tank or boiler drum.

- pH control: Regulating the flow of acid or base to maintain a desired pH level.

Head-to-Head: Control Valve vs. On-Off Valve – The Key Differences

Now that we have a solid understanding of each valve type, let’s put them side-by-side to highlight their fundamental differences.

| Feature | On-Off Valve | Control Valve |

|---|---|---|

| Primary Function | To start or stop flow (isolation). | To regulate or modulate flow. |

| Operation | Fully open or fully closed (binary). | Operates at intermediate positions (throttling). |

| Actuation | Typically fast-acting (e.g., quarter-turn). | Slower, more precise actuation. |

| Control Signal | Simple on/off signal (e.g., open/close). | Variable control signal (e.g., 4-20 mA). |

| Design Focus | Tight shut-off, low pressure drop when open. | Precise flow characteristics, controllability. |

| Flow Path | Often straight and unobstructed when open. | Typically a more tortuous path for throttling. |

| Typical Valve Types | Ball, Gate, Plug, standard Butterfly. | Globe, Angle, Diaphragm, Segmented Ball. |

| Positioner | Generally not required. | Often equipped with a positioner for accuracy. |

| Cost | Generally lower cost. | Higher cost due to complexity and precision. |

| Application | Isolation, emergency shutdown, diverting flow. | Process control loops (pressure, temp, flow). |

| Wear and Tear | Minimal wear on internal parts. | Subject to wear and erosion from throttling. |

How to Choose the Right Valve: A Guide for Engineers

Selecting the appropriate valve is a critical decision in any engineering design. Making the wrong choice can lead to poor process control, equipment damage, safety hazards, and increased operational costs. Here are the key factors to consider when deciding between a control valve and an on-off valve:

1. What is the primary function?

This is the most fundamental question.

- Do you need to simply start and stop the flow? Is the primary requirement to isolate a piece of equipment for maintenance or to provide a positive shut-off in an emergency? If so, an on-off valve is the correct choice.

- Do you need to continuously regulate a process variable? Is the goal to maintain a specific pressure, temperature, or flow rate? If your application involves a control loop and requires precise modulation of flow, a control valve is essential.

2. What are the process conditions?

The nature of the fluid and the operating conditions will significantly influence your valve selection.

- Fluid Properties: Is the fluid clean, corrosive, viscous, or does it contain solids? Diaphragm valves are excellent for corrosive fluids, while ball valves can handle some slurries. For highly erosive services, hardened trim materials in a control valve may be necessary.

- Pressure and Temperature: Ensure the selected valve’s pressure and temperature ratings are suitable for the application. High-pressure and high-temperature services often require robustly constructed valves.

- Shut-off Requirements: How critical is a tight shut-off? For applications requiring zero leakage, a soft-seated ball valve or a high-performance butterfly valve might be the best on-off option. For control valves, the required leakage class (e.g., Class IV, V, or VI) must be specified.

3. What are the performance requirements?

For On-Off Valves: The main performance criteria are a low pressure drop when fully open and the ability to provide a tight seal when closed. The speed of operation might also be a factor in emergency shutdown applications.

For Control Valves: The key performance characteristic is its flow characteristic, which describes the relationship between the valve’s stem travel and the flow rate. The most common characteristics are:

- Linear: Flow rate is directly proportional to the valve travel. Suitable for applications with a relatively constant pressure drop across the valve.

- Equal Percentage: Equal increments of valve travel produce an equal percentage change in the existing flow rate. This is the most common characteristic and is suitable for applications with varying pressure drops.

- Quick Opening: Provides a large increase in flow for a small amount of valve travel. This is more suited for on-off applications.

The correct flow characteristic is crucial for stable process control.

4. Cost Considerations

In general, on-off valves are less expensive than control valves. The simplicity of their design and the lack of sophisticated instrumentation contribute to their lower cost. Control valves, on the other hand, are more complex instruments. The precision-engineered trim, the need for an actuator and a positioner, and the more robust construction required for throttling all contribute to a higher initial cost.

However, it’s crucial to consider the total cost of ownership. Installing an on-off valve in a control application to save on initial cost will likely lead to poor process control, increased process variability, and potentially higher long-term operational costs. Conversely, using an expensive control valve for a simple on-off application is an unnecessary expense.

The Bottom Line: The Right Tool for the Right Job

The distinction between control valves and on-off valves is a cornerstone of process engineering. While both are essential for managing fluid flow, their roles are distinct and not interchangeable. The on-off valve is the dependable gatekeeper, providing simple, reliable isolation. The control valve is the sophisticated maestro, precisely orchestrating the flow to maintain the delicate balance of a process.

For every engineer, understanding these fundamental differences is key to designing safe, efficient, and reliable systems. By carefully considering the primary function, process conditions, performance requirements, and cost, you can confidently select the right valve for the job, ensuring optimal performance and a smooth-running operation for years to come.