Pressure gauges are critical components in process instrumentation, providing real-time feedback on system pressures to ensure safety, reliability, and efficiency. However, for these gauges to operate accurately and withstand challenging process conditions, a variety of accessories are often required. These accessories serve to protect the gauge, improve readability, allow for isolation and calibration, and adapt the gauge to specific process conditions.

In this blog, we’ll explore the most common and essential accessories used with pressure gauges, their functions, applications, and selection considerations.

1. Syphons

Function:

Syphons protect pressure gauges from high-temperature steam or vapors by acting as a cooling barrier. They trap condensate and prevent direct exposure of the gauge to hot process media.

Types:

Pigtail Syphon (coil type): Commonly used in steam lines. The coil traps steam condensate.

U-type Syphon: Suitable for vertical installations.

Straight Syphon: Used where horizontal installations are required with limited space.

Material:

Usually made from carbon steel, stainless steel, or alloy steel depending on the process fluid.

Application Tip:

Always fill the syphon with water before installation to ensure proper function.

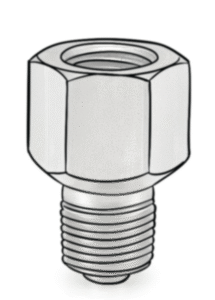

2. Snubbers

Function:

Snubbers protect pressure gauges from pressure spikes, pulsation, and vibrations. They dampen rapid pressure fluctuations which can damage the gauge internals or lead to inaccurate readings.

Types:

Porous metal snubbers: Use sintered metal to control flow.

Piston-type snubbers: Have adjustable damping for fine-tuning.

Capillary snubbers: Use small tubes to limit flow rate and reduce pulsation.

Selection Criteria:

Type of media (gas or liquid)

Degree of pulsation

Operating pressure

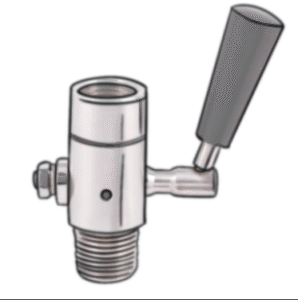

3. Gauge Cocks

Function:

Gauge cocks provide isolation between the pressure gauge and the process. This allows for safe gauge removal, replacement, or calibration without process shutdown.

Types:

2-way gauge cock: Allows isolation only.

3-way gauge cock: Allows for isolation and venting or calibration.

4-way cock: For complex switching operations (rare in industrial use).

Applications:

Common in oil & gas, chemical, and power plants where frequent maintenance or calibration is required.

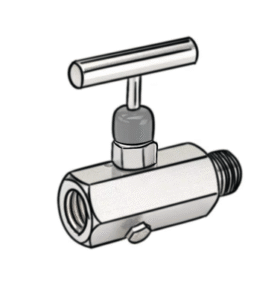

4. Manifold Valves

Function:

Manifold valves allow for multiple functions such as pressure gauge isolation, venting, and calibration from a single assembly.

Types:

Block and Bleed Manifolds (2-valve): Used for isolation and pressure release.

3-Valve Manifolds: Common for differential pressure applications but can be adapted for gauges.

Material Selection:

Stainless steel is widely used for corrosive or high-pressure applications.

5. Overpressure Protectors

Function:

These devices protect pressure gauges from being exposed to pressures beyond their range. They automatically isolate the gauge during overpressure conditions.

Operating Principle:

They use a spring-loaded mechanism to cut off the connection when pressure exceeds a pre-set limit.

Typical Use Case:

Low-range gauges (0-1 bar or 0-30 psi) in hydraulic systems that may experience sudden surges.

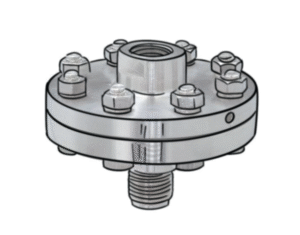

6. Diaphragm Seals (Chemical Seals)

Function:

Diaphragm seals isolate the gauge from corrosive, viscous, or slurry-filled media. They transfer pressure through a filled fluid to the gauge.

Types:

Welded flush diaphragm seals: Ideal for sanitary applications (e.g., food, pharma).

Flanged diaphragm seals: Used in high-pressure or corrosive applications.

Threaded diaphragm seals: For general-purpose industrial use.

Fill Fluids:

Glycerin, silicone oil, or halocarbon depending on temperature and chemical compatibility.

Key Consideration:

The system must be fully filled and calibrated to maintain accuracy.

7. Capillary Tubes

Function:

Capillary tubes provide a remote mounting option for pressure gauges, especially in applications where space or temperature constraints exist.

Material:

Typically stainless steel, PTFE, or armored versions for rugged environments.

Application Example:

Remote reading of boiler pressure where the gauge is placed far from the heat source for safety.

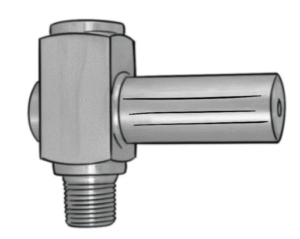

8. Vent Valves / Bleed Valves

Function:

These valves allow trapped air or pressure to be vented from the system before or during gauge installation.

Use Case:

During calibration or when installing gauges in liquid systems where air pockets affect accuracy.

9. Test and Calibration Adapters

Function:

These adapters allow quick connection of a pressure gauge to a calibration device or test pump without removing it from the process line.

Variants:

Quick-connect couplings

Threaded adaptors for different gauge sizes

Calibration manifolds

10. Pressure Gauge Holders / Mounting Accessories

Purpose:

Ensure proper support and mounting of pressure gauges for optimal visibility and mechanical protection.

Common Accessories:

Panel mounting brackets

Surface or wall mount flanges

U-clamps and back flanges

Protective covers and hoods

11. Liquid Filling (Glycerin/Oil)

Function:

While not a separate accessory, liquid filling is an important option that enhances gauge durability. The filling absorbs vibrations, prevents moisture entry, and improves needle stability.

Applications:

Pumps and compressors

Outdoor installations with vibration

High-humidity areas

Common Fill Liquids:

Glycerin: General-purpose

Silicone Oil: For high/low temperatures

Halocarbon: For chemical compatibility

12. Safety Accessories

Bourdon Tube Blowout Disc:

In case of gauge failure, these allow pressure relief to the rear, protecting the operator.

Safety Glass / Laminated Glass:

Prevents glass from shattering upon rupture.

Back Flanged Cases:

Directs blowout safely toward the back.

Installation Guidelines for Accessories

To ensure long-term performance and safety, follow these best practices:

Orientation: Always install snubbers and syphons in the correct orientation.

Compatibility: Match materials with the process medium (e.g., stainless steel for corrosive fluids).

Pre-Filling: Fill syphons and diaphragm seals before startup.

Calibration: Regularly test using calibration adaptors and manifolds.

Venting: Always vent trapped air in diaphragm seals or capillaries.

Environmental Protection: Use filled gauges and weatherproof cases in outdoor environments.

Conclusion

Pressure gauge accessories are not just optional extras—they are essential elements for ensuring accuracy, longevity, safety, and reliability of pressure measurement systems. Whether it’s protecting a gauge from pulsation using a snubber, isolating it with a gauge cock, or ensuring process compatibility with diaphragm seals, the right accessory can make a significant difference.

Selecting the appropriate combination of these accessories depends on process parameters such as pressure range, media type, temperature, vibration, and maintenance requirements. By understanding the function and application of each accessory, instrumentation professionals can design more robust and serviceable measurement systems.