Displacer Level Transmitters: A Deep Dive into Principle, Advantages, and Limitations

In the realm of industrial process control, accurate and reliable level measurement is paramount. Among the plethora of available technologies, the displacer level transmitter stands out as a time-tested and robust solution for a wide range of applications. This comprehensive guide will delve into the inner workings of displacer level transmitters, exploring their fundamental principle, highlighting their significant advantages, and acknowledging their inherent limitations.

The Core Principle: Archimedes’ Law in Action

At the heart of every displacer level transmitter lies a fundamental principle of physics discovered over two millennia ago: Archimedes’ principle. This principle states that a body immersed in a fluid experiences an upward buoyant force equal to the weight of the fluid it displaces.

A displacer level transmitter utilizes a cylindrical element, known as a displacer, which is suspended within the vessel containing the liquid to be measured. This displacer has a specific weight and is designed to be denser than the process liquid. As the liquid level rises and immerses the displacer, the buoyant force acting upon it increases. This increase in buoyant force effectively reduces the apparent weight of the displacer.

The change in the apparent weight of the displacer is directly proportional to the liquid level. The transmitter’s mechanism is engineered to precisely measure this change and convert it into a standardized electrical signal, typically a 4-20 mA output, which can be interpreted by a control system.

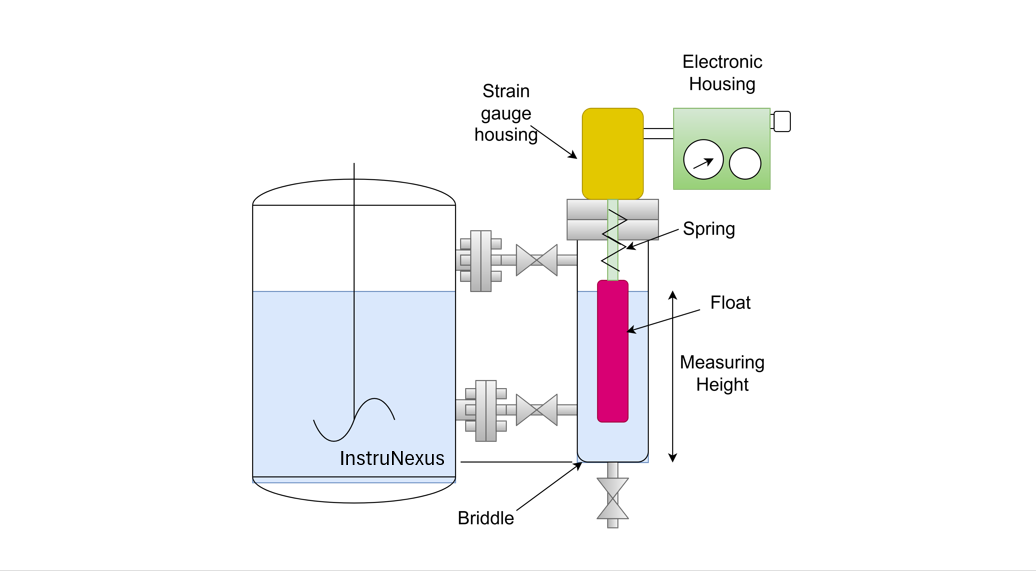

Key Components and their Function

To fully grasp the operation, it’s essential to understand the primary components of a displacer level transmitter:

Displacer: The sensing element that is partially or fully immersed in the process liquid. Its length is chosen based on the required measurement range.

Torque Tube or Spring Mechanism: This is the core mechanical component that translates the change in the displacer’s apparent weight into a rotational or linear motion.

Transmitter Head: This houses the electronic components that convert the mechanical motion into a standardized output signal.

The following diagram illustrates the fundamental working principle of a displacer level transmitter with a torque tube mechanism:

Unpacking the Two Main Designs: Torque Tube vs. Spring-Operated

Displacer level transmitters primarily come in two distinct designs, each with its own method of translating the buoyant force into a measurable signal.

The Robust Torque Tube Design

The torque tube design is the more traditional and widely used configuration. In this setup, the displacer is connected to one end of a horizontal torque tube via a lever arm. The other end of the torque tube is fixed. As the liquid level changes, the corresponding change in the displacer’s apparent weight creates a twisting force, or torque, on the tube. This minute rotation of the torque tube is then converted by the transmitter electronics into a proportional output signal.

The torque tube itself acts as a frictionless seal, isolating the process fluid from the sensitive internal components of the transmitter. This design is renowned for its reliability and durability, especially in high-pressure and high-temperature applications.

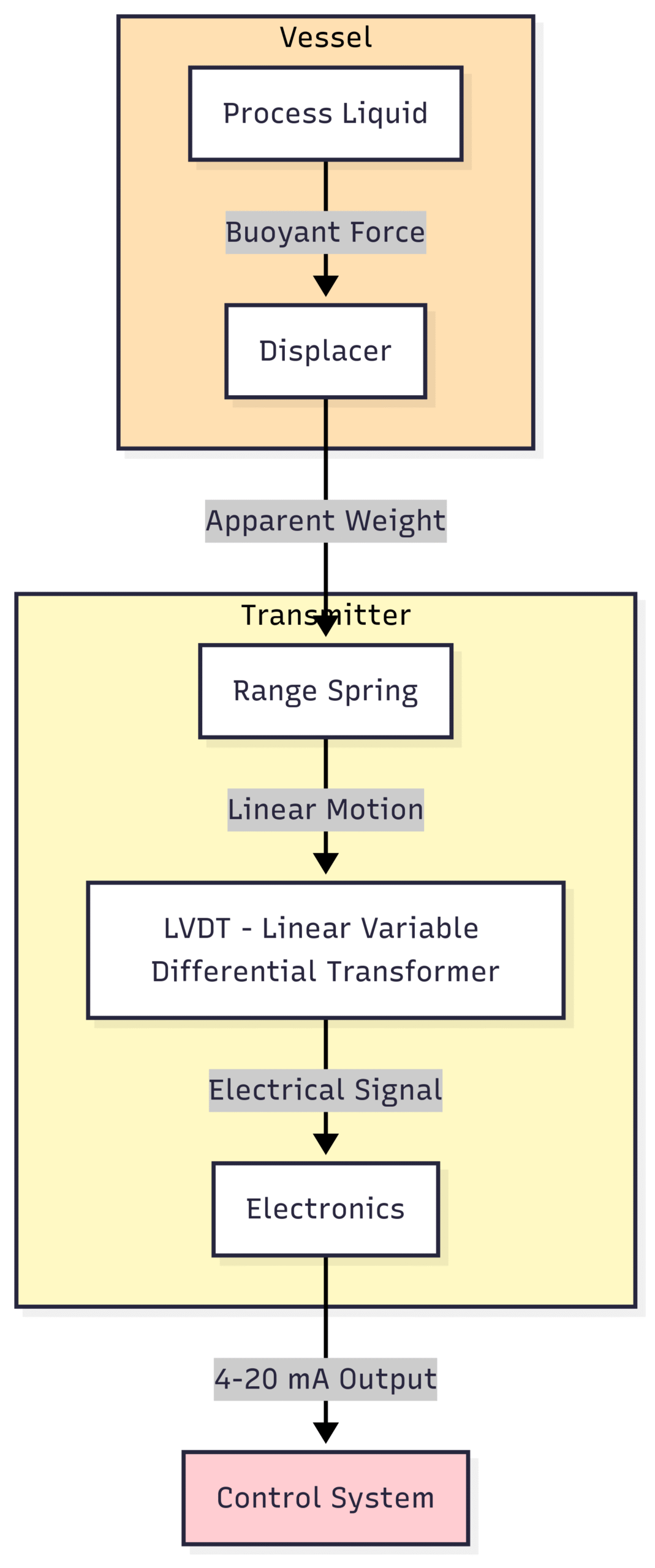

The Responsive Spring-Operated (LVDT) Design

The spring-operated design, often incorporating a Linear Variable Differential Transformer (LVDT), offers an alternative approach. Here, the displacer is suspended from a precision spring. As the buoyant force on the displacer changes, the spring compresses or extends. This linear movement is transferred to the core of an LVDT. The LVDT then produces an electrical output that is directly proportional to the displacement of its core, and consequently, to the liquid level.

This design is known for its high sensitivity and good linearity. The absence of a torque tube can sometimes simplify the mechanical construction.

Here is a simplified block diagram illustrating the components of a spring-operated displacer level transmitter:

The Compelling Advantages of Displacer Level Transmitters

Displacer level transmitters have remained a popular choice in various industries for several key reasons:

High Reliability and Durability

One of the most significant advantages of displacer level transmitters is their robust construction. They are designed to withstand harsh process conditions, including high temperatures and high pressures, that would be challenging for other level measurement technologies. The use of durable materials for the displacer and torque tube ensures a long operational life with minimal maintenance requirements.

Accuracy and Repeatability

When properly calibrated for a specific liquid, displacer transmitters offer excellent accuracy and repeatability. The direct relationship between buoyant force and liquid level, governed by a fundamental law of physics, contributes to their reliable performance.

Versatility in Application

Displacer level transmitters are highly versatile and can be used for a variety of challenging measurements, including:

Interface Level Measurement: They can accurately detect the interface between two immiscible liquids with different specific gravities. The displacer is calibrated to sink in the lighter liquid and float in the heavier liquid.

Density Measurement: By fully immersing a displacer of a known volume, these transmitters can be used to measure the density of the process fluid.

Foamy or Turbulent Surfaces: The performance of a displacer transmitter is largely unaffected by foam, vapor, or turbulence on the liquid surface, which can be a significant issue for non-contact measurement methods like ultrasonic or radar.

No Need for Compensation for Dielectric Constant Changes

Unlike capacitance-based level sensors, the accuracy of a displacer transmitter is not affected by changes in the dielectric constant of the process fluid. This makes them a reliable choice for applications where the composition of the liquid might vary.

Proven Technology

Having been used in the industry for many decades, displacer level transmitters are a proven and well-understood technology. This means that engineers and technicians are generally familiar with their installation, calibration, and troubleshooting.

Acknowledging the Limitations of Displacer Level Transmitters

Despite their numerous advantages, displacer level transmitters are not without their limitations. It is crucial to consider these drawbacks to determine if they are the right fit for a specific application.

Sensitivity to Density Changes

The most significant limitation of a displacer level transmitter is its sensitivity to changes in the specific gravity (density) of the process fluid. Since the buoyant force is directly proportional to the fluid density, any variation in density will lead to an inaccurate level reading. Therefore, they are best suited for applications where the liquid density is stable and known. If the density varies, recalibration is necessary to maintain accuracy.

Potential for Buildup and Coating

In applications involving liquids that are sticky, viscous, or contain suspended solids, there is a risk of material buildup or coating on the displacer. This added weight can alter the apparent weight of the displacer, leading to measurement errors. Regular cleaning and maintenance may be required in such environments to ensure continued accuracy.

Mechanical Moving Parts

Displacer level transmitters are mechanical devices with moving parts, primarily the torque tube or spring mechanism. While designed for durability, these components can be subject to wear and tear over time, especially in applications with significant vibration or frequent level fluctuations. This can potentially lead to a need for periodic maintenance or replacement.

Limited Measurement Span

The measurement range, or span, of a displacer level transmitter is limited by the length of the displacer. For very large tanks or vessels, the required displacer length can become impractical and expensive.

Installation Complexity

The installation of a displacer level transmitter can be more involved than that of some non-contact technologies. It often requires a flanged connection on the vessel, and care must be taken to ensure the displacer can move freely without contacting the vessel walls or other internal structures. For externally mounted caged displacers, additional piping and isolation valves are necessary.

The following table summarizes the key advantages and limitations:

| Advantages | Limitations |

| High Reliability in Harsh Conditions | Sensitive to Changes in Liquid Density |

| Good Accuracy and Repeatability | Prone to Buildup and Coating |

| Suitable for Interface and Density Measurement | Contains Mechanical Moving Parts |

| Unaffected by Foam, Vapor, or Turbulence | Limited Measurement Span |

| Independent of Dielectric Constant Changes | Potentially Complex Installation |

| Proven and Well-Understood Technology | Requires Recalibration for Different Fluids |

Common Applications Across Industries

The unique characteristics of displacer level transmitters make them well-suited for a variety of critical applications in numerous industries:

Oil and Gas: Measuring levels in separators, scrubbers, and storage tanks. They are particularly valuable for interface level detection between oil and water.

Chemical Processing: Monitoring levels in reactors, distillation columns, and storage vessels containing various chemicals. The availability of corrosion-resistant materials makes them suitable for aggressive media.

Power Generation: Used in feedwater heaters, condenser hotwells, and boiler steam drums to ensure safe and efficient operation.

Pulp and Paper: Measuring levels in black liquor tanks and other process vessels.

Food and Beverage: While less common due to sanitary concerns in some applications, they can be used in storage tanks for liquids with consistent densities.

Conclusion: A Timeless and Trusted Technology

The displacer level transmitter, with its foundation in the elegant simplicity of Archimedes’ principle, continues to be a cornerstone of industrial level measurement. Its robustness, reliability in demanding environments, and versatility in handling complex measurements like interfaces and densities ensure its enduring relevance.

While the advent of newer, non-contact technologies has provided more options for process engineers, the displacer transmitter holds its own, particularly in applications where its inherent strengths outweigh its limitations. By carefully considering the process conditions, especially the stability of the fluid density, and understanding the principles of its operation, the displacer level transmitter can provide years of accurate and trouble-free service, making it a truly timeless and trusted technology in the world of process control.