The Quest for a Better Flow Measurement

For decades, industries relied on mechanical flow meters like turbine and positive displacement meters. While effective in their time, these technologies often come with limitations such as moving parts that wear and tear, susceptibility to fluid properties, and pressure drop that can impact process efficiency. The advent of electronic, non-intrusive, and highly accurate technologies like Coriolis and ultrasonic flow meters has revolutionized fluid measurement, offering greater reliability and a wealth of data.

Understanding Coriolis Flow Meters: The Mass Flow Marvel

Coriolis flow meters are widely regarded as the gold standard for many applications due to their exceptional accuracy and ability to measure mass flow directly, independent of fluid properties.

The Operating Principle: A Dance of Physics

The operation of a Coriolis flow meter is a fascinating application of the Coriolis effect – the same phenomenon that influences weather patterns and ocean currents. Imagine a spinning playground merry-go-round. If you try to walk from the center to the edge, you’ll feel a sideways force pushing you. This is the Coriolis effect in action.

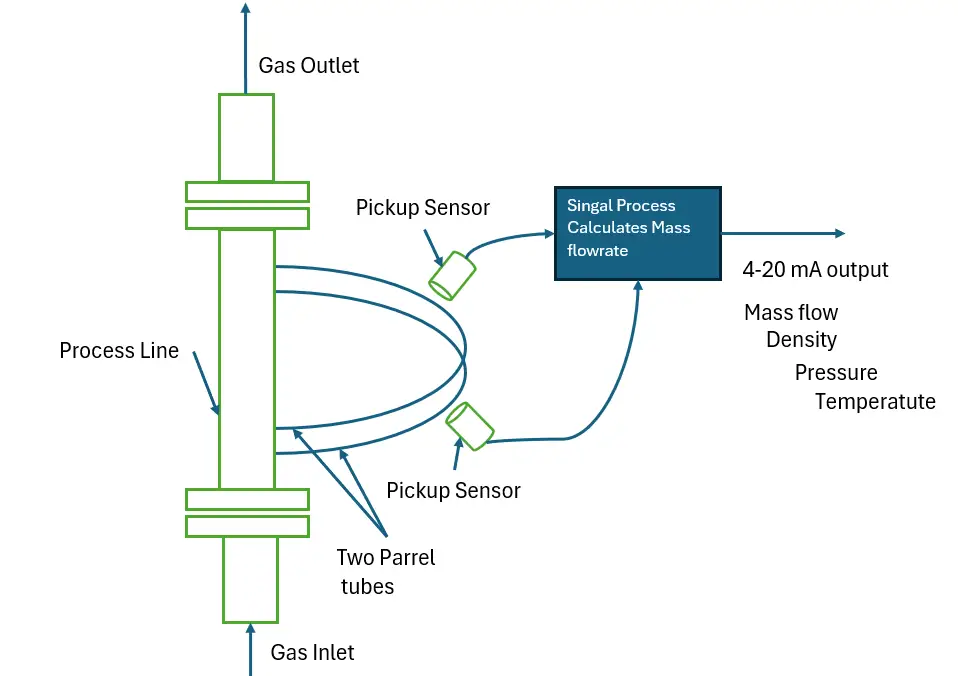

Inside a Coriolis flow meter, one or two tubes, typically U-shaped or straight, are vibrated at their natural resonant frequency by a small electromagnetic coil. As the fluid flows through these vibrating tubes, it is forced to accelerate as it moves toward the point of peak vibration and decelerate as it moves away. This acceleration and deceleration create a twisting force, or deflection, in the tubes.

This twisting is directly proportional to the mass flow rate of the fluid passing through the tubes. Strategically placed sensors continuously monitor the tube’s vibration and detect the phase shift (the tiny time difference) between the inlet and outlet ends of the vibrating tube. The greater the phase shift, the greater the mass flow rate.

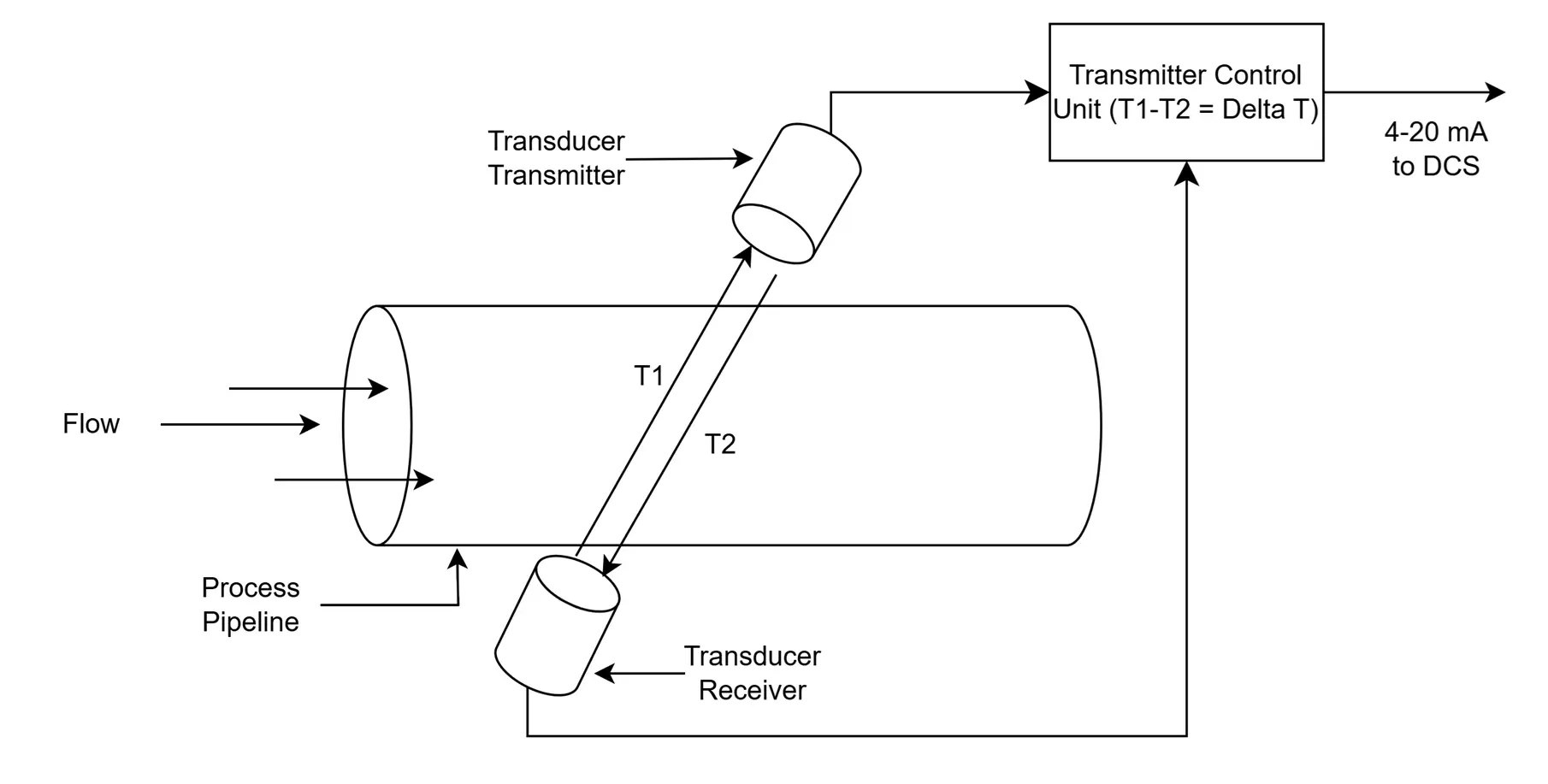

Block Diagram of a Coriolis Flow Meter:

Unpacking the Advantages of Coriolis Flow Meters:

- Unparalleled Accuracy: Coriolis meters are renowned for their high accuracy, typically in the range of ±0.1% to ±0.5% of the measured value. This makes them ideal for critical applications like custody transfer and chemical dosing.

- Direct Mass Flow Measurement: This is the standout feature. Many industrial processes require precise mass measurements, and Coriolis meters provide this directly, eliminating the need for separate temperature and pressure sensors to compensate for density changes.

- Fluid Independence: The measurement is largely unaffected by changes in fluid properties such as density, viscosity, temperature, and pressure. This makes them incredibly versatile for a wide range of fluids, from gases to viscous liquids and slurries.

- Multivariable Measurement: A single Coriolis meter can provide not just mass flow rate, but also volumetric flow rate, density, temperature, and concentration (e.g., Brix or Plato in the food and beverage industry). This rich data stream can significantly enhance process control.

- No Moving Parts: The absence of internal moving parts means minimal wear and tear, leading to low maintenance requirements and long operational life.

- No Straight Pipe Run Requirement: Unlike many other flow meter technologies, Coriolis meters do not require a specific length of straight pipe upstream or downstream of the meter, making them suitable for installations with limited space.

The Not-So-Bright Side: Limitations of Coriolis Flow Meters

- High Initial Cost: The sophisticated technology and construction of Coriolis meters make them one of the more expensive flow meter options upfront.

- Potential for Pressure Drop: The design of the flow tubes can introduce a pressure drop in the process line, which might be a concern in low-pressure systems.

- Size and Weight: Larger Coriolis meters can be bulky and heavy, requiring substantial support for installation.

- Sensitivity to Vibrations: While manufacturers have made significant strides in mitigating this, external vibrations close to the meter’s operating frequency can potentially interfere with the measurement.

- Not Ideal for Very Low Flow Rates of Gases: While excellent for liquids, measuring very low gas flow rates can be challenging due to the low mass involved.

Where Coriolis Meters Shine: Key Applications

The exceptional accuracy and reliability of Coriolis meters make them the preferred choice for:

- Custody Transfer: In the oil and gas and chemical industries, where the precise measurement of transferred product is a contractual and financial necessity.

- Chemical Injection and Dosing: For applications requiring the precise addition of chemicals, such as in water treatment and pharmaceutical manufacturing.

- Food and Beverage Processing: For measuring ingredients, monitoring concentration (e.g., sugar content in soft drinks), and in Clean-in-Place (CIP) systems.

- Pharmaceuticals and Biotechnology: Where stringent hygiene and accuracy are paramount.

- General Process Control: In any application where high accuracy and real-time multivariable data can optimize the process.

Riding the Sound Waves: An Introduction to Ultrasonic Flow Meters

Ultrasonic flow meters represent a powerful and versatile non-intrusive flow measurement technology. They work by sending and receiving sound waves through a fluid to determine its velocity. There are two main types of ultrasonic flow meters: transit-time and Doppler.

The Operating Principle: A Tale of Two Technologies

1. Transit-Time Ultrasonic Flow Meters

Transit-time ultrasonic flow meters are the more common type and are used for clean, single-phase fluids. They operate on a simple yet elegant principle: sound travels faster with the flow and slower against it.

The meter consists of two transducers, each capable of sending and receiving ultrasonic pulses. These transducers are mounted on the outside of the pipe at a specific angle. One transducer sends a pulse diagonally across the pipe to the other transducer, and the time it takes for the pulse to travel this distance is measured. Then, the second transducer sends a pulse back to the first, and this travel time is also measured.

The difference between the upstream and downstream transit times is directly proportional to the velocity of the fluid. The meter’s processor then calculates the volumetric flow rate based on this velocity and the pipe’s cross-sectional area.

Block Diagram of a Transit-Time Ultrasonic Flow Meter:

2. Doppler Ultrasonic Flow Meters

Doppler ultrasonic flow meters are designed for fluids that contain suspended solids or gas bubbles, which are often problematic for transit-time meters. They utilize the Doppler effect, the same principle that causes the pitch of a siren to change as it moves towards or away from you.

In a Doppler meter, a single transducer sends a high-frequency sound wave into the fluid. This sound wave is reflected off the moving particles or bubbles in the fluid. The motion of these reflectors causes a frequency shift in the reflected sound wave. This frequency shift is directly proportional to the velocity of the fluid. The processor then calculates the volumetric flow rate.

The Symphony of Advantages: Benefits of Ultrasonic Flow Meters

- Non-Intrusive and Clamp-On Design: This is the hallmark of ultrasonic meters. The transducers are typically mounted on the outside of the pipe, meaning no pipe cutting, no process shutdown for installation, and no risk of leaks.

- No Pressure Drop: Since there is no obstruction in the flow path, ultrasonic meters do not cause any pressure drop, which is a significant advantage in low-pressure systems and for energy conservation.

- Versatility for Large Pipes: They are an excellent and cost-effective solution for measuring flow in very large diameter pipes, where other technologies would be prohibitively expensive or impractical.

- Low Maintenance: With no moving parts and no contact with the process fluid, maintenance requirements are minimal.

- Good Accuracy: While not typically as accurate as Coriolis meters, modern ultrasonic meters can achieve accuracies in the range of ±0.5% to ±2% of the reading.

- Bi-directional Flow Measurement: Most ultrasonic meters can measure flow in both directions.

The Dissonant Notes: Limitations of Ultrasonic Flow Meters

- Fluid and Condition Dependencies: Transit-time meters require a clean, single-phase fluid, as entrained solids or bubbles can scatter the ultrasonic signal. Conversely, Doppler meters require the presence of these reflectors to function.

- Requirement for a Full Pipe: The pipe must be completely full of fluid for an accurate measurement.

- Straight Pipe Run Requirement: To ensure a fully developed and uniform flow profile, ultrasonic meters typically require a significant length of straight, unobstructed pipe upstream (often 10-20 pipe diameters) and downstream (often 5 pipe diameters) of the meter. This can be a major installation constraint.

- Sensitivity to Pipe Properties: The acoustic properties of the pipe material must be known and accounted for. Old or corroded pipes can pose a challenge.

- Indirect Volumetric Measurement: They measure fluid velocity and infer the volumetric flow rate. To get mass flow, density must be determined separately.

Where Ultrasonic Meters Perform Best: Key Applications

The non-intrusive nature and versatility of ultrasonic meters make them ideal for:

- Water and Wastewater Management: For large pipelines in distribution networks and treatment plants where interrupting the flow is not an option.

- HVAC and Energy Management: For measuring chilled and hot water flow in building automation systems.

- Oil and Gas (Upstream and Midstream): For measuring crude oil and natural gas in large transport pipelines.

- Chemical Processing (for clean fluids): Where a non-contact measurement is desirable to avoid material compatibility issues.

- Retrofit Applications: Clamp-on ultrasonic meters are perfect for adding flow measurement points to existing piping systems without costly modifications.

Head-to-Head: Coriolis vs. Ultrasonic Flow Meters

| Feature | Coriolis Flow Meter | Ultrasonic Flow Meter |

|---|---|---|

| Operating Principle | Coriolis Effect (direct mass flow) | Sound wave propagation (velocity) |

| Primary Measurement | Mass Flow | Fluid Velocity (inferring volumetric flow) |

| Accuracy | Very High (±0.1% to ±0.5%) | Good (±0.5% to ±2%) |

| Fluid Types | Wide range (liquids, gases, slurries) | Transit-time: Clean liquids/gases; Doppler: Liquids with solids/bubbles |

| Installation | Invasive (requires pipe cutting) | Non-invasive (clamp-on) or wetted (spool piece) |

| Straight Pipe Run | Not required | Required (typically 10-20D upstream, 5D downstream) |

| Pressure Drop | Yes (can be significant) | No |

| Cost | High | Medium to High (cost-effective for large pipes) |

| Multivariable Output | Yes (mass flow, density, temperature) | Primarily volumetric flow |

| Maintenance | Low | Very Low |

| Key Advantage | Unmatched accuracy and direct mass flow | Non-intrusive, no pressure drop, ideal for large pipes |

| Key Disadvantage | High cost and pressure drop | Straight run requirement and fluid limitations |

Making the Right Choice: Which Flow Meter is for You?

The decision between a Coriolis and an ultrasonic flow meter ultimately hinges on the specific requirements of your application. Here’s a simplified decision-making framework:

Choose a Coriolis Flow Meter if:

- You need the highest possible accuracy. For applications like custody transfer or precise chemical dosing, the accuracy of a Coriolis meter is indispensable.

- You need to measure mass flow directly. If your process is based on mass rather than volume, a Coriolis meter is the most direct and reliable solution.

- You are dealing with a fluid whose properties (density, viscosity) change. The immunity of Coriolis meters to these changes ensures consistent and accurate measurements.

- You can accommodate a pressure drop and a higher initial investment.

- You have limited straight pipe available for installation.

Choose an Ultrasonic Flow Meter if:

- You cannot shut down your process for installation. The clamp-on nature of ultrasonic meters is a game-changer for existing systems.

- You are measuring flow in a very large pipe. For pipe diameters above 12 inches, ultrasonic meters are often the more economical choice.

- You cannot tolerate any pressure drop in your system.

- You are measuring a relatively clean, single-phase fluid (for transit-time) or a fluid with suspended particles (for Doppler).

- You have ample straight pipe available to meet the installation requirements.

The Future of Flow Measurement

Both Coriolis and ultrasonic technologies continue to evolve. Manufacturers are developing more compact and cost-effective Coriolis meters, as well as more robust ultrasonic meters with advanced signal processing to handle more challenging fluid conditions. The integration of smart diagnostics and digital communication protocols like HART and Modbus is becoming standard, allowing these meters to provide not just data, but actionable insights into your process health.

In conclusion, both Coriolis and ultrasonic flow meters are powerful tools in the modern industrial landscape. The “better” technology is the one that aligns with the demands of your application, your budget, and your installation constraints. By understanding the fundamental principles, advantages, and limitations of each, you can confidently select the flow meter that will provide accurate, reliable, and valuable data for years to come, ensuring the efficiency and safety of your operations.