DP Level Transmitter Range Selection (mmWC) — Worked Examples

This page shows practical DP level range calculations for: Open Tank, Closed Tank (Dry Leg), Closed Tank (Wet Leg), Closed Tank with Elevation (Wet Leg), and Closed Tank with Suppression — with full breakdown and sample numbers.

Global Assumptions & Conversions

- Gravity: g = 9.81 m/s²

- Key formula: ΔP = ρ × g × h

- Water column conversion: 1 mmWC = 9.81 Pa

- Convert Pa to mmWC: mmWC = ΔP(Pa) / 9.81

Sample data used in worked examples:

Level range (H) = 0 to 3.0 m

Process liquid density (ρp) = 1000 kg/m³ (water)

Wet leg density (ρwl) = 1000 kg/m³ (water)

General DP Relationship (All Cases)

A DP transmitter measures:

ΔP = P(HP) − P(LP)

P = ρ × g × h

mmWC = Pa / 9.81

Where HP is the bottom connection pressure, LP is the top connection pressure reference (atmosphere / vapor space / wet leg).

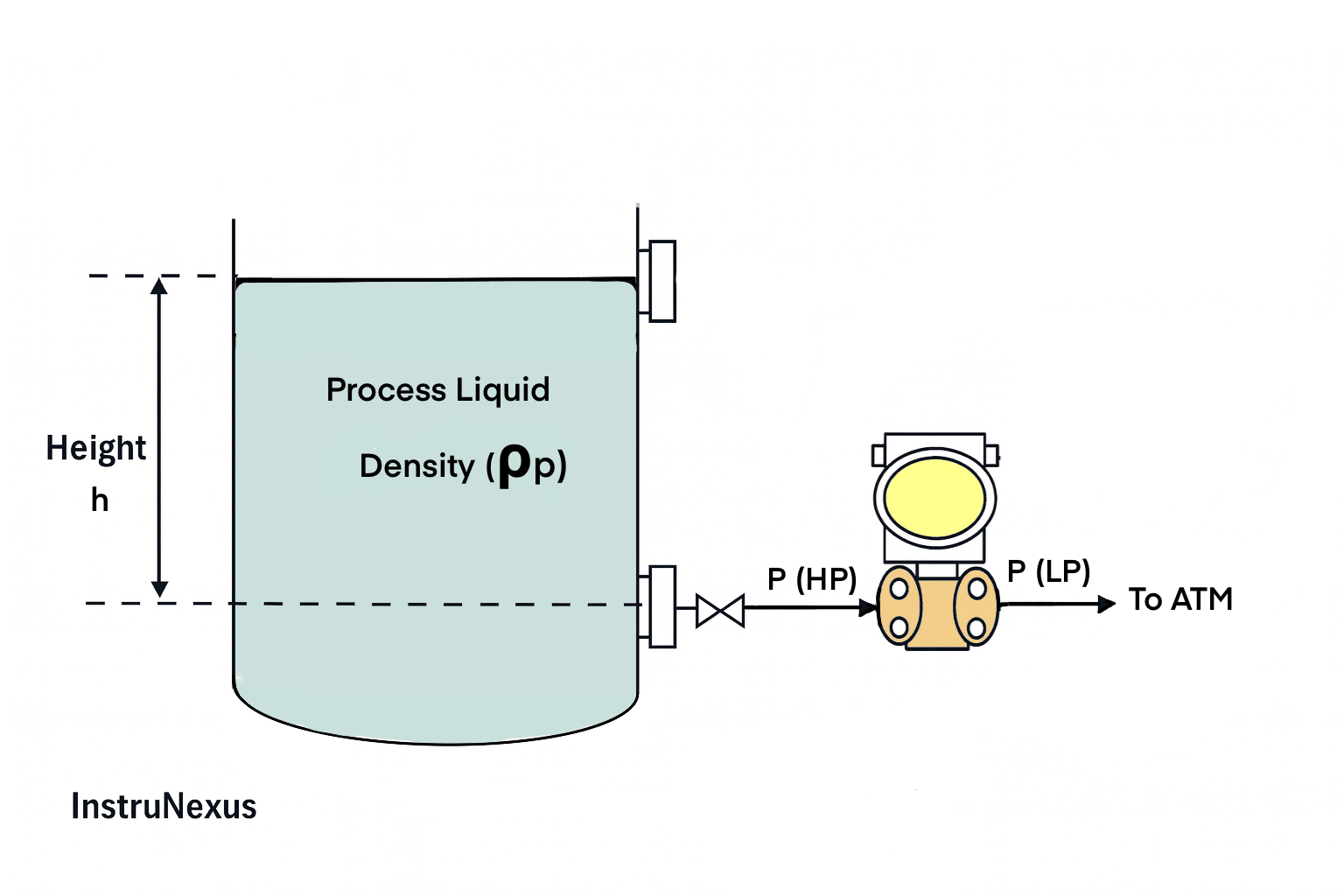

1) Open Tank (LP Vented to Atmosphere)

Concept

LP side is vented to atmosphere, so P(LP) = 0 (gauge reference). DP is only due to liquid head at the bottom tap.

Formulas

P(HP) = ρp × g × h

P(LP) = 0

ΔP = P(HP) − P(LP) = ρp × g × h

LRV = ΔP at h = 0%

URV = ΔP at h = 100%

Sample Calculation (0 to 3.0 m water)

Given: ρp = 1000 kg/m³, g = 9.81 m/s², level h = 0 to 3.0 m

At 0% (h = 0 m):

ΔP = 1000 × 9.81 × 0 = 0 Pa

LRV = 0 / 9.81 = 0 mmWC

At 100% (h = 3.0 m):

ΔP = 1000 × 9.81 × 3.0 = 29430 Pa

URV = 29430 / 9.81 = 3000 mmWC

Range: 0 to 3000 mmWC

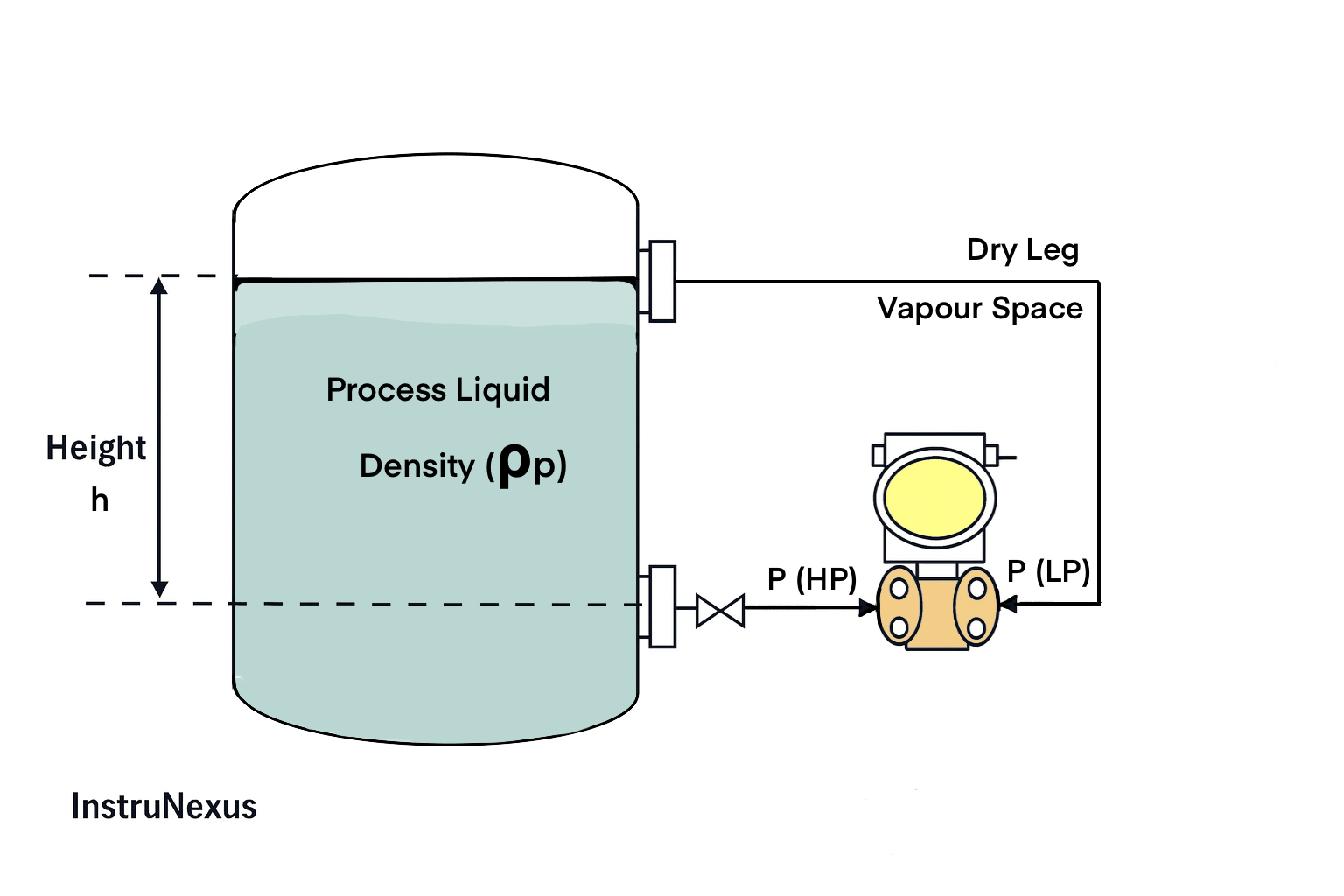

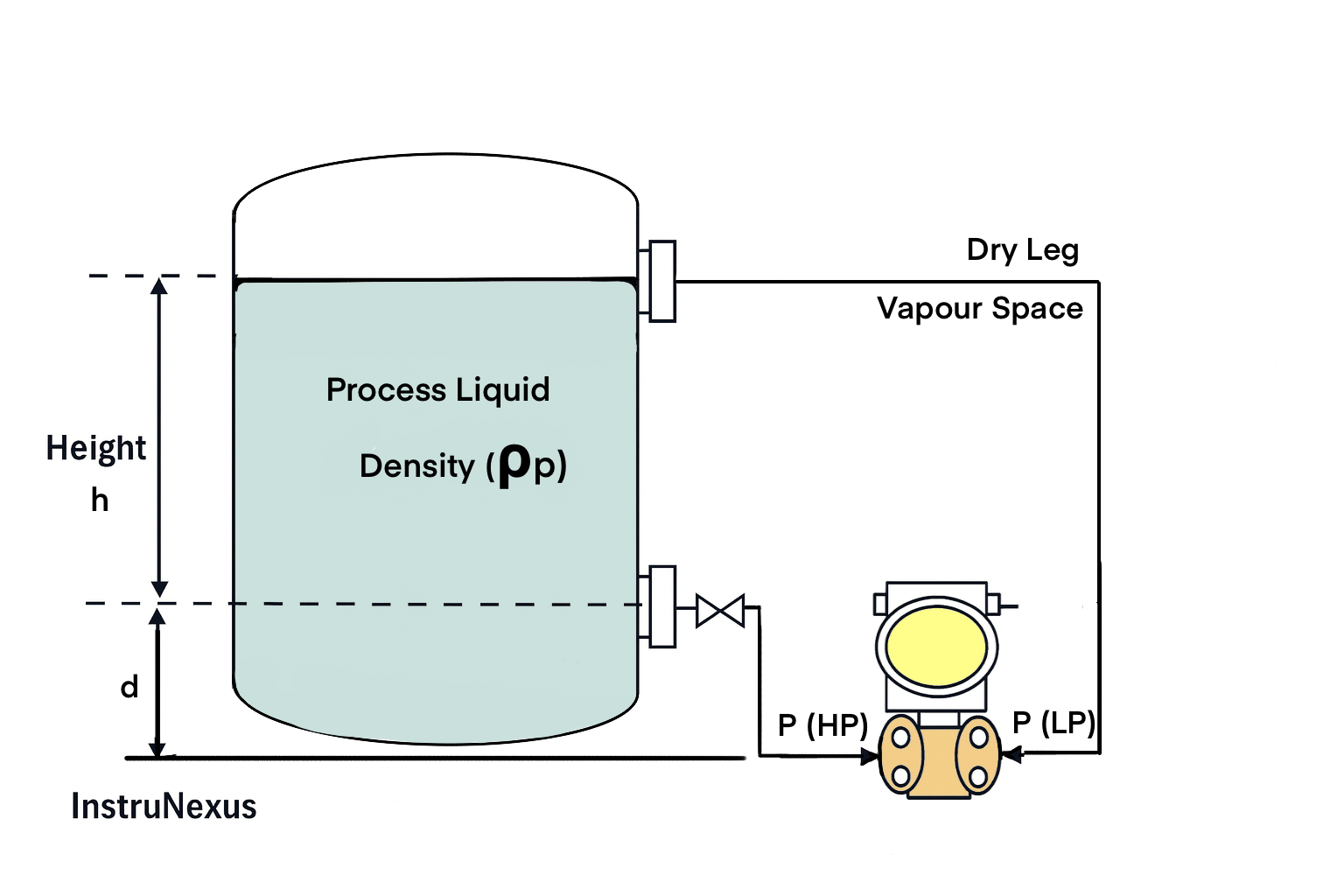

2) Closed Tank (Dry Leg on LP)

Concept

LP is connected to the vapor space at the top of the tank with a dry impulse line. Gas density is negligible, so the LP head is typically neglected for range selection (P(LP) ≈ 0 gauge).

Formulas

P(HP) = ρp × g × h

P(LP) ≈ 0 (gas head neglected)

ΔP = ρp × g × h

LRV = ΔP at h = 0%

URV = ΔP at h = 100%

Sample Calculation (0 to 3.0 m water)

Given: ρp = 1000 kg/m³, g = 9.81 m/s², level h = 0 to 3.0 m

At 0% (h = 0 m):

ΔP = 1000 × 9.81 × 0 = 0 Pa

LRV = 0 / 9.81 = 0 mmWC

At 100% (h = 3.0 m):

ΔP = 1000 × 9.81 × 3.0 = 29430 Pa

URV = 29430 / 9.81 = 3000 mmWC

Range: 0 to 3000 mmWC

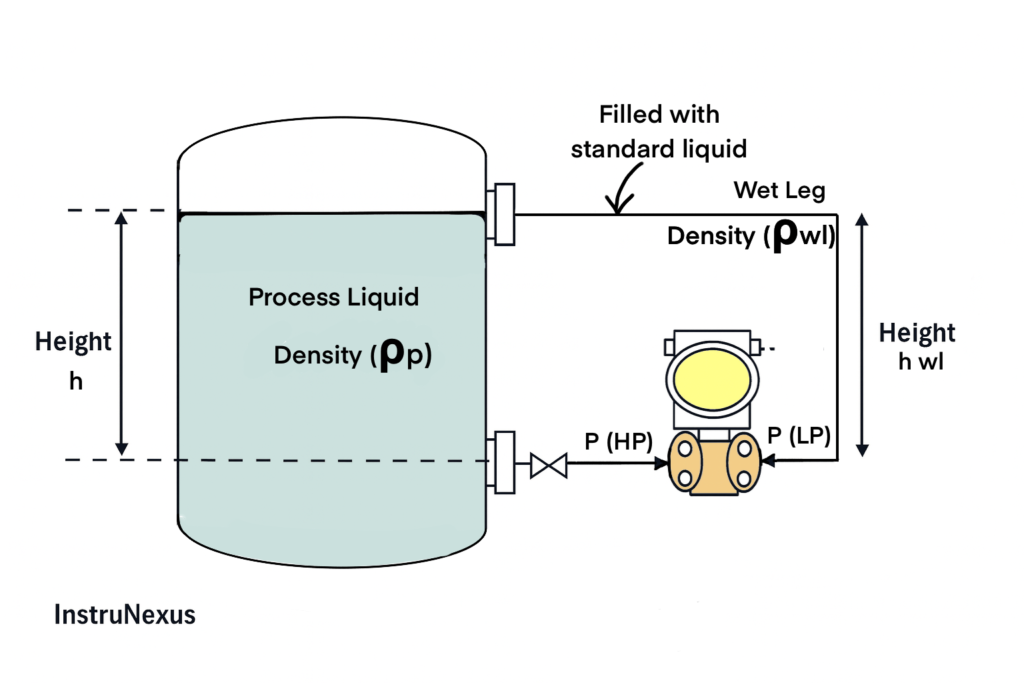

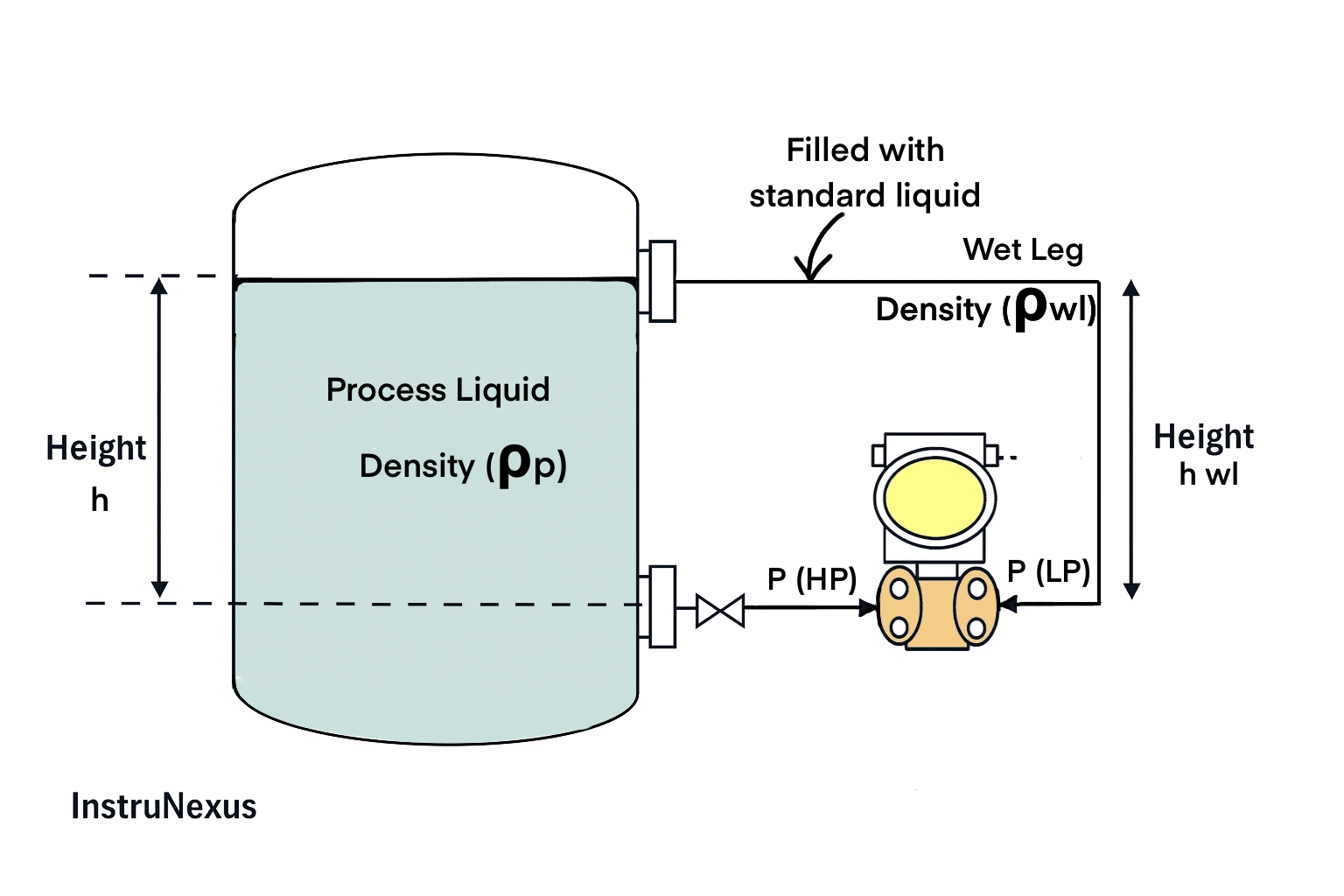

3) Closed Tank (Wet Leg on LP) — General Case

Concept

In a wet leg, the LP impulse line is intentionally kept filled with liquid (often condensate). This creates a constant LP pressure head that must be subtracted from the HP pressure.

Formulas

P(HP) = ρp × g × h

P(LP) = ρwl × g × hwl (constant wet leg head)

ΔP = P(HP) − P(LP)

ΔP = (ρp × g × h) − (ρwl × g × hwl)

LRV = (ρp × g × h at 0%) − (ρwl × g × hwl)

URV = (ρp × g × h at 100%) − (ρwl × g × hwl)

Note: Wet leg calculations often produce a negative LRV (called elevated zero), because LP constant head can be larger than HP at low levels.

4) Closed Tank with Elevation (Wet Leg on LP) — Worked Example

Given (Example)

- Process level range, h = 0 to 3.0 m

- Process density, ρp = 1000 kg/m³

- Wet leg density, ρwl = 1000 kg/m³

- Wet leg height on LP side, hwl = 3.0 m

- g = 9.81 m/s²

Formulas

P(LP) = ρwl × g × hwl (constant)

P(HP) = ρp × g × h

ΔP = P(HP) − P(LP)

mmWC = Pa / 9.81

Step-by-step Sample Calculation

Step 1: LP constant pressure (wet leg)

P(LP) = 1000 × 9.81 × 3.0 = 29430 Pa

P(LP) in mmWC = 29430 / 9.81 = 3000 mmWC (constant)

Step 2: LRV at 0% (h = 0 m)

P(HP) = 1000 × 9.81 × 0 = 0 Pa

ΔP = P(HP) − P(LP) = 0 − 29430 = −29430 Pa

LRV = −29430 / 9.81 = −3000 mmWC

Step 3: URV at 100% (h = 3.0 m)

P(HP) = 1000 × 9.81 × 3.0 = 29430 Pa

ΔP = 29430 − 29430 = 0 Pa

URV = 0 / 9.81 = 0 mmWC

Range (Elevation / elevated zero): −3000 to 0 mmWC

5) Closed Tank with Suppression (Transmitter Below Bottom Tap)

Concept

Suppression happens when the HP side sees a constant additional head (for example, transmitter mounted below the bottom nozzle). This shifts the LRV to a positive value (called suppressed zero).

Given (Example)

- Process level range, h = 0 to 3.0 m

- Transmitter is mounted d = 0.8 m below the bottom tap (HP leg always full of liquid)

- ρp = 1000 kg/m³, g = 9.81 m/s²

- LP is dry leg: P(LP) ≈ 0

Formulas

Total HP head height = d + h

P(HP) = ρp × g × (d + h)

P(LP) ≈ 0

ΔP = P(HP) − P(LP) = ρp × g × (d + h)

LRV = ΔP at h = 0%

URV = ΔP at h = 100%

mmWC = Pa / 9.81

Step-by-step Sample Calculation

Given: ρp = 1000 kg/m³, g = 9.81 m/s², d = 0.8 m, level h = 0 to 3.0 m

At 0% (h = 0 m):

ΔP = 1000 × 9.81 × (0.8 + 0) = 7848 Pa

LRV = 7848 / 9.81 = 800 mmWC

At 100% (h = 3.0 m):

ΔP = 1000 × 9.81 × (0.8 + 3.0) = 37278 Pa

URV = 37278 / 9.81 = 3800 mmWC

Range (Suppression / suppressed zero): +800 to +3800 mmWC