For decades, analog pressure gauges with their familiar dials and needles were the go-to instruments for measuring pressure. However, with the advent of digital technology, a new king has been crowned: the digital pressure gauge. Offering unparalleled accuracy, advanced features, and robust performance, digital pressure gauges have become indispensable tools for instrumentation professionals and a critical area of study for students aspiring to enter the field.

This comprehensive blog post will delve into the intricacies of digital pressure gauges, exploring their core features, underlying working principles, and diverse field applications across various industries. We will also visualize their operation through block diagrams and provide insights to help you select the right digital pressure gauge for your specific needs.

From Springs and Gears to Sensors and Screens: The Evolution of Pressure Measurement

Traditional analog pressure gauges, typically of the Bourdon tube, diaphragm, or bellows type, rely on the mechanical deformation of an element to move a pointer on a calibrated scale. While these instruments have served industries well and are still in use, they are susceptible to mechanical shock, vibration, parallax error in readings, and require periodic calibration.

Digital pressure gauges, on the other hand, represent a significant leap forward. They utilize sophisticated pressure sensors and electronics to provide a direct numerical reading of the pressure, eliminating the guesswork and potential for human error associated with analog gauges.

Under the Hood: The Working Principle of a Digital Pressure Gauge

At the heart of every digital pressure gauge lies a pressure sensor, a transducer that converts the physical pressure into an electrical signal. The most common type of sensor used is the piezoresistive sensor.

Here’s a simplified breakdown of the working principle, illustrated by a block diagram:

Block Diagram: Working Principle of a Digital Pressure Gauge

- Pressure Input: The process fluid or gas enters the gauge through the pressure port and exerts force on the diaphragm of the pressure sensor.

- Pressure Sensor (Transducer): The piezoresistive sensor, typically a silicon diaphragm with embedded strain gauges, deforms under this pressure. This deformation changes the electrical resistance of the strain gauges.

- Signal Conditioning: The change in resistance results in a small change in voltage. The signal conditioning circuitry, which includes amplifiers and filters, cleans up this raw signal, amplifies it to a usable level, and compensates for temperature variations.

- Analog-to-Digital Converter (ADC): The conditioned analog signal is then converted into a digital signal by the ADC. The resolution of the ADC plays a crucial role in the overall resolution of the pressure gauge.

- Microprocessor: The digital signal is processed by the onboard microprocessor. The microprocessor linearizes the signal, applies calibration data, and converts it into the desired pressure unit (e.g., psi, bar, kPa).

- Display: The final, accurate pressure reading is then shown on the digital display, which is typically an LCD or LED screen.

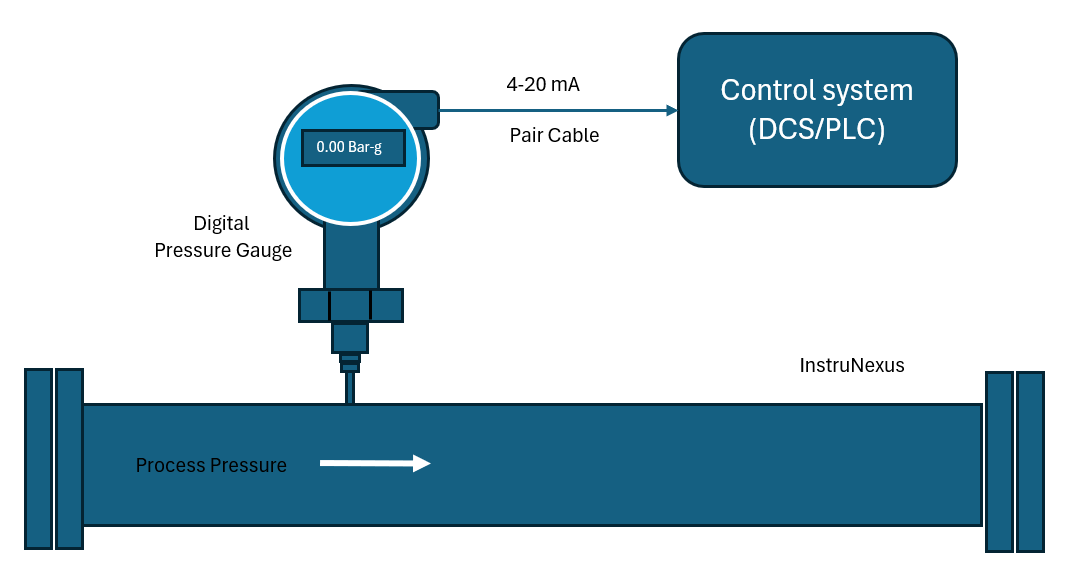

- Data Output (Optional): Many digital pressure gauges offer data output options, such as 4-20mA, voltage signals, or digital communication protocols like HART, Modbus, or IO-Link, allowing for integration with control systems, data loggers, and PLCs.

Key Features of Digital Pressure Gauges: A Comprehensive Overview

Digital pressure gauges come packed with a variety of features that enhance their functionality and usability. Understanding these features is crucial for selecting the right instrument for a given application.

| Feature | Description | Importance for Instrumentation Professionals |

|---|---|---|

| High Accuracy | The degree of conformity of a measured quantity to its actual (true) value. Digital gauges offer significantly higher accuracy (e.g., ±0.025% to ±0.5% of full scale) compared to their analog counterparts. | Essential for critical processes, calibration standards, and applications requiring precise pressure control. Reduces measurement uncertainty and improves process efficiency and safety. |

| High Resolution | The smallest change in pressure that the gauge can detect and display. Digital displays can show readings to several decimal places. | Allows for the detection of minute pressure fluctuations, which is critical in laboratory research, leak detection, and low-pressure applications. |

| Digital Display | Clear and easy-to-read LCD or LED screens that eliminate parallax error. Many displays are backlit for readability in low-light conditions. | Reduces the risk of misinterpretation of readings, especially in fast-paced or poorly lit environments. Improves data logging accuracy. |

| Multiple Pressure Units | The ability to display pressure readings in various units (e.g., psi, bar, kPa, MPa, inH₂O, mmHg) with the push of a button. | Offers flexibility and convenience, eliminating the need for manual conversions and reducing the chance of errors. Useful for professionals working with international standards. |

| Peak Hold and Tare Functions | The peak hold function captures and displays the highest (max) and lowest (min) pressure readings over a period. The tare function allows the user to zero the display at any point. | Peak hold is invaluable for capturing pressure spikes and drops in dynamic systems. The tare function is useful for measuring pressure differentials or compensating for static head pressure. |

| Data Logging and Storage | Many advanced models have internal memory to log pressure readings at user-defined intervals. This data can then be downloaded to a computer for analysis. | Enables process monitoring, trend analysis, and troubleshooting without the need for constant manual recording. Provides a historical record for quality control and regulatory compliance. |

| Communication Outputs | Analog outputs (4-20mA, 0-5V) and digital communication protocols (HART, Modbus, IO-Link) allow for seamless integration with PLCs, DCS, and SCADA systems. | Facilitates process automation, remote monitoring, and centralized control. Enables the gauge to act as a smart sensor within a larger control loop. |

| Battery Powered and Low Power Consumption | Many digital pressure gauges are battery-powered, making them highly portable for field use. They often feature auto-shutoff and low-power modes to extend battery life. | Ideal for applications where a permanent power source is unavailable or inconvenient. Enhances flexibility and reduces installation costs. |

| Robust Construction and Ingress Protection (IP) Rating | Housed in durable materials like stainless steel and engineered to withstand harsh industrial environments. The IP rating indicates the level of protection against dust and water ingress. | Ensures long-term reliability and performance in demanding conditions, such as outdoor installations, wash-down areas, and dusty environments. |

| Intrinsic Safety (IS) Certifications | For applications in hazardous areas where explosive gases or dust may be present, intrinsically safe models are available. These are designed to prevent the ignition of the surrounding atmosphere. | A critical safety requirement in industries like oil and gas, chemical processing, and mining. Ensures compliance with safety regulations and protects personnel and assets. |

Field Applications: Where Digital Pressure Gauges Shine

The versatility and advanced features of digital pressure gauges have led to their widespread adoption across a multitude of industries. Here are some key field applications:

1. Oil and Gas Industry

The oil and gas sector operates under extreme conditions and requires highly accurate and reliable pressure monitoring for safety and efficiency.

- Wellhead and Pipeline Monitoring: Digital gauges are used to monitor casing and tubing pressures at the wellhead and to track pressure along pipelines to detect leaks and ensure consistent flow. Their data logging capabilities are crucial for trend analysis and predictive maintenance.

- Refining Processes: In refineries, precise pressure control is vital in distillation columns, reactors, and other process vessels. The high accuracy of digital gauges ensures optimal process conditions, maximizing yield and product quality.

- Calibration and Testing: Portable digital pressure gauges with high accuracy serve as calibration standards for other pressure instruments in the field, ensuring the reliability of the entire measurement system.

Block Diagram: Digital Pressure Gauge in Pipeline Monitoring

2. Manufacturing and Automation

In manufacturing, consistent pressure is often a critical parameter for product quality and process efficiency.

- Hydraulic and Pneumatic Systems: Digital gauges are used to monitor and troubleshoot hydraulic presses, pneumatic actuators, and other fluid power systems. The peak hold function is particularly useful for diagnosing pressure spikes that can damage equipment.

- Industrial Gas Supply: Monitoring the pressure of industrial gases like nitrogen, oxygen, and argon is essential for various manufacturing processes. Digital gauges provide the accuracy needed to ensure proper gas delivery.

- Leak Detection: The high resolution of digital pressure gauges makes them ideal for leak testing of components and systems. By monitoring for small pressure drops over time, manufacturers can ensure product integrity.

3. HVAC (Heating, Ventilation, and Air Conditioning)

HVAC systems rely on precise pressure differentials for proper operation and energy efficiency.

- Filter Monitoring: Digital differential pressure gauges are used to monitor the pressure drop across air filters. An increase in pressure drop indicates a clogged filter that needs replacement, ensuring good indoor air quality and preventing strain on the system’s fan.

- Duct and Building Pressure: Maintaining the correct pressure within air ducts and buildings is crucial for proper ventilation and to prevent the infiltration of outside air. Digital manometers (a type of low-pressure digital gauge) are used to measure and balance these pressures.

- Refrigerant Charging and Diagnostics: HVAC technicians use digital manifold gauges to accurately charge refrigeration systems and diagnose problems. The ability to display saturation temperatures alongside pressure readings simplifies the process.

4. Pharmaceutical and Biotechnology

The pharmaceutical industry operates under stringent regulations that demand high levels of accuracy and data integrity.

- Bioreactors and Fermenters: Maintaining precise pressure control in bioreactors is critical for optimal cell growth and product yield. Digital pressure gauges with sanitary connections and data logging capabilities are essential for this application.

- Sterilization and Autoclaving: Digital gauges are used to monitor the pressure and temperature during sterilization cycles in autoclaves, ensuring that medical and laboratory equipment is properly sterilized.

- Cleanroom Environments: Differential pressure gauges are used to monitor the pressure differences between cleanrooms and adjacent areas, preventing the ingress of contaminants.

5. Automotive and Aerospace

In these industries, performance, safety, and reliability are non-negotiable.

- Engine and Transmission Testing: Digital pressure gauges are used in dynamometers and test benches to monitor oil pressure, fuel pressure, and other critical fluid pressures during engine and transmission development and testing.

- Tire Pressure Monitoring Systems (TPMS): While the sensors in your car’s TPMS are a specialized form of digital pressure gauge, handheld digital tire pressure gauges are used by technicians for accurate inflation and diagnostics.

- Aircraft Systems: Digital pressure gauges are used to monitor hydraulic systems, cabin pressure, and engine parameters in aircraft, providing pilots with critical information for safe operation.

Selecting the Right Digital Pressure Gauge: A Practical Guide

With a wide array of options available, selecting the most suitable digital pressure gauge requires careful consideration of the application’s specific requirements. Here’s a checklist to guide you through the process:

- Define the Pressure Range: The gauge’s range should be appropriate for the process being measured. A good rule of thumb is to select a gauge where the normal operating pressure is in the middle third of the gauge’s range.

- Determine the Required Accuracy: How critical is the measurement? For calibration or critical processes, a higher accuracy gauge is necessary. For general monitoring, a lower accuracy gauge may suffice.

- Consider the Process Media: The wetted parts of the gauge (the sensor and pressure connection) must be chemically compatible with the process fluid or gas to prevent corrosion and ensure long-term reliability.

- Evaluate the Operating Environment: Will the gauge be exposed to extreme temperatures, vibration, moisture, or dust? Choose a gauge with the appropriate IP rating and operating temperature range.

- Assess the Need for Advanced Features: Do you require data logging, communication outputs, or peak hold functionality? Select a gauge with the features that will add value to your process.

- Check for Hazardous Area Certifications: If the gauge will be used in a potentially explosive environment, ensure it has the necessary intrinsic safety certifications (e.g., ATEX, IECEx, cULus).

- Power Requirements: Consider whether a battery-powered, loop-powered, or externally powered gauge is more suitable for your installation.

The Future is Digital: Embracing the Next Generation of Pressure Measurement

The transition from analog to digital pressure gauges is a testament to the continuous drive for greater accuracy, efficiency, and safety in industrial processes. For instrumentation professionals, a thorough understanding of digital pressure gauges is no longer just an advantage; it’s a necessity. For students, mastering this technology is a stepping stone to a successful career in the dynamic field of instrumentation and control.

As technology continues to evolve, we can expect to see even more advanced features integrated into digital pressure gauges, such as wireless connectivity, cloud-based data storage and analysis, and enhanced diagnostic capabilities. By embracing these innovations, industries can further optimize their processes, improve product quality, and ensure a safer working environment for everyone.