In functional safety, the primary difference between 1oo1, 1oo2, 2oo2, and 2oo3 configurations lies in their levels of fault tolerance and their behavior upon failure. A 1oo1 system is the simplest but has no redundancy. 1oo2 prioritizes safety, tripping if one channel fails. 2oo2 prioritizes availability, requiring two channels to trip, making it less safe. 2oo3 offers the best of both worlds, providing high safety and high availability by tolerating a single failure of any kind.

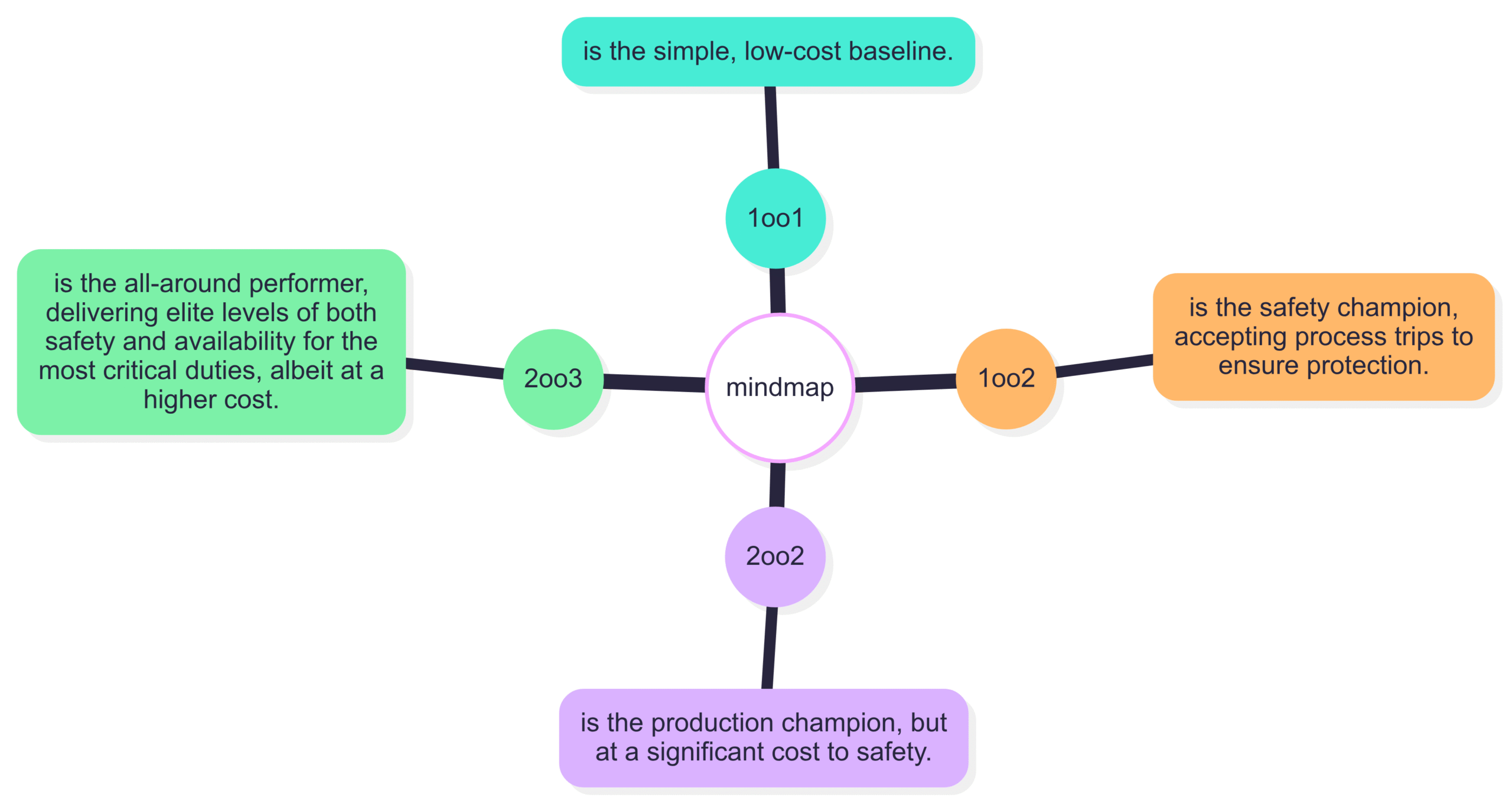

Here’s a quick summary:

| Configuration | Meaning | Primary Goal | Fault Tolerance (to trip) | Fault Tolerance (to fail dangerously) |

| 1oo1 | 1 out of 1 channel must vote to trip. | Simplicity | None | None |

| 1oo2 | 1 out of 2 channels must vote to trip. | Safety | None | Tolerates 1 dangerous failure |

| 2oo2 | 2 out of 2 channels must vote to trip. | Availability | Tolerates 1 spurious trip | None |

| 2oo3 | 2 out of 3 channels must vote to trip. | Safety & Availability | Tolerates 1 spurious trip | Tolerates 1 dangerous failure |

Decoding Functional Safety Architectures: A Deep Dive into 1oo1, 1oo2, 2oo2, and 2oo3 Configurations

Welcome to the intricate world of functional safety! If you’re involved in designing, operating, or maintaining safety systems in the process industries, you’ve undoubtedly come across terms like SIL (Safety Integrity Level) and standards like IEC 61511. These frameworks are the bedrock of ensuring that our industrial processes operate safely, protecting people, the environment, and assets.

A cornerstone of functional safety design is architectural redundancy. How we structure the components of a Safety Instrumented Function (SIF) — the sensors, logic solvers, and final elements — has a profound impact on its performance. This structure, often called “voting logic,” determines how the system behaves when things go wrong.

This guide will demystify the most common architectural configurations: 1oo1, 1oo2, 2oo2, and 2oo3. We’ll explore what they are, how they work, their pros and cons, and where they fit best, all within the context of IEC 61511. Get ready for a deep dive with diagrams, formulas, and practical insights. 🚀

The “Why” Behind It All: Architectural Redundancy

Before we jump into the numbers and letters, let’s understand why we need these configurations. A SIF is designed to take a process to a safe state when a dangerous condition is detected. But what if the SIF itself fails?

There are two main failure modes we worry about:

Fail-Safe (or Spurious) Trip: The SIF activates when there’s no actual demand, causing an unnecessary and often costly shutdown of the process.

Fail-to-Function (or Dangerous) Failure: The SIF fails to activate when a real demand occurs, leading to a potentially catastrophic event.

The goal of a well-designed safety architecture is to find the optimal balance between preventing dangerous failures and avoiding spurious trips. This is where redundancy comes in. By using more than one component (or “channel”) to perform a function, we can build a system that is resilient to single failures, enhancing either its safety, its availability (uptime), or both.

This is all quantified by a metric called the Average Probability of Failure on Demand (PFDavg), which represents the likelihood that the SIF will fail dangerously when a demand occurs. The lower the PFDavg, the higher the Safety Integrity Level (SIL) the system can achieve.

Understanding “M out of N” (MooN) Voting

The naming convention “MooN” is quite simple once you get the hang of it. It stands for “M out of N” channels must vote to initiate the safety action (the trip).

N is the total number of redundant channels.

M is the minimum number of channels that must agree to cause a trip.

Let’s apply this:

1oo1: 1 out of 1 channel must vote to trip.

1oo2: 1 out of 2 channels must vote to trip.

2oo2: 2 out of 2 channels must vote to trip.

2oo3: 2 out of 3 channels must vote to trip.

This simple logic forms the basis for the distinct behaviors and performance characteristics of each architecture.

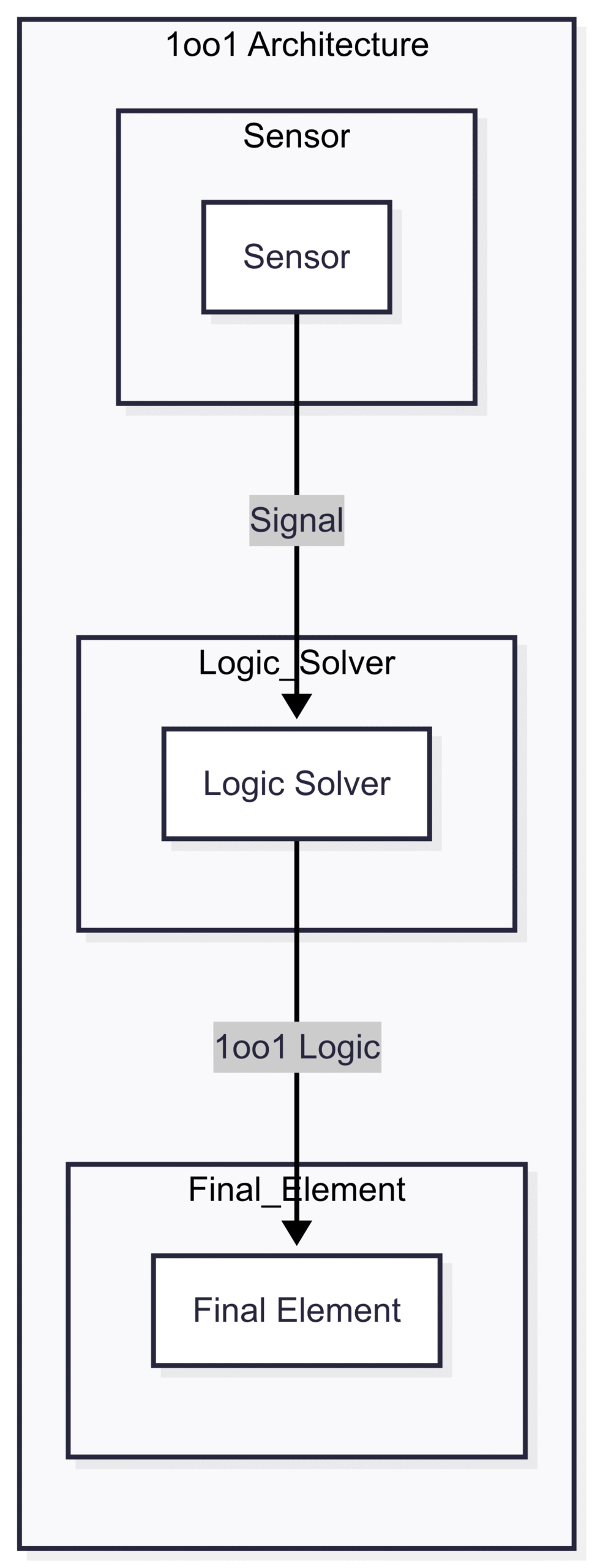

The Simplest Form: 1oo1 (Simplex) Configuration

The 1oo1 configuration, also known as a simplex system, is the most basic architecture. It consists of a single channel: one sensor, one logic solver (or a single input/output on a safety PLC), and one final element.

How it Works

It’s straightforward: if the single sensor detects a hazardous condition, it signals the logic solver, which in turn commands the final element to move the process to a safe state.

Strengths and Weaknesses

Pros:

Simplicity: Easy to design, install, and maintain.

Low Cost: Minimal hardware and installation expenses.

Cons:

No Fault Tolerance: Any single component failure has an immediate consequence.

Low Availability: An undetected dangerous failure renders the SIF useless. A detected failure (e.g., a sensor diagnostic failure) will typically cause a fail-safe trip, leading to process downtime. It has the highest spurious trip rate for a single channel failure.

Performance and Calculations

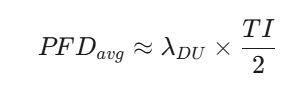

The PFD avg for a 1oo1 system is primarily driven by the rate of dangerous undetected failures (λ_DU) and how often you test for them (the Proof Test Interval, or TI).

The simplified formula for PFDavg is:

This formula highlights that the only defense against a hidden dangerous failure is periodic proof testing.

Use Cases

1oo1 architectures are suitable for:

SIFs with SIL 1 requirements.

Applications where the consequence of a spurious trip is low, and the process is not highly critical.

Systems with very reliable components (low λ_DU).

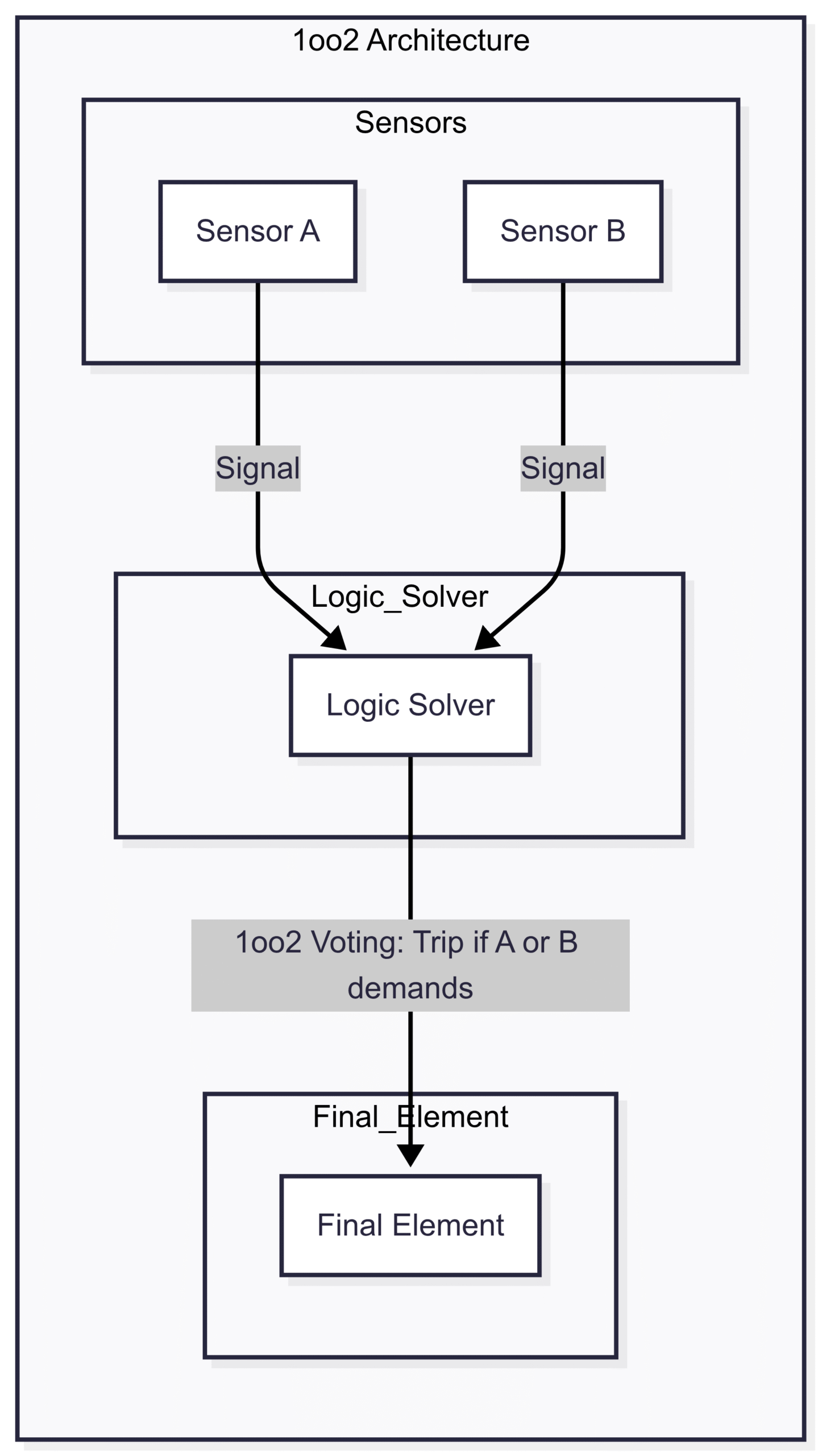

Prioritizing Safety: 1oo2 Configuration

The 1oo2 configuration is our first step into true redundancy. It uses two channels, and the logic is set up so that if either channel detects a hazard, the system will trip. Its design philosophy is “when in doubt, shut it down.”

How it Works

Two channels (A and B) monitor the process. If Channel A demands a trip, the system trips. If Channel B demands a trip, the system trips. A dangerous failure of the entire SIF can only occur if both channels fail dangerously and are unable to respond to a real demand.

Strengths and Weaknesses

Pros:

High Safety: It provides excellent fault tolerance against dangerous failures. A single dangerous failure in one channel is covered by the other, significantly lowering the PFDavg.

Good Diagnostics: Discrepancies between the two channels can be flagged for maintenance, allowing for online repair before a second failure occurs.

Cons:

High Spurious Trip Rate: This is the major drawback. A fail-safe fault in either channel will cause an unwanted shutdown. The spurious trip rate is roughly double that of a 1oo1 system.

Vulnerable to Common Cause Failures: Since both channels are often identical and installed similarly, they can be susceptible to failing from the same root cause (e.g., plugging, corrosion, calibration error).

Performance and Calculations

The PFDavg calculation for a 1oo2 system is more complex. It must account for two scenarios: a random failure of both channels independently, and a single common cause failure (CCF) that takes out both channels.

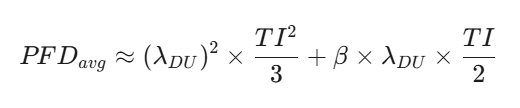

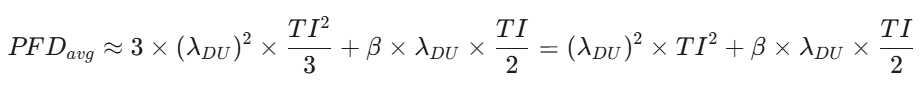

The simplified formula, incorporating the Beta factor (beta), which represents the fraction of failures that are due to a common cause, is:

In most practical cases, the common cause failure term (β * λ_DU * Ti/2) dominates the calculation, meaning the PFDavg is significantly better than 1oo1.

Use Cases

1oo2 architectures are ideal for:

SIL 2 and SIL 3 applications where safety is the absolute priority.

Processes where a dangerous failure would have catastrophic consequences, and a spurious trip, while costly, is an acceptable trade-off.

Emergency Shutdown (ESD) systems.

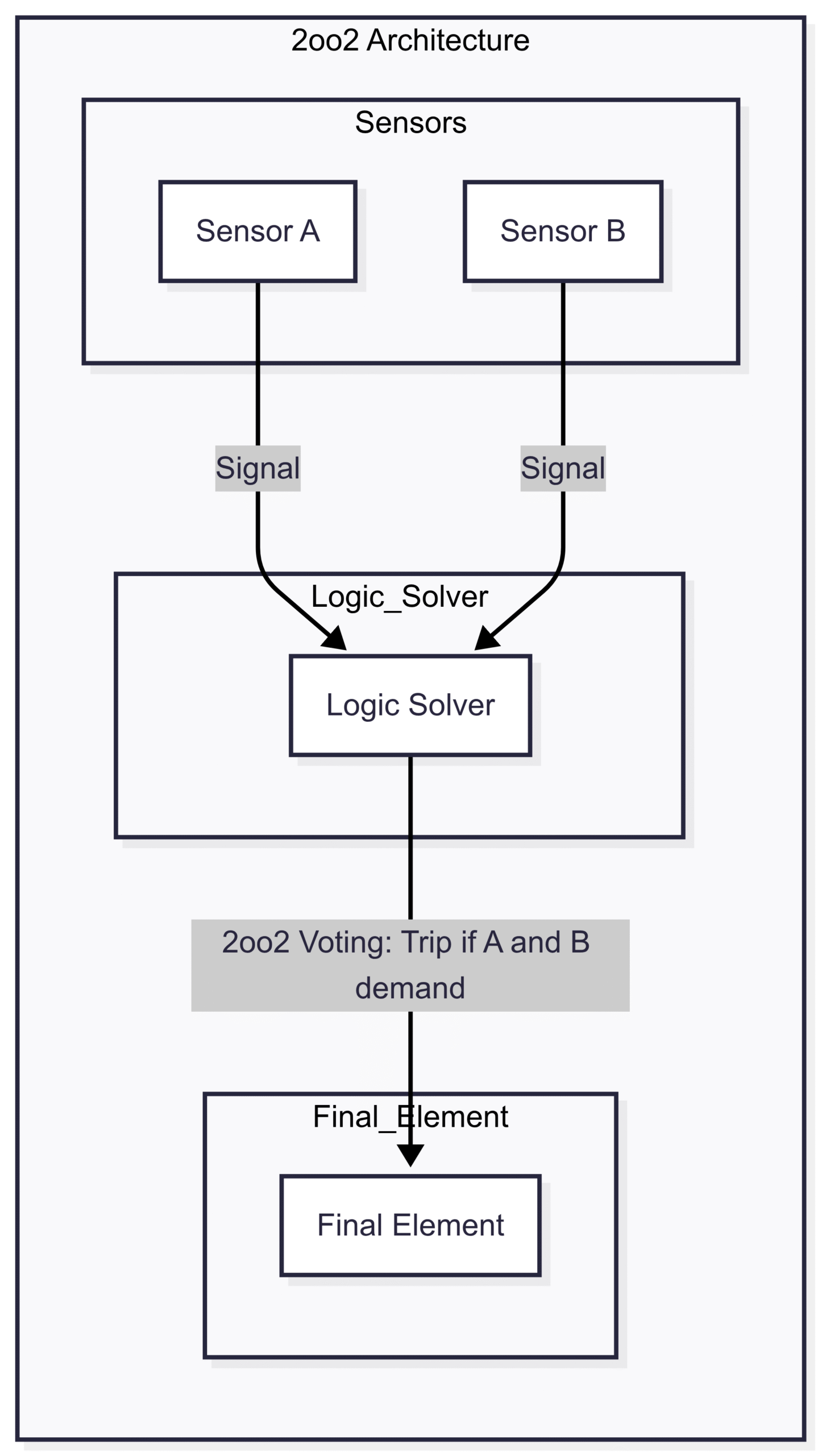

Prioritizing Uptime: 2oo2 Configuration

The 2oo2 configuration also uses two channels, but its voting logic is the opposite of 1oo2. To initiate a trip, both channels must agree that a hazardous condition exists. Its design philosophy is “don’t shut down unless you’re absolutely sure.”

How it Works

If only Channel A detects a hazard, nothing happens. The system waits for Channel B to confirm. A trip only occurs when both A and B demand it. This makes the system highly resilient to spurious trips.

Strengths and Weaknesses

Pros:

High Availability: It offers excellent protection against nuisance trips. A single fail-safe fault in one channel won’t shut down the process. The system can continue operating while the faulty channel is repaired.

Good Diagnostics: Like 1oo2, discrepancies are alarmed, prompting maintenance.

Cons:

Poor Safety: This is the critical downside. A single, undetected dangerous failure in one channel effectively turns the system into a 1oo1 configuration, but with its PFDavg masked. If that single channel fails dangerously, the SIF is completely blind to a real demand until the second channel also fails. The PFDavg is no better than a 1oo1 system.

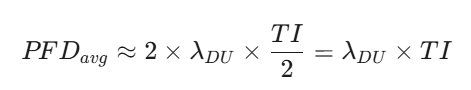

Performance and Calculations

Because a single dangerous undetected failure defeats the entire safety function, its probability of failure is simply the sum of the probabilities of either channel failing.

The simplified PFDavg formula is:

Notice this is roughly twice as bad as a 1oo1 system! For this reason, pure 2oo2 architectures are rarely used for safety applications without significant additional diagnostics that can automatically trip the system if one channel is known to have failed dangerously. Such a system is often called a 1oo2D system.

Use Cases

Standard 2oo2 architectures are generally not recommended for SIFs governed by IEC 61511 due to their poor safety performance. However, they are frequently used in:

Basic Process Control Systems (BPCS) where the primary goal is process continuity and avoiding nuisance trips.

Fire and Gas systems where false alarms leading to extinguishing agent release are extremely costly and disruptive.

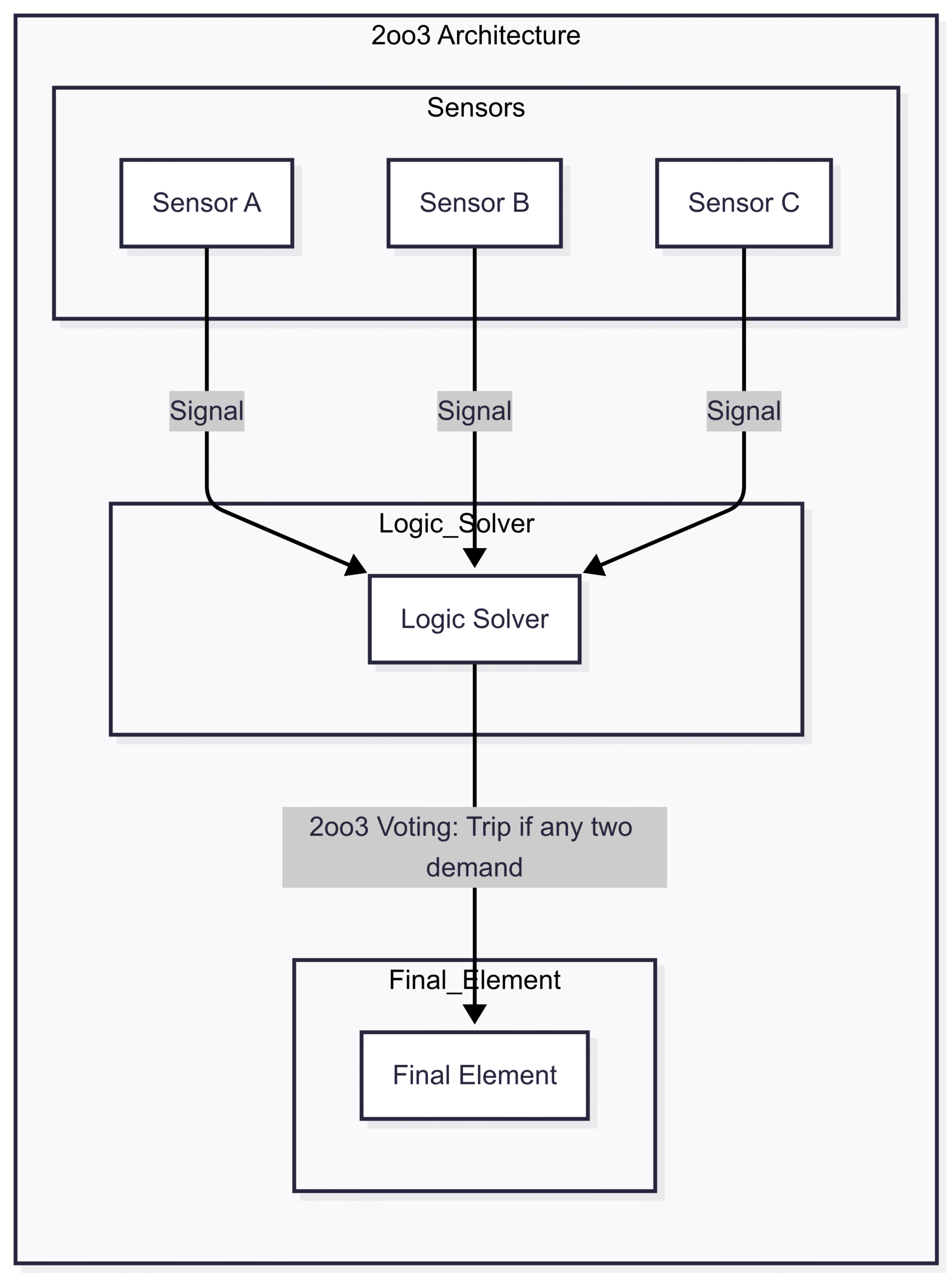

The Gold Standard: 2oo3 Configuration

The 2oo3 configuration is the most advanced and robust of the common architectures. It uses three independent channels and a “majority voting” system. A trip is initiated only if at least two out of the three channels agree on a hazardous condition.

How it Works

This clever arrangement provides tolerance for a single failure of any kind.

If one channel fails safe (spurious trip): The other two channels hold the system online (1 vote to trip, 2 votes to stay running). No spurious trip occurs.

If one channel fails dangerously: The other two channels are still available to detect a real demand and vote to trip the system safely. The safety function is maintained.

Strengths and Weaknesses

Pros:

High Safety AND High Availability: This is the key advantage. It combines the safety of a 1oo2 system with the spurious trip protection of a 2oo2 system. It can tolerate a single failure, whether safe or dangerous, without compromising its primary function or process uptime.

Excellent Diagnostics and Online Maintenance: The voting logic can immediately identify a disagreeing channel, which can be taken offline for repair while the system continues to operate safely in a degraded (but still functional) 2oo2 mode.

Cons:

High Cost and Complexity: It requires three full sets of hardware and a more complex logic solver, making it the most expensive option to implement and maintain.

Physical Space: Three sets of instrumentation can require more space for installation.

Performance and Calculations

The PFDavg calculation for 2oo3 is complex, but it essentially looks at the probability of having two or more channels in a failed state at once. It achieves a PFDavg that is comparable to or better than 1oo2, but with a much lower spurious trip rate.

The simplified formula is:

The key takeaway is that it provides a very low PFDavg, suitable for the highest SIL ratings.

Use Cases

2oo3 architectures are the gold standard for the most critical applications:

High SIL 3 applications.

Processes where the consequences of a dangerous failure are immense, and the cost of a spurious trip is also extremely high.

Critical rotating equipment (e.g., steam turbines), nuclear applications, and high-stakes chemical reactor systems.

At-a-Glance Comparison

Let’s pull it all together in a summary table to make the differences crystal clear.

| Feature | 1oo1 (Simplex) | 1oo2 (High Safety) | 2oo2 (High Availability) | 2oo3 (Safety & Availability) |

| Voting Logic | 1 of 1 | 1 of 2 | 2 of 2 | 2 of 3 |

| SIL Capability | SIL 1 (maybe SIL 2) | SIL 2, SIL 3 | SIL 1 (Poor Safety) | SIL 3 |

| Fault Tolerance (Safe) | None | None (1 failure = trip) | Tolerates 1 failure | Tolerates 1 failure |

| Fault Tolerance (Dangerous) | None | Tolerates 1 failure | None | Tolerates 1 failure |

| Spurious Trip Rate | Base Rate | High (2x Base Rate) | Very Low | Very Low |

| PFDavg | Base Rate | Very Low | High (Similar to 1oo1) | Very Low |

| Hardware Cost | Low | Medium | Medium | High |

| Complexity | Low | Medium | Medium | High |

| Best For… | Low-risk, non-critical | Safety is paramount | Uptime is paramount | Both safety and uptime are critical |

How to Choose the Right Configuration

Choosing the right architecture isn’t just an academic exercise; it’s a critical engineering decision with real-world consequences. The decision should be based on a thorough analysis, typically a Layer of Protection Analysis (LOPA), which determines the required SIL for each safety function.

Key factors to consider include:

Required SIL: The higher the required SIL, the more likely you’ll need a redundant architecture like 1oo2 or 2oo3. A 1oo1 system often struggles to meet SIL 2 requirements, and a 2oo2 system should not be used for high SIL targets.

Cost of a Spurious Trip: Ask yourself: What happens if this SIF shuts down the process unnecessarily? If the answer involves millions in lost production, environmental penalties, or damage to equipment, you need an architecture with high availability (like 2oo2 or, preferably, 2oo3).

Process Safety Time: How quickly does a hazard escalate? If you have a very short time to act, you need an exceptionally reliable system.

Maintenance and Testing: Can you perform maintenance online? Architectures like 2oo3 are ideal for online repair. Your proof testing strategy will also influence your PFDavg calculations and, therefore, your choice.

Common Cause Failures (CCF): No discussion of redundancy is complete without mentioning CCFs. No matter how many redundant channels you have, if a single external event (e.g., a power surge, plugged impulse lines, incorrect calibration) can knock out all of them, your redundancy is worthless. Mitigating CCFs through physical separation, diversity of equipment (using different models or manufacturers), and robust maintenance procedures is essential for any redundant architecture.

Conclusion: Balancing Safety and Production

The choice between 1oo1, 1oo2, 2oo2, and 2oo3 architectures is a fundamental exercise in risk management. There is no single “best” configuration; there is only the best configuration for a specific application.

1oo1 is the simple, low-cost baseline.

1oo2 is the safety champion, accepting process trips to ensure protection.

2oo2 is the production champion, but at a significant cost to safety.

2oo3 is the all-around performer, delivering elite levels of both safety and availability for the most critical duties, albeit at a higher cost.

By understanding the unique trade-offs of each voting scheme, you can design and implement Safety Instrumented Functions that are not only compliant with IEC 61511 but are also robust, reliable, and perfectly tailored to the specific risks of your process. Making the right choice ensures your plant operates not just productively, but safely. 🛡️