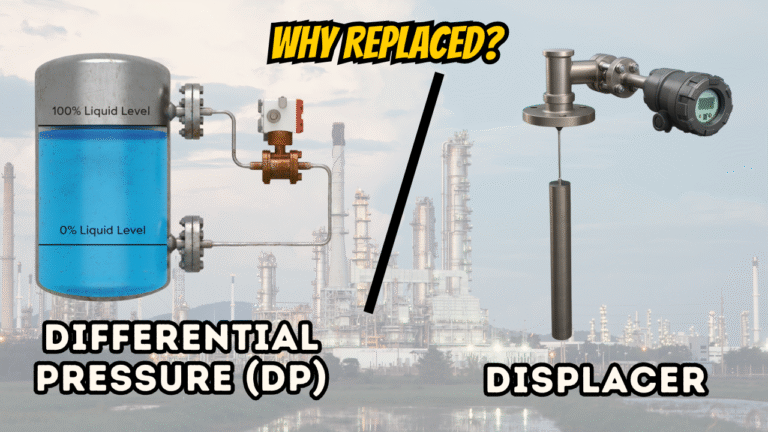

Why DP Level is replaced with Dispalcer Level Transmitters?

Comparing Differential Pressure vs. Displacer Transmitters in the Oil & Gas Industry

The Challenge of Accurate Level Measurement

In the oil and gas industry, accurately measuring fluid levels in vessels like separators, scrubbers, and storage tanks is critical for safety, efficiency, and process control. While Differential Pressure (DP) transmitters are widely used, they have limitations in complex scenarios. Displacer-type transmitters, based on Archimedes' buoyancy principle, often provide a more robust and reliable solution. This tool explores the key operational challenges where displacers are chosen to replace DP transmitters.

Interactive Scenario Explorer

Select a common challenge to see how each technology performs.

Differential Pressure (DP) Transmitter

Measures hydrostatic head pressure.

Displacer Level Transmitter

Measures buoyant force.

Performance Summary

A comparative rating of each technology across key operational factors.

Decision Guide: When to Choose Which

✔ Stick with DP Transmitters When...

- The process fluid has a constant, known density.

- The application is simple level measurement (not interface).

- The process environment is clean with no foam or buildup.

- Budget is a primary constraint and vessel intrusion is not possible.

- The application is for clean fluids like stored condensate or refined products.

✔ Replace with Displacer Transmitters When...

- Fluid density varies due to temperature, pressure, or composition changes.

- Measuring the interface between two liquids (e.g., oil/water) is required.

- The vessel experiences foam, turbulence, or agitation.

- High reliability and low maintenance are critical for process uptime.

- Dealing with challenging applications like separators, knockout drums, or alkylation units.

Unabridged Technical Report: A Comparative Analysis of Differential Pressure and Displacer Level Transmitters in Oil & Gas Applications

Abstract

Level measurement is a fundamental parameter in the process control strategies of the oil and gas industry, critical for safety, operational efficiency, and environmental compliance. For decades, differential pressure (DP) transmitters have been a common choice due to their versatility and cost-effectiveness. However, their inferential measurement principle, which derives level from hydrostatic pressure, makes them susceptible to significant inaccuracies in applications with changing process conditions. This report provides an unabridged technical analysis of the operational principles and inherent limitations of DP transmitters. It details the reasons why displacer-type level transmitters, which operate on the direct measurement principle of buoyancy, are frequently chosen as a more robust and reliable replacement in critical and complex applications. The analysis provides a deep dive into key challenges including varying fluid densities, multi-liquid interface level measurement, the presence of foam or turbulence, and long-term maintenance and reliability considerations. The report concludes that the displacer's direct measurement method provides superior accuracy, repeatability, and a lower total cost of ownership in the majority of dynamic oil and gas applications.

1.0 Introduction

From upstream production separators operating at high pressures to vast atmospheric storage tanks in downstream refineries, the precise control of liquid levels is paramount. A failure in level measurement can have cascading consequences, including safety incidents from vessel overfill, environmental releases, severe economic losses from inefficient separation leading to off-spec products, and catastrophic equipment damage, such as a gas compressor ingesting liquid from a faulty knock-out drum. Differential pressure transmitters became an industry staple due to their external mounting, perceived simplicity, and a well-established knowledge base. However, as processes become more optimized and marginal gains in efficiency are sought, the hidden costs and risks associated with the inaccuracies of this inferential measurement technique become more apparent. This report provides a comprehensive technical examination of why the direct measurement approach of displacer transmitters is often favored to mitigate these risks and improve process control.

2.0 In-Depth Principles of Operation

2.1 Differential Pressure (DP) Transmitter

A DP transmitter does not measure level; it measures pressure and infers level. Its operation is governed by the formula P = h * ρ * g (Pressure = height * density * gravity). The instrument is connected to the vessel via two tapping points. The high-pressure (HP) side is connected to a nozzle near the vessel bottom, sensing the total pressure of the liquid column plus any gas pressure in the vapor space. The low-pressure (LP) side is connected to a nozzle in the vapor space, sensing only the gas pressure. The transmitter electronically subtracts the LP reading from the HP reading, leaving only the hydrostatic pressure of the liquid column. To convert this pressure into a level, the transmitter is calibrated with a fixed density (specific gravity) value. The 0% level (zero) is set to the pressure at the HP tap with no liquid, and the 100% level (span) is set to the pressure when liquid is at the desired maximum height. This calibration is only accurate if the fluid density remains constant.

Installation complexity arises with closed, pressurized vessels. To provide a stable reference on the LP side, a "wet leg" or "dry leg" is used. A dry leg is simply an empty tube running from the top nozzle to the transmitter, which can fill with condensing vapors and cause errors. A wet leg is a tube that is intentionally filled with a stable reference fluid, creating a constant pressure head on the LP side, which must be factored into the transmitter's calibration. Both configurations require maintenance and are sources of potential error.

2.2 Displacer Level Transmitter

A displacer transmitter operates on Archimedes' Principle: a body submerged in a fluid is buoyed up by a force equal to the weight of the displaced fluid. The core components are a displacer element, a torque tube, and a transmitter head. The displacer is a precisely weighted cylinder or rod, denser than the process fluid, suspended in the liquid. As the liquid level rises, it submerges more of the displacer. This increases the buoyant force, which effectively reduces the displacer's apparent weight. This change in weight is transferred to a torque tube. The torque tube is a brilliant piece of engineering: it is a hollow rod that twists in proportion to the applied force but provides a frictionless, hermetic seal, meaning no process fluid can ever leak out. The twisting motion is minute but precisely measured by sensors (e.g., a Hall effect sensor) in the transmitter head, which converts this rotation into a 4-20 mA signal directly proportional to level. The measurement is a direct function of the liquid surface position along the length of the displacer.

Displacers can be installed internally in a vessel, or more commonly, in an external cage—a chamber piped to the vessel with isolation valves. This cage arrangement allows the instrument to be isolated, drained, and maintained without shutting down the entire process, a significant operational advantage.

3.0 Comparative Analysis of Key Performance Factors

3.1 Varying Fluid Density

DP Limitation: This is the technology's Achilles' heel. Since the DP transmitter's calibration is fixed for a single density value, any deviation in the actual process fluid's density creates a direct, proportional error. For example, consider a 10-meter tall tank where a DP is calibrated for a fluid with a specific gravity (SG) of 0.8. If the batch of fluid changes to one with an SG of 0.75 (a 6.25% decrease), the level reading will also be 6.25% lower than the true level. At a true 8-meter level, the transmitter would incorrectly read 7.5 meters—an error of 50 cm. This can lead to premature shutdown of pumps or an overfill scenario.

Displacer Advantage: A displacer's reading is also affected by density, but the effect is orders of magnitude smaller and often negligible. The measurement is based on where the surface level is along the displacer's length. A density change only alters the magnitude of the buoyant force, not the position of the level. While this can cause a very small calibration shift, it is insignificant compared to the gross errors seen in DP transmitters. The displacer provides a true reading of the liquid's position, regardless of moderate density fluctuations.

3.2 Interface Level Measurement

DP Limitation: Using a standard DP transmitter for interface is fundamentally flawed for dynamic processes. It requires a constant total level and stable, known densities of both liquids. The instrument measures a single pressure value generated by a composite of two different fluid densities. It is impossible to distinguish a change in interface from a change in the overall level or a change in either fluid's density. Special multi-tap DP systems exist but are complex, expensive, and still suffer from density-related inaccuracies.

Displacer Advantage: This is a primary application where displacers excel and are considered the industry-standard technology. The displacer is sized and weighted to have a density between the two liquids. It will sink through the lighter upper liquid (e.g., hydrocarbon) and float on the heavier lower liquid (e.g., water). The buoyant force is then a direct and precise function of how much of the displacer is submerged in the heavier liquid. It effectively ignores the upper liquid and gives a direct reading of the interface position, crucial for preventing water carryover in crude separators or controlling chemical reaction zones.

3.3 Process Conditions (Foam, Turbulence, Vaporization)

DP Limitation: DP transmitters are highly susceptible to noisy process conditions. Foam, being aerated liquid, has a density but is not true level; it can add hydrostatic pressure and cause a false high reading. Turbulence in the vessel creates pressure fluctuations, leading to a "noisy" 4-20 mA signal that must be heavily dampened, slowing the instrument's response time. Most critically, if the process fluid is near its boiling point, the pressure drop in the impulse line can cause the liquid to flash to vapor, creating gas bubbles that drastically alter the pressure reading and render the measurement useless.

Displacer Advantage: The common use of an external cage or internal stilling well isolates the displacer from these issues. The cage acts as a baffle, calming turbulence and knocking down foam, allowing the displacer to measure a clear, stable liquid level. Since the measurement is based on buoyancy, low-density foam has almost no effect on the displacer's apparent weight. The direct mounting to the vessel eliminates any possibility of flashing in impulse lines.

3.4 Installation, Maintenance, and Total Cost of Ownership

DP Transmitter: The initial purchase price (CAPEX) of a DP transmitter is often lower than a displacer. However, the Total Cost of Ownership (TCO) is frequently higher. Installation costs include not only mounting the transmitter but also fabricating, installing, and leak-testing impulse lines and valve manifolds. In colder climates, these lines require expensive insulation and electric heat tracing to prevent freezing. The ongoing operational cost (OPEX) is the primary concern. Impulse lines are the number one failure point, prone to clogging, freezing, leaking, and vibration-induced cracking. They require periodic flushing and blow-downs, which consumes maintenance hours and involves risks of personnel exposure to process fluids.

Displacer Transmitter: The CAPEX for a displacer system, especially one with an external cage and isolation valves, is typically higher. However, the installation is simpler, requiring only the piping of the cage to the vessel nozzles. The TCO is significantly lower. With no impulse lines, the most common failure points are eliminated. Maintenance is minimal, often limited to periodic calibration checks which can be done without removing the instrument. The robust mechanical design of the torque tube provides decades of reliable, worry-free service, leading to higher process uptime and lower lifetime costs.

4.0 Application-Specific Scenarios

4.1 Glycol and Amine Contactors (Gas Sweetening)

These processes are notorious for foaming. A DP transmitter would give erroneous high readings, potentially leading process control systems to reduce the chemical circulation rate, causing off-spec gas. A displacer in a stilling well easily ignores the foam and provides an accurate reading of the true liquid level, ensuring efficient operation.

4.2 High-Pressure Production Separators

These vessels separate oil, gas, and water near the wellhead. Process conditions are highly dynamic, with fluctuations in temperature and pressure causing density shifts in the hydrocarbon liquid. Furthermore, precise oil/water interface control is required to prevent water from contaminating the oil outlet and oil from being sent to the water treatment system. This is a perfect application for a displacer, which handles the density changes and provides the critical interface measurement that a DP cannot.

4.3 Compressor Knock-Out Drums

The sole purpose of a KO drum is to prevent liquids from entering and destroying a multi-million dollar gas compressor. The level measurement must be absolutely reliable. The robustness and fail-safe nature of a displacer, free from the risk of clogged or frozen impulse lines, makes it the preferred choice for this safety-critical application.

5.0 Conclusion

While Differential Pressure transmitters remain a viable, low-cost option for simple, non-critical applications involving clean fluids with stable, known densities, they carry significant inherent risks and operational costs when applied to the complex and dynamic processes common in the oil and gas industry. Their reliance on inferential measurement based on a single, fixed density value is a fundamental vulnerability that can compromise process safety, product quality, and operational efficiency.

The displacer level transmitter, by employing the direct physical principle of buoyancy, provides a fundamentally more reliable, repeatable, and accurate measurement in the face of changing densities, liquid interfaces, foam, and turbulence. Its robust, low-maintenance design eliminates the common failure points associated with DP impulse lines. When evaluating instrumentation based on fitness-for-purpose and total cost of ownership rather than initial purchase price alone, the displacer is frequently and justifiably the superior technology. It is selected to replace DP transmitters in critical services to ensure superior process control and long-term operational integrity.