HAZOP Study: A Comprehensive Guide to Hazard Identification and Risk Assessment

Introduction to HAZOP Studies: Ensuring Process Safety 🛡️

In the intricate world of industrial processes, particularly in sectors like oil and gas, chemicals, and pharmaceuticals, ensuring the safety of operations is paramount. Accidents can lead to catastrophic consequences, including loss of life, environmental damage, and significant financial repercussions. To proactively identify potential hazards and assess associated risks, various methodologies have been developed. Among these, the Hazard and Operability (HAZOP) study stands out as a robust and widely recognized technique.

This comprehensive guide delves into the intricacies of HAZOP studies, exploring their fundamental principles, systematic methodology, key benefits, inherent limitations, the crucial role of the HAZOP team, and the diverse applications across industries. Whether you are a seasoned safety professional or new to the field of process safety management, this detailed exploration will equip you with a thorough understanding of HAZOP studies and their vital role in preventing accidents and fostering a culture of safety.

Understanding the Core Principles of HAZOP 💡

At its core, a HAZOP study is a structured and systematic technique used to identify potential hazards and operability problems in a process or system. It operates on the fundamental principle that deviations from the intended design or operating conditions can lead to undesirable consequences. The HAZOP methodology achieves this by:

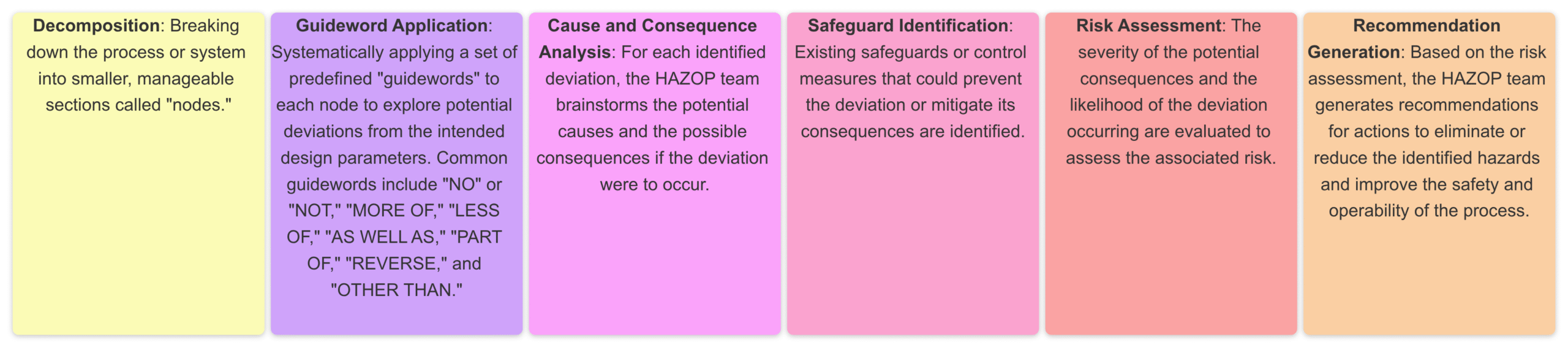

Decomposition: Breaking down the process or system into smaller, manageable sections called “nodes.”

Guideword Application: Systematically applying a set of predefined “guidewords” to each node to explore potential deviations from the intended design parameters. Common guidewords include “NO” or “NOT,” “MORE OF,” “LESS OF,” “AS WELL AS,” “PART OF,” “REVERSE,” and “OTHER THAN.”

Cause and Consequence Analysis: For each identified deviation, the HAZOP team brainstorms the potential causes and the possible consequences if the deviation were to occur.

Safeguard Identification: Existing safeguards or control measures that could prevent the deviation or mitigate its consequences are identified.

Risk Assessment: The severity of the potential consequences and the likelihood of the deviation occurring are evaluated to assess the associated risk.

Recommendation Generation: Based on the risk assessment, the HAZOP team generates recommendations for actions to eliminate or reduce the identified hazards and improve the safety and operability of the process.

The Systematic HAZOP Methodology: A Step-by-Step Approach 🪜

Conducting an effective HAZOP study involves a well-defined series of steps:

Definition of Scope and Objectives: Clearly define the boundaries of the system or process to be studied and the specific objectives of the HAZOP study. This includes identifying the project phase (e.g., design, commissioning, operation), the level of detail required, and any specific concerns to be addressed.

Team Selection and Preparation: Assembling a multidisciplinary team with relevant expertise is crucial for a successful HAZOP study. The team typically includes process engineers, safety engineers, operations personnel, maintenance technicians, and a HAZOP facilitator. Adequate preparation involves gathering all necessary documentation, such as process flow diagrams (PFDs), piping and instrumentation diagrams (P&IDs), operating procedures, safety data sheets (SDSs), and equipment specifications.

Process Decomposition and Node Selection: The process or system is divided into smaller sections or “nodes” based on functional boundaries or critical equipment. The selection of appropriate nodes ensures a systematic and thorough analysis without becoming overly complex.

HAZOP Meeting Execution: The HAZOP meeting is the core of the study. Guided by the facilitator, the team systematically examines each node by applying the predefined guidewords to the design parameters (e.g., flow, pressure, temperature, level, composition). For each guideword-parameter combination, the team brainstorms potential deviations, their possible causes, and the resulting consequences. Existing safeguards are identified, and an initial qualitative assessment of the risk is made.

Documentation and Recording: Detailed documentation of the HAZOP meeting is essential. This includes recording each identified deviation, its causes, consequences, existing safeguards, the assessed risk level, and any recommendations for further action. Standardized HAZOP worksheets or software tools are typically used for this purpose.

Risk Assessment and Evaluation: Following the HAZOP meeting, a more detailed risk assessment may be conducted for the identified hazards. This can involve using risk matrices or other risk ranking methodologies to prioritize the recommendations based on the severity and likelihood of the potential consequences.

Development of Action Items and Recommendations: The HAZOP team develops specific and actionable recommendations to address the identified hazards and operability issues. These recommendations should be clearly defined, assigned to responsible individuals, and have agreed-upon deadlines for completion.

Follow-up and Implementation: The implementation of the recommendations is a critical step in the HAZOP process. Progress on action items should be tracked, and completed actions should be verified to ensure their effectiveness in mitigating the identified risks.

Review and Audit: Periodically reviewing and auditing the HAZOP study and the implementation of recommendations helps to ensure its ongoing effectiveness and identify any areas for improvement. HAZOP studies should also be revisited whenever significant changes are made to the process or system.

The Tangible Benefits of Conducting HAZOP Studies ✅

Investing time and resources in conducting HAZOP studies yields numerous significant benefits:

Enhanced Safety: The primary benefit is the proactive identification of potential hazards and the implementation of measures to prevent accidents and incidents, thereby creating a safer working environment for personnel and the surrounding community.

Improved Operability: By identifying potential operability problems, HAZOP studies can lead to improvements in process efficiency, reduced downtime, and enhanced product quality.

Regulatory Compliance: Many regulatory bodies mandate or strongly recommend the use of HAZOP studies in high-hazard industries to ensure compliance with safety regulations and standards.

Reduced Liability: By systematically identifying and mitigating risks, organizations can reduce their potential liability associated with accidents and incidents.

Cost Savings: Preventing accidents and operational disruptions can lead to significant cost savings in terms of avoided property damage, lost production, environmental cleanup, and potential fines.

Enhanced Teamwork and Communication: The multidisciplinary nature of HAZOP studies fosters collaboration and communication among different departments and disciplines within an organization.

Knowledge Transfer: The HAZOP process facilitates the sharing of knowledge and experience among team members, leading to a better understanding of the process and its potential hazards.

Improved Design: Conducting HAZOP studies during the early design stages of a project can identify potential safety and operability issues before they are built into the system, allowing for more cost-effective design modifications.

Recognizing the Inherent Limitations of HAZOP Studies 🚧

While HAZOP studies are a powerful tool, it’s important to acknowledge their inherent limitations:

Reliance on Team Expertise: The effectiveness of a HAZOP study heavily depends on the knowledge, experience, and diligence of the team members. Gaps in expertise or a lack of thoroughness can lead to missed hazards.

Subjectivity: The assessment of likelihood and severity of consequences can involve a degree of subjectivity, which may lead to inconsistencies in risk ranking.

Focus on Deviations: HAZOP studies primarily focus on deviations from normal operating conditions and may not always effectively identify hazards arising from unforeseen combinations of events or external factors.

Time and Resource Intensive: Conducting a comprehensive HAZOP study can be a time-consuming and resource-intensive process, requiring significant effort in planning, preparation, meetings, and follow-up.

Not a Substitute for Other Safety Measures: HAZOP studies are just one component of a comprehensive process safety management system and should be used in conjunction with other safety measures, such as risk assessments, safety audits, and emergency preparedness plans.

“What If” Scenarios: While HAZOP uses guidewords systematically, the identification of potential deviations and their causes still relies on the team’s ability to envision “what if” scenarios.

The Crucial Role of the HAZOP Team: Collaboration for Safety 🤝

The success of a HAZOP study hinges on the composition and effectiveness of the HAZOP team. A well-balanced and experienced team is essential for a thorough and insightful analysis. Key roles within a HAZOP team typically include:

HAZOP Facilitator: An independent and experienced facilitator is crucial for guiding the team through the HAZOP methodology, ensuring that all nodes and guidewords are systematically considered, managing discussions, and keeping the meeting focused and productive.

Process Engineer: Provides detailed knowledge of the process design, operating parameters, and intended functions of equipment.

Safety Engineer: Contributes expertise in hazard identification, risk assessment methodologies, safety regulations, and industry best practices.

Operations Personnel: Offers practical insights into the day-to-day operation of the process, potential operational challenges, and historical incident data.

Maintenance Technician: Provides knowledge of equipment maintenance requirements, potential failure modes, and maintenance history.

Instrumentation and Control Engineer: Contributes expertise on the control systems, safety interlocks, and instrumentation that are critical for safe operation.

Scribe: Responsible for accurately documenting the discussions, identified deviations, causes, consequences, safeguards, risk assessments, and recommendations during the HAZOP meeting.

Effective teamwork, open communication, and a collaborative environment are essential for the HAZOP team to function optimally and generate meaningful results.

Diverse Applications of HAZOP Studies Across Industries 🏭🏢🧪

HAZOP studies are a versatile technique with broad applicability across various industries where hazardous materials or complex processes are involved. Some key application areas include:

Oil and Gas: Used extensively for the design, operation, and modification of offshore platforms, refineries, pipelines, and petrochemical plants.

Chemical Processing: Applied to a wide range of chemical manufacturing processes to identify hazards associated with reactions, handling of hazardous substances, and process equipment.

Pharmaceuticals: Utilized in the development and production of pharmaceutical products to ensure the safety of personnel and the integrity of the manufacturing process.

Nuclear Power: Employed in nuclear facilities to identify potential hazards related to reactor operation, radiation exposure, and waste management.

Food and Beverage: Increasingly used in the food and beverage industry to assess hazards related to processing, handling of allergens, and sanitation.

Water and Wastewater Treatment: Applied to identify potential hazards associated with chemical handling, biological processes, and equipment malfunctions.

Transportation: Used to analyze the safety of transportation systems involving hazardous materials, such as pipelines, railways, and roadways.

HAZOP studies can be applied at various stages of a project lifecycle, from initial concept development and detailed design to commissioning, operation, and decommissioning. Conducting HAZOP studies early in the design phase can be particularly beneficial as it allows for the incorporation of safety features before significant investments are made.

Conclusion: Embracing HAZOP for a Safer Future 🌍

In conclusion, the Hazard and Operability (HAZOP) study is a powerful and systematic methodology that plays a vital role in ensuring process safety across a multitude of industries. By proactively identifying potential hazards and operability problems through a structured and collaborative approach, HAZOP studies enable organizations to implement effective safeguards, mitigate risks, and ultimately prevent accidents and incidents.

While HAZOP studies have certain limitations, their numerous benefits, including enhanced safety, improved operability, regulatory compliance, and cost savings, underscore their importance in a comprehensive process safety management system. The success of a HAZOP study relies heavily on the expertise and collaboration of a multidisciplinary team guided by a skilled facilitator.

By embracing the principles and methodology of HAZOP studies, organizations can foster a stronger safety culture, protect their personnel and the environment, and contribute to a safer and more sustainable future for all. The proactive and systematic nature of HAZOP makes it an indispensable tool for any organization committed to operational excellence and the highest standards of safety.

In a HAZOP review, should the Causes column be limited strictly to causes originating within the analyzed node, or can causes external to the node also be considered?

Similarly, should the Consequences be restricted to impacts within the same node, or may consequences extending beyond the node be included?

Both cause and consequences can be outside the node,