Electronic vs. Mechanical Pressure Sensors: A Comprehensive Guide for Instrumentation Professionals

In the world of instrumentation and process control, the accurate measurement of pressure is paramount. It’s a fundamental parameter that can significantly impact the safety, efficiency, and quality of a vast array of industrial processes. For decades, instrumentation professionals and students have relied on a variety of pressure sensing technologies. The two broadest categories, and the subject of much discussion, are electronic and mechanical pressure sensors.

This comprehensive guide will delve into the intricacies of both electronic and mechanical pressure sensors, exploring their working principles, pros, and cons. We will also provide illustrative block diagrams to demystify their operation, compare them head-to-head, and look at their diverse applications and the future of pressure sensing technology. By the end of this nearly 2000-word article, you’ll have a robust understanding to help you select the right sensor for your specific needs.

The Old Guard: Mechanical Pressure Sensors

Mechanical pressure sensors, often referred to as analog or traditional sensors, have been the bedrock of pressure measurement for over a century. Their operation relies on a direct, physical response to pressure changes, which is then translated into a readable format, typically a dial gauge.

How Mechanical Pressure Sensors Work

The most common type of mechanical pressure sensor is the Bourdon tube pressure gauge. Its design is elegant in its simplicity.

Block Diagram of a Bourdon Tube Pressure Gauge:

- Pressure Input: The process fluid or gas enters the sensor.

- Bourdon Tube: This is a flattened, C-shaped, helical, or spiral tube that is sealed at one end. When pressure is applied, the tube attempts to straighten.

- Linkage System: The movement of the free end of the Bourdon tube is connected to a system of levers and gears.

- Pointer and Dial Scale: The linkage system amplifies the small movement of the tube and rotates a pointer on a calibrated dial, providing a visual indication of the pressure.

Other types of mechanical pressure sensors include diaphragm and bellows elements, which also rely on the physical displacement of a flexible element under pressure.

Pros of Mechanical Pressure Sensors:

- No Power Required: This is arguably their biggest advantage. Mechanical sensors are self-contained and operate solely on the principle of mechanical deformation. This makes them ideal for remote locations, hazardous areas where electrical power could be a safety risk, and applications where power outages are a concern.

- Robustness and Durability: Many mechanical gauges are built to withstand harsh industrial environments, including high vibration and shock. Their simple, sturdy construction contributes to a long operational life.

- Low Cost: Generally, mechanical pressure gauges have a lower initial purchase price compared to their electronic counterparts, making them a cost-effective solution for simple pressure monitoring tasks.

- Ease of Installation and Use: Their installation is straightforward, typically involving threading the gauge into a process connection. Reading the dial is intuitive, requiring no special training.

- Direct Local Reading: They provide an immediate, at-a-glance pressure reading at the point of measurement, which is crucial for operators who need to quickly check process conditions on the plant floor.

Cons of Mechanical Pressure Sensors:

- Lower Accuracy and Precision: Compared to electronic sensors, mechanical gauges typically have lower accuracy. Parallax error (error due to the viewing angle of the observer) can also affect reading precision.

- Limited Features: They offer no advanced functionalities like remote signal transmission, data logging, or programmable alarms. What you see on the dial is all the information you get.

- Susceptibility to Overpressure and Vibration: While robust, severe overpressure can permanently deform the Bourdon tube, leading to inaccurate readings or complete failure. Continuous, high-frequency vibration can cause wear and tear on the internal mechanical components.

- Hysteresis and Wear: The mechanical components can experience wear over time, leading to inaccuracies and a phenomenon known as hysteresis, where the reading at a certain pressure may differ depending on whether the pressure is increasing or decreasing.

- Manual Data Collection: For processes that require data logging and analysis, manual reading and recording are necessary, which is time-consuming and prone to human error.

The New Wave: Electronic Pressure Sensors

Electronic pressure sensors, also known as pressure transducers or transmitters, represent the modern approach to pressure measurement. They convert the detected pressure into an electrical signal, offering a host of advanced capabilities.

How Electronic Pressure Sensors Work

Electronic pressure sensors utilize various sensing principles. Two of the most prevalent are piezoresistive and capacitive.

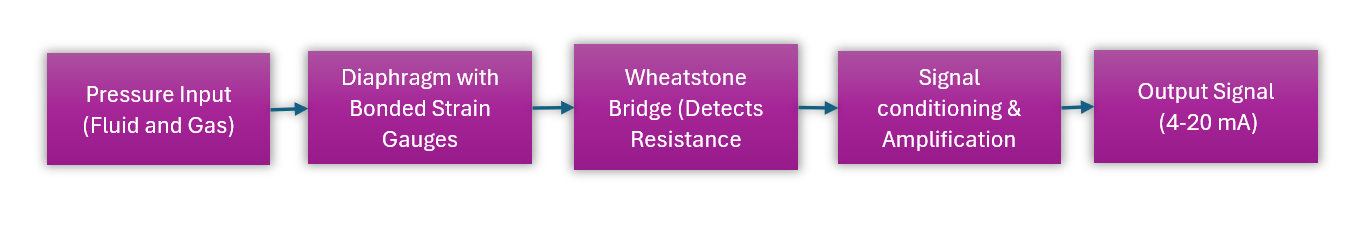

Block Diagram of a Piezoresistive Pressure Sensor:

- Pressure Input: The process medium exerts pressure on a flexible diaphragm.

- Piezoresistive Strain Gauges: Bonded to or diffused into the diaphragm are piezoresistive materials whose electrical resistance changes when they are stretched or compressed.

- Wheatstone Bridge: The strain gauges are typically arranged in a Wheatstone bridge circuit. The change in resistance unbalances the bridge, producing a small output voltage.

- Signal Conditioning and Amplification: The low-level voltage signal is conditioned (filtered, linearized, and temperature compensated) and amplified.

- Output Signal: The conditioned signal is converted into a standard industrial output, such as a 4-20mA current loop, a voltage signal, or a digital signal (e.g., HART, Profibus).

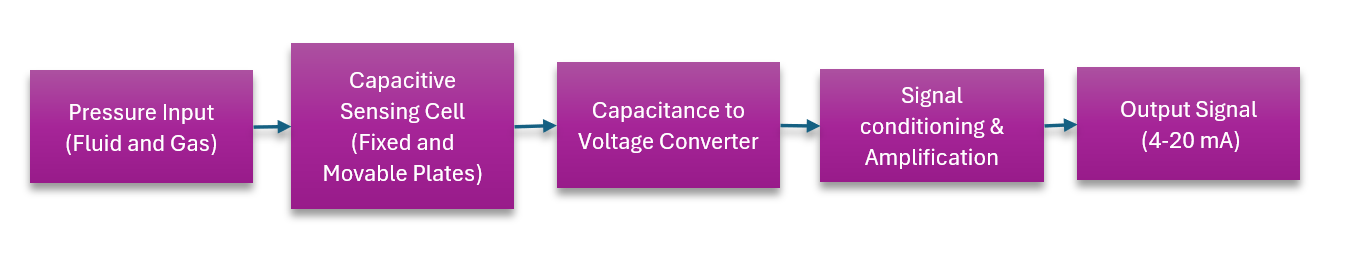

Block Diagram of a Capacitive Pressure Sensor:

- Pressure Input: Pressure deflects a flexible diaphragm, which acts as one plate of a capacitor.

- Sensing Diaphragm and Fixed Plate: The diaphragm moves closer to or further away from a fixed plate, changing the capacitance of the sensor.

- Capacitance to Voltage Converter: An electronic circuit measures this change in capacitance and converts it into a corresponding voltage signal.

- Signal Conditioning and Amplification: Similar to the piezoresistive sensor, the signal is conditioned and amplified.

- Output Signal: The final, robust output signal is generated.

Pros of Electronic Pressure Sensors:

- High Accuracy and Precision: Electronic sensors offer significantly higher accuracy and resolution than their mechanical counterparts. They are less susceptible to human reading errors.

- Remote Signal Transmission: The ability to transmit a signal (e.g., 4-20mA) over long distances to a central control room (PLC, DCS) is a major advantage for modern industrial automation.

- Data Logging and Analysis: The electrical output can be easily integrated with data acquisition systems, allowing for continuous monitoring, historical trend analysis, and predictive maintenance.

- Advanced Features: Many electronic sensors come with features like digital displays, programmable switch outputs, and digital communication protocols (HART, Foundation Fieldbus) that allow for remote configuration and diagnostics.

- Wide Operating Ranges and High Overpressure Protection: They are available in a vast range of pressure measurement capabilities, from very low to extremely high pressures. Many designs incorporate features that provide excellent protection against overpressure conditions.

- Compact Size and Lightweight: Electronic sensors are generally smaller and lighter than mechanical gauges, which can be advantageous in space-constrained applications.

Cons of Electronic Pressure Sensors:

- Requires Power: Electronic sensors need an external power source (e.g., loop power, DC voltage) to operate. This can be a limitation in remote or hazardous areas.

- Higher Initial Cost: The initial investment for an electronic pressure sensor is typically higher than for a mechanical gauge.

- Susceptibility to Electrical Noise and Interference: The electronic circuitry can be susceptible to electromagnetic interference (EMI) and radio frequency interference (RFI) if not properly shielded and grounded.

- Complexity: The internal electronics make them more complex than mechanical gauges. Troubleshooting and repair may require specialized knowledge and equipment.

- Environmental Sensitivity: Extreme temperatures can affect the performance of the electronic components, although many sensors are designed with temperature compensation.

Head-to-Head Comparison: Electronic vs. Mechanical

| Feature | Electronic Pressure Sensor | Mechanical Pressure Sensor |

|---|---|---|

| Power Requirement | Requires external power | Self-powered |

| Accuracy & Precision | High | Lower |

| Output | Electrical signal (4-20mA, V, digital) | Visual dial reading |

| Remote Monitoring | Yes, via signal transmission | No |

| Data Logging | Yes, easily integrated | Manual recording only |

| Advanced Features | Programmable alarms, digital comms | None |

| Initial Cost | Higher | Lower |

| Durability | Good, but electronics can be sensitive | Very robust mechanically |

| Susceptibility | Electrical noise, temperature extremes | Overpressure, vibration, wear |

| Ideal Applications | Process control, automation, data analysis | Local indication, remote/hazardous areas |

Applications in the Field

The choice between electronic and mechanical pressure sensors often comes down to the specific application requirements.

Typical Applications for Mechanical Pressure Sensors:

- Local pressure indication on pumps, compressors, and filters.

- Hydraulic and pneumatic systems where a simple visual check is sufficient.

- Remote oil and gas wellheads where power is unavailable.

- Fire suppression systems and portable gas cylinders.

- As a redundant, fail-safe backup to an electronic sensor.

Typical Applications for Electronic Pressure Sensors:

- Closed-loop process control in chemical plants, refineries, and manufacturing facilities.

- HVAC systems for monitoring and controlling air and fluid pressures.

- Aerospace applications for measuring altitude and cabin pressure.

- Medical devices such as ventilators and blood pressure monitors.

- Automotive systems for monitoring oil, fuel, and tire pressure.

The Future of Pressure Sensing

The trend in pressure measurement is undeniably moving towards more intelligent and connected electronic sensors. The rise of the Industrial Internet of Things (IIoT) is a major driving force. We are seeing the development of:

- Wireless Pressure Sensors: These sensors eliminate the need for costly and complex wiring, making them easier and more economical to deploy in a wider range of applications.

- Smart Sensors with Onboard Diagnostics: Future sensors will have more advanced self-diagnostic capabilities, alerting maintenance personnel to potential issues before they lead to a failure.

- Miniaturization: Advances in MEMS (Micro-Electro-Mechanical Systems) technology are leading to even smaller, more efficient, and more cost-effective electronic sensors.

- Integration of Artificial Intelligence (AI): AI algorithms will be used to analyze pressure data in real-time, enabling more sophisticated predictive maintenance and process optimization.

While the future is bright for electronic sensors, the trusty mechanical gauge is far from obsolete. Its simplicity, reliability, and independence from a power source ensure its place in the instrumentation toolbox for many years to come, especially for applications where a straightforward, localized pressure reading is all that’s needed.

Conclusion: Making the Right Choice

The debate between electronic and mechanical pressure sensors is not about which is definitively “better,” but rather which is the most appropriate tool for the job.

For the modern instrumentation professional focused on process automation, data-driven decision-making, and high levels of accuracy, electronic pressure sensors are the clear choice. Their ability to integrate seamlessly into control systems and provide a wealth of diagnostic information is invaluable in today’s industrial landscape.

However, for applications demanding simplicity, robustness in the absence of power, and a cost-effective solution for local pressure indication, the mechanical pressure sensor remains an unbeatable classic.

As a student of instrumentation, understanding the fundamental principles, advantages, and limitations of both types of sensors is crucial. This knowledge will form the foundation upon which you can build a successful career, making informed decisions that ensure the safety, efficiency, and reliability of the processes you will one day control. The key is to analyze the specific needs of your application – considering factors like accuracy requirements, environmental conditions, data needs, and budget – to select the pressure sensor that will deliver optimal performance and value.